Safety Assessment And Thermal Runaway Metrics For RT Na–S Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RT Na-S Battery Safety Background and Objectives

Room Temperature Sodium-Sulfur (RT Na-S) battery technology represents a significant evolution in energy storage systems, emerging from the traditional high-temperature Na-S batteries that operate at approximately 300-350°C. The development of RT Na-S batteries began in the early 2000s, with researchers seeking to harness the high theoretical energy density of sodium-sulfur chemistry (760 Wh/kg) while eliminating the safety concerns and complex thermal management systems associated with high operating temperatures.

The evolution of this technology has been driven by the increasing global demand for sustainable and cost-effective energy storage solutions. Unlike lithium-ion batteries, RT Na-S systems utilize abundant, low-cost materials, with sodium being approximately 1000 times more abundant in the Earth's crust than lithium. This abundance translates to potential cost advantages, making RT Na-S batteries particularly attractive for grid-scale energy storage applications.

Despite these advantages, the safety aspects of RT Na-S battery systems remain a critical concern. The reactive nature of sodium metal, combined with the potential for polysulfide shuttle effects and dendrite formation, presents significant safety challenges. Historical incidents involving sodium-based batteries have highlighted the importance of robust safety assessment frameworks and thermal runaway prevention strategies.

The primary technical objectives for RT Na-S battery safety assessment include developing standardized testing protocols that can accurately predict and quantify thermal runaway risks under various operating conditions. These protocols must address the unique characteristics of sodium-sulfur chemistry, including sodium's reactivity with moisture and oxygen, and the complex electrochemical reactions occurring at the electrode-electrolyte interfaces.

Another key objective is establishing clear thermal runaway metrics specific to RT Na-S systems. While thermal runaway mechanisms in lithium-ion batteries are well-documented, the triggers, progression patterns, and severity indicators for RT Na-S batteries require distinct characterization. These metrics must account for the different failure modes, such as sodium dendrite penetration, electrolyte decomposition, and sulfur electrode degradation.

Additionally, there is a pressing need to develop early warning systems and inherent safety features that can detect precursors to thermal events and mitigate their consequences. This includes advanced battery management systems capable of monitoring subtle electrochemical and thermal signatures that precede catastrophic failure.

The ultimate goal of safety assessment for RT Na-S battery systems is to enable their widespread adoption by establishing confidence in their operational safety across various applications, from grid storage to potentially electric vehicles, while maintaining their cost and sustainability advantages over competing technologies.

The evolution of this technology has been driven by the increasing global demand for sustainable and cost-effective energy storage solutions. Unlike lithium-ion batteries, RT Na-S systems utilize abundant, low-cost materials, with sodium being approximately 1000 times more abundant in the Earth's crust than lithium. This abundance translates to potential cost advantages, making RT Na-S batteries particularly attractive for grid-scale energy storage applications.

Despite these advantages, the safety aspects of RT Na-S battery systems remain a critical concern. The reactive nature of sodium metal, combined with the potential for polysulfide shuttle effects and dendrite formation, presents significant safety challenges. Historical incidents involving sodium-based batteries have highlighted the importance of robust safety assessment frameworks and thermal runaway prevention strategies.

The primary technical objectives for RT Na-S battery safety assessment include developing standardized testing protocols that can accurately predict and quantify thermal runaway risks under various operating conditions. These protocols must address the unique characteristics of sodium-sulfur chemistry, including sodium's reactivity with moisture and oxygen, and the complex electrochemical reactions occurring at the electrode-electrolyte interfaces.

Another key objective is establishing clear thermal runaway metrics specific to RT Na-S systems. While thermal runaway mechanisms in lithium-ion batteries are well-documented, the triggers, progression patterns, and severity indicators for RT Na-S batteries require distinct characterization. These metrics must account for the different failure modes, such as sodium dendrite penetration, electrolyte decomposition, and sulfur electrode degradation.

Additionally, there is a pressing need to develop early warning systems and inherent safety features that can detect precursors to thermal events and mitigate their consequences. This includes advanced battery management systems capable of monitoring subtle electrochemical and thermal signatures that precede catastrophic failure.

The ultimate goal of safety assessment for RT Na-S battery systems is to enable their widespread adoption by establishing confidence in their operational safety across various applications, from grid storage to potentially electric vehicles, while maintaining their cost and sustainability advantages over competing technologies.

Market Analysis for RT Na-S Battery Systems

The global energy storage market is witnessing significant growth, with projections indicating a compound annual growth rate (CAGR) of 20-25% through 2030. Within this expanding landscape, Room Temperature Sodium-Sulfur (RT Na-S) battery systems are emerging as a promising alternative to traditional lithium-ion batteries, particularly for stationary energy storage applications.

Market demand for RT Na-S batteries is primarily driven by several key factors. First, the increasing integration of renewable energy sources into power grids necessitates efficient, large-scale energy storage solutions to address intermittency issues. Second, concerns about the long-term availability and rising costs of lithium and cobalt are prompting exploration of alternative battery chemistries. Third, the growing focus on sustainability and environmental impact favors technologies with abundant, low-cost raw materials like sodium and sulfur.

The stationary energy storage sector represents the most immediate market opportunity for RT Na-S technology. This includes grid-scale applications, commercial and industrial energy management systems, and residential storage solutions. Market research suggests that grid-scale storage alone could represent a market exceeding $40 billion by 2030, with RT Na-S potentially capturing a significant portion if safety and performance metrics can be adequately addressed.

Geographically, the market shows distinct regional characteristics. Asia-Pacific, particularly China, leads in terms of manufacturing capacity development and deployment targets for advanced battery technologies. North America and Europe follow with strong research initiatives and increasing commercial interest, driven by supportive regulatory frameworks for renewable energy integration and energy storage.

Customer segments demonstrate varying priorities that influence market adoption. Utility companies prioritize long-term reliability, safety, and cost-effectiveness over energy density. Commercial and industrial users seek solutions that provide energy arbitrage capabilities and backup power with minimal maintenance requirements. Residential consumers value safety above all other considerations, followed by longevity and installation simplicity.

Price sensitivity analysis indicates that RT Na-S systems must achieve a levelized cost of storage below $150/kWh to compete effectively with lithium-ion alternatives in most applications. Current cost projections suggest this threshold could be reached within 3-5 years as manufacturing scales and technology matures.

Market barriers include concerns about safety (particularly thermal runaway risks), limited field demonstration data, and the established market position of competing technologies. However, the potential for significantly lower material costs and supply chain advantages positions RT Na-S technology favorably for long-duration storage applications where lithium-ion economics become less competitive.

Market demand for RT Na-S batteries is primarily driven by several key factors. First, the increasing integration of renewable energy sources into power grids necessitates efficient, large-scale energy storage solutions to address intermittency issues. Second, concerns about the long-term availability and rising costs of lithium and cobalt are prompting exploration of alternative battery chemistries. Third, the growing focus on sustainability and environmental impact favors technologies with abundant, low-cost raw materials like sodium and sulfur.

The stationary energy storage sector represents the most immediate market opportunity for RT Na-S technology. This includes grid-scale applications, commercial and industrial energy management systems, and residential storage solutions. Market research suggests that grid-scale storage alone could represent a market exceeding $40 billion by 2030, with RT Na-S potentially capturing a significant portion if safety and performance metrics can be adequately addressed.

Geographically, the market shows distinct regional characteristics. Asia-Pacific, particularly China, leads in terms of manufacturing capacity development and deployment targets for advanced battery technologies. North America and Europe follow with strong research initiatives and increasing commercial interest, driven by supportive regulatory frameworks for renewable energy integration and energy storage.

Customer segments demonstrate varying priorities that influence market adoption. Utility companies prioritize long-term reliability, safety, and cost-effectiveness over energy density. Commercial and industrial users seek solutions that provide energy arbitrage capabilities and backup power with minimal maintenance requirements. Residential consumers value safety above all other considerations, followed by longevity and installation simplicity.

Price sensitivity analysis indicates that RT Na-S systems must achieve a levelized cost of storage below $150/kWh to compete effectively with lithium-ion alternatives in most applications. Current cost projections suggest this threshold could be reached within 3-5 years as manufacturing scales and technology matures.

Market barriers include concerns about safety (particularly thermal runaway risks), limited field demonstration data, and the established market position of competing technologies. However, the potential for significantly lower material costs and supply chain advantages positions RT Na-S technology favorably for long-duration storage applications where lithium-ion economics become less competitive.

Technical Challenges in RT Na-S Battery Safety

Room temperature sodium-sulfur (RT Na-S) batteries face significant technical challenges in safety assessment and thermal runaway prevention. Unlike traditional high-temperature Na-S batteries operating at 300-350°C, RT Na-S systems operate below 100°C but introduce new safety concerns that require comprehensive evaluation and mitigation strategies.

The primary safety challenge stems from sodium's high reactivity with moisture and oxygen, creating potential fire hazards during cell manufacturing, operation, and disposal. Even at room temperature, sodium remains highly reactive, necessitating robust encapsulation and protection systems that don't compromise electrochemical performance.

Polysulfide shuttle effects represent another critical safety concern, where soluble sodium polysulfides migrate between electrodes, causing capacity fading and potentially dangerous side reactions. These migrations can lead to dendrite formation and internal short circuits, triggering thermal events that may cascade into full thermal runaway.

Electrolyte stability presents a persistent challenge, as most RT Na-S batteries utilize organic or polymer-based electrolytes that decompose at elevated temperatures or under electrical stress. This decomposition generates flammable gases and heat, potentially initiating thermal runaway sequences that are difficult to contain once triggered.

Interface stability between sodium metal anodes and electrolytes remains problematic, with continuous SEI (Solid Electrolyte Interphase) formation consuming active materials and generating heat. Unstable interfaces can lead to localized heating spots that accelerate degradation reactions and compromise cell integrity during cycling.

Current safety assessment methodologies developed for lithium-ion systems require significant adaptation for RT Na-S batteries due to fundamental differences in failure mechanisms and thermal behaviors. Standard tests like nail penetration, crush, and overcharge may not accurately represent RT Na-S failure modes, creating gaps in safety evaluation protocols.

Thermal runaway propagation in multi-cell configurations presents unique challenges, as the heat release characteristics and propagation pathways differ from conventional battery chemistries. The lack of standardized metrics specifically designed for RT Na-S systems complicates risk assessment and safety design validation.

Advanced sensing and early warning systems for RT Na-S batteries remain underdeveloped, with conventional temperature and voltage monitoring proving insufficient to detect precursors to thermal events. The industry lacks consensus on critical safety parameters and thresholds specific to this chemistry, hampering the development of effective battery management systems.

The primary safety challenge stems from sodium's high reactivity with moisture and oxygen, creating potential fire hazards during cell manufacturing, operation, and disposal. Even at room temperature, sodium remains highly reactive, necessitating robust encapsulation and protection systems that don't compromise electrochemical performance.

Polysulfide shuttle effects represent another critical safety concern, where soluble sodium polysulfides migrate between electrodes, causing capacity fading and potentially dangerous side reactions. These migrations can lead to dendrite formation and internal short circuits, triggering thermal events that may cascade into full thermal runaway.

Electrolyte stability presents a persistent challenge, as most RT Na-S batteries utilize organic or polymer-based electrolytes that decompose at elevated temperatures or under electrical stress. This decomposition generates flammable gases and heat, potentially initiating thermal runaway sequences that are difficult to contain once triggered.

Interface stability between sodium metal anodes and electrolytes remains problematic, with continuous SEI (Solid Electrolyte Interphase) formation consuming active materials and generating heat. Unstable interfaces can lead to localized heating spots that accelerate degradation reactions and compromise cell integrity during cycling.

Current safety assessment methodologies developed for lithium-ion systems require significant adaptation for RT Na-S batteries due to fundamental differences in failure mechanisms and thermal behaviors. Standard tests like nail penetration, crush, and overcharge may not accurately represent RT Na-S failure modes, creating gaps in safety evaluation protocols.

Thermal runaway propagation in multi-cell configurations presents unique challenges, as the heat release characteristics and propagation pathways differ from conventional battery chemistries. The lack of standardized metrics specifically designed for RT Na-S systems complicates risk assessment and safety design validation.

Advanced sensing and early warning systems for RT Na-S batteries remain underdeveloped, with conventional temperature and voltage monitoring proving insufficient to detect precursors to thermal events. The industry lacks consensus on critical safety parameters and thresholds specific to this chemistry, hampering the development of effective battery management systems.

Current Thermal Runaway Prevention Solutions

01 Thermal runaway prevention mechanisms in RT Na-S batteries

Room temperature sodium-sulfur batteries can incorporate various safety mechanisms to prevent thermal runaway incidents. These include specialized separators that shut down ion transport at elevated temperatures, thermal fuses that disconnect electrical pathways during overheating, and pressure relief mechanisms that safely vent gases before dangerous pressures build up. These preventive measures are critical for ensuring the safe operation of RT Na-S batteries under various conditions.- Thermal runaway prevention mechanisms in RT Na-S batteries: Room temperature sodium-sulfur batteries can incorporate various safety mechanisms to prevent thermal runaway events. These include specialized separators that shut down ion transport at elevated temperatures, thermal fuses that disconnect electrical pathways when overheating occurs, and pressure relief mechanisms that safely vent gases before dangerous pressures build up. These preventive measures are critical for maintaining battery stability during abnormal operating conditions and preventing catastrophic failure.

- Safety assessment protocols for RT Na-S battery systems: Comprehensive safety assessment protocols for room temperature sodium-sulfur batteries include accelerated aging tests, abuse testing under extreme conditions, and thermal stability evaluations. These protocols typically measure parameters such as heat generation rates, gas evolution, and temperature distribution during various failure modes. Standard testing procedures involve nail penetration tests, crush tests, overcharge/overdischarge cycles, and external heating to evaluate the battery's response to mechanical and electrical abuse.

- Electrolyte modifications for enhanced thermal stability: Specialized electrolyte formulations can significantly improve the thermal stability of room temperature sodium-sulfur batteries. These include flame-retardant additives, ionic liquids with high thermal decomposition temperatures, and solid-state electrolytes that eliminate the risk of liquid electrolyte leakage and combustion. These modifications help suppress exothermic reactions between sodium and sulfur components during thermal events, thereby increasing the temperature threshold for thermal runaway and improving overall battery safety.

- Real-time monitoring systems for thermal runaway detection: Advanced monitoring systems can detect early signs of thermal runaway in room temperature sodium-sulfur batteries. These systems utilize temperature sensors, gas sensors, and impedance measurement techniques to identify abnormal battery behavior before catastrophic failure occurs. Machine learning algorithms can analyze battery parameters to predict potential safety issues, while battery management systems can implement protective measures such as current limitation or circuit disconnection when dangerous conditions are detected.

- Thermal runaway propagation prevention in battery packs: Preventing thermal runaway propagation between cells is crucial for large-scale room temperature sodium-sulfur battery systems. Design strategies include physical barriers between cells, heat-absorbing materials, and thermal isolation structures. Cell-to-cell spacing, cooling systems, and fire-resistant materials can limit heat transfer during failure events. These approaches ensure that a single cell failure does not cascade throughout the entire battery pack, significantly improving the overall safety profile of the battery system.

02 Safety assessment protocols for RT Na-S battery systems

Comprehensive safety assessment protocols have been developed specifically for room temperature sodium-sulfur battery systems. These protocols include accelerated aging tests, abuse testing under extreme conditions, thermal stability evaluations, and electrochemical impedance spectroscopy to detect internal short circuits. These standardized testing methodologies help quantify safety margins and establish reliable thermal runaway metrics for RT Na-S batteries.Expand Specific Solutions03 Electrolyte modifications for enhanced thermal stability

Specialized electrolyte formulations can significantly improve the thermal stability of room temperature sodium-sulfur batteries. These include flame-retardant additives, ionic liquid electrolytes with high thermal decomposition temperatures, and solid-state electrolytes that eliminate the risk of liquid electrolyte leakage and combustion. These modifications effectively increase the temperature threshold for thermal runaway events.Expand Specific Solutions04 Real-time monitoring systems for thermal runaway detection

Advanced monitoring systems have been developed to detect early signs of thermal runaway in room temperature sodium-sulfur batteries. These systems utilize temperature sensors, gas sensors for detecting sulfur-containing compounds, voltage fluctuation monitoring, and machine learning algorithms that can predict potential failure based on battery performance patterns. Early detection allows for preventive measures before catastrophic failure occurs.Expand Specific Solutions05 Structural design improvements for thermal management

Innovative structural designs can significantly improve thermal management in room temperature sodium-sulfur battery systems. These include phase change materials for heat absorption, optimized cell spacing to prevent thermal propagation between cells, heat-dissipating materials integrated into battery casings, and thermal isolation barriers between battery modules. These design improvements help maintain uniform temperature distribution and prevent localized hotspots that could trigger thermal runaway.Expand Specific Solutions

Leading RT Na-S Battery Manufacturers and Research Institutions

Room Temperature Sodium-Sulfur (RT Na-S) battery technology is currently in the early growth phase, with a projected market size reaching $1.2 billion by 2030. The competitive landscape features established players like NGK Insulators, which pioneered high-temperature Na-S batteries, alongside emerging competitors including CATL, LG Energy Solution, and Samsung SDI who are investing in RT Na-S research. Technical maturity remains moderate, with companies addressing key challenges in electrode stability and safety metrics. Academic-industrial partnerships are accelerating development, with institutions like Texas A&M University and Zhejiang University collaborating with industry leaders. Safety assessment frameworks and thermal runaway prevention represent critical differentiation points as companies race to commercialize this promising energy storage technology.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered sodium-sulfur battery technology with their NAS® battery system, though traditionally focused on high-temperature versions operating at 300-350°C. For room temperature Na-S systems, NGK has developed proprietary ceramic separators with enhanced ionic conductivity and mechanical stability to prevent dendrite formation. Their safety assessment framework includes multi-level thermal management systems with phase-change materials to absorb heat during potential thermal events. NGK employs real-time monitoring with distributed temperature sensors and predictive algorithms to detect early signs of thermal runaway. Their safety protocols include cell-level isolation mechanisms that can electrically disconnect compromised cells before cascading failures occur. NGK has established comprehensive testing protocols that evaluate thermal stability under various abuse conditions including overcharging, external heating, and mechanical damage.

Strengths: Decades of experience with sodium-sulfur chemistry; established manufacturing infrastructure; proprietary ceramic separator technology with proven safety record. Weaknesses: Traditional focus on high-temperature systems requires significant adaptation for room temperature applications; higher production costs compared to lithium-ion alternatives; ceramic components may introduce fragility concerns in certain applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a hybrid safety approach for RT Na-S batteries combining physical and chemical protection mechanisms. Their system features a nano-engineered carbon host structure for sulfur cathodes that minimizes polysulfide dissolution while improving thermal stability. LG's proprietary electrolyte formulation includes flame-retardant additives and ionic liquid components that remain stable at higher temperatures than conventional electrolytes. Their cells incorporate a multi-functional separator with ceramic coating that maintains dimensional stability under thermal stress while providing an additional barrier against internal short circuits. LG has implemented a hierarchical thermal management system with phase-change materials strategically positioned between cells to absorb and redistribute heat during thermal events. Their safety assessment methodology includes abuse testing under various state-of-charge conditions to map the full safety envelope of their RT Na-S systems.

Strengths: Extensive battery manufacturing infrastructure that can be adapted to Na-S production; strong supply chain relationships; advanced thermal modeling capabilities. Weaknesses: Primary expertise in lithium-ion technology requires significant knowledge transfer; current safety protocols optimized for lithium chemistry may require substantial modification; higher initial investment in specialized manufacturing equipment.

Critical Safety Metrics and Testing Protocols

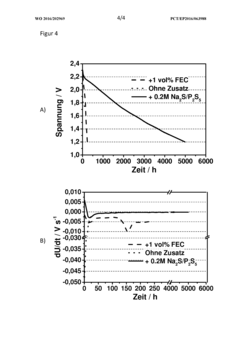

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentWO2016202969A1

Innovation

- A sodium-sulfur battery design using a carbon-sulfur composite cathode, an organic solvent-based electrolyte with a conductive salt and phosphorus polysulfide as an additive to suppress the polysulfide shuttle, allowing operation at room temperature with enhanced energy efficiency and discharge capacity.

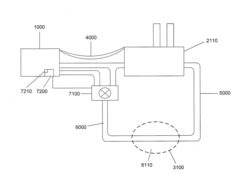

System and method for the thermal management of battery-based energy storage systems

PatentInactiveUS20100243017A1

Innovation

- A thermal management system utilizing a geothermal heat source, either directly or through a heat conduit, to regulate the temperature of battery-based energy storage systems, incorporating control units and heat exchangers to maintain optimal operating temperatures and efficiently manage heat exchange, thereby preventing overheating and enhancing system performance.

Regulatory Framework for Na-S Battery Systems

The regulatory landscape for Room Temperature Sodium-Sulfur (RT Na-S) battery systems is currently evolving as these technologies advance toward commercial deployment. Unlike traditional high-temperature Na-S batteries which have established safety protocols, RT Na-S systems present unique regulatory challenges due to their novel chemistry and operating conditions.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are working to develop comprehensive standards specifically addressing sodium-based battery technologies. The IEC Technical Committee 21 has begun incorporating considerations for Na-S systems within its framework for secondary cells and batteries.

In the United States, regulatory oversight falls primarily under the jurisdiction of the Department of Transportation (DOT) for transport safety, the Consumer Product Safety Commission (CPSC) for consumer applications, and the Occupational Safety and Health Administration (OSHA) for workplace implementations. The DOT has established specific provisions for sodium batteries under 49 CFR 173.189, though these regulations were primarily designed for high-temperature systems and require updating for RT Na-S technologies.

The European Union approaches battery regulation through the Battery Directive (2006/66/EC) and its recent update, Regulation 2023/1542, which now includes provisions for emerging battery chemistries. While not explicitly addressing RT Na-S systems, these frameworks establish requirements for safety documentation, performance testing, and end-of-life management that will apply to sodium-based technologies.

Safety certification bodies such as UL (Underwriters Laboratories) and TÜV are developing testing protocols specific to sodium-sulfur battery systems. UL 1973 (Standard for Batteries for Use in Stationary, Vehicle Auxiliary Power and Light Electric Rail Applications) and UL 9540A (Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems) are being adapted to address the unique thermal runaway characteristics of RT Na-S batteries.

A significant regulatory gap exists in thermal runaway metrics specifically calibrated for RT Na-S systems. Current thermal runaway assessment methodologies were largely developed for lithium-ion technologies and may not adequately capture the failure modes unique to sodium-sulfur chemistry, particularly regarding polysulfide formation and sodium reactivity with moisture.

Industry stakeholders and research institutions are collaborating with regulatory bodies to establish appropriate safety thresholds and testing protocols that address the specific thermal, chemical, and electrical safety considerations of RT Na-S batteries. These efforts aim to create a balanced regulatory framework that ensures public safety while enabling technological advancement in this promising energy storage domain.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are working to develop comprehensive standards specifically addressing sodium-based battery technologies. The IEC Technical Committee 21 has begun incorporating considerations for Na-S systems within its framework for secondary cells and batteries.

In the United States, regulatory oversight falls primarily under the jurisdiction of the Department of Transportation (DOT) for transport safety, the Consumer Product Safety Commission (CPSC) for consumer applications, and the Occupational Safety and Health Administration (OSHA) for workplace implementations. The DOT has established specific provisions for sodium batteries under 49 CFR 173.189, though these regulations were primarily designed for high-temperature systems and require updating for RT Na-S technologies.

The European Union approaches battery regulation through the Battery Directive (2006/66/EC) and its recent update, Regulation 2023/1542, which now includes provisions for emerging battery chemistries. While not explicitly addressing RT Na-S systems, these frameworks establish requirements for safety documentation, performance testing, and end-of-life management that will apply to sodium-based technologies.

Safety certification bodies such as UL (Underwriters Laboratories) and TÜV are developing testing protocols specific to sodium-sulfur battery systems. UL 1973 (Standard for Batteries for Use in Stationary, Vehicle Auxiliary Power and Light Electric Rail Applications) and UL 9540A (Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems) are being adapted to address the unique thermal runaway characteristics of RT Na-S batteries.

A significant regulatory gap exists in thermal runaway metrics specifically calibrated for RT Na-S systems. Current thermal runaway assessment methodologies were largely developed for lithium-ion technologies and may not adequately capture the failure modes unique to sodium-sulfur chemistry, particularly regarding polysulfide formation and sodium reactivity with moisture.

Industry stakeholders and research institutions are collaborating with regulatory bodies to establish appropriate safety thresholds and testing protocols that address the specific thermal, chemical, and electrical safety considerations of RT Na-S batteries. These efforts aim to create a balanced regulatory framework that ensures public safety while enabling technological advancement in this promising energy storage domain.

Environmental Impact and Sustainability Considerations

Room temperature sodium-sulfur (RT Na-S) battery systems present significant environmental advantages compared to conventional lithium-ion batteries, primarily due to the abundant nature of their core materials. Sodium is the sixth most abundant element in the Earth's crust, comprising approximately 2.8% of its mass, while sulfur is readily available as a byproduct of petroleum refining processes. This abundance translates to reduced environmental impact from mining operations, which is a notable concern with lithium and cobalt extraction for conventional batteries.

The manufacturing process for RT Na-S batteries generally requires less energy compared to lithium-ion batteries, resulting in a lower carbon footprint during production. Life cycle assessments indicate that RT Na-S batteries can achieve up to 30% reduction in greenhouse gas emissions during manufacturing compared to equivalent capacity lithium-ion systems. This advantage becomes particularly significant when considering large-scale energy storage applications.

End-of-life management for RT Na-S batteries presents both challenges and opportunities. The absence of toxic heavy metals like cobalt and nickel simplifies recycling processes. However, the reactive nature of sodium requires careful handling during disassembly. Current recycling technologies can recover approximately 85-90% of sodium and sulfur components, which can be reintroduced into the manufacturing stream, creating a more circular material economy.

Water usage represents another important sustainability metric for battery technologies. RT Na-S battery production typically consumes 40-50% less water than comparable lithium-ion manufacturing processes. This reduced water footprint becomes increasingly important in regions facing water scarcity challenges, where battery manufacturing facilities may compete with agricultural and municipal water needs.

Land use considerations also favor RT Na-S technology. The higher energy density potential of these systems (theoretical maximum of 760 Wh/kg) means smaller physical footprints for equivalent energy storage capacity. This translates to reduced land requirements for large-scale installations, preserving natural habitats and minimizing ecosystem disruption.

Safety incidents involving thermal runaway in RT Na-S batteries can have environmental consequences through the release of sulfur dioxide and other sulfur compounds. However, modern containment systems and thermal management approaches have significantly reduced these risks. Environmental monitoring data from existing installations shows minimal impact on surrounding air and soil quality during normal operation, with containment systems effectively managing the rare failure events.

Carbon footprint analyses across the full lifecycle reveal that RT Na-S batteries can achieve carbon neutrality approximately 30% faster than lithium-ion equivalents when used in renewable energy applications. This accelerated carbon payback period enhances their value as a sustainable energy storage solution for grid applications and renewable energy integration.

The manufacturing process for RT Na-S batteries generally requires less energy compared to lithium-ion batteries, resulting in a lower carbon footprint during production. Life cycle assessments indicate that RT Na-S batteries can achieve up to 30% reduction in greenhouse gas emissions during manufacturing compared to equivalent capacity lithium-ion systems. This advantage becomes particularly significant when considering large-scale energy storage applications.

End-of-life management for RT Na-S batteries presents both challenges and opportunities. The absence of toxic heavy metals like cobalt and nickel simplifies recycling processes. However, the reactive nature of sodium requires careful handling during disassembly. Current recycling technologies can recover approximately 85-90% of sodium and sulfur components, which can be reintroduced into the manufacturing stream, creating a more circular material economy.

Water usage represents another important sustainability metric for battery technologies. RT Na-S battery production typically consumes 40-50% less water than comparable lithium-ion manufacturing processes. This reduced water footprint becomes increasingly important in regions facing water scarcity challenges, where battery manufacturing facilities may compete with agricultural and municipal water needs.

Land use considerations also favor RT Na-S technology. The higher energy density potential of these systems (theoretical maximum of 760 Wh/kg) means smaller physical footprints for equivalent energy storage capacity. This translates to reduced land requirements for large-scale installations, preserving natural habitats and minimizing ecosystem disruption.

Safety incidents involving thermal runaway in RT Na-S batteries can have environmental consequences through the release of sulfur dioxide and other sulfur compounds. However, modern containment systems and thermal management approaches have significantly reduced these risks. Environmental monitoring data from existing installations shows minimal impact on surrounding air and soil quality during normal operation, with containment systems effectively managing the rare failure events.

Carbon footprint analyses across the full lifecycle reveal that RT Na-S batteries can achieve carbon neutrality approximately 30% faster than lithium-ion equivalents when used in renewable energy applications. This accelerated carbon payback period enhances their value as a sustainable energy storage solution for grid applications and renewable energy integration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!