Magnesium Nitride and Its Revolutionary Impact on Metal Forming

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitride Overview and Objectives

Magnesium nitride (Mg3N2) has emerged as a groundbreaking material in the field of metal forming, offering unprecedented possibilities for enhancing the properties and processing of magnesium-based alloys. This compound, formed by the reaction of magnesium with nitrogen, has been known to scientists for decades but has only recently gained significant attention in industrial applications, particularly in the automotive and aerospace sectors.

The development of magnesium nitride technology can be traced back to the early 20th century, with initial studies focusing on its synthesis and basic properties. However, it wasn't until the late 1990s and early 2000s that researchers began to explore its potential in metal forming processes. The evolution of this technology has been driven by the increasing demand for lightweight, high-strength materials in various industries, coupled with advancements in materials science and manufacturing techniques.

The primary objective of magnesium nitride research in metal forming is to overcome the limitations of traditional magnesium alloys, such as poor formability at room temperature and high reactivity. By incorporating magnesium nitride into the metal matrix or using it as a surface treatment, researchers aim to enhance the mechanical properties, corrosion resistance, and formability of magnesium-based materials. This could potentially lead to a wider adoption of magnesium alloys in structural applications, contributing to weight reduction and improved fuel efficiency in transportation systems.

Current technological trends in this field include the development of novel synthesis methods for magnesium nitride, optimization of its incorporation into magnesium alloys, and exploration of its effects on microstructure and properties. Researchers are also investigating the use of magnesium nitride in advanced forming processes, such as superplastic forming and severe plastic deformation techniques, to further expand the capabilities of magnesium-based materials.

The potential impact of magnesium nitride on metal forming extends beyond just improving material properties. It opens up new possibilities for designing complex shapes and structures that were previously challenging or impossible to achieve with conventional magnesium alloys. This could revolutionize product design in industries ranging from consumer electronics to medical devices, enabling the creation of lighter, stronger, and more versatile components.

As research in this area progresses, the ultimate goal is to establish magnesium nitride as a key enabler in the widespread adoption of magnesium alloys across various industrial sectors. This would not only contribute to advancements in material science but also support global efforts towards sustainability and energy efficiency through the use of lightweight, recyclable materials.

The development of magnesium nitride technology can be traced back to the early 20th century, with initial studies focusing on its synthesis and basic properties. However, it wasn't until the late 1990s and early 2000s that researchers began to explore its potential in metal forming processes. The evolution of this technology has been driven by the increasing demand for lightweight, high-strength materials in various industries, coupled with advancements in materials science and manufacturing techniques.

The primary objective of magnesium nitride research in metal forming is to overcome the limitations of traditional magnesium alloys, such as poor formability at room temperature and high reactivity. By incorporating magnesium nitride into the metal matrix or using it as a surface treatment, researchers aim to enhance the mechanical properties, corrosion resistance, and formability of magnesium-based materials. This could potentially lead to a wider adoption of magnesium alloys in structural applications, contributing to weight reduction and improved fuel efficiency in transportation systems.

Current technological trends in this field include the development of novel synthesis methods for magnesium nitride, optimization of its incorporation into magnesium alloys, and exploration of its effects on microstructure and properties. Researchers are also investigating the use of magnesium nitride in advanced forming processes, such as superplastic forming and severe plastic deformation techniques, to further expand the capabilities of magnesium-based materials.

The potential impact of magnesium nitride on metal forming extends beyond just improving material properties. It opens up new possibilities for designing complex shapes and structures that were previously challenging or impossible to achieve with conventional magnesium alloys. This could revolutionize product design in industries ranging from consumer electronics to medical devices, enabling the creation of lighter, stronger, and more versatile components.

As research in this area progresses, the ultimate goal is to establish magnesium nitride as a key enabler in the widespread adoption of magnesium alloys across various industrial sectors. This would not only contribute to advancements in material science but also support global efforts towards sustainability and energy efficiency through the use of lightweight, recyclable materials.

Market Demand Analysis for Advanced Metal Forming

The market demand for advanced metal forming techniques has been steadily increasing, driven by the growing need for lightweight, high-strength materials across various industries. Magnesium nitride, a compound with unique properties, has emerged as a potential game-changer in this field. The automotive sector, in particular, has shown significant interest in magnesium-based alloys due to their excellent strength-to-weight ratio, which aligns with the industry's push for fuel efficiency and reduced emissions.

Aerospace and defense industries are also key drivers of demand for advanced metal forming technologies. These sectors require materials that can withstand extreme conditions while maintaining structural integrity. The potential of magnesium nitride to enhance the formability and strength of magnesium alloys has caught the attention of aerospace manufacturers looking to develop next-generation aircraft components.

Consumer electronics represent another substantial market for advanced metal forming. As devices become thinner and more durable, there is a growing demand for materials that can be formed into complex shapes while maintaining strength and lightweight properties. Magnesium nitride's potential to improve the formability of magnesium alloys could lead to innovative designs in smartphones, laptops, and wearable devices.

The construction industry, although traditionally slower to adopt new materials, has shown increasing interest in lightweight, corrosion-resistant metals for architectural applications. Magnesium alloys enhanced by nitride compounds could offer new possibilities for creating strong, lightweight structures that are easier to transport and assemble.

Market analysis indicates that the global advanced metal forming market is expected to grow significantly in the coming years. This growth is fueled by the increasing adoption of lightweight materials in various end-use industries and the continuous development of new forming technologies. The Asia-Pacific region, particularly China and Japan, is anticipated to be a major contributor to this growth due to their robust manufacturing sectors and investments in research and development.

The potential impact of magnesium nitride on metal forming processes aligns well with the broader industry trends towards sustainability and resource efficiency. As manufacturers seek to reduce material waste and energy consumption in their production processes, technologies that enable more precise and efficient metal forming are likely to see increased demand.

However, the market adoption of magnesium nitride-enhanced metal forming processes will depend on several factors, including the scalability of production, cost-effectiveness compared to existing technologies, and the ability to meet stringent industry standards. Ongoing research and development efforts will be crucial in addressing these challenges and realizing the full market potential of this innovative technology.

Aerospace and defense industries are also key drivers of demand for advanced metal forming technologies. These sectors require materials that can withstand extreme conditions while maintaining structural integrity. The potential of magnesium nitride to enhance the formability and strength of magnesium alloys has caught the attention of aerospace manufacturers looking to develop next-generation aircraft components.

Consumer electronics represent another substantial market for advanced metal forming. As devices become thinner and more durable, there is a growing demand for materials that can be formed into complex shapes while maintaining strength and lightweight properties. Magnesium nitride's potential to improve the formability of magnesium alloys could lead to innovative designs in smartphones, laptops, and wearable devices.

The construction industry, although traditionally slower to adopt new materials, has shown increasing interest in lightweight, corrosion-resistant metals for architectural applications. Magnesium alloys enhanced by nitride compounds could offer new possibilities for creating strong, lightweight structures that are easier to transport and assemble.

Market analysis indicates that the global advanced metal forming market is expected to grow significantly in the coming years. This growth is fueled by the increasing adoption of lightweight materials in various end-use industries and the continuous development of new forming technologies. The Asia-Pacific region, particularly China and Japan, is anticipated to be a major contributor to this growth due to their robust manufacturing sectors and investments in research and development.

The potential impact of magnesium nitride on metal forming processes aligns well with the broader industry trends towards sustainability and resource efficiency. As manufacturers seek to reduce material waste and energy consumption in their production processes, technologies that enable more precise and efficient metal forming are likely to see increased demand.

However, the market adoption of magnesium nitride-enhanced metal forming processes will depend on several factors, including the scalability of production, cost-effectiveness compared to existing technologies, and the ability to meet stringent industry standards. Ongoing research and development efforts will be crucial in addressing these challenges and realizing the full market potential of this innovative technology.

Current Challenges in Magnesium Nitride Synthesis

The synthesis of magnesium nitride (Mg3N2) presents several significant challenges that hinder its widespread application in metal forming processes. One of the primary obstacles is the high reactivity of magnesium with oxygen and moisture, which necessitates stringent control over the reaction environment. This sensitivity to air and water makes large-scale production and handling of Mg3N2 particularly demanding, requiring sophisticated containment systems and inert atmospheres throughout the synthesis and storage processes.

Another major challenge lies in the high temperatures required for the direct nitridation of magnesium. Conventional synthesis methods often involve heating magnesium powder in a nitrogen atmosphere at temperatures exceeding 700°C. These extreme conditions not only increase energy consumption and production costs but also pose safety risks and limit the scalability of the process. Furthermore, the high-temperature synthesis can lead to sintering and agglomeration of particles, potentially reducing the surface area and reactivity of the final product.

The purity and stoichiometry of the synthesized Mg3N2 also present significant hurdles. Achieving a uniform and complete nitridation of magnesium is challenging, often resulting in products with varying nitrogen content or residual unreacted magnesium. These impurities can significantly affect the properties and performance of Mg3N2 in metal forming applications, leading to inconsistent results and reduced efficiency in downstream processes.

Control over particle size and morphology during synthesis is another critical challenge. The physical characteristics of Mg3N2 particles, including size distribution and shape, play a crucial role in their reactivity and effectiveness in metal forming. However, achieving precise control over these parameters during high-temperature synthesis is difficult, often resulting in heterogeneous products that may not meet the stringent requirements of advanced metal forming techniques.

The stability of Mg3N2 under various environmental conditions also poses challenges for its practical application. The compound's tendency to hydrolyze in the presence of moisture, forming magnesium hydroxide and ammonia, necessitates careful handling and storage procedures. This instability complicates the integration of Mg3N2 into existing metal forming processes and limits its shelf life, potentially increasing operational costs and complexity.

Lastly, the development of cost-effective and scalable production methods remains a significant challenge. Current synthesis techniques often involve batch processes with limited throughput, making large-scale production economically unfeasible for many applications. The lack of continuous, high-volume production methods hampers the widespread adoption of Mg3N2 in industrial metal forming processes, despite its promising properties.

Another major challenge lies in the high temperatures required for the direct nitridation of magnesium. Conventional synthesis methods often involve heating magnesium powder in a nitrogen atmosphere at temperatures exceeding 700°C. These extreme conditions not only increase energy consumption and production costs but also pose safety risks and limit the scalability of the process. Furthermore, the high-temperature synthesis can lead to sintering and agglomeration of particles, potentially reducing the surface area and reactivity of the final product.

The purity and stoichiometry of the synthesized Mg3N2 also present significant hurdles. Achieving a uniform and complete nitridation of magnesium is challenging, often resulting in products with varying nitrogen content or residual unreacted magnesium. These impurities can significantly affect the properties and performance of Mg3N2 in metal forming applications, leading to inconsistent results and reduced efficiency in downstream processes.

Control over particle size and morphology during synthesis is another critical challenge. The physical characteristics of Mg3N2 particles, including size distribution and shape, play a crucial role in their reactivity and effectiveness in metal forming. However, achieving precise control over these parameters during high-temperature synthesis is difficult, often resulting in heterogeneous products that may not meet the stringent requirements of advanced metal forming techniques.

The stability of Mg3N2 under various environmental conditions also poses challenges for its practical application. The compound's tendency to hydrolyze in the presence of moisture, forming magnesium hydroxide and ammonia, necessitates careful handling and storage procedures. This instability complicates the integration of Mg3N2 into existing metal forming processes and limits its shelf life, potentially increasing operational costs and complexity.

Lastly, the development of cost-effective and scalable production methods remains a significant challenge. Current synthesis techniques often involve batch processes with limited throughput, making large-scale production economically unfeasible for many applications. The lack of continuous, high-volume production methods hampers the widespread adoption of Mg3N2 in industrial metal forming processes, despite its promising properties.

Existing Magnesium Nitride Applications

01 Magnesium nitride formation and applications

Magnesium nitride can be formed through various processes and has applications in semiconductor manufacturing and metal forming. It can be used as a precursor for creating thin films or as a component in composite materials for improved mechanical properties.- Magnesium nitride synthesis and applications: Magnesium nitride is synthesized and used in various applications, including metal forming processes. It can be produced through different methods and has properties that make it suitable for use in metallurgy and materials science.

- Metal forming processes using magnesium nitride: Magnesium nitride is utilized in metal forming processes to improve the properties of metals and alloys. It can be incorporated into the metal matrix or used as a surface treatment to enhance hardness, wear resistance, and other mechanical properties.

- Thin film deposition and semiconductor applications: Magnesium nitride is employed in thin film deposition processes for semiconductor applications. It can be used as a buffer layer, dielectric material, or in the formation of compound semiconductors, contributing to the development of advanced electronic devices.

- Magnesium nitride in energy storage and conversion: The material is explored for its potential in energy storage and conversion applications. It can be used in the development of advanced batteries, fuel cells, and other energy-related technologies, leveraging its unique properties and chemical characteristics.

- Surface treatment and coating technologies: Magnesium nitride is utilized in surface treatment and coating technologies for various metals and alloys. It can be applied through different methods to enhance surface properties, corrosion resistance, and overall performance of metal components.

02 Metal forming processes using magnesium nitride

Magnesium nitride can be incorporated into metal forming processes to enhance material properties or as a protective layer. It may be used in powder metallurgy, sintering, or as a coating to improve wear resistance and surface hardness of metal components.Expand Specific Solutions03 Synthesis and preparation methods of magnesium nitride

Various methods for synthesizing and preparing magnesium nitride are explored, including direct nitridation of magnesium, plasma-enhanced chemical vapor deposition, and reactive sputtering. These methods aim to produce high-quality magnesium nitride for specific applications in metal forming and other industries.Expand Specific Solutions04 Magnesium nitride in thin film and coating technologies

Magnesium nitride is utilized in thin film and coating technologies for metal forming applications. It can be deposited as a protective layer or used to modify surface properties of metals, potentially improving corrosion resistance, hardness, and wear resistance.Expand Specific Solutions05 Magnesium nitride in composite materials for metal forming

Magnesium nitride is incorporated into composite materials to enhance their properties for metal forming applications. These composites may exhibit improved strength, thermal stability, and formability, making them suitable for various metal forming processes and advanced manufacturing techniques.Expand Specific Solutions

Key Players in Magnesium Nitride Research

The development of magnesium nitride and its impact on metal forming is in an early stage, with significant potential for growth. The market size is relatively small but expanding, driven by increasing demand for lightweight materials in automotive and aerospace industries. The technology's maturity is still evolving, with key players like Proterial Ltd., Tokuyama Corp., and Honda Motor Co., Ltd. investing in research and development. These companies are exploring innovative applications of magnesium nitride in metal forming processes, aiming to enhance material properties and manufacturing efficiency. As the technology progresses, collaboration between academic institutions like Nanchang University and industry leaders is expected to accelerate advancements and commercial adoption.

Institute of Metal Research Chinese Academy of Sciences

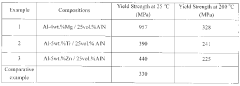

Technical Solution: The Institute of Metal Research (IMR) has developed advanced techniques for synthesizing high-purity magnesium nitride (Mg3N2) powders using a direct nitridation method. Their process involves reacting high-purity magnesium metal with nitrogen gas at elevated temperatures (600-800°C) under controlled pressure conditions. This results in fine Mg3N2 particles with high surface area and reactivity[1]. IMR has also explored the use of Mg3N2 as a precursor for creating novel magnesium-based alloys and composites with enhanced mechanical properties. Their research has shown that Mg3N2 can be used to introduce nitrogen into magnesium alloys, leading to significant grain refinement and improved strength[2][3].

Strengths: High-purity Mg3N2 synthesis, expertise in magnesium alloy development, and potential for improved mechanical properties. Weaknesses: Scalability of the process for industrial production and potential high costs associated with high-purity materials and controlled reaction conditions.

SixPoint Materials, Inc.

Technical Solution: SixPoint Materials has developed proprietary technology for the production of high-purity magnesium nitride (Mg3N2) powders and single crystals. Their process involves a novel vapor-phase synthesis method that allows for precise control over particle size, morphology, and purity. SixPoint's Mg3N2 materials have found applications in advanced ceramics, semiconductor manufacturing, and metal forming processes. In the context of metal forming, SixPoint has collaborated with industry partners to explore the use of their high-purity Mg3N2 as a sintering aid for magnesium-based alloys. Their research has shown that the addition of small amounts of Mg3N2 during the sintering process can lead to improved densification and enhanced mechanical properties of the final magnesium components[10]. SixPoint has also investigated the potential of Mg3N2 as a precursor for creating nitride coatings on metal surfaces, which could enhance wear resistance and corrosion protection in various industrial applications[11].

Strengths: High-purity Mg3N2 production capabilities, versatile applications in multiple industries. Weaknesses: Potentially high production costs, limited scale of current operations.

Breakthrough Magnesium Nitride Innovations

Method for manufacturing high strength ultra-fine/NANO-structured al /ALN or al alloy/ALN composite materials

PatentWO2006129965A1

Innovation

- A method involving mechanical milling or mechanical alloying in a nitride-forming atmosphere, followed by heat treatment and hot consolidation, ensures homogeneous distribution of aluminum nitride reinforcements and prevents oxide layer formation, using nitrogen or ammonia gases for direct nitride formation without additional processes.

Environmental Impact Assessment

The environmental impact assessment of magnesium nitride in metal forming processes reveals both potential benefits and challenges. Magnesium nitride's unique properties offer opportunities for more energy-efficient and environmentally friendly metal forming techniques. The compound's ability to enhance material properties at lower temperatures could lead to reduced energy consumption in manufacturing processes, potentially decreasing greenhouse gas emissions associated with traditional high-temperature metal forming methods.

However, the production and use of magnesium nitride also present environmental considerations. The synthesis of magnesium nitride typically involves energy-intensive processes, which may offset some of the environmental gains achieved in its application. Additionally, the potential release of nitrogen compounds during the metal forming process requires careful management to prevent air and water pollution.

The lifecycle analysis of magnesium nitride in metal forming applications indicates a mixed environmental profile. While it may reduce the overall carbon footprint of certain manufacturing processes, the extraction and processing of raw materials for magnesium nitride production could have localized environmental impacts. These may include habitat disruption, water usage concerns, and potential soil contamination if not properly managed.

From a waste management perspective, the use of magnesium nitride in metal forming could lead to the generation of new types of industrial byproducts. The development of appropriate recycling and disposal methods for these materials is crucial to minimize long-term environmental impacts. Furthermore, the potential for magnesium nitride to improve the durability and performance of metal products could indirectly contribute to resource conservation by extending product lifespans and reducing the need for frequent replacements.

The adoption of magnesium nitride in metal forming processes also presents opportunities for cleaner production technologies. By enabling more precise control over material properties, it may reduce material waste and improve overall resource efficiency in manufacturing. This could lead to a decrease in the volume of industrial waste generated and the associated environmental burdens of waste disposal.

In conclusion, while magnesium nitride shows promise for revolutionizing metal forming with potential environmental benefits, a comprehensive and ongoing assessment is necessary to fully understand and mitigate its ecological impacts throughout its lifecycle. Balancing the environmental advantages with the challenges will be crucial for the sustainable integration of this technology into industrial processes.

However, the production and use of magnesium nitride also present environmental considerations. The synthesis of magnesium nitride typically involves energy-intensive processes, which may offset some of the environmental gains achieved in its application. Additionally, the potential release of nitrogen compounds during the metal forming process requires careful management to prevent air and water pollution.

The lifecycle analysis of magnesium nitride in metal forming applications indicates a mixed environmental profile. While it may reduce the overall carbon footprint of certain manufacturing processes, the extraction and processing of raw materials for magnesium nitride production could have localized environmental impacts. These may include habitat disruption, water usage concerns, and potential soil contamination if not properly managed.

From a waste management perspective, the use of magnesium nitride in metal forming could lead to the generation of new types of industrial byproducts. The development of appropriate recycling and disposal methods for these materials is crucial to minimize long-term environmental impacts. Furthermore, the potential for magnesium nitride to improve the durability and performance of metal products could indirectly contribute to resource conservation by extending product lifespans and reducing the need for frequent replacements.

The adoption of magnesium nitride in metal forming processes also presents opportunities for cleaner production technologies. By enabling more precise control over material properties, it may reduce material waste and improve overall resource efficiency in manufacturing. This could lead to a decrease in the volume of industrial waste generated and the associated environmental burdens of waste disposal.

In conclusion, while magnesium nitride shows promise for revolutionizing metal forming with potential environmental benefits, a comprehensive and ongoing assessment is necessary to fully understand and mitigate its ecological impacts throughout its lifecycle. Balancing the environmental advantages with the challenges will be crucial for the sustainable integration of this technology into industrial processes.

Economic Feasibility Analysis

The economic feasibility of implementing magnesium nitride in metal forming processes is a critical consideration for industries seeking to adopt this revolutionary technology. Initial cost analysis indicates that while the upfront investment for magnesium nitride-based systems may be higher than traditional metal forming methods, the long-term benefits could potentially outweigh these costs.

One of the primary economic advantages of magnesium nitride in metal forming is its potential to significantly reduce energy consumption. The unique properties of magnesium nitride allow for lower processing temperatures, which translates to reduced energy requirements and associated costs. This energy efficiency not only contributes to cost savings but also aligns with growing environmental regulations and sustainability goals, potentially offering additional economic benefits through compliance and improved corporate image.

The durability and longevity of magnesium nitride-treated tools and components present another area of economic benefit. The enhanced wear resistance and thermal stability of magnesium nitride coatings can extend the lifespan of metal forming equipment, reducing replacement and maintenance costs over time. This increased tool life can lead to improved production efficiency and reduced downtime, further contributing to overall cost savings.

From a production standpoint, magnesium nitride's ability to enable more complex and precise metal forming processes could lead to higher-value products and expanded market opportunities. The potential for creating lighter, stronger, and more intricately designed components may open up new revenue streams in industries such as aerospace, automotive, and consumer electronics, where such attributes are highly valued.

However, the economic feasibility also faces challenges. The current limited availability of magnesium nitride and the specialized equipment required for its application may result in higher initial costs. Additionally, the need for workforce training and potential process modifications could incur short-term expenses. These factors must be carefully weighed against the projected long-term benefits.

Market demand and competitive advantage also play crucial roles in the economic equation. As industries increasingly prioritize lightweight, high-strength materials, the demand for magnesium nitride-enabled products is expected to grow. Early adopters of this technology may gain a significant competitive edge, potentially capturing larger market shares and commanding premium prices for their advanced products.

In conclusion, while the economic feasibility of magnesium nitride in metal forming shows promise, a comprehensive cost-benefit analysis specific to each implementation scenario is essential. Factors such as production volume, target markets, regulatory environment, and long-term strategic goals must be carefully considered to determine the true economic viability of adopting this innovative technology.

One of the primary economic advantages of magnesium nitride in metal forming is its potential to significantly reduce energy consumption. The unique properties of magnesium nitride allow for lower processing temperatures, which translates to reduced energy requirements and associated costs. This energy efficiency not only contributes to cost savings but also aligns with growing environmental regulations and sustainability goals, potentially offering additional economic benefits through compliance and improved corporate image.

The durability and longevity of magnesium nitride-treated tools and components present another area of economic benefit. The enhanced wear resistance and thermal stability of magnesium nitride coatings can extend the lifespan of metal forming equipment, reducing replacement and maintenance costs over time. This increased tool life can lead to improved production efficiency and reduced downtime, further contributing to overall cost savings.

From a production standpoint, magnesium nitride's ability to enable more complex and precise metal forming processes could lead to higher-value products and expanded market opportunities. The potential for creating lighter, stronger, and more intricately designed components may open up new revenue streams in industries such as aerospace, automotive, and consumer electronics, where such attributes are highly valued.

However, the economic feasibility also faces challenges. The current limited availability of magnesium nitride and the specialized equipment required for its application may result in higher initial costs. Additionally, the need for workforce training and potential process modifications could incur short-term expenses. These factors must be carefully weighed against the projected long-term benefits.

Market demand and competitive advantage also play crucial roles in the economic equation. As industries increasingly prioritize lightweight, high-strength materials, the demand for magnesium nitride-enabled products is expected to grow. Early adopters of this technology may gain a significant competitive edge, potentially capturing larger market shares and commanding premium prices for their advanced products.

In conclusion, while the economic feasibility of magnesium nitride in metal forming shows promise, a comprehensive cost-benefit analysis specific to each implementation scenario is essential. Factors such as production volume, target markets, regulatory environment, and long-term strategic goals must be carefully considered to determine the true economic viability of adopting this innovative technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!