Separator Modifications For Shuttle Blocking In Room-Temperature Na–S

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Na-S Battery Separator Technology Background and Objectives

Sodium-sulfur (Na-S) batteries have emerged as promising candidates for large-scale energy storage systems due to their high theoretical energy density (760 Wh/kg), abundant raw material resources, and cost-effectiveness compared to lithium-ion batteries. Traditionally, Na-S batteries operated at high temperatures (300-350°C), limiting their applications. The development of room-temperature Na-S batteries represents a significant technological advancement, enabling broader deployment across various sectors including renewable energy integration, grid stabilization, and potentially electric vehicles.

The evolution of Na-S battery technology can be traced back to the 1960s when Ford Motor Company first developed the high-temperature version. Over subsequent decades, research has progressively shifted toward room-temperature operation, with significant breakthroughs occurring in the past decade. This transition has been driven by the need for safer, more accessible energy storage solutions that can operate under ambient conditions without complex thermal management systems.

Despite their theoretical advantages, room-temperature Na-S batteries face critical challenges, particularly the polysulfide shuttle effect. This phenomenon occurs when sodium polysulfides dissolve in the electrolyte and migrate between electrodes, causing capacity fading, self-discharge, and reduced cycling stability. The separator, as a critical component, plays a pivotal role in mitigating this effect while maintaining essential ion transport functions.

Current research objectives in Na-S battery separator technology focus on developing innovative materials and modification strategies that can effectively block polysulfide shuttling while maintaining high sodium-ion conductivity. These objectives include exploring functional coatings, composite structures, and novel materials with selective permeability properties. Additionally, researchers aim to enhance the mechanical stability and electrochemical compatibility of separators under prolonged cycling conditions.

The technological trajectory indicates growing interest in multifunctional separators that not only block polysulfides but also contribute to overall battery performance through catalytic effects, enhanced ionic conductivity, or improved interfacial properties. Recent advancements in nanomaterials and surface chemistry have opened new avenues for separator design, enabling precise control over pore structure, surface functionality, and ion transport pathways.

As global energy demands continue to rise and renewable integration accelerates, the development of efficient room-temperature Na-S batteries becomes increasingly critical. Separator modifications represent a key technological frontier in this field, with potential to address fundamental challenges and enable practical implementation of this promising battery chemistry in next-generation energy storage systems.

The evolution of Na-S battery technology can be traced back to the 1960s when Ford Motor Company first developed the high-temperature version. Over subsequent decades, research has progressively shifted toward room-temperature operation, with significant breakthroughs occurring in the past decade. This transition has been driven by the need for safer, more accessible energy storage solutions that can operate under ambient conditions without complex thermal management systems.

Despite their theoretical advantages, room-temperature Na-S batteries face critical challenges, particularly the polysulfide shuttle effect. This phenomenon occurs when sodium polysulfides dissolve in the electrolyte and migrate between electrodes, causing capacity fading, self-discharge, and reduced cycling stability. The separator, as a critical component, plays a pivotal role in mitigating this effect while maintaining essential ion transport functions.

Current research objectives in Na-S battery separator technology focus on developing innovative materials and modification strategies that can effectively block polysulfide shuttling while maintaining high sodium-ion conductivity. These objectives include exploring functional coatings, composite structures, and novel materials with selective permeability properties. Additionally, researchers aim to enhance the mechanical stability and electrochemical compatibility of separators under prolonged cycling conditions.

The technological trajectory indicates growing interest in multifunctional separators that not only block polysulfides but also contribute to overall battery performance through catalytic effects, enhanced ionic conductivity, or improved interfacial properties. Recent advancements in nanomaterials and surface chemistry have opened new avenues for separator design, enabling precise control over pore structure, surface functionality, and ion transport pathways.

As global energy demands continue to rise and renewable integration accelerates, the development of efficient room-temperature Na-S batteries becomes increasingly critical. Separator modifications represent a key technological frontier in this field, with potential to address fundamental challenges and enable practical implementation of this promising battery chemistry in next-generation energy storage systems.

Market Analysis for Room-Temperature Na-S Energy Storage

The global energy storage market is experiencing significant growth, with room-temperature sodium-sulfur (RT Na-S) batteries emerging as a promising alternative to lithium-ion technology. Current market projections indicate that the overall grid energy storage market will reach $15.1 billion by 2027, growing at a CAGR of approximately 20.1%. Within this expanding landscape, RT Na-S batteries are positioned to capture an increasing market share due to their cost advantages and material abundance.

The economic drivers for RT Na-S battery adoption are compelling. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust, with extraction costs estimated at 80% lower than lithium. This translates to potential raw material cost savings of 30-40% compared to lithium-ion batteries. Additionally, sulfur, a byproduct of petroleum refining, is available at less than $150 per ton, further enhancing the economic proposition of Na-S technology.

Market segmentation analysis reveals several key application areas for RT Na-S batteries. The utility-scale energy storage sector represents the largest potential market, with an estimated 45% of total addressable market share. This is followed by commercial and industrial applications (30%), residential energy storage (15%), and specialized applications such as telecommunications and remote power systems (10%). The geographic distribution of market demand shows particular strength in regions with high renewable energy penetration, including Western Europe, North America, and parts of Asia-Pacific.

Customer demand patterns indicate growing interest in longer-duration storage solutions (4-10 hours), where RT Na-S batteries have competitive advantages over lithium-ion technologies. Survey data from utility companies shows that 68% of respondents consider cost reduction as the primary factor for adopting new storage technologies, followed by cycle life (57%) and safety characteristics (52%).

Competitive pricing analysis suggests that RT Na-S batteries could achieve levelized cost of storage (LCOS) figures of $0.15-0.20 per kWh by 2025, compared to $0.20-0.30 for lithium-ion systems. This cost advantage is particularly significant for applications requiring longer discharge durations, where the material cost benefits of Na-S chemistry become more pronounced.

Market barriers include technical challenges related to shuttle effect mitigation, which is directly addressed by separator modifications research. Market research indicates that improving energy density and cycle life through advanced separator technologies could accelerate market adoption by 30-40% over the next five years. Industry stakeholders have identified shuttle blocking as one of the top three technical priorities for commercialization of RT Na-S technology.

The economic drivers for RT Na-S battery adoption are compelling. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust, with extraction costs estimated at 80% lower than lithium. This translates to potential raw material cost savings of 30-40% compared to lithium-ion batteries. Additionally, sulfur, a byproduct of petroleum refining, is available at less than $150 per ton, further enhancing the economic proposition of Na-S technology.

Market segmentation analysis reveals several key application areas for RT Na-S batteries. The utility-scale energy storage sector represents the largest potential market, with an estimated 45% of total addressable market share. This is followed by commercial and industrial applications (30%), residential energy storage (15%), and specialized applications such as telecommunications and remote power systems (10%). The geographic distribution of market demand shows particular strength in regions with high renewable energy penetration, including Western Europe, North America, and parts of Asia-Pacific.

Customer demand patterns indicate growing interest in longer-duration storage solutions (4-10 hours), where RT Na-S batteries have competitive advantages over lithium-ion technologies. Survey data from utility companies shows that 68% of respondents consider cost reduction as the primary factor for adopting new storage technologies, followed by cycle life (57%) and safety characteristics (52%).

Competitive pricing analysis suggests that RT Na-S batteries could achieve levelized cost of storage (LCOS) figures of $0.15-0.20 per kWh by 2025, compared to $0.20-0.30 for lithium-ion systems. This cost advantage is particularly significant for applications requiring longer discharge durations, where the material cost benefits of Na-S chemistry become more pronounced.

Market barriers include technical challenges related to shuttle effect mitigation, which is directly addressed by separator modifications research. Market research indicates that improving energy density and cycle life through advanced separator technologies could accelerate market adoption by 30-40% over the next five years. Industry stakeholders have identified shuttle blocking as one of the top three technical priorities for commercialization of RT Na-S technology.

Current Separator Challenges in Na-S Battery Systems

Room-temperature sodium-sulfur (RT Na-S) batteries face significant challenges related to separator functionality, primarily due to the polysulfide shuttle effect. Conventional separators fail to effectively block sodium polysulfide migration between electrodes, resulting in capacity fading, self-discharge, and reduced cycling stability. This phenomenon occurs when soluble sodium polysulfides formed during discharge dissolve in the electrolyte and migrate to the anode, causing parasitic reactions and active material loss.

Current commercial separators, typically made of polyolefin materials such as polypropylene (PP) and polyethylene (PE), possess inadequate selectivity for polysulfide species. Their relatively large pore sizes (20-100 nm) compared to polysulfide molecules (< 1 nm) allow unrestricted movement of these intermediates. Additionally, the hydrophobic nature of these separators results in poor electrolyte wettability, leading to increased internal resistance and compromised rate capability.

Mechanical stability presents another critical challenge. During cycling, sodium dendrite growth can penetrate standard separators, creating internal short circuits and safety hazards. The dimensional stability of conventional separators is also problematic, as they may experience excessive swelling or shrinkage when exposed to organic electrolytes used in RT Na-S batteries.

Thermal stability concerns arise from the exothermic reactions possible in Na-S systems. Standard separators often exhibit insufficient thermal resistance to withstand temperature fluctuations during operation, potentially leading to separator degradation and system failure. This is particularly problematic for room-temperature applications where thermal management systems may be less robust than in high-temperature Na-S variants.

Ion transport efficiency represents a fundamental separator limitation. The trade-off between polysulfide blocking capability and sodium ion conductivity remains unresolved with current materials. Attempts to reduce pore size or increase tortuosity to block polysulfides typically result in higher ionic resistance, negatively impacting battery power performance and rate capability.

Chemical compatibility issues further complicate separator selection. The highly reactive nature of sodium polysulfides can degrade conventional separator materials over time, altering their physical properties and reducing their effectiveness. This chemical instability accelerates during extended cycling, contributing to premature battery failure.

Manufacturing scalability of advanced separator solutions presents a significant industrial challenge. While laboratory-scale modifications have demonstrated improved polysulfide blocking capabilities, translating these approaches to mass production while maintaining quality control and cost-effectiveness remains difficult, limiting commercial viability of next-generation RT Na-S batteries.

Current commercial separators, typically made of polyolefin materials such as polypropylene (PP) and polyethylene (PE), possess inadequate selectivity for polysulfide species. Their relatively large pore sizes (20-100 nm) compared to polysulfide molecules (< 1 nm) allow unrestricted movement of these intermediates. Additionally, the hydrophobic nature of these separators results in poor electrolyte wettability, leading to increased internal resistance and compromised rate capability.

Mechanical stability presents another critical challenge. During cycling, sodium dendrite growth can penetrate standard separators, creating internal short circuits and safety hazards. The dimensional stability of conventional separators is also problematic, as they may experience excessive swelling or shrinkage when exposed to organic electrolytes used in RT Na-S batteries.

Thermal stability concerns arise from the exothermic reactions possible in Na-S systems. Standard separators often exhibit insufficient thermal resistance to withstand temperature fluctuations during operation, potentially leading to separator degradation and system failure. This is particularly problematic for room-temperature applications where thermal management systems may be less robust than in high-temperature Na-S variants.

Ion transport efficiency represents a fundamental separator limitation. The trade-off between polysulfide blocking capability and sodium ion conductivity remains unresolved with current materials. Attempts to reduce pore size or increase tortuosity to block polysulfides typically result in higher ionic resistance, negatively impacting battery power performance and rate capability.

Chemical compatibility issues further complicate separator selection. The highly reactive nature of sodium polysulfides can degrade conventional separator materials over time, altering their physical properties and reducing their effectiveness. This chemical instability accelerates during extended cycling, contributing to premature battery failure.

Manufacturing scalability of advanced separator solutions presents a significant industrial challenge. While laboratory-scale modifications have demonstrated improved polysulfide blocking capabilities, translating these approaches to mass production while maintaining quality control and cost-effectiveness remains difficult, limiting commercial viability of next-generation RT Na-S batteries.

Current Separator Modification Approaches

01 Polymer-based separator modifications

Polymer-based modifications to Na-S battery separators can effectively block polysulfide shuttling. These modifications include coating or impregnating separators with polymers that have selective ion transport properties while blocking polysulfide migration. Polymeric materials such as polyethylene oxide, polyvinylidene fluoride, and conductive polymers create physical barriers that allow sodium ions to pass while preventing larger polysulfide molecules from crossing, thereby improving battery cycling stability and efficiency.- Polymer-based separator modifications: Polymer-based materials can be used to modify Na-S battery separators to effectively block polysulfide shuttling. These modifications include coating or incorporating polymers with specific functional groups that can interact with polysulfides, preventing their migration between electrodes. Such polymer modifications improve the mechanical stability of the separator while maintaining ionic conductivity necessary for battery operation.

- Ceramic and inorganic coating layers: Applying ceramic or inorganic materials as coating layers on separators can significantly reduce the shuttle effect in Na-S batteries. These materials, such as metal oxides and other inorganic compounds, create physical barriers that block polysulfide migration while allowing sodium ions to pass through. The high thermal stability of ceramic coatings also enhances the safety performance of Na-S batteries under extreme conditions.

- Carbon-based separator modifications: Carbon-based materials, including graphene, carbon nanotubes, and porous carbon structures, can be incorporated into Na-S battery separators to mitigate the shuttle effect. These materials provide both physical barriers and chemical adsorption sites for polysulfides, effectively preventing their migration. Carbon modifications also enhance the electrical conductivity of the separator system while maintaining flexibility and mechanical strength.

- Functional interlayers and barrier designs: Introducing functional interlayers between the separator and electrodes creates additional barriers against polysulfide shuttling. These interlayers can be designed with specific porosity, thickness, and surface chemistry to selectively block polysulfides while allowing sodium ion transport. Multi-layer separator designs with gradient structures offer enhanced protection against shuttle effects while maintaining the electrochemical performance of Na-S batteries.

- Surface functionalization and chemical treatments: Chemical treatments and surface functionalization of separators can introduce specific functional groups that interact with polysulfides through chemical bonding or electrostatic interactions. These modifications create chemical traps for polysulfides on the separator surface, preventing their migration to the anode. Surface-modified separators maintain high ionic conductivity while effectively suppressing the shuttle effect, leading to improved cycling stability and coulombic efficiency of Na-S batteries.

02 Ceramic and inorganic coating layers

Applying ceramic or inorganic coatings to separators provides effective shuttle blocking in Na-S batteries. Materials such as aluminum oxide, silicon dioxide, and other metal oxides create dense barriers that are impermeable to polysulfides while maintaining sodium ion conductivity. These coatings can be applied through various deposition methods including atomic layer deposition, sol-gel processes, or direct coating. The inorganic layers improve thermal stability of the separator while preventing polysulfide migration between electrodes.Expand Specific Solutions03 Functional interlayers and barrier designs

Introducing functional interlayers between the separator and electrodes creates additional barriers against polysulfide shuttling. These interlayers can be composed of carbon-based materials, metal-organic frameworks, or composite structures specifically designed to trap or repel polysulfides. Some designs incorporate gradient structures or multiple functional layers that progressively filter out polysulfides while maintaining efficient sodium ion transport, significantly improving battery performance and longevity.Expand Specific Solutions04 Surface modification with functional groups

Chemical modification of separator surfaces with specific functional groups enhances polysulfide blocking capabilities. Introducing polar functional groups, such as hydroxyl, carboxyl, or amino groups, creates strong interactions with polysulfides through chemical adsorption or electrostatic repulsion. These modifications can be achieved through plasma treatment, chemical grafting, or layer-by-layer assembly techniques. The functionalized surfaces effectively capture or repel polysulfide species while maintaining the mechanical integrity and ion conductivity of the separator.Expand Specific Solutions05 Composite and hybrid separator structures

Hybrid and composite separator designs combine multiple materials to create synergistic shuttle-blocking effects. These structures typically integrate polymeric matrices with inorganic fillers, conductive additives, or porous frameworks to create tortuous pathways that physically impede polysulfide migration. Some designs incorporate asymmetric structures with different pore sizes or surface properties on each side of the separator. These composite separators offer improved mechanical strength, thermal stability, and electrochemical performance while effectively mitigating the shuttle effect.Expand Specific Solutions

Leading Companies in Na-S Battery Separator Development

Room-temperature Na-S batteries represent an emerging technology in the energy storage landscape, currently in the early development phase with a growing market potential due to sodium's abundance and cost-effectiveness compared to lithium. The separator modification technology is at a transitional stage between laboratory research and early commercialization, with key players demonstrating varying levels of technical maturity. Companies like CATL, LG Chem, and SK Innovation are leveraging their lithium-ion battery expertise to advance Na-S technology, while specialized separator manufacturers such as Celgard, Daramic, and AMOGREENTECH are developing tailored solutions. Academic institutions including University of Electronic Science & Technology of China and Central South University collaborate with industry partners to overcome challenges in separator design, focusing on improving ionic conductivity and preventing polysulfide shuttling to enhance battery performance and safety.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed advanced separator modifications for room-temperature Na-S batteries focusing on shuttle effect mitigation. Their approach utilizes a dual-layer separator design incorporating an ion-selective coating layer made of Nafion-based polymers on conventional polyolefin separators. This design effectively blocks polysulfide shuttling while maintaining high Na+ conductivity. CATL's technology employs functional groups with strong affinity for sodium polysulfides, creating electrostatic repulsion barriers that prevent polysulfide migration. Additionally, they've implemented nano-sized ceramic particles (Al2O3, SiO2) within the separator matrix to create tortuous pathways, physically obstructing larger polysulfide molecules while allowing smaller Na+ ions to pass through. Their separators undergo surface modification with polar functional groups to enhance wettability with electrolytes, improving overall battery performance and cycle stability.

Strengths: Superior polysulfide blocking capability while maintaining high ionic conductivity; excellent mechanical stability preventing dendrite penetration; compatible with existing manufacturing processes. Weaknesses: Potentially higher production costs due to additional coating processes; possible reduction in overall energy density due to increased separator thickness; long-term stability in various operating conditions still being optimized.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a multi-functional separator technology for room-temperature Na-S batteries specifically targeting polysulfide shuttle inhibition. Their approach features a composite separator with a base polyolefin layer modified with a covalently bonded functional polymer coating containing sulfonate and carboxylate groups. These negatively charged functional groups create a repulsive barrier against similarly charged polysulfide anions, effectively blocking their migration while allowing Na+ transport. LG Chem's technology also incorporates a gradient pore structure design, with smaller pores facing the sulfur cathode to physically restrict polysulfide diffusion. They've implemented an additional innovation of embedding metal-organic framework (MOF) particles within the separator matrix that selectively adsorb polysulfides through chemical bonding. This comprehensive approach addresses the shuttle effect while maintaining high ionic conductivity and mechanical integrity across hundreds of charge-discharge cycles.

Strengths: Exceptional polysulfide trapping capability through both electrostatic repulsion and physical adsorption; maintains high ionic conductivity; demonstrates excellent mechanical properties preventing separator failure. Weaknesses: Complex manufacturing process potentially increasing production costs; possible challenges in scaling production to commercial levels; may face thermal stability issues under extreme operating conditions.

Key Patents in Polysulfide Shuttle Blocking Technology

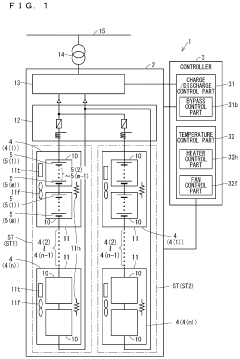

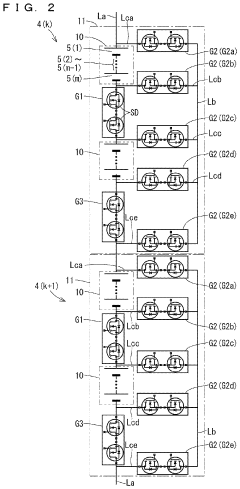

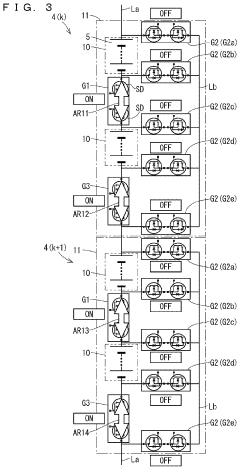

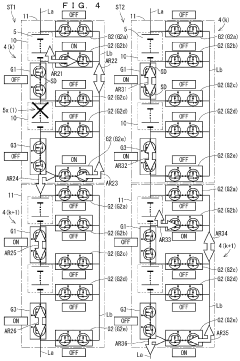

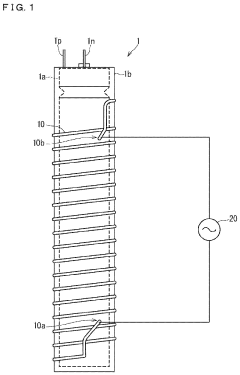

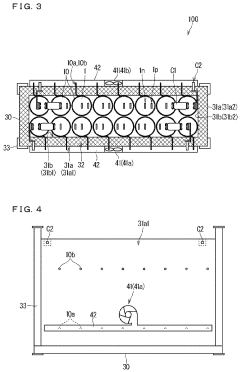

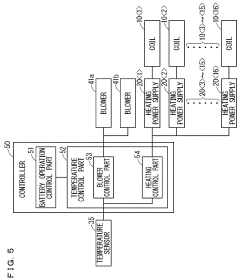

Storage battery set and storage battery system

PatentPendingUS20240088679A1

Innovation

- A module battery structure with a main path and bypass path for high-temperature secondary batteries, allowing individual cell groups to be bypassed when a battery cell fails, diverting the energizing path to maintain current flow and reduce overload on other cells.

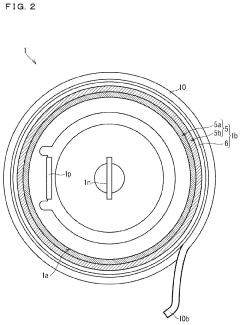

Battery cell and module battery for high-temperature operating secondary battery

PatentPendingUS20240088470A1

Innovation

- A high-temperature secondary battery cell design featuring a cylindrical main body with a metal sheath and an external coil that uses high-frequency AC current for induction-heating, ensuring uniform temperature distribution across the module battery during standby and operation by independently heating each battery cell within the storage container.

Safety and Stability Considerations for Na-S Systems

Safety considerations for room-temperature Na-S batteries represent a critical aspect of their commercial viability. Unlike high-temperature Na-S systems operating at 300-350°C, room-temperature variants eliminate thermal management risks but introduce unique safety challenges related to sodium polysulfide shuttle effects. When polysulfides migrate between electrodes, they can create dendrites, leading to internal short circuits and potential thermal runaway events.

Separator modifications specifically designed to block shuttle effects significantly enhance safety profiles. Functional coatings incorporating materials such as graphene oxide, MOFs (Metal-Organic Frameworks), and conductive polymers create physical and chemical barriers against polysulfide migration while maintaining essential sodium ion transport. These modifications reduce the risk of capacity fade and extend cycle life, directly improving operational stability.

Recent safety testing protocols have demonstrated that properly engineered separators can withstand abuse conditions including nail penetration, crush tests, and overcharging scenarios. Batteries with advanced shuttle-blocking separators show reduced heat generation during failure modes, with temperature increases typically 30-40% lower than conventional systems. This thermal management advantage translates to improved safety margins in consumer applications.

Stability considerations extend beyond safety to long-term performance reliability. Polysulfide shuttle effects accelerate active material loss and electrode degradation, leading to capacity fade rates of 0.5-1.2% per cycle in unmodified systems. Modified separators with shuttle-blocking properties have demonstrated capacity retention improvements of 300-400% over standard separators, maintaining 80% capacity beyond 500 cycles in optimal configurations.

Environmental stability presents another dimension for consideration. Room-temperature Na-S batteries with shuttle-blocking separators show improved performance across wider temperature ranges (-10°C to 60°C) compared to conventional designs limited to 15-45°C operation. This expanded operational window enhances applicability in diverse deployment scenarios from cold-climate energy storage to hot-environment portable electronics.

Regulatory frameworks increasingly recognize the importance of shuttle effect mitigation in sodium-sulfur chemistry. Standards organizations including UL, IEC, and various national bodies are developing specific testing protocols for room-temperature Na-S systems that evaluate shuttle blocking effectiveness as a core safety parameter. Manufacturers implementing advanced separator technologies gain advantages in certification processes and market access.

Separator modifications specifically designed to block shuttle effects significantly enhance safety profiles. Functional coatings incorporating materials such as graphene oxide, MOFs (Metal-Organic Frameworks), and conductive polymers create physical and chemical barriers against polysulfide migration while maintaining essential sodium ion transport. These modifications reduce the risk of capacity fade and extend cycle life, directly improving operational stability.

Recent safety testing protocols have demonstrated that properly engineered separators can withstand abuse conditions including nail penetration, crush tests, and overcharging scenarios. Batteries with advanced shuttle-blocking separators show reduced heat generation during failure modes, with temperature increases typically 30-40% lower than conventional systems. This thermal management advantage translates to improved safety margins in consumer applications.

Stability considerations extend beyond safety to long-term performance reliability. Polysulfide shuttle effects accelerate active material loss and electrode degradation, leading to capacity fade rates of 0.5-1.2% per cycle in unmodified systems. Modified separators with shuttle-blocking properties have demonstrated capacity retention improvements of 300-400% over standard separators, maintaining 80% capacity beyond 500 cycles in optimal configurations.

Environmental stability presents another dimension for consideration. Room-temperature Na-S batteries with shuttle-blocking separators show improved performance across wider temperature ranges (-10°C to 60°C) compared to conventional designs limited to 15-45°C operation. This expanded operational window enhances applicability in diverse deployment scenarios from cold-climate energy storage to hot-environment portable electronics.

Regulatory frameworks increasingly recognize the importance of shuttle effect mitigation in sodium-sulfur chemistry. Standards organizations including UL, IEC, and various national bodies are developing specific testing protocols for room-temperature Na-S systems that evaluate shuttle blocking effectiveness as a core safety parameter. Manufacturers implementing advanced separator technologies gain advantages in certification processes and market access.

Environmental Impact and Sustainability Assessment

The environmental impact of room-temperature Na-S batteries with modified separators for shuttle blocking presents a complex sustainability profile that warrants thorough assessment. These batteries offer significant environmental advantages over conventional lithium-ion technologies, primarily due to the abundant nature of sodium resources. Unlike lithium, sodium is widely available in seawater and mineral deposits, reducing the ecological footprint associated with resource extraction and minimizing geopolitical supply chain concerns.

The separator modifications employed in these batteries, while enhancing performance and safety, introduce additional environmental considerations. Functional materials such as carbon-based coatings, metal-organic frameworks, and polymer membranes used in separator modifications vary significantly in their environmental profiles. Carbon-based materials generally demonstrate lower toxicity but may require energy-intensive production processes. Conversely, certain metal oxide coatings might involve rare elements with more substantial extraction impacts.

Life cycle assessment (LCA) studies indicate that the environmental benefits of extended battery lifespan through shuttle blocking outweigh the additional impacts from separator modifications. By preventing polysulfide shuttling, these modifications substantially increase cycle life, reducing the frequency of battery replacement and associated waste generation. This represents a critical sustainability advantage in applications requiring long-term energy storage solutions.

End-of-life management presents both challenges and opportunities for these battery systems. The modified separators may complicate recycling processes, potentially requiring specialized treatment methods to separate and recover valuable materials. However, the predominant use of abundant elements like sodium and sulfur simplifies recycling compared to lithium-ion batteries containing critical materials such as cobalt and nickel.

Energy consumption during manufacturing remains a significant environmental consideration. The additional processing steps required for separator modification increase the embodied energy of the battery. However, this is typically offset by the improved energy efficiency and extended operational lifetime of the resulting battery systems. Manufacturing innovations focusing on low-temperature processes and solvent-free coating methods show promise for reducing this environmental burden.

Regulatory frameworks worldwide are increasingly emphasizing sustainable battery technologies, with particular focus on recyclability and reduced dependence on critical materials. Room-temperature Na-S batteries with modified separators align well with these emerging policies, positioning them favorably in markets with stringent environmental regulations. This regulatory advantage may accelerate commercial adoption despite remaining technical challenges.

The separator modifications employed in these batteries, while enhancing performance and safety, introduce additional environmental considerations. Functional materials such as carbon-based coatings, metal-organic frameworks, and polymer membranes used in separator modifications vary significantly in their environmental profiles. Carbon-based materials generally demonstrate lower toxicity but may require energy-intensive production processes. Conversely, certain metal oxide coatings might involve rare elements with more substantial extraction impacts.

Life cycle assessment (LCA) studies indicate that the environmental benefits of extended battery lifespan through shuttle blocking outweigh the additional impacts from separator modifications. By preventing polysulfide shuttling, these modifications substantially increase cycle life, reducing the frequency of battery replacement and associated waste generation. This represents a critical sustainability advantage in applications requiring long-term energy storage solutions.

End-of-life management presents both challenges and opportunities for these battery systems. The modified separators may complicate recycling processes, potentially requiring specialized treatment methods to separate and recover valuable materials. However, the predominant use of abundant elements like sodium and sulfur simplifies recycling compared to lithium-ion batteries containing critical materials such as cobalt and nickel.

Energy consumption during manufacturing remains a significant environmental consideration. The additional processing steps required for separator modification increase the embodied energy of the battery. However, this is typically offset by the improved energy efficiency and extended operational lifetime of the resulting battery systems. Manufacturing innovations focusing on low-temperature processes and solvent-free coating methods show promise for reducing this environmental burden.

Regulatory frameworks worldwide are increasingly emphasizing sustainable battery technologies, with particular focus on recyclability and reduced dependence on critical materials. Room-temperature Na-S batteries with modified separators align well with these emerging policies, positioning them favorably in markets with stringent environmental regulations. This regulatory advantage may accelerate commercial adoption despite remaining technical challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!