LSA Engine Pressure Management Techniques

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Pressure Management Background and Objectives

Pressure management in LSA (Luxury Sport Automobile) engines represents a critical domain in modern automotive engineering, evolving significantly since the introduction of forced induction technologies in the early 20th century. The progression from basic mechanical superchargers to sophisticated electronic boost control systems marks a transformative journey in engine efficiency and performance optimization. This technical research aims to comprehensively examine current pressure management techniques in LSA engines and identify potential pathways for innovation.

The fundamental objective of LSA engine pressure management is to optimize the air-fuel mixture delivery across varying operational conditions while maintaining ideal combustion parameters. This balancing act between performance, efficiency, and emissions compliance has become increasingly complex with stricter regulatory frameworks worldwide, particularly Euro 7 and CAFE standards, which demand unprecedented precision in combustion control.

Historical development of pressure management in high-performance engines reveals a clear trajectory from purely mechanical systems toward integrated electro-mechanical solutions with predictive capabilities. Early systems focused primarily on preventing engine knock and maintaining structural integrity, while contemporary approaches emphasize dynamic pressure modulation to optimize performance across the entire operating envelope of the vehicle.

Current technical objectives in LSA engine pressure management center on achieving four key outcomes: maximizing volumetric efficiency, minimizing turbo lag, optimizing transient response, and ensuring thermal stability under high-load conditions. These objectives must be accomplished while simultaneously reducing emissions and improving fuel economy—a challenging technical dichotomy that drives innovation in this field.

The convergence of computational fluid dynamics (CFD), machine learning algorithms, and advanced materials science has created new possibilities for pressure management that were unimaginable a decade ago. Real-time combustion monitoring and adjustment, predictive boost control based on driver behavior patterns, and variable geometry intake systems represent the cutting edge of current development efforts.

Market pressures, particularly the shift toward electrification, have paradoxically accelerated innovation in internal combustion pressure management as manufacturers seek to extract maximum efficiency from traditional powertrains during the transition period. This has led to increased research investment in technologies like dynamic compression ratio systems, integrated exhaust energy recovery, and advanced intercooling techniques.

Our technical goal through this research is to identify breakthrough opportunities in LSA engine pressure management that can deliver a 15% improvement in power density while reducing emissions by 20% compared to current best-in-class solutions, establishing a new benchmark for high-performance luxury powertrains in the transitional era between conventional and alternative propulsion systems.

The fundamental objective of LSA engine pressure management is to optimize the air-fuel mixture delivery across varying operational conditions while maintaining ideal combustion parameters. This balancing act between performance, efficiency, and emissions compliance has become increasingly complex with stricter regulatory frameworks worldwide, particularly Euro 7 and CAFE standards, which demand unprecedented precision in combustion control.

Historical development of pressure management in high-performance engines reveals a clear trajectory from purely mechanical systems toward integrated electro-mechanical solutions with predictive capabilities. Early systems focused primarily on preventing engine knock and maintaining structural integrity, while contemporary approaches emphasize dynamic pressure modulation to optimize performance across the entire operating envelope of the vehicle.

Current technical objectives in LSA engine pressure management center on achieving four key outcomes: maximizing volumetric efficiency, minimizing turbo lag, optimizing transient response, and ensuring thermal stability under high-load conditions. These objectives must be accomplished while simultaneously reducing emissions and improving fuel economy—a challenging technical dichotomy that drives innovation in this field.

The convergence of computational fluid dynamics (CFD), machine learning algorithms, and advanced materials science has created new possibilities for pressure management that were unimaginable a decade ago. Real-time combustion monitoring and adjustment, predictive boost control based on driver behavior patterns, and variable geometry intake systems represent the cutting edge of current development efforts.

Market pressures, particularly the shift toward electrification, have paradoxically accelerated innovation in internal combustion pressure management as manufacturers seek to extract maximum efficiency from traditional powertrains during the transition period. This has led to increased research investment in technologies like dynamic compression ratio systems, integrated exhaust energy recovery, and advanced intercooling techniques.

Our technical goal through this research is to identify breakthrough opportunities in LSA engine pressure management that can deliver a 15% improvement in power density while reducing emissions by 20% compared to current best-in-class solutions, establishing a new benchmark for high-performance luxury powertrains in the transitional era between conventional and alternative propulsion systems.

Market Demand Analysis for Advanced Pressure Management Systems

The global market for advanced pressure management systems in LSA (Light Sport Aircraft) engines has witnessed significant growth over the past five years, driven primarily by increasing safety regulations and the growing popularity of recreational aviation. Current market analysis indicates that the demand for sophisticated pressure management techniques is expected to grow at a compound annual rate of 7.2% through 2028, outpacing the overall aviation components market.

This accelerated growth is largely attributed to the rising awareness among aircraft manufacturers and operators about the critical role that precise pressure management plays in engine efficiency, fuel consumption, and overall aircraft performance. The recreational aviation sector, particularly in North America and Europe, represents the largest market segment, accounting for approximately 65% of the total demand for advanced pressure management systems.

Industry surveys reveal that aircraft operators are increasingly prioritizing technologies that can extend engine life while reducing maintenance costs. Advanced pressure management systems, which can optimize combustion processes and reduce thermal stress on engine components, directly address these concerns. A recent industry report highlighted that aircraft equipped with state-of-the-art pressure management systems demonstrated a 12% reduction in maintenance costs and a 15% improvement in engine longevity.

Environmental regulations are also driving market demand, as newer emission standards require more precise control over combustion processes. The European Union's stricter emission guidelines for recreational aircraft, set to take full effect by 2025, have already prompted manufacturers to invest heavily in advanced pressure management technologies. Similarly, the FAA's proposed updates to light aircraft emission standards are expected to further stimulate market growth in North America.

From a regional perspective, North America currently leads the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 21%. However, the Asia-Pacific region is projected to experience the fastest growth rate over the next decade, driven by the expanding middle class and increasing recreational aviation activities in countries like China, India, and Australia.

Customer preference analysis indicates a growing demand for integrated systems that combine pressure management with other engine monitoring functions. This trend toward comprehensive engine management solutions represents a significant opportunity for technology providers who can offer holistic approaches rather than standalone pressure management components.

The aftermarket segment for pressure management systems is also showing robust growth, as owners of older aircraft seek to upgrade their engines with modern technology to improve performance and comply with evolving regulations. This retrofit market is expected to grow at 9.3% annually, presenting a lucrative opportunity for component manufacturers and service providers specializing in system integration and customization.

This accelerated growth is largely attributed to the rising awareness among aircraft manufacturers and operators about the critical role that precise pressure management plays in engine efficiency, fuel consumption, and overall aircraft performance. The recreational aviation sector, particularly in North America and Europe, represents the largest market segment, accounting for approximately 65% of the total demand for advanced pressure management systems.

Industry surveys reveal that aircraft operators are increasingly prioritizing technologies that can extend engine life while reducing maintenance costs. Advanced pressure management systems, which can optimize combustion processes and reduce thermal stress on engine components, directly address these concerns. A recent industry report highlighted that aircraft equipped with state-of-the-art pressure management systems demonstrated a 12% reduction in maintenance costs and a 15% improvement in engine longevity.

Environmental regulations are also driving market demand, as newer emission standards require more precise control over combustion processes. The European Union's stricter emission guidelines for recreational aircraft, set to take full effect by 2025, have already prompted manufacturers to invest heavily in advanced pressure management technologies. Similarly, the FAA's proposed updates to light aircraft emission standards are expected to further stimulate market growth in North America.

From a regional perspective, North America currently leads the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 21%. However, the Asia-Pacific region is projected to experience the fastest growth rate over the next decade, driven by the expanding middle class and increasing recreational aviation activities in countries like China, India, and Australia.

Customer preference analysis indicates a growing demand for integrated systems that combine pressure management with other engine monitoring functions. This trend toward comprehensive engine management solutions represents a significant opportunity for technology providers who can offer holistic approaches rather than standalone pressure management components.

The aftermarket segment for pressure management systems is also showing robust growth, as owners of older aircraft seek to upgrade their engines with modern technology to improve performance and comply with evolving regulations. This retrofit market is expected to grow at 9.3% annually, presenting a lucrative opportunity for component manufacturers and service providers specializing in system integration and customization.

Current Challenges in LSA Engine Pressure Control

Light Sport Aircraft (LSA) engines face significant pressure management challenges that impede optimal performance and reliability. The primary issue stems from the regulatory constraints that limit LSA engines to 100 horsepower while maintaining strict weight parameters. This power limitation creates a delicate balance between performance demands and pressure control capabilities, particularly during varied flight conditions.

Temperature fluctuations present a major challenge for LSA engine pressure systems. These engines typically operate in diverse environmental conditions, from ground-level heat to high-altitude cold. Such thermal variations cause pressure differentials that are difficult to manage with the simplified systems common in LSA engines, leading to inconsistent performance and potential safety concerns.

Fuel delivery systems in LSA engines often lack the sophisticated pressure regulation found in larger aircraft engines. The simplified fuel injection or carburetion systems struggle to maintain optimal fuel-air mixtures across different altitudes and power settings. This limitation directly impacts combustion efficiency and can result in power fluctuations during critical flight phases such as takeoff or landing.

Weight constraints represent another significant challenge. Advanced pressure management systems typically add weight, which conflicts with LSA certification requirements. Engineers must therefore compromise between effective pressure control and maintaining the aircraft's light-weight classification, often resulting in less robust pressure management solutions.

Altitude compensation presents particular difficulties for LSA engines. As these aircraft climb, decreasing atmospheric pressure affects both intake air density and fuel vaporization rates. Without complex compensating mechanisms, maintaining consistent power output becomes problematic, especially for pilots transitioning between significantly different altitudes during a single flight.

Vibration effects further complicate pressure management in LSA engines. The lightweight construction of these aircraft provides less dampening for engine vibrations, which can affect pressure sensor readings and mechanical pressure regulators. These vibration-induced inaccuracies lead to suboptimal pressure settings and potential engine performance degradation over time.

Cost considerations also limit technological solutions. While advanced electronic pressure management systems exist, their implementation in LSA engines is often prohibitively expensive for manufacturers targeting the recreational and training markets. This economic constraint forces continued reliance on simpler mechanical systems with inherent pressure control limitations.

Temperature fluctuations present a major challenge for LSA engine pressure systems. These engines typically operate in diverse environmental conditions, from ground-level heat to high-altitude cold. Such thermal variations cause pressure differentials that are difficult to manage with the simplified systems common in LSA engines, leading to inconsistent performance and potential safety concerns.

Fuel delivery systems in LSA engines often lack the sophisticated pressure regulation found in larger aircraft engines. The simplified fuel injection or carburetion systems struggle to maintain optimal fuel-air mixtures across different altitudes and power settings. This limitation directly impacts combustion efficiency and can result in power fluctuations during critical flight phases such as takeoff or landing.

Weight constraints represent another significant challenge. Advanced pressure management systems typically add weight, which conflicts with LSA certification requirements. Engineers must therefore compromise between effective pressure control and maintaining the aircraft's light-weight classification, often resulting in less robust pressure management solutions.

Altitude compensation presents particular difficulties for LSA engines. As these aircraft climb, decreasing atmospheric pressure affects both intake air density and fuel vaporization rates. Without complex compensating mechanisms, maintaining consistent power output becomes problematic, especially for pilots transitioning between significantly different altitudes during a single flight.

Vibration effects further complicate pressure management in LSA engines. The lightweight construction of these aircraft provides less dampening for engine vibrations, which can affect pressure sensor readings and mechanical pressure regulators. These vibration-induced inaccuracies lead to suboptimal pressure settings and potential engine performance degradation over time.

Cost considerations also limit technological solutions. While advanced electronic pressure management systems exist, their implementation in LSA engines is often prohibitively expensive for manufacturers targeting the recreational and training markets. This economic constraint forces continued reliance on simpler mechanical systems with inherent pressure control limitations.

Current Pressure Management Solutions and Implementation Methods

01 Engine pressure monitoring and control systems

Systems for monitoring and controlling pressure in engines to optimize performance and prevent damage. These systems include sensors to measure pressure levels, control units to process data, and mechanisms to adjust pressure based on operating conditions. Such systems help maintain optimal engine efficiency, reduce emissions, and extend engine life by preventing excessive pressure conditions.- Engine pressure monitoring and control systems: Systems for monitoring and controlling pressure in engines, particularly in internal combustion engines. These systems include sensors for measuring pressure parameters, control units for processing the data, and mechanisms for adjusting engine operation based on pressure readings. The technology helps optimize engine performance, improve fuel efficiency, and reduce emissions by maintaining optimal pressure conditions during operation.

- LSA (Latent Semantic Analysis) applications in engine diagnostics: Implementation of Latent Semantic Analysis techniques for engine diagnostic purposes. These systems analyze patterns in engine pressure data to identify anomalies, predict failures, and optimize performance. By applying LSA algorithms to pressure sensor readings, the technology can detect subtle relationships between operating parameters that might indicate developing problems before they cause significant damage or performance degradation.

- Supercharged and turbocharged engine pressure management: Specialized systems for managing pressure in forced induction engines, including supercharged and turbocharged configurations. These technologies focus on boost pressure control, intercooling efficiency, and pressure relief mechanisms to prevent engine damage while maximizing power output. The systems include electronic controllers, wastegates, bypass valves, and sensors working together to maintain optimal pressure levels throughout the operating range.

- Pressure sensing technologies for engine applications: Advanced pressure sensing technologies specifically designed for engine environments. These include various types of pressure transducers, optical sensors, piezoelectric devices, and wireless monitoring systems capable of withstanding high temperatures and vibrations. The sensors provide real-time data on intake pressure, exhaust pressure, oil pressure, and combustion chamber pressure to enable precise engine management and diagnostics.

- Fuel system pressure regulation in LSA engines: Specialized pressure regulation systems for fuel delivery in LSA (Lightweight Sport Aircraft) engines and other high-performance applications. These systems maintain optimal fuel pressure across varying operating conditions to ensure proper atomization, combustion efficiency, and power output. The technology includes pressure regulators, fuel pumps, electronic controls, and monitoring systems that work together to deliver precise fuel quantities at the correct pressure.

02 Fuel injection pressure regulation

Technologies focused on regulating and optimizing fuel injection pressure in engines. These innovations include pressure regulators, electronic control systems, and adaptive algorithms that adjust fuel pressure based on engine load, speed, and environmental conditions. Proper fuel pressure regulation ensures efficient combustion, improved power output, and reduced emissions across various operating conditions.Expand Specific Solutions03 Pressure sensing and diagnostic technologies

Advanced technologies for sensing, measuring, and diagnosing pressure-related parameters in engine systems. These include pressure sensors, transducers, and diagnostic algorithms that can detect abnormal pressure conditions, predict potential failures, and provide real-time feedback to engine management systems. These technologies enable preventive maintenance and help avoid catastrophic engine failures due to pressure-related issues.Expand Specific Solutions04 Turbocharger and supercharger pressure management

Systems specifically designed to manage and optimize pressure in forced induction systems such as turbochargers and superchargers. These include boost controllers, wastegates, bypass valves, and electronic management systems that regulate intake pressure to prevent engine damage while maximizing performance. Proper boost pressure management is crucial for balancing power output with engine reliability in forced induction applications.Expand Specific Solutions05 Lubrication system pressure optimization

Technologies focused on optimizing oil pressure in engine lubrication systems. These include oil pumps with variable pressure capabilities, pressure relief valves, sensors, and control algorithms that adjust oil pressure based on engine operating conditions. Maintaining optimal oil pressure ensures proper lubrication of engine components, reduces friction and wear, and contributes to overall engine efficiency and longevity.Expand Specific Solutions

Leading Manufacturers and Suppliers in LSA Engine Technology

LSA Engine Pressure Management Techniques market is in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. The competitive landscape features established automotive giants like Ford, GM, Volkswagen, and Hyundai alongside specialized technology providers such as Robert Bosch and Cummins. These companies are at varying stages of technical maturity, with Ford, Bosch, and Southwest Research Institute demonstrating advanced capabilities through patented solutions. European manufacturers (Mercedes-Benz, BMW) focus on premium applications, while Asian players (Weichai Power, Mitsubishi) are rapidly closing the technology gap. The market is characterized by continuous innovation in electronic pressure control systems, variable pressure regulation, and integration with engine management systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced LSA (Low Swirl Assisted) Engine Pressure Management systems that integrate electronic control units with high-precision sensors to optimize combustion pressure in real-time. Their technology utilizes a network of strategically placed pressure sensors throughout the engine to continuously monitor combustion chamber conditions. The system employs predictive algorithms that adjust fuel injection timing and quantity based on detected pressure variations, effectively managing cylinder pressure peaks. Bosch's solution incorporates adaptive control strategies that modify pressure parameters based on engine load, ambient conditions, and fuel quality. Their proprietary software can detect pressure anomalies within milliseconds and implement corrective measures to prevent engine damage while maintaining performance. The system also features closed-loop feedback mechanisms that continuously optimize pressure profiles across all operating conditions, resulting in up to 5% improvement in fuel efficiency while reducing emissions.

Strengths: Superior sensor integration and real-time adaptive control algorithms provide exceptional precision in pressure management. The system's ability to respond to changing conditions makes it highly versatile across different engine types and operating environments. Weaknesses: Higher implementation cost compared to mechanical solutions and requires sophisticated electronic infrastructure, potentially limiting adoption in lower-cost vehicle segments.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative LSA Engine Pressure Management system that focuses on precision control across diverse driving conditions. Their approach utilizes a network of high-frequency pressure sensors integrated with the engine control module to continuously monitor and adjust combustion parameters. The system features dynamic pressure mapping technology that creates real-time models of cylinder conditions, allowing for microsecond-level adjustments to fuel delivery and spark timing. GM's solution incorporates a patented variable pressure relief valve system that automatically modulates based on engine load and speed to maintain optimal cylinder pressures. Their technology includes advanced thermal modeling algorithms that account for temperature effects on pressure dynamics, ensuring consistent performance across all operating conditions. The system also features adaptive learning capabilities that optimize pressure profiles based on individual driving patterns and fuel quality variations. GM has implemented this technology across multiple vehicle platforms, demonstrating fuel economy improvements of 3-4% and significant reductions in combustion-related emissions. The system's modular design allows for scalability across different engine sizes and configurations, from small displacement turbocharged engines to larger naturally aspirated powerplants.

Strengths: Excellent integration with existing vehicle systems and consumer-friendly operation that requires no special driver intervention. The technology's adaptability to different driving styles enhances both performance and efficiency. Weaknesses: Requires periodic calibration updates to maintain optimal performance and may have limited effectiveness with lower-quality fuels in some markets.

Key Patents and Innovations in LSA Pressure Control Systems

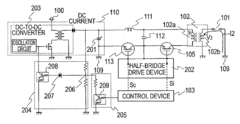

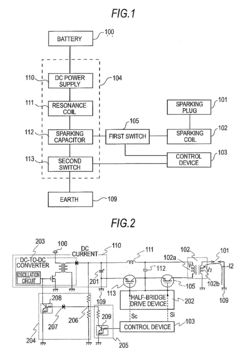

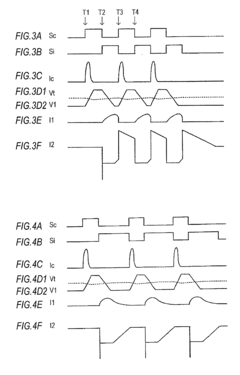

Ignition apparatus

PatentInactiveUS20120293088A1

Innovation

- A compact capacitive discharge ignition apparatus is designed with a sparking coil, energy supply device, and control system that includes a DC power supply, resonance coil, sparking capacitor, and switches to generate high voltage through LC resonance, enabling efficient energy storage and supply to the sparking coil, allowing for continuous spark discharge and quick re-establishment of the plasma path.

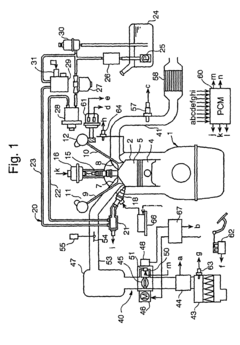

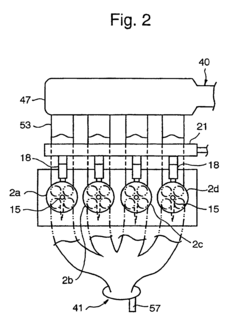

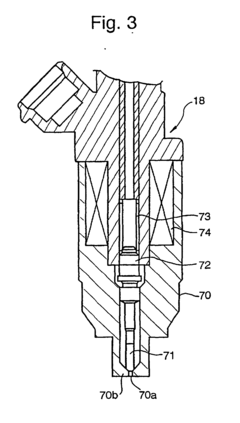

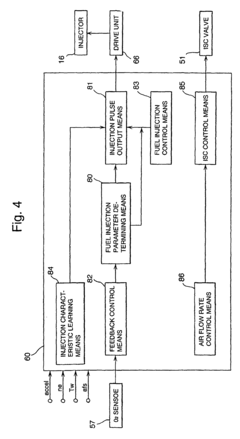

Fuel injection control system for direct injection-spark ignition engine

PatentInactiveEP0947684B1

Innovation

- A fuel injection control system that performs fuel injection feedback control based on air-fuel ratio detected by an oxygen sensor, executes intake stroke split injections, and learns the fuel injection quantity characteristic to determine a leaning correction value, reflecting it on the control of fuel injection in the minute injection zone to maintain accurate stoichiometric air-fuel ratios, while also controlling ignition timing and intake air flow to stabilize engine speed.

Environmental Impact and Emissions Compliance Considerations

LSA (Luxury Sport Architecture) engine pressure management techniques must be evaluated not only for performance but also for their environmental impact and regulatory compliance. Modern emission standards such as Euro 7, China 6b, and US EPA Tier 3 impose increasingly stringent limits on pollutants including NOx, particulate matter, and CO2. These regulations directly influence pressure management system design, as combustion chamber pressure significantly affects emission formation.

Advanced pressure management systems in LSA engines contribute to reduced emissions through precise control of air-fuel ratios and combustion temperatures. Variable valve timing and lift technologies, when integrated with sophisticated pressure management, can reduce pumping losses by up to 15%, directly translating to lower CO2 emissions. Additionally, direct injection systems operating at optimized pressures (typically 200-350 bar) demonstrate up to 25% reduction in particulate matter compared to conventional port injection systems.

Thermal management aspects of pressure systems also play a crucial role in emissions compliance. Exhaust gas recirculation (EGR) systems, which rely on precise pressure differentials, can reduce NOx emissions by 40-60% when properly calibrated. However, these systems must be carefully balanced to avoid efficiency penalties that could increase overall carbon footprint.

Real-world driving emissions (RDE) testing has revealed that many pressure management technologies perform differently under laboratory versus actual driving conditions. This discrepancy has prompted manufacturers to implement more robust pressure control algorithms that maintain optimal performance across diverse operating environments, ensuring compliance with not just test-cycle standards but also in-use requirements.

The materials used in pressure management components also carry environmental implications. Traditional materials may contain heavy metals or require energy-intensive manufacturing processes. Advanced ceramic coatings and composite materials are emerging as environmentally preferable alternatives, reducing the lifecycle environmental impact while maintaining or improving pressure management capabilities.

Looking forward, zero-emission vehicle mandates in various markets will necessitate hybrid pressure management solutions that can transition between combustion and electric propulsion modes. These systems must maintain emissions compliance during cold starts and transient operations when the combustion engine is activated intermittently, presenting unique challenges for pressure control strategies.

Cost-benefit analysis indicates that while advanced pressure management technologies may increase initial manufacturing costs by 5-8%, the avoided regulatory non-compliance penalties and potential carbon taxation savings justify these investments, particularly in premium LSA applications where performance expectations remain high despite environmental constraints.

Advanced pressure management systems in LSA engines contribute to reduced emissions through precise control of air-fuel ratios and combustion temperatures. Variable valve timing and lift technologies, when integrated with sophisticated pressure management, can reduce pumping losses by up to 15%, directly translating to lower CO2 emissions. Additionally, direct injection systems operating at optimized pressures (typically 200-350 bar) demonstrate up to 25% reduction in particulate matter compared to conventional port injection systems.

Thermal management aspects of pressure systems also play a crucial role in emissions compliance. Exhaust gas recirculation (EGR) systems, which rely on precise pressure differentials, can reduce NOx emissions by 40-60% when properly calibrated. However, these systems must be carefully balanced to avoid efficiency penalties that could increase overall carbon footprint.

Real-world driving emissions (RDE) testing has revealed that many pressure management technologies perform differently under laboratory versus actual driving conditions. This discrepancy has prompted manufacturers to implement more robust pressure control algorithms that maintain optimal performance across diverse operating environments, ensuring compliance with not just test-cycle standards but also in-use requirements.

The materials used in pressure management components also carry environmental implications. Traditional materials may contain heavy metals or require energy-intensive manufacturing processes. Advanced ceramic coatings and composite materials are emerging as environmentally preferable alternatives, reducing the lifecycle environmental impact while maintaining or improving pressure management capabilities.

Looking forward, zero-emission vehicle mandates in various markets will necessitate hybrid pressure management solutions that can transition between combustion and electric propulsion modes. These systems must maintain emissions compliance during cold starts and transient operations when the combustion engine is activated intermittently, presenting unique challenges for pressure control strategies.

Cost-benefit analysis indicates that while advanced pressure management technologies may increase initial manufacturing costs by 5-8%, the avoided regulatory non-compliance penalties and potential carbon taxation savings justify these investments, particularly in premium LSA applications where performance expectations remain high despite environmental constraints.

Durability and Reliability Testing Methodologies

Durability and reliability testing methodologies for LSA Engine Pressure Management Techniques require comprehensive validation protocols to ensure system integrity under various operating conditions. These methodologies typically follow a multi-phase approach, beginning with accelerated life testing where pressure management components are subjected to pressure cycles far exceeding normal operational parameters.

Thermal cycling tests represent a critical component of durability assessment, with pressure management systems undergoing rapid temperature fluctuations between -40°C and 150°C to simulate extreme environmental conditions. These tests typically run for 1,000 to 5,000 cycles, with pressure sensors and regulators monitored continuously for performance degradation.

Vibration testing employs both sinusoidal and random vibration profiles to replicate real-world engine conditions. Test fixtures mount pressure management components in multiple orientations while applying frequencies ranging from 10Hz to 2000Hz at varying amplitudes. This methodology identifies potential failure points in pressure sensor mounts, regulator diaphragms, and connection interfaces.

Contamination resistance testing evaluates system performance when exposed to particulates, oils, and moisture. Standardized contaminants are introduced into the pressure management system at controlled rates while monitoring response times and accuracy. This methodology has proven particularly valuable in identifying potential failure modes in pressure relief valves and sensor elements.

Long-term endurance testing remains the gold standard for reliability assessment, with pressure management systems operated continuously for 3,000+ hours under varying load conditions. Data logging occurs at predetermined intervals, tracking drift in pressure regulation accuracy, response times, and leak rates. Statistical analysis of this data enables the calculation of Mean Time Between Failures (MTBF) and reliability projections.

Failure mode and effects analysis (FMEA) methodologies complement physical testing by systematically identifying potential failure mechanisms in pressure management systems. Critical components undergo destructive testing to establish safety margins and validate theoretical failure thresholds. These results inform design modifications and maintenance schedules.

Advanced non-destructive testing techniques, including acoustic emission monitoring and thermographic imaging, have recently been integrated into LSA engine pressure management testing protocols. These methodologies enable real-time detection of developing faults before catastrophic failure occurs, significantly enhancing test efficiency and data quality.

Industry standards such as SAE J1455 and ISO 16750 provide baseline requirements for testing methodologies, though leading manufacturers typically exceed these standards with proprietary test protocols developed through decades of field experience and failure analysis.

Thermal cycling tests represent a critical component of durability assessment, with pressure management systems undergoing rapid temperature fluctuations between -40°C and 150°C to simulate extreme environmental conditions. These tests typically run for 1,000 to 5,000 cycles, with pressure sensors and regulators monitored continuously for performance degradation.

Vibration testing employs both sinusoidal and random vibration profiles to replicate real-world engine conditions. Test fixtures mount pressure management components in multiple orientations while applying frequencies ranging from 10Hz to 2000Hz at varying amplitudes. This methodology identifies potential failure points in pressure sensor mounts, regulator diaphragms, and connection interfaces.

Contamination resistance testing evaluates system performance when exposed to particulates, oils, and moisture. Standardized contaminants are introduced into the pressure management system at controlled rates while monitoring response times and accuracy. This methodology has proven particularly valuable in identifying potential failure modes in pressure relief valves and sensor elements.

Long-term endurance testing remains the gold standard for reliability assessment, with pressure management systems operated continuously for 3,000+ hours under varying load conditions. Data logging occurs at predetermined intervals, tracking drift in pressure regulation accuracy, response times, and leak rates. Statistical analysis of this data enables the calculation of Mean Time Between Failures (MTBF) and reliability projections.

Failure mode and effects analysis (FMEA) methodologies complement physical testing by systematically identifying potential failure mechanisms in pressure management systems. Critical components undergo destructive testing to establish safety margins and validate theoretical failure thresholds. These results inform design modifications and maintenance schedules.

Advanced non-destructive testing techniques, including acoustic emission monitoring and thermographic imaging, have recently been integrated into LSA engine pressure management testing protocols. These methodologies enable real-time detection of developing faults before catastrophic failure occurs, significantly enhancing test efficiency and data quality.

Industry standards such as SAE J1455 and ISO 16750 provide baseline requirements for testing methodologies, though leading manufacturers typically exceed these standards with proprietary test protocols developed through decades of field experience and failure analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!