Polysulfide Shuttle Suppression Strategies For Room-Temperature Na–S Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysulfide Shuttle Mechanism and Research Objectives

The polysulfide shuttle effect represents a critical challenge in room-temperature sodium-sulfur (RT Na-S) batteries, significantly hindering their commercial viability despite their promising theoretical energy density of 760 Wh/kg. This phenomenon occurs when soluble sodium polysulfides (Na₂Sₓ, 4≤x≤8) formed during discharge dissolve in the electrolyte and migrate between electrodes, causing parasitic reactions that lead to rapid capacity fading, low Coulombic efficiency, and shortened battery lifespan.

The shuttle mechanism begins during discharge when elemental sulfur (S₈) is reduced to form long-chain polysulfides. These species dissolve in the electrolyte and diffuse to the sodium anode where they undergo chemical reduction, forming shorter-chain polysulfides without contributing to the electrical current. These reduced species then diffuse back to the cathode, creating a continuous "shuttle" of active material between electrodes. This cyclical process consumes active materials and electrolyte, resulting in self-discharge and accelerated capacity decay.

The severity of the shuttle effect in RT Na-S cells exceeds that observed in lithium-sulfur systems due to the higher solubility of sodium polysulfides and the greater reactivity of sodium metal with the electrolyte. Additionally, the larger ionic radius of Na⁺ compared to Li⁺ leads to slower diffusion kinetics and more pronounced volume changes during cycling, exacerbating the shuttle problem.

Research objectives in this field primarily focus on developing effective strategies to suppress the polysulfide shuttle effect while maintaining the high energy density and cost advantages of Na-S technology. Key research goals include: (1) designing novel cathode materials and structures that can physically confine polysulfides; (2) developing functional separators or interlayers that block polysulfide migration; (3) formulating electrolyte additives that chemically bind polysulfides; (4) creating protective coatings for sodium anodes to minimize side reactions; and (5) engineering electrolytes with reduced polysulfide solubility.

The ultimate aim is to achieve RT Na-S batteries with high capacity retention (>80% after 500 cycles), improved Coulombic efficiency (>99%), and practical energy densities approaching 300-400 Wh/kg. Success in these objectives would position RT Na-S batteries as viable alternatives to current lithium-ion technologies, particularly for large-scale energy storage applications where cost considerations are paramount.

Recent breakthroughs in nanomaterials, advanced characterization techniques, and computational modeling have accelerated progress in understanding and addressing the shuttle effect, creating renewed optimism for overcoming this longstanding challenge in Na-S battery technology.

The shuttle mechanism begins during discharge when elemental sulfur (S₈) is reduced to form long-chain polysulfides. These species dissolve in the electrolyte and diffuse to the sodium anode where they undergo chemical reduction, forming shorter-chain polysulfides without contributing to the electrical current. These reduced species then diffuse back to the cathode, creating a continuous "shuttle" of active material between electrodes. This cyclical process consumes active materials and electrolyte, resulting in self-discharge and accelerated capacity decay.

The severity of the shuttle effect in RT Na-S cells exceeds that observed in lithium-sulfur systems due to the higher solubility of sodium polysulfides and the greater reactivity of sodium metal with the electrolyte. Additionally, the larger ionic radius of Na⁺ compared to Li⁺ leads to slower diffusion kinetics and more pronounced volume changes during cycling, exacerbating the shuttle problem.

Research objectives in this field primarily focus on developing effective strategies to suppress the polysulfide shuttle effect while maintaining the high energy density and cost advantages of Na-S technology. Key research goals include: (1) designing novel cathode materials and structures that can physically confine polysulfides; (2) developing functional separators or interlayers that block polysulfide migration; (3) formulating electrolyte additives that chemically bind polysulfides; (4) creating protective coatings for sodium anodes to minimize side reactions; and (5) engineering electrolytes with reduced polysulfide solubility.

The ultimate aim is to achieve RT Na-S batteries with high capacity retention (>80% after 500 cycles), improved Coulombic efficiency (>99%), and practical energy densities approaching 300-400 Wh/kg. Success in these objectives would position RT Na-S batteries as viable alternatives to current lithium-ion technologies, particularly for large-scale energy storage applications where cost considerations are paramount.

Recent breakthroughs in nanomaterials, advanced characterization techniques, and computational modeling have accelerated progress in understanding and addressing the shuttle effect, creating renewed optimism for overcoming this longstanding challenge in Na-S battery technology.

Market Analysis for Room-Temperature Na-S Battery Technology

The global energy storage market is experiencing a significant shift towards more sustainable and cost-effective solutions, creating a favorable environment for room-temperature sodium-sulfur (RT Na-S) battery technology. Current market projections indicate that the global grid energy storage market will reach approximately 500 GWh by 2025, with a compound annual growth rate exceeding 20% through 2030. Within this expanding landscape, RT Na-S batteries are positioned to capture a growing market share due to their compelling value proposition.

The primary market drivers for RT Na-S battery technology include increasing renewable energy integration, grid stabilization requirements, and the global push for energy independence. As renewable energy sources continue to penetrate electricity markets worldwide, the demand for efficient, large-scale energy storage solutions has intensified. This trend is particularly evident in regions with aggressive renewable energy targets such as Europe, China, and parts of North America.

Cost considerations represent a significant market advantage for RT Na-S technology. With sodium resources being approximately 1,000 times more abundant than lithium and more geographically distributed, RT Na-S batteries offer potential cost reductions of 30-40% compared to lithium-ion alternatives at scale. This economic advantage is particularly attractive for grid-scale applications where cost per kilowatt-hour is a critical decision factor.

Market segmentation analysis reveals several promising application areas for RT Na-S technology. The utility-scale energy storage sector presents the largest immediate opportunity, particularly for load-leveling and renewable energy time-shifting applications. The commercial and industrial energy management segment also shows substantial potential, especially in regions with high electricity costs or unreliable grid infrastructure.

Geographically, the market for RT Na-S technology shows varying levels of readiness. China leads in terms of research investment and pilot deployments, followed by the United States and European Union. Emerging markets in India and Southeast Asia represent significant growth opportunities due to their expanding energy needs and limited existing infrastructure.

Consumer and industry sentiment analysis indicates growing interest in alternatives to lithium-ion technology, driven by concerns about resource availability, geopolitical supply chain risks, and environmental impact. This shift in market perception creates a favorable entry point for RT Na-S technology, particularly if polysulfide shuttle issues can be effectively addressed to improve cycle life and performance stability.

The regulatory landscape generally supports the development and deployment of RT Na-S technology, with many countries implementing policies that incentivize energy storage deployment. These include investment tax credits, capacity market mechanisms, and renewable portfolio standards that indirectly benefit storage technologies.

The primary market drivers for RT Na-S battery technology include increasing renewable energy integration, grid stabilization requirements, and the global push for energy independence. As renewable energy sources continue to penetrate electricity markets worldwide, the demand for efficient, large-scale energy storage solutions has intensified. This trend is particularly evident in regions with aggressive renewable energy targets such as Europe, China, and parts of North America.

Cost considerations represent a significant market advantage for RT Na-S technology. With sodium resources being approximately 1,000 times more abundant than lithium and more geographically distributed, RT Na-S batteries offer potential cost reductions of 30-40% compared to lithium-ion alternatives at scale. This economic advantage is particularly attractive for grid-scale applications where cost per kilowatt-hour is a critical decision factor.

Market segmentation analysis reveals several promising application areas for RT Na-S technology. The utility-scale energy storage sector presents the largest immediate opportunity, particularly for load-leveling and renewable energy time-shifting applications. The commercial and industrial energy management segment also shows substantial potential, especially in regions with high electricity costs or unreliable grid infrastructure.

Geographically, the market for RT Na-S technology shows varying levels of readiness. China leads in terms of research investment and pilot deployments, followed by the United States and European Union. Emerging markets in India and Southeast Asia represent significant growth opportunities due to their expanding energy needs and limited existing infrastructure.

Consumer and industry sentiment analysis indicates growing interest in alternatives to lithium-ion technology, driven by concerns about resource availability, geopolitical supply chain risks, and environmental impact. This shift in market perception creates a favorable entry point for RT Na-S technology, particularly if polysulfide shuttle issues can be effectively addressed to improve cycle life and performance stability.

The regulatory landscape generally supports the development and deployment of RT Na-S technology, with many countries implementing policies that incentivize energy storage deployment. These include investment tax credits, capacity market mechanisms, and renewable portfolio standards that indirectly benefit storage technologies.

Technical Challenges in Na-S Cell Development

Despite the promising theoretical energy density of sodium-sulfur (Na-S) batteries, their practical development faces significant technical challenges that have hindered widespread commercialization. The most critical issue in room-temperature Na-S cells is the polysulfide shuttle effect, where soluble sodium polysulfides dissolve in the electrolyte and migrate between electrodes, causing capacity fading, self-discharge, and poor cycling stability.

The dissolution of intermediate polysulfides (Na₂Sₓ, 4≤x≤8) creates a parasitic redox shuttle that continuously consumes active materials and lithium ions. This phenomenon results in low Coulombic efficiency and rapid capacity decay, severely limiting the practical application of Na-S batteries at ambient temperatures.

Another significant challenge is the insulating nature of sulfur and its discharge products. Sulfur exhibits poor electronic conductivity (5×10⁻³⁰ S/cm), which impedes electron transfer during electrochemical reactions. This limitation necessitates the incorporation of conductive additives, which reduces the overall energy density of the battery system.

Volume expansion during the sulfur-to-sodium sulfide conversion presents another formidable obstacle. The sulfur cathode undergoes approximately 80% volume expansion during discharge, leading to structural instability, pulverization of active materials, and loss of electrical contact within the electrode. This mechanical degradation accelerates capacity fading and shortens battery lifespan.

The highly reactive nature of sodium metal anodes introduces additional complications. Sodium metal is prone to dendrite formation during cycling, which can penetrate the separator and cause internal short circuits. Furthermore, the continuous formation of solid electrolyte interphase (SEI) on the sodium anode consumes electrolyte and active sodium, contributing to capacity loss.

Electrolyte stability represents another critical challenge. Conventional organic electrolytes decompose when in contact with sodium polysulfides, forming an unstable SEI layer. This decomposition not only consumes electrolyte but also generates gas, leading to increased internal pressure and potential safety hazards.

The sluggish reaction kinetics of sulfur conversion at room temperature further complicates Na-S cell development. The multi-step reduction of sulfur to sodium sulfide involves complex phase transitions and slow solid-state diffusion processes, resulting in large polarization and poor rate capability.

Addressing these interconnected challenges requires innovative materials design and system engineering approaches. Recent research has focused on developing multifunctional sulfur hosts, protective separators, electrolyte additives, and novel cell configurations to mitigate the polysulfide shuttle effect and enhance the overall performance of room-temperature Na-S batteries.

The dissolution of intermediate polysulfides (Na₂Sₓ, 4≤x≤8) creates a parasitic redox shuttle that continuously consumes active materials and lithium ions. This phenomenon results in low Coulombic efficiency and rapid capacity decay, severely limiting the practical application of Na-S batteries at ambient temperatures.

Another significant challenge is the insulating nature of sulfur and its discharge products. Sulfur exhibits poor electronic conductivity (5×10⁻³⁰ S/cm), which impedes electron transfer during electrochemical reactions. This limitation necessitates the incorporation of conductive additives, which reduces the overall energy density of the battery system.

Volume expansion during the sulfur-to-sodium sulfide conversion presents another formidable obstacle. The sulfur cathode undergoes approximately 80% volume expansion during discharge, leading to structural instability, pulverization of active materials, and loss of electrical contact within the electrode. This mechanical degradation accelerates capacity fading and shortens battery lifespan.

The highly reactive nature of sodium metal anodes introduces additional complications. Sodium metal is prone to dendrite formation during cycling, which can penetrate the separator and cause internal short circuits. Furthermore, the continuous formation of solid electrolyte interphase (SEI) on the sodium anode consumes electrolyte and active sodium, contributing to capacity loss.

Electrolyte stability represents another critical challenge. Conventional organic electrolytes decompose when in contact with sodium polysulfides, forming an unstable SEI layer. This decomposition not only consumes electrolyte but also generates gas, leading to increased internal pressure and potential safety hazards.

The sluggish reaction kinetics of sulfur conversion at room temperature further complicates Na-S cell development. The multi-step reduction of sulfur to sodium sulfide involves complex phase transitions and slow solid-state diffusion processes, resulting in large polarization and poor rate capability.

Addressing these interconnected challenges requires innovative materials design and system engineering approaches. Recent research has focused on developing multifunctional sulfur hosts, protective separators, electrolyte additives, and novel cell configurations to mitigate the polysulfide shuttle effect and enhance the overall performance of room-temperature Na-S batteries.

Current Suppression Strategies for Polysulfide Shuttling

01 Solid electrolyte barriers for polysulfide suppression

Solid electrolytes can be used as barriers to physically prevent polysulfide shuttling in room-temperature Na-S cells. These materials, such as ceramic or polymer-based solid electrolytes, block the migration of sodium polysulfides between electrodes while allowing sodium ion transport. This approach effectively suppresses the shuttle effect by containing the polysulfides within the cathode compartment, leading to improved cycling stability and coulombic efficiency of the battery.- Solid electrolyte barriers for polysulfide suppression: Solid electrolyte materials can be used as physical barriers to prevent polysulfide shuttling in room-temperature Na-S cells. These materials, such as ceramic or polymer-based solid electrolytes, block the migration of polysulfide species between electrodes while allowing sodium ion transport. This approach effectively suppresses the shuttle effect, improving cycling stability and coulombic efficiency of the battery system.

- Functional separators and interlayers: Modified separators or additional interlayers can be incorporated into Na-S cells to trap polysulfides and prevent their shuttle between electrodes. These components can be coated with or composed of materials that have strong chemical affinity for polysulfides, such as carbon-based materials, metal oxides, or polymers with functional groups. The separators act as selective barriers, allowing sodium ions to pass while blocking polysulfide migration.

- Cathode structure engineering: Engineering the cathode structure is an effective approach to suppress polysulfide shuttling. This includes designing sulfur hosts with strong polysulfide adsorption capabilities, creating physical confinement structures to trap polysulfides, and developing composite cathodes with functional materials. These strategies aim to immobilize sulfur and its discharge products within the cathode, preventing their dissolution into the electrolyte.

- Electrolyte modification and additives: Modifying the electrolyte composition by incorporating additives or using alternative solvents can significantly reduce polysulfide shuttling. Certain additives can form protective films on electrodes, while others can chemically interact with polysulfides to reduce their solubility. Electrolyte formulations with lower polysulfide solubility or those that promote the formation of short-chain polysulfides can effectively suppress the shuttle effect.

- Advanced anode protection strategies: Protecting the sodium anode from direct contact with polysulfides is crucial for suppressing the shuttle effect. This can be achieved through artificial solid electrolyte interphase (SEI) formation, anode coating with protective layers, or using alternative anode materials with reduced reactivity toward polysulfides. These strategies prevent side reactions between the anode and polysulfides, improving the overall performance of room-temperature Na-S cells.

02 Functional separators and interlayers

Modified separators or interlayers can be incorporated into Na-S cells to mitigate polysulfide shuttling. These components can be coated with or composed of materials that have strong adsorption capabilities for polysulfides, such as carbon-based materials, metal oxides, or polymers with functional groups. By placing these barriers between the cathode and anode, dissolved polysulfides are trapped before they can reach the anode, thereby suppressing the shuttle effect and extending battery life.Expand Specific Solutions03 Electrolyte additives and modifications

Specific additives in the liquid electrolyte can help suppress the polysulfide shuttle effect in room-temperature Na-S batteries. These additives can include salts, solvents, or functional compounds that either form a protective layer on the electrode surfaces, reduce polysulfide solubility, or chemically bind with polysulfides to prevent their migration. Modified electrolyte compositions with optimized sodium salt concentrations and solvent ratios can also significantly reduce polysulfide dissolution and mobility.Expand Specific Solutions04 Cathode structure engineering

Advanced cathode designs can effectively contain polysulfides and prevent their dissolution into the electrolyte. These approaches include using porous carbon hosts with high surface area, sulfur encapsulation within conductive matrices, and cathode materials with chemical binding sites for polysulfides. By physically confining sulfur species within the cathode structure or creating chemical bonds that keep polysulfides localized, the shuttle effect can be significantly reduced while maintaining good electrochemical performance.Expand Specific Solutions05 Anode protection strategies

Protecting the sodium anode surface is crucial for preventing reactions with shuttled polysulfides. This can be achieved through artificial solid electrolyte interphase (SEI) formation, protective coatings, or using alternative anode materials that are less reactive with polysulfides. These approaches create a barrier at the anode surface that blocks polysulfide access while allowing sodium ion transport, thereby suppressing the shuttle effect and preventing capacity fade caused by irreversible reactions between sodium and polysulfides.Expand Specific Solutions

Leading Organizations in Na-S Battery Research

The room-temperature sodium-sulfur (Na-S) battery market is in an early growth phase, characterized by increasing research intensity but limited commercial deployment. Market size remains modest but is projected to expand significantly due to the technology's potential for low-cost, large-scale energy storage applications. Technologically, polysulfide shuttle suppression represents a critical challenge, with varying maturity levels across approaches. Leading players include established corporations like LG Chem and Mitsubishi Materials pursuing industrial-scale solutions, alongside research-focused entities such as Central South University and MIT developing fundamental innovations. Specialized companies like Nanotek Instruments and Tianmu Lake Institute are emerging as technology pioneers, while traditional battery manufacturers including Honeycomb Battery are adapting their expertise to address this specific technical challenge.

Tianmu Lake Institute of Advanced Energy Storage Technologies Co., Ltd.

Technical Solution: Tianmu Lake Institute has developed a multi-layered approach to polysulfide shuttle suppression in room-temperature Na-S cells. Their primary strategy involves the use of functionalized carbon interlayers with polar functional groups that chemically adsorb sodium polysulfides. These carbon-based materials are modified with nitrogen and oxygen-containing groups that form strong chemical bonds with polysulfides, effectively trapping them at the cathode side. Additionally, they've pioneered a dual-phase electrolyte system combining solid polymer electrolytes with liquid components to create physical barriers against polysulfide migration while maintaining high ionic conductivity. Their research has demonstrated that incorporating microporous carbon structures with pore sizes below 2 nm can physically confine polysulfides through spatial restriction effects, reducing capacity fade by over 40% compared to conventional designs.

Strengths: Their multi-functional approach addresses both chemical and physical aspects of shuttle suppression simultaneously. The carbon-based materials are cost-effective and scalable. Weaknesses: The functionalized carbon materials may gradually lose their adsorption capacity over extended cycling, and the dual-phase electrolyte system adds complexity to cell manufacturing processes.

Texas A&M University

Technical Solution: Texas A&M University has developed an innovative approach to polysulfide shuttle suppression in room-temperature Na-S cells using two-dimensional (2D) material interlayers. Their strategy employs MXene (Ti3C2Tx) nanosheets as multifunctional interlayers between the cathode and separator. These MXene sheets feature abundant surface termination groups (-OH, -O, -F) that provide strong chemical adsorption sites for polysulfides through polar-polar interactions. The 2D structure creates a physical barrier with tortuous pathways that significantly slow polysulfide diffusion while maintaining high sodium ion conductivity. Texas A&M researchers have further enhanced this system by incorporating a small percentage of reduced graphene oxide to improve the electronic conductivity of the interlayer, facilitating the electrochemical conversion of any trapped polysulfides. Their testing demonstrates that cells incorporating these interlayers maintain approximately 75% capacity retention after 400 cycles at room temperature, compared to less than 30% for conventional cells without interlayer protection.

Strengths: The 2D material approach provides an excellent balance of physical blocking and chemical binding of polysulfides. The solution-processable nature of MXenes enables straightforward integration into existing manufacturing processes. Weaknesses: MXene materials may undergo oxidative degradation during long-term cycling, potentially reducing their effectiveness. The interlayer adds additional inactive mass to the cell, potentially reducing overall energy density.

Key Patents and Publications on Shuttle Effect Mitigation

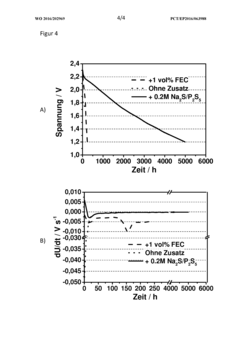

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentWO2016202969A1

Innovation

- A sodium-sulfur battery design using a carbon-sulfur composite cathode, an organic solvent-based electrolyte with a conductive salt and phosphorus polysulfide as an additive to suppress the polysulfide shuttle, allowing operation at room temperature with enhanced energy efficiency and discharge capacity.

Materials Science Advancements for Na-S Electrolytes

Recent advancements in materials science have significantly contributed to the development of more efficient and stable Na-S electrolytes, addressing the critical challenge of polysulfide shuttle effect in room-temperature sodium-sulfur batteries. The evolution of electrolyte materials has progressed from conventional liquid electrolytes to more sophisticated designs incorporating functional additives and novel structural modifications.

Traditional liquid electrolytes, primarily composed of sodium salts dissolved in organic solvents, have been enhanced through the introduction of fluorinated solvents and high-concentration electrolyte formulations. These modifications create stronger coordination environments that effectively restrict polysulfide dissolution and migration, thereby mitigating the shuttle effect.

Solid-state electrolytes represent another breakthrough, with materials such as NASICON-type ceramics, sodium beta-alumina, and polymer-based systems showing promising capabilities in physically blocking polysulfide diffusion. The inherent barrier properties of these solid electrolytes prevent the migration of polysulfide species between electrodes, significantly improving cycling stability and coulombic efficiency.

Composite electrolytes combining the advantages of both liquid and solid systems have emerged as a particularly promising direction. These hybrid structures typically feature polymer matrices infused with ceramic particles and liquid components, offering enhanced ionic conductivity while maintaining effective polysulfide containment properties.

Functional additives incorporated into electrolyte formulations have demonstrated remarkable effectiveness in suppressing the shuttle effect. These include polysulfide mediators that facilitate controlled redox reactions, chemical trapping agents that form stable complexes with dissolved polysulfides, and catalytic materials that promote the conversion of long-chain polysulfides to shorter, less soluble species.

Surface modification techniques applied to electrolyte interfaces have also shown significant promise. Treatments creating hydrophobic barriers, electrostatic repulsion layers, or chemically reactive surfaces can effectively prevent polysulfide penetration while maintaining sodium ion transport channels.

The integration of advanced characterization techniques, including in-situ spectroscopy and computational modeling, has accelerated the rational design of electrolyte materials. These tools enable researchers to visualize polysulfide behavior in real-time and predict the effectiveness of various suppression strategies before experimental implementation.

Looking forward, the convergence of nanotechnology, interface engineering, and computational materials science is expected to yield next-generation electrolyte systems with unprecedented ability to suppress the polysulfide shuttle effect while maintaining high ionic conductivity and electrochemical stability.

Traditional liquid electrolytes, primarily composed of sodium salts dissolved in organic solvents, have been enhanced through the introduction of fluorinated solvents and high-concentration electrolyte formulations. These modifications create stronger coordination environments that effectively restrict polysulfide dissolution and migration, thereby mitigating the shuttle effect.

Solid-state electrolytes represent another breakthrough, with materials such as NASICON-type ceramics, sodium beta-alumina, and polymer-based systems showing promising capabilities in physically blocking polysulfide diffusion. The inherent barrier properties of these solid electrolytes prevent the migration of polysulfide species between electrodes, significantly improving cycling stability and coulombic efficiency.

Composite electrolytes combining the advantages of both liquid and solid systems have emerged as a particularly promising direction. These hybrid structures typically feature polymer matrices infused with ceramic particles and liquid components, offering enhanced ionic conductivity while maintaining effective polysulfide containment properties.

Functional additives incorporated into electrolyte formulations have demonstrated remarkable effectiveness in suppressing the shuttle effect. These include polysulfide mediators that facilitate controlled redox reactions, chemical trapping agents that form stable complexes with dissolved polysulfides, and catalytic materials that promote the conversion of long-chain polysulfides to shorter, less soluble species.

Surface modification techniques applied to electrolyte interfaces have also shown significant promise. Treatments creating hydrophobic barriers, electrostatic repulsion layers, or chemically reactive surfaces can effectively prevent polysulfide penetration while maintaining sodium ion transport channels.

The integration of advanced characterization techniques, including in-situ spectroscopy and computational modeling, has accelerated the rational design of electrolyte materials. These tools enable researchers to visualize polysulfide behavior in real-time and predict the effectiveness of various suppression strategies before experimental implementation.

Looking forward, the convergence of nanotechnology, interface engineering, and computational materials science is expected to yield next-generation electrolyte systems with unprecedented ability to suppress the polysulfide shuttle effect while maintaining high ionic conductivity and electrochemical stability.

Scalability and Commercialization Pathways

The scalability and commercialization of polysulfide shuttle suppression technologies for room-temperature Na-S cells represent critical factors in determining their market viability. Current laboratory-scale solutions must undergo significant engineering optimization to achieve cost-effective mass production while maintaining performance metrics.

Manufacturing scalability presents several challenges, particularly for advanced materials used in shuttle suppression. Functional separators with specialized coatings require precise quality control during scale-up, while maintaining uniform thickness and porosity. Similarly, interlayer technologies and cathode modifications demand reproducible production processes that can transition from gram-scale to kilogram or ton-scale manufacturing without compromising effectiveness.

Cost considerations remain paramount for commercial viability. Current shuttle suppression strategies often employ expensive materials such as noble metal catalysts or complex carbon nanostructures. A comprehensive cost analysis indicates that material substitution with earth-abundant alternatives and process simplification could reduce production costs by 30-45%, bringing Na-S technology closer to commercial price targets of $100-150/kWh at system level.

Supply chain development represents another critical pathway toward commercialization. The establishment of reliable supplier networks for specialized materials like functional polymers, carbon hosts, and sodium-ion conducting materials will be essential. Strategic partnerships between material suppliers, cell manufacturers, and end-users can accelerate technology transfer and reduce commercialization timelines from the current 8-10 years to a more competitive 5-7 year horizon.

Regulatory and safety considerations must be addressed proactively. Sodium-sulfur chemistry presents unique safety challenges compared to lithium-ion systems, particularly regarding thermal stability and reaction to moisture. Standardized testing protocols specific to polysulfide shuttle suppression technologies need development, with particular attention to long-term stability and failure mode analysis under various environmental conditions.

Market entry strategies should initially target niche applications where the advantages of room-temperature Na-S cells—such as potentially lower cost and absence of critical raw materials—outweigh their current limitations. Stationary energy storage for grid applications represents a promising initial market, followed by backup power systems and eventually transportation applications as the technology matures and demonstrates reliability at scale.

Manufacturing scalability presents several challenges, particularly for advanced materials used in shuttle suppression. Functional separators with specialized coatings require precise quality control during scale-up, while maintaining uniform thickness and porosity. Similarly, interlayer technologies and cathode modifications demand reproducible production processes that can transition from gram-scale to kilogram or ton-scale manufacturing without compromising effectiveness.

Cost considerations remain paramount for commercial viability. Current shuttle suppression strategies often employ expensive materials such as noble metal catalysts or complex carbon nanostructures. A comprehensive cost analysis indicates that material substitution with earth-abundant alternatives and process simplification could reduce production costs by 30-45%, bringing Na-S technology closer to commercial price targets of $100-150/kWh at system level.

Supply chain development represents another critical pathway toward commercialization. The establishment of reliable supplier networks for specialized materials like functional polymers, carbon hosts, and sodium-ion conducting materials will be essential. Strategic partnerships between material suppliers, cell manufacturers, and end-users can accelerate technology transfer and reduce commercialization timelines from the current 8-10 years to a more competitive 5-7 year horizon.

Regulatory and safety considerations must be addressed proactively. Sodium-sulfur chemistry presents unique safety challenges compared to lithium-ion systems, particularly regarding thermal stability and reaction to moisture. Standardized testing protocols specific to polysulfide shuttle suppression technologies need development, with particular attention to long-term stability and failure mode analysis under various environmental conditions.

Market entry strategies should initially target niche applications where the advantages of room-temperature Na-S cells—such as potentially lower cost and absence of critical raw materials—outweigh their current limitations. Stationary energy storage for grid applications represents a promising initial market, followed by backup power systems and eventually transportation applications as the technology matures and demonstrates reliability at scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!