Manufacturing Considerations For Large-Format RT Na–S Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RT Na-S Battery Development Background and Objectives

Room temperature sodium-sulfur (RT Na-S) batteries represent a significant evolution in energy storage technology, emerging from the traditional high-temperature Na-S battery systems that operate at approximately 300-350°C. The development of RT Na-S technology began in the early 2000s as researchers sought to overcome the safety concerns and complex thermal management requirements associated with high-temperature systems. This technological shift was primarily motivated by the increasing demand for safer, more cost-effective, and environmentally friendly energy storage solutions.

The evolution of RT Na-S batteries has been marked by several key milestones. Initial research focused on addressing the fundamental challenges of room temperature operation, particularly the poor ionic conductivity of solid electrolytes at lower temperatures and the formation of sodium polysulfides that can dissolve in the electrolyte, causing capacity fading. By 2010, significant progress had been made in developing novel electrolyte compositions and electrode materials that enabled stable operation at ambient temperatures.

Current RT Na-S battery technology offers theoretical energy densities of 760 Wh/kg, substantially higher than commercial lithium-ion batteries. This high energy density, combined with the abundant and low-cost nature of sodium and sulfur resources, positions RT Na-S batteries as a promising alternative for large-scale energy storage applications.

The primary objective of RT Na-S battery development is to create commercially viable large-format cells that can be manufactured at scale while maintaining performance, safety, and cost advantages. Specific technical goals include achieving practical energy densities exceeding 300 Wh/kg, cycle life of over 1,000 cycles, and production costs below $100/kWh. These targets would make RT Na-S batteries competitive with existing technologies for grid storage and potentially for electric vehicle applications.

Additional development objectives focus on addressing key manufacturing challenges, including the handling of reactive sodium metal, uniform deposition of sulfur cathodes, electrolyte stability, and cell sealing techniques appropriate for large-format cells. The optimization of these manufacturing processes is critical for transitioning from laboratory-scale prototypes to industrial production.

The strategic importance of RT Na-S technology development extends beyond technical performance metrics. As global energy systems transition toward renewable sources, the need for efficient, sustainable, and economical energy storage solutions becomes increasingly urgent. RT Na-S batteries, with their potential for low environmental impact and reliance on abundant materials, align well with sustainability goals and could help mitigate supply chain risks associated with lithium-ion battery materials.

The evolution of RT Na-S batteries has been marked by several key milestones. Initial research focused on addressing the fundamental challenges of room temperature operation, particularly the poor ionic conductivity of solid electrolytes at lower temperatures and the formation of sodium polysulfides that can dissolve in the electrolyte, causing capacity fading. By 2010, significant progress had been made in developing novel electrolyte compositions and electrode materials that enabled stable operation at ambient temperatures.

Current RT Na-S battery technology offers theoretical energy densities of 760 Wh/kg, substantially higher than commercial lithium-ion batteries. This high energy density, combined with the abundant and low-cost nature of sodium and sulfur resources, positions RT Na-S batteries as a promising alternative for large-scale energy storage applications.

The primary objective of RT Na-S battery development is to create commercially viable large-format cells that can be manufactured at scale while maintaining performance, safety, and cost advantages. Specific technical goals include achieving practical energy densities exceeding 300 Wh/kg, cycle life of over 1,000 cycles, and production costs below $100/kWh. These targets would make RT Na-S batteries competitive with existing technologies for grid storage and potentially for electric vehicle applications.

Additional development objectives focus on addressing key manufacturing challenges, including the handling of reactive sodium metal, uniform deposition of sulfur cathodes, electrolyte stability, and cell sealing techniques appropriate for large-format cells. The optimization of these manufacturing processes is critical for transitioning from laboratory-scale prototypes to industrial production.

The strategic importance of RT Na-S technology development extends beyond technical performance metrics. As global energy systems transition toward renewable sources, the need for efficient, sustainable, and economical energy storage solutions becomes increasingly urgent. RT Na-S batteries, with their potential for low environmental impact and reliance on abundant materials, align well with sustainability goals and could help mitigate supply chain risks associated with lithium-ion battery materials.

Market Analysis for Large-Format Na-S Energy Storage

The global energy storage market is witnessing significant growth, with large-format sodium-sulfur (Na-S) batteries emerging as a promising technology for grid-scale applications. Current market projections indicate that the grid energy storage market will reach approximately $15.5 billion by 2025, with an annual growth rate exceeding 20% over the next decade. Within this expanding market, Na-S technology is positioned to capture a growing share due to its cost advantages and material abundance compared to lithium-ion alternatives.

The demand for large-format Na-S energy storage is primarily driven by three key market segments. First, utility-scale energy storage for grid stabilization and peak shaving represents the largest potential market, as power companies seek economical solutions to integrate renewable energy sources. This segment alone is expected to require over 100 GWh of storage capacity by 2030.

Second, the industrial sector presents substantial opportunities, particularly for manufacturing facilities and data centers requiring reliable backup power and energy cost management. This segment values the long duration discharge capabilities that Na-S systems can provide.

Third, the renewable energy integration market is rapidly expanding as solar and wind installations continue to grow globally. The intermittent nature of these energy sources creates an inherent need for storage solutions that can operate at scale and provide extended discharge periods.

Regional analysis reveals varying adoption patterns for Na-S technology. Asia-Pacific currently leads in implementation, with Japan and China making significant investments in manufacturing capacity and deployment. Europe follows with growing interest driven by aggressive decarbonization targets, while North America shows increasing adoption primarily in utility applications.

Cost considerations remain central to market penetration. Current large-format Na-S systems have an installed cost ranging from $250-400 per kWh, which must decrease to below $150 per kWh to achieve widespread adoption. Manufacturing scale-up represents the most promising pathway to this cost reduction, highlighting the critical importance of addressing manufacturing considerations.

Market barriers include competition from other emerging storage technologies, regulatory uncertainties regarding safety standards for large-format batteries, and limited awareness of Na-S advantages among potential end-users. However, the technology's inherent advantages of abundant raw materials, long cycle life, and high energy density position it favorably for long-duration storage applications where lithium-ion batteries are less economically viable.

The demand for large-format Na-S energy storage is primarily driven by three key market segments. First, utility-scale energy storage for grid stabilization and peak shaving represents the largest potential market, as power companies seek economical solutions to integrate renewable energy sources. This segment alone is expected to require over 100 GWh of storage capacity by 2030.

Second, the industrial sector presents substantial opportunities, particularly for manufacturing facilities and data centers requiring reliable backup power and energy cost management. This segment values the long duration discharge capabilities that Na-S systems can provide.

Third, the renewable energy integration market is rapidly expanding as solar and wind installations continue to grow globally. The intermittent nature of these energy sources creates an inherent need for storage solutions that can operate at scale and provide extended discharge periods.

Regional analysis reveals varying adoption patterns for Na-S technology. Asia-Pacific currently leads in implementation, with Japan and China making significant investments in manufacturing capacity and deployment. Europe follows with growing interest driven by aggressive decarbonization targets, while North America shows increasing adoption primarily in utility applications.

Cost considerations remain central to market penetration. Current large-format Na-S systems have an installed cost ranging from $250-400 per kWh, which must decrease to below $150 per kWh to achieve widespread adoption. Manufacturing scale-up represents the most promising pathway to this cost reduction, highlighting the critical importance of addressing manufacturing considerations.

Market barriers include competition from other emerging storage technologies, regulatory uncertainties regarding safety standards for large-format batteries, and limited awareness of Na-S advantages among potential end-users. However, the technology's inherent advantages of abundant raw materials, long cycle life, and high energy density position it favorably for long-duration storage applications where lithium-ion batteries are less economically viable.

Technical Barriers in RT Na-S Cell Manufacturing

Despite significant advancements in room temperature sodium-sulfur (RT Na-S) battery technology, several critical manufacturing barriers continue to impede large-scale commercialization. The primary challenge lies in the highly reactive nature of sodium metal, which requires stringent handling protocols and specialized equipment for safe processing. This reactivity necessitates manufacturing environments with extremely low moisture and oxygen levels (<1 ppm), significantly increasing production complexity and costs.

Material compatibility issues present another substantial hurdle. The corrosive nature of polysulfides formed during battery operation demands specialized current collectors and cell components that can withstand this harsh chemical environment while maintaining performance over thousands of cycles. Finding cost-effective materials that meet these requirements remains difficult, particularly for large-format cells where material quantities increase substantially.

Scaling up electrode manufacturing processes introduces additional complications. Achieving uniform sodium distribution and consistent sulfur loading across large-area electrodes requires precise control over coating processes. The tendency of sulfur to sublimate during high-temperature processing further complicates manufacturing, necessitating specialized equipment and process controls to maintain material integrity during production.

Interface engineering between the sodium anode and electrolyte represents perhaps the most significant technical barrier. Controlling the solid-electrolyte interphase (SEI) formation in large-format cells is exceptionally challenging, as inconsistencies can lead to dendrite formation, capacity fade, and potential safety hazards. Current manufacturing techniques struggle to produce uniform interfaces across the large surface areas required for high-capacity cells.

Quality control and testing methodologies for large-format RT Na-S cells remain underdeveloped. The unique chemistry and failure modes of these batteries require specialized testing protocols that can accurately predict long-term performance and safety characteristics. Developing reliable non-destructive testing methods suitable for production environments presents a significant technical challenge.

Cell design optimization for large-format applications introduces additional complexities. Managing thermal gradients and mechanical stresses in larger cells requires sophisticated engineering solutions that balance performance, safety, and manufacturability. The lack of standardized designs for large-format RT Na-S cells further complicates manufacturing process development.

Finally, end-of-life considerations and recycling processes for RT Na-S batteries remain largely unaddressed. Developing cost-effective methods to recover valuable materials while safely handling reactive components will be essential for sustainable manufacturing at scale. Current recycling infrastructure is ill-equipped to handle these specialized battery chemistries, creating a significant barrier to environmentally responsible manufacturing.

Material compatibility issues present another substantial hurdle. The corrosive nature of polysulfides formed during battery operation demands specialized current collectors and cell components that can withstand this harsh chemical environment while maintaining performance over thousands of cycles. Finding cost-effective materials that meet these requirements remains difficult, particularly for large-format cells where material quantities increase substantially.

Scaling up electrode manufacturing processes introduces additional complications. Achieving uniform sodium distribution and consistent sulfur loading across large-area electrodes requires precise control over coating processes. The tendency of sulfur to sublimate during high-temperature processing further complicates manufacturing, necessitating specialized equipment and process controls to maintain material integrity during production.

Interface engineering between the sodium anode and electrolyte represents perhaps the most significant technical barrier. Controlling the solid-electrolyte interphase (SEI) formation in large-format cells is exceptionally challenging, as inconsistencies can lead to dendrite formation, capacity fade, and potential safety hazards. Current manufacturing techniques struggle to produce uniform interfaces across the large surface areas required for high-capacity cells.

Quality control and testing methodologies for large-format RT Na-S cells remain underdeveloped. The unique chemistry and failure modes of these batteries require specialized testing protocols that can accurately predict long-term performance and safety characteristics. Developing reliable non-destructive testing methods suitable for production environments presents a significant technical challenge.

Cell design optimization for large-format applications introduces additional complexities. Managing thermal gradients and mechanical stresses in larger cells requires sophisticated engineering solutions that balance performance, safety, and manufacturability. The lack of standardized designs for large-format RT Na-S cells further complicates manufacturing process development.

Finally, end-of-life considerations and recycling processes for RT Na-S batteries remain largely unaddressed. Developing cost-effective methods to recover valuable materials while safely handling reactive components will be essential for sustainable manufacturing at scale. Current recycling infrastructure is ill-equipped to handle these specialized battery chemistries, creating a significant barrier to environmentally responsible manufacturing.

Current Manufacturing Approaches for RT Na-S Cells

01 Electrode materials for RT Na-S cells

Various electrode materials can be used in room temperature sodium-sulfur cells to enhance performance. These include carbon-based materials, metal oxides, and composite electrodes that improve sulfur utilization and prevent polysulfide shuttling. The electrode design focuses on increasing active material loading while maintaining good electronic conductivity, which is crucial for large-format cells. These materials help overcome challenges related to the insulating nature of sulfur and sodium polysulfides.- Electrode materials for RT Na-S cells: Various electrode materials can be used in room temperature sodium-sulfur cells to enhance performance. These include carbon-based materials, metal oxides, and composite structures that improve sulfur utilization and prevent polysulfide shuttling. The electrode design focuses on providing sufficient electronic conductivity while accommodating volume changes during cycling. Advanced materials with hierarchical pore structures can improve the electrochemical performance and cycle life of large-format RT Na-S cells.

- Electrolyte formulations for RT Na-S batteries: Specialized electrolyte formulations are crucial for room temperature sodium-sulfur batteries to address challenges like polysulfide dissolution and sodium dendrite formation. These formulations may include solid-state electrolytes, gel polymer electrolytes, or liquid electrolytes with additives that enhance ionic conductivity while suppressing side reactions. The electrolyte composition significantly impacts the battery's cycle life, rate capability, and safety characteristics, especially in large-format cells.

- Cell design and assembly for large-format RT Na-S batteries: The design and assembly of large-format room temperature sodium-sulfur cells require specific considerations to ensure safety, performance, and longevity. This includes optimized cell configurations, sealing technologies, and thermal management systems. The cell architecture must accommodate the volume changes during cycling while maintaining structural integrity. Advanced manufacturing techniques are employed to ensure uniform electrode coating and electrolyte distribution, which are critical for large-format cells.

- Separator technologies for RT Na-S cells: Specialized separator technologies are essential for room temperature sodium-sulfur cells to prevent polysulfide shuttling while maintaining high ionic conductivity. These separators may incorporate functional coatings or be made from composite materials that selectively block polysulfides. The separator design must balance mechanical strength, ionic conductivity, and chemical stability to ensure long-term performance in large-format cells. Advanced separator materials can significantly improve the cycle life and energy density of RT Na-S batteries.

- Performance enhancement and safety features for large-format RT Na-S batteries: Various strategies are employed to enhance the performance and safety of large-format room temperature sodium-sulfur batteries. These include the incorporation of additives to suppress dendrite formation, the use of protective coatings to prevent side reactions, and the implementation of advanced battery management systems. Safety features such as pressure relief mechanisms, thermal runaway prevention, and overcharge protection are particularly important for large-format cells. These enhancements collectively improve the energy density, cycle life, and operational safety of RT Na-S batteries.

02 Electrolyte formulations for RT Na-S batteries

Specialized electrolyte formulations are essential for room temperature sodium-sulfur cells. These include solid-state electrolytes, gel polymer electrolytes, and liquid electrolytes with additives that suppress the shuttle effect. The electrolyte composition significantly affects ionic conductivity, interfacial stability, and cycle life of the battery. For large-format cells, electrolytes must maintain stability across a wide temperature range and prevent dendrite formation during repeated charge-discharge cycles.Expand Specific Solutions03 Cell design and architecture for large-format RT Na-S batteries

The design and architecture of large-format room temperature sodium-sulfur cells focus on thermal management, safety features, and efficient packaging. Various cell configurations include prismatic, pouch, and cylindrical designs, each with specific advantages for large-format applications. The cell architecture incorporates features to manage volume changes during cycling and prevent internal short circuits. Advanced designs also include pressure relief mechanisms and thermal runaway prevention systems essential for scaling up to large-format cells.Expand Specific Solutions04 Separator technologies for RT Na-S cells

Specialized separator technologies are crucial for room temperature sodium-sulfur batteries to prevent polysulfide shuttling while maintaining high ionic conductivity. These include coated membranes, composite separators with functional layers, and modified polymer separators. For large-format cells, separators must provide uniform ion transport across the entire cell area while maintaining mechanical integrity under various operating conditions. Advanced separator designs also incorporate flame-retardant properties to enhance safety in large-format applications.Expand Specific Solutions05 Manufacturing processes for large-format RT Na-S cells

Specialized manufacturing processes are required for producing large-format room temperature sodium-sulfur cells. These include advanced electrode coating techniques, precision assembly methods, and quality control procedures specific to sodium-sulfur chemistry. The manufacturing process must address challenges such as moisture sensitivity of materials, uniform application of electrode slurries, and precise electrolyte filling. Automated assembly lines with controlled atmosphere environments are typically employed to ensure consistency and performance in large-format cell production.Expand Specific Solutions

Key Industry Players in Na-S Battery Development

The room temperature sodium-sulfur battery market is in an early growth phase, characterized by increasing commercial interest but limited large-scale deployment. The global market size is projected to expand significantly as energy storage demands grow, though it remains smaller than conventional lithium-ion technologies. Technologically, NGK Insulators leads with established high-temperature sodium-sulfur systems, while companies like Sion Power, Honeycomb Battery, and research institutions including Shanghai Institute of Ceramics and Forschungszentrum Jülich are advancing room-temperature variants. University collaborations (MIT, Monash, USC) are addressing key manufacturing challenges including electrode design, electrolyte stability, and safety systems. Major industrial players such as POSCO Holdings, Shell, and Ford are exploring applications, indicating growing commercial interest in this promising energy storage technology.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered high-temperature sodium-sulfur (NaS) battery technology and has recently developed room temperature sodium-sulfur (RT-NaS) cells through their proprietary ceramic electrolyte manufacturing process. Their approach involves using beta-alumina solid electrolyte (BASE) modified for room temperature operation, combined with a specialized sulfur cathode containing carbon nanostructures to enhance conductivity. NGK's manufacturing process includes precision ceramic processing techniques that create thin but mechanically robust electrolyte layers, critical for room temperature operation. Their large-format cells utilize a planar design rather than the traditional tubular configuration used in high-temperature versions, allowing for higher energy density and improved thermal management. NGK has implemented specialized sealing technologies to prevent moisture ingress and sodium corrosion issues that typically plague room temperature sodium-based batteries.

Strengths: Decades of experience with sodium-sulfur technology; established manufacturing infrastructure; proprietary ceramic electrolyte technology; proven large-scale energy storage deployment capability. Weaknesses: Traditional focus on high-temperature NaS cells requires significant manufacturing process adaptation; higher production costs compared to lithium-ion batteries; challenges with electrolyte thickness reduction while maintaining mechanical integrity.

Honeycomb Battery Co.

Technical Solution: Honeycomb Battery has developed an innovative manufacturing approach for room temperature sodium-sulfur cells using a honeycomb-structured carbon matrix to host sulfur cathodes. Their process involves creating a hierarchical porous carbon framework that effectively contains polysulfides while providing excellent ionic and electronic conductivity. The company employs a scalable template-assisted synthesis method to create these structures, followed by sulfur impregnation using a melt-diffusion process. For the anode, they utilize a proprietary sodium metal protection layer that prevents dendrite formation and unwanted side reactions. Honeycomb's manufacturing process incorporates roll-to-roll techniques for electrode preparation and automated assembly processes for large-format cells. Their electrolyte formulation includes flame-retardant additives and ionic liquid components that enhance safety and performance at room temperature, addressing key challenges in RT-NaS technology commercialization.

Strengths: Innovative honeycomb structure effectively addresses polysulfide shuttle effect; scalable manufacturing processes adaptable to existing battery production lines; enhanced safety features through electrolyte engineering. Weaknesses: Limited production scale compared to established battery manufacturers; relatively new technology with less field validation; challenges in maintaining consistent quality of complex honeycomb structures in mass production.

Critical Patents and Innovations in Na-S Cell Design

Lithium batteries

PatentInactiveUS6936382B2

Innovation

- A lithium electrochemical cell design featuring a solid lithium anode, a solid cathode with an electroactive sulfur-containing material, and a non-aqueous electrolyte comprising lithium salts, non-aqueous solvents, and capacity-enhancing reactive components such as anion receptors and electron transfer mediators, which enhance energy density and cycle life.

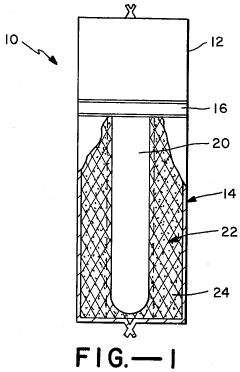

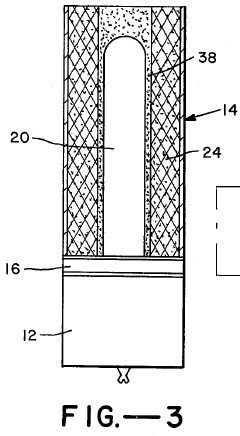

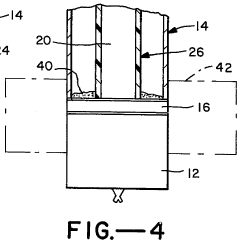

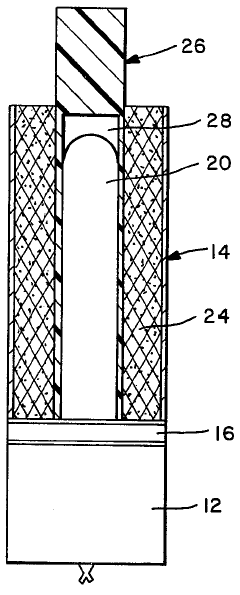

Sodium-sulfur cell with method of constructing the sulfur electrode

PatentInactiveUS4269909A

Innovation

- A method where a cover sleeve is positioned around the beta-alumina electrolyte tube, filled with a mixture of sulfur and graphite, allowing the sulfur to solidify and then removing the sleeve to fill the space with additional graphite, creating a cushion for sulfur expansion without damaging the electrolyte tube.

Supply Chain Considerations for Na-S Battery Materials

The supply chain for Na-S battery materials presents unique challenges and opportunities compared to traditional lithium-ion battery production. Sodium resources are abundantly available worldwide, with significant reserves in countries like China, the United States, and India. Unlike lithium, sodium is extracted primarily from salt deposits and seawater, offering a more geographically distributed and cost-effective resource base. This geographical diversity reduces supply chain vulnerabilities associated with resource concentration.

Sulfur, the cathode material, is predominantly sourced as a byproduct from petroleum refining and natural gas processing. The global sulfur market is mature with established logistics networks, though quality considerations for battery-grade sulfur require additional processing steps. Countries with significant petroleum industries, including the United States, Russia, and Middle Eastern nations, maintain substantial sulfur production capabilities.

Critical components for room temperature Na-S cells include specialized separators, electrolytes, and conductive additives. The beta-alumina solid electrolyte, essential for traditional high-temperature Na-S batteries, is replaced with polymer or composite electrolytes in room temperature versions, requiring different material inputs and manufacturing processes. These specialized materials may create supply bottlenecks as production scales.

Manufacturing infrastructure for large-format Na-S cells remains underdeveloped compared to lithium-ion facilities. Significant capital investment will be required to establish dedicated production lines capable of handling sodium's reactive properties and sulfur's unique processing requirements. The transition from laboratory to industrial scale presents challenges in maintaining material consistency and performance metrics.

Recycling infrastructure represents another critical supply chain consideration. While sodium and sulfur are theoretically highly recyclable, commercial recycling processes for Na-S batteries are still emerging. Developing efficient recycling pathways will be essential for creating a sustainable circular economy for these materials and reducing long-term supply dependencies.

Transportation logistics for raw materials and finished cells must account for sodium's reactivity with water and air. Special packaging and handling protocols increase complexity and cost throughout the supply chain. However, the lower toxicity of sodium compared to lithium offers potential regulatory advantages in certain markets.

As production scales, manufacturers must balance cost optimization with supply security. Diversifying supplier relationships while maintaining quality standards will be crucial for establishing resilient supply chains capable of supporting large-scale deployment of room temperature Na-S battery technology.

Sulfur, the cathode material, is predominantly sourced as a byproduct from petroleum refining and natural gas processing. The global sulfur market is mature with established logistics networks, though quality considerations for battery-grade sulfur require additional processing steps. Countries with significant petroleum industries, including the United States, Russia, and Middle Eastern nations, maintain substantial sulfur production capabilities.

Critical components for room temperature Na-S cells include specialized separators, electrolytes, and conductive additives. The beta-alumina solid electrolyte, essential for traditional high-temperature Na-S batteries, is replaced with polymer or composite electrolytes in room temperature versions, requiring different material inputs and manufacturing processes. These specialized materials may create supply bottlenecks as production scales.

Manufacturing infrastructure for large-format Na-S cells remains underdeveloped compared to lithium-ion facilities. Significant capital investment will be required to establish dedicated production lines capable of handling sodium's reactive properties and sulfur's unique processing requirements. The transition from laboratory to industrial scale presents challenges in maintaining material consistency and performance metrics.

Recycling infrastructure represents another critical supply chain consideration. While sodium and sulfur are theoretically highly recyclable, commercial recycling processes for Na-S batteries are still emerging. Developing efficient recycling pathways will be essential for creating a sustainable circular economy for these materials and reducing long-term supply dependencies.

Transportation logistics for raw materials and finished cells must account for sodium's reactivity with water and air. Special packaging and handling protocols increase complexity and cost throughout the supply chain. However, the lower toxicity of sodium compared to lithium offers potential regulatory advantages in certain markets.

As production scales, manufacturers must balance cost optimization with supply security. Diversifying supplier relationships while maintaining quality standards will be crucial for establishing resilient supply chains capable of supporting large-scale deployment of room temperature Na-S battery technology.

Safety and Scalability Assessment of Large-Format Na-S Cells

The safety and scalability assessment of large-format Na-S cells represents a critical consideration in the advancement of room temperature sodium-sulfur battery technology. Traditional high-temperature Na-S batteries operate at approximately 300-350°C, presenting significant safety hazards and limiting their widespread adoption. Room temperature variants offer promising alternatives but introduce unique safety challenges that must be systematically addressed.

Primary safety concerns include the reactivity of metallic sodium with moisture and oxygen, which can lead to fire hazards if cell integrity is compromised. The formation of sodium dendrites during cycling poses additional risks of internal short circuits. Furthermore, sulfur and its intermediate reaction products (polysulfides) can be corrosive to cell components and potentially toxic if released.

Implementing robust safety measures requires multi-layered approaches. Advanced battery management systems (BMS) with precise monitoring capabilities can detect abnormal conditions before they escalate. Physical safety features such as pressure relief mechanisms, thermal fuses, and improved separator designs significantly enhance cell resilience against thermal runaway scenarios.

Scalability assessment reveals several manufacturing challenges when transitioning from laboratory-scale to industrial production. The handling of reactive materials, particularly metallic sodium, necessitates specialized equipment and controlled environments. Current manufacturing processes often involve complex steps that are difficult to automate efficiently, resulting in higher production costs and reduced throughput.

Material supply chains present another scalability concern. While sodium is abundant, high-purity sodium metal production at scale remains costly. Similarly, specialized electrolytes and separators required for room temperature operation face availability constraints that could impede mass production efforts.

Economic viability depends on achieving competitive manufacturing costs. Current estimates suggest that large-format room temperature Na-S cells remain more expensive than lithium-ion alternatives on a per-kWh basis. However, as manufacturing processes mature and economies of scale take effect, this gap is expected to narrow significantly within the next 3-5 years.

Regulatory compliance adds another dimension to scalability assessment. Safety certification standards for large-format Na-S cells are still evolving, creating uncertainty for manufacturers. Proactive engagement with regulatory bodies and standardization organizations will be essential to establish clear guidelines that balance safety requirements with commercial viability.

Primary safety concerns include the reactivity of metallic sodium with moisture and oxygen, which can lead to fire hazards if cell integrity is compromised. The formation of sodium dendrites during cycling poses additional risks of internal short circuits. Furthermore, sulfur and its intermediate reaction products (polysulfides) can be corrosive to cell components and potentially toxic if released.

Implementing robust safety measures requires multi-layered approaches. Advanced battery management systems (BMS) with precise monitoring capabilities can detect abnormal conditions before they escalate. Physical safety features such as pressure relief mechanisms, thermal fuses, and improved separator designs significantly enhance cell resilience against thermal runaway scenarios.

Scalability assessment reveals several manufacturing challenges when transitioning from laboratory-scale to industrial production. The handling of reactive materials, particularly metallic sodium, necessitates specialized equipment and controlled environments. Current manufacturing processes often involve complex steps that are difficult to automate efficiently, resulting in higher production costs and reduced throughput.

Material supply chains present another scalability concern. While sodium is abundant, high-purity sodium metal production at scale remains costly. Similarly, specialized electrolytes and separators required for room temperature operation face availability constraints that could impede mass production efforts.

Economic viability depends on achieving competitive manufacturing costs. Current estimates suggest that large-format room temperature Na-S cells remain more expensive than lithium-ion alternatives on a per-kWh basis. However, as manufacturing processes mature and economies of scale take effect, this gap is expected to narrow significantly within the next 3-5 years.

Regulatory compliance adds another dimension to scalability assessment. Safety certification standards for large-format Na-S cells are still evolving, creating uncertainty for manufacturers. Proactive engagement with regulatory bodies and standardization organizations will be essential to establish clear guidelines that balance safety requirements with commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!