Mapping the Growth of Isocyanate Synthesis Technologies

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Synthesis Evolution and Objectives

Isocyanate synthesis has evolved significantly since its inception in the early 20th century. The journey began with the groundbreaking work of Adolf von Baeyer in 1884, who first synthesized isocyanates. However, it wasn't until the 1930s that the industrial production of isocyanates gained momentum, primarily driven by the growing demand for polyurethane materials.

The evolution of isocyanate synthesis technologies has been marked by continuous improvements in efficiency, safety, and environmental sustainability. Early methods relied heavily on phosgene, a highly toxic gas, which posed significant safety and environmental concerns. This led to the development of alternative synthesis routes, such as non-phosgene processes, which have gained traction in recent decades.

One of the key objectives in the field of isocyanate synthesis has been to enhance process efficiency while reducing environmental impact. This has resulted in the exploration of novel catalysts, reaction conditions, and process designs. Researchers have focused on developing more selective catalysts that can improve yield and reduce unwanted by-products, thereby increasing overall process efficiency.

Another important goal has been the development of safer and more sustainable production methods. This includes the pursuit of phosgene-free synthesis routes, which not only address safety concerns but also align with increasingly stringent environmental regulations. The industry has been actively seeking alternatives to traditional raw materials, exploring bio-based feedstocks and circular economy approaches to reduce reliance on fossil resources.

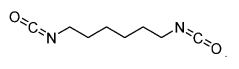

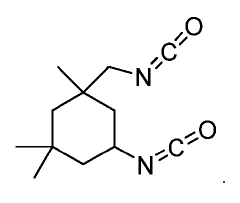

The quest for improved isocyanate synthesis technologies has also been driven by the need for product customization. As the applications of isocyanates have expanded beyond polyurethanes to include coatings, adhesives, and elastomers, there has been a growing demand for tailored isocyanate products with specific properties. This has led to research into new molecular structures and functionalities, pushing the boundaries of isocyanate chemistry.

Looking ahead, the objectives for isocyanate synthesis technologies are likely to focus on further enhancing sustainability, improving process intensification, and exploring new applications. This may involve the development of more efficient catalytic systems, the integration of continuous flow technologies, and the exploration of novel raw materials. Additionally, there is a growing interest in leveraging advanced computational methods and artificial intelligence to accelerate the discovery and optimization of new synthesis routes.

The evolution of isocyanate synthesis technologies has been marked by continuous improvements in efficiency, safety, and environmental sustainability. Early methods relied heavily on phosgene, a highly toxic gas, which posed significant safety and environmental concerns. This led to the development of alternative synthesis routes, such as non-phosgene processes, which have gained traction in recent decades.

One of the key objectives in the field of isocyanate synthesis has been to enhance process efficiency while reducing environmental impact. This has resulted in the exploration of novel catalysts, reaction conditions, and process designs. Researchers have focused on developing more selective catalysts that can improve yield and reduce unwanted by-products, thereby increasing overall process efficiency.

Another important goal has been the development of safer and more sustainable production methods. This includes the pursuit of phosgene-free synthesis routes, which not only address safety concerns but also align with increasingly stringent environmental regulations. The industry has been actively seeking alternatives to traditional raw materials, exploring bio-based feedstocks and circular economy approaches to reduce reliance on fossil resources.

The quest for improved isocyanate synthesis technologies has also been driven by the need for product customization. As the applications of isocyanates have expanded beyond polyurethanes to include coatings, adhesives, and elastomers, there has been a growing demand for tailored isocyanate products with specific properties. This has led to research into new molecular structures and functionalities, pushing the boundaries of isocyanate chemistry.

Looking ahead, the objectives for isocyanate synthesis technologies are likely to focus on further enhancing sustainability, improving process intensification, and exploring new applications. This may involve the development of more efficient catalytic systems, the integration of continuous flow technologies, and the exploration of novel raw materials. Additionally, there is a growing interest in leveraging advanced computational methods and artificial intelligence to accelerate the discovery and optimization of new synthesis routes.

Market Demand Analysis for Isocyanates

The global isocyanate market has experienced significant growth in recent years, driven by increasing demand across various industries. Isocyanates are essential components in the production of polyurethanes, which find widespread applications in construction, automotive, furniture, and electronics sectors. The market demand for isocyanates is closely tied to the growth of these end-use industries.

In the construction sector, isocyanates are extensively used in insulation materials, sealants, and adhesives. The booming construction industry, particularly in emerging economies, has been a major driver for isocyanate demand. Rapid urbanization and infrastructure development projects have fueled the need for energy-efficient building materials, where polyurethane-based products excel.

The automotive industry represents another significant market for isocyanates. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, the use of polyurethane-based components has increased. Isocyanates are crucial in producing lightweight, durable materials for car interiors, seating, and exterior parts. The growing trend towards electric vehicles has also created new opportunities for isocyanate-based materials in battery encapsulation and thermal management systems.

The furniture industry has been a consistent consumer of isocyanates, primarily in the production of flexible and rigid foams for cushioning and insulation. The rising demand for comfortable, durable, and aesthetically pleasing furniture has sustained the growth of isocyanates in this sector. Additionally, the increasing popularity of memory foam mattresses and pillows has further boosted isocyanate consumption.

In the electronics industry, isocyanates play a vital role in the production of protective coatings, encapsulants, and adhesives. The rapid expansion of the electronics market, driven by technological advancements and increasing consumer demand for smart devices, has contributed to the growth of isocyanate usage in this sector.

The packaging industry has also emerged as a significant consumer of isocyanates, particularly in the production of rigid foams for insulation in refrigerated transport and storage. As global trade and e-commerce continue to expand, the demand for efficient packaging and transportation solutions has increased, driving the need for isocyanate-based materials.

Market analysts project continued growth in the isocyanate market, with Asia-Pacific region expected to lead in terms of consumption. The region's rapid industrialization, growing population, and increasing disposable income are key factors driving this trend. North America and Europe are also anticipated to maintain steady demand, primarily driven by technological advancements and stringent regulations promoting energy-efficient materials.

In the construction sector, isocyanates are extensively used in insulation materials, sealants, and adhesives. The booming construction industry, particularly in emerging economies, has been a major driver for isocyanate demand. Rapid urbanization and infrastructure development projects have fueled the need for energy-efficient building materials, where polyurethane-based products excel.

The automotive industry represents another significant market for isocyanates. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, the use of polyurethane-based components has increased. Isocyanates are crucial in producing lightweight, durable materials for car interiors, seating, and exterior parts. The growing trend towards electric vehicles has also created new opportunities for isocyanate-based materials in battery encapsulation and thermal management systems.

The furniture industry has been a consistent consumer of isocyanates, primarily in the production of flexible and rigid foams for cushioning and insulation. The rising demand for comfortable, durable, and aesthetically pleasing furniture has sustained the growth of isocyanates in this sector. Additionally, the increasing popularity of memory foam mattresses and pillows has further boosted isocyanate consumption.

In the electronics industry, isocyanates play a vital role in the production of protective coatings, encapsulants, and adhesives. The rapid expansion of the electronics market, driven by technological advancements and increasing consumer demand for smart devices, has contributed to the growth of isocyanate usage in this sector.

The packaging industry has also emerged as a significant consumer of isocyanates, particularly in the production of rigid foams for insulation in refrigerated transport and storage. As global trade and e-commerce continue to expand, the demand for efficient packaging and transportation solutions has increased, driving the need for isocyanate-based materials.

Market analysts project continued growth in the isocyanate market, with Asia-Pacific region expected to lead in terms of consumption. The region's rapid industrialization, growing population, and increasing disposable income are key factors driving this trend. North America and Europe are also anticipated to maintain steady demand, primarily driven by technological advancements and stringent regulations promoting energy-efficient materials.

Current Challenges in Isocyanate Production

The production of isocyanates faces several significant challenges in the current technological landscape. One of the primary issues is the high energy consumption associated with traditional synthesis methods. The conventional process, which involves the reaction of amines with phosgene, requires elevated temperatures and pressures, leading to substantial energy costs and environmental concerns.

Safety considerations pose another major challenge in isocyanate production. The use of phosgene, a highly toxic gas, as a key reagent presents significant risks to workers and the environment. Stringent safety protocols and specialized equipment are necessary to mitigate these risks, adding complexity and cost to the manufacturing process.

Raw material availability and cost fluctuations also impact isocyanate production. The dependence on petroleum-derived feedstocks makes the industry vulnerable to oil price volatility. This challenge is compounded by the increasing global demand for isocyanates, particularly in the polyurethane industry, which puts pressure on manufacturers to secure stable and cost-effective raw material sources.

Environmental regulations present a growing challenge for isocyanate producers. Stricter emissions controls and waste management requirements necessitate continuous improvements in production processes and waste treatment technologies. The industry is under pressure to develop more sustainable production methods that reduce carbon footprint and minimize the generation of hazardous by-products.

The scalability of production processes remains a significant hurdle, especially for newer, more environmentally friendly synthesis routes. While alternative methods, such as non-phosgene processes, show promise in laboratory settings, scaling these technologies to meet industrial demand presents technical and economic challenges. Achieving consistent product quality and yield at large scales is crucial for commercial viability.

Product purity and quality control are ongoing challenges in isocyanate synthesis. The presence of impurities can significantly affect the performance of end products, particularly in high-performance applications. Developing more efficient purification techniques and implementing robust quality control measures are essential for meeting stringent industry standards.

Lastly, the industry faces challenges in innovation and intellectual property. As companies strive to develop proprietary technologies for more efficient and sustainable isocyanate production, protecting these innovations through patents becomes crucial. Navigating the complex landscape of existing patents while pushing the boundaries of technology requires significant investment in research and development, as well as legal expertise.

Safety considerations pose another major challenge in isocyanate production. The use of phosgene, a highly toxic gas, as a key reagent presents significant risks to workers and the environment. Stringent safety protocols and specialized equipment are necessary to mitigate these risks, adding complexity and cost to the manufacturing process.

Raw material availability and cost fluctuations also impact isocyanate production. The dependence on petroleum-derived feedstocks makes the industry vulnerable to oil price volatility. This challenge is compounded by the increasing global demand for isocyanates, particularly in the polyurethane industry, which puts pressure on manufacturers to secure stable and cost-effective raw material sources.

Environmental regulations present a growing challenge for isocyanate producers. Stricter emissions controls and waste management requirements necessitate continuous improvements in production processes and waste treatment technologies. The industry is under pressure to develop more sustainable production methods that reduce carbon footprint and minimize the generation of hazardous by-products.

The scalability of production processes remains a significant hurdle, especially for newer, more environmentally friendly synthesis routes. While alternative methods, such as non-phosgene processes, show promise in laboratory settings, scaling these technologies to meet industrial demand presents technical and economic challenges. Achieving consistent product quality and yield at large scales is crucial for commercial viability.

Product purity and quality control are ongoing challenges in isocyanate synthesis. The presence of impurities can significantly affect the performance of end products, particularly in high-performance applications. Developing more efficient purification techniques and implementing robust quality control measures are essential for meeting stringent industry standards.

Lastly, the industry faces challenges in innovation and intellectual property. As companies strive to develop proprietary technologies for more efficient and sustainable isocyanate production, protecting these innovations through patents becomes crucial. Navigating the complex landscape of existing patents while pushing the boundaries of technology requires significant investment in research and development, as well as legal expertise.

Current Isocyanate Synthesis Methods

01 Novel catalysts for isocyanate synthesis

Development of new catalysts to improve the efficiency and selectivity of isocyanate production. These catalysts may include metal complexes, organometallic compounds, or heterogeneous catalysts that enhance reaction rates and reduce side product formation.- Novel catalysts for isocyanate synthesis: Development of new catalytic systems to improve the efficiency and selectivity of isocyanate production. These catalysts may include metal complexes, organometallic compounds, or heterogeneous catalysts that enhance reaction rates and reduce side product formation.

- Continuous flow processes for isocyanate production: Implementation of continuous flow reactors and processes for the synthesis of isocyanates, offering advantages such as improved heat transfer, better control of reaction parameters, and increased productivity compared to batch processes.

- Green chemistry approaches in isocyanate synthesis: Development of environmentally friendly methods for isocyanate production, including the use of renewable feedstocks, solvent-free reactions, and processes with reduced waste generation and energy consumption.

- Novel precursors and intermediates for isocyanate synthesis: Exploration of new starting materials and reaction intermediates to improve the overall efficiency of isocyanate production, potentially leading to more cost-effective and sustainable manufacturing processes.

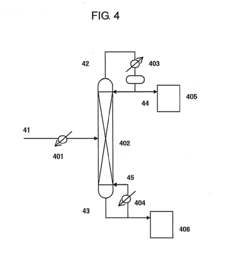

- Process intensification and optimization: Implementation of advanced process control strategies, reactor designs, and separation techniques to enhance the overall efficiency and productivity of isocyanate synthesis processes, including the use of microreactors and process modeling tools.

02 Continuous flow processes for isocyanate production

Implementation of continuous flow reactors and processes for the synthesis of isocyanates. This approach offers advantages such as improved heat transfer, better control of reaction parameters, and increased productivity compared to batch processes.Expand Specific Solutions03 Green chemistry approaches in isocyanate synthesis

Development of environmentally friendly methods for isocyanate production, including the use of renewable feedstocks, non-toxic reagents, and solvent-free reactions. These approaches aim to reduce the environmental impact of isocyanate synthesis and improve sustainability.Expand Specific Solutions04 Novel precursors and intermediates for isocyanate synthesis

Exploration of new starting materials and reaction intermediates to enhance isocyanate production. This includes the development of novel synthetic routes, the use of alternative precursors, and the design of more efficient reaction pathways.Expand Specific Solutions05 Process intensification and optimization

Implementation of advanced process control, reactor design, and separation techniques to improve the overall efficiency of isocyanate production. This includes the use of microreactors, process modeling, and in-situ product separation methods to enhance yield and reduce energy consumption.Expand Specific Solutions

Key Players in Isocyanate Industry

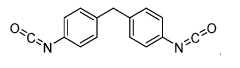

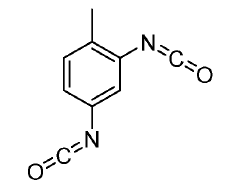

The isocyanate synthesis technologies market is in a growth phase, driven by increasing demand in various industries such as automotive, construction, and electronics. The global market size is projected to reach several billion dollars by 2025, with a compound annual growth rate of around 5-6%. Technologically, the field is moderately mature but continues to evolve, with major players like BASF, Covestro, and Wanhua Chemical leading innovation. These companies, along with others like Asahi Kasei and Mitsui Chemicals, are investing heavily in R&D to improve efficiency, reduce environmental impact, and develop novel applications. The competitive landscape is characterized by a mix of established chemical giants and specialized manufacturers, with increasing focus on sustainable and bio-based isocyanate production methods.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate synthesis technologies focusing on sustainability and efficiency. Their approach includes the use of novel catalysts and process intensification techniques. BASF's gas-phase phosgenation process for TDI production significantly reduces energy consumption and CO2 emissions[1]. They have also implemented a proprietary micro-reactor technology for isocyanate synthesis, allowing for better control of reaction conditions and improved product quality[2]. Additionally, BASF has explored bio-based raw materials for isocyanate production, aiming to reduce reliance on fossil resources[3].

Strengths: Advanced process technologies, focus on sustainability, and strong R&D capabilities. Weaknesses: High investment costs for new technologies and potential regulatory challenges for bio-based materials.

Covestro Deutschland AG

Technical Solution: Covestro has made significant advancements in isocyanate synthesis, particularly in the production of MDI and TDI. Their gas-phase technology for TDI production has reduced energy consumption by up to 60% compared to conventional methods[4]. Covestro has also developed a novel AdiP technology (Adiabatic-Isothermal Phosgenation) for MDI production, which improves yield and reduces byproducts[5]. Furthermore, they have invested in carbon capture and utilization (CCU) technology to produce aniline, a key precursor for MDI, using CO2 as a raw material, potentially reducing the carbon footprint of isocyanate production[6].

Strengths: Energy-efficient processes, innovative CCU technology, and strong market position. Weaknesses: Dependence on fossil-based raw materials and potential volatility in feedstock prices.

Innovative Patents in Isocyanate Synthesis

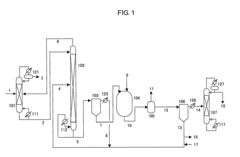

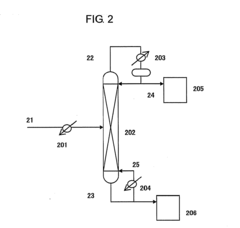

Flow chemistry synthesis of isocyanates

PatentWO2021119606A1

Innovation

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

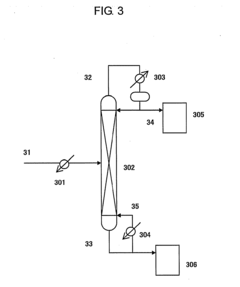

Process for producing isocyanate using diaryl carbonate

PatentInactiveEP2275405A1

Innovation

- A process involving the reaction of diaryl carbonates with amine compounds to form aryl carbamates, followed by transferring the reaction mixture to a thermal decomposition vessel where the aryl carbamates undergo thermal decomposition to produce isocyanates, with specific conditions and solvents used to enhance yield and purity, including the use of aromatic hydroxy compounds as solvents and acid cleaning to remove high-boiling point by-products.

Environmental Impact of Isocyanate Production

The environmental impact of isocyanate production is a critical concern in the chemical industry, given the widespread use of these compounds in various applications. Isocyanate synthesis typically involves the reaction of amines with phosgene or its derivatives, which can lead to significant environmental challenges if not properly managed.

One of the primary environmental concerns associated with isocyanate production is the potential release of toxic substances. Phosgene, a key raw material in many isocyanate synthesis processes, is highly toxic and can pose severe risks to human health and the environment if accidentally released. Additionally, the production process may generate hazardous by-products and waste streams that require careful handling and disposal.

Air pollution is another significant environmental impact of isocyanate manufacturing. The release of volatile organic compounds (VOCs) and other air pollutants during production can contribute to smog formation and negatively affect air quality in surrounding areas. Furthermore, the energy-intensive nature of isocyanate synthesis processes often results in substantial greenhouse gas emissions, contributing to climate change.

Water pollution is also a potential consequence of isocyanate production. Wastewater from manufacturing facilities may contain trace amounts of isocyanates, unreacted raw materials, and other chemical contaminants. If not properly treated, these pollutants can harm aquatic ecosystems and potentially contaminate drinking water sources.

To address these environmental concerns, the isocyanate industry has been implementing various mitigation strategies. Advanced process technologies, such as closed-loop systems and improved catalysts, have been developed to minimize waste generation and reduce emissions. Many manufacturers have also adopted stringent environmental management systems and invested in state-of-the-art pollution control equipment to comply with increasingly strict regulations.

Efforts to improve the sustainability of isocyanate production have led to the exploration of alternative raw materials and synthesis routes. For instance, research into bio-based isocyanates and phosgene-free production methods aims to reduce the environmental footprint of these compounds. Additionally, the industry has been focusing on enhancing energy efficiency and implementing renewable energy sources to decrease the carbon intensity of isocyanate manufacturing.

As the demand for isocyanates continues to grow, particularly in emerging economies, addressing the environmental impact of their production remains a crucial challenge. Balancing the need for these versatile chemicals with environmental protection requires ongoing innovation in process technologies, continued investment in pollution control measures, and a commitment to sustainable practices throughout the industry.

One of the primary environmental concerns associated with isocyanate production is the potential release of toxic substances. Phosgene, a key raw material in many isocyanate synthesis processes, is highly toxic and can pose severe risks to human health and the environment if accidentally released. Additionally, the production process may generate hazardous by-products and waste streams that require careful handling and disposal.

Air pollution is another significant environmental impact of isocyanate manufacturing. The release of volatile organic compounds (VOCs) and other air pollutants during production can contribute to smog formation and negatively affect air quality in surrounding areas. Furthermore, the energy-intensive nature of isocyanate synthesis processes often results in substantial greenhouse gas emissions, contributing to climate change.

Water pollution is also a potential consequence of isocyanate production. Wastewater from manufacturing facilities may contain trace amounts of isocyanates, unreacted raw materials, and other chemical contaminants. If not properly treated, these pollutants can harm aquatic ecosystems and potentially contaminate drinking water sources.

To address these environmental concerns, the isocyanate industry has been implementing various mitigation strategies. Advanced process technologies, such as closed-loop systems and improved catalysts, have been developed to minimize waste generation and reduce emissions. Many manufacturers have also adopted stringent environmental management systems and invested in state-of-the-art pollution control equipment to comply with increasingly strict regulations.

Efforts to improve the sustainability of isocyanate production have led to the exploration of alternative raw materials and synthesis routes. For instance, research into bio-based isocyanates and phosgene-free production methods aims to reduce the environmental footprint of these compounds. Additionally, the industry has been focusing on enhancing energy efficiency and implementing renewable energy sources to decrease the carbon intensity of isocyanate manufacturing.

As the demand for isocyanates continues to grow, particularly in emerging economies, addressing the environmental impact of their production remains a crucial challenge. Balancing the need for these versatile chemicals with environmental protection requires ongoing innovation in process technologies, continued investment in pollution control measures, and a commitment to sustainable practices throughout the industry.

Safety Regulations in Isocyanate Handling

The handling of isocyanates in industrial settings is subject to stringent safety regulations due to their potential health hazards and reactivity. These regulations have evolved significantly over the years, keeping pace with the growth of isocyanate synthesis technologies. Occupational safety and health administrations worldwide have established comprehensive guidelines for the safe handling, storage, and use of isocyanates.

One of the primary focuses of these regulations is exposure control. Workers are required to use appropriate personal protective equipment (PPE), including respiratory protection, chemical-resistant gloves, and protective clothing. Ventilation systems in production facilities must meet specific standards to minimize airborne concentrations of isocyanate vapors. Regular air monitoring is mandated to ensure that exposure levels remain below permissible limits.

Storage and transportation of isocyanates are also heavily regulated. Containers must be properly labeled with hazard information and stored in cool, dry areas away from incompatible materials. Spill containment measures and emergency response plans are required to be in place. Transportation of isocyanates is governed by strict packaging and documentation requirements to prevent accidents during transit.

Training and education form a crucial component of isocyanate safety regulations. Employers are required to provide comprehensive training to workers on the hazards of isocyanates, proper handling techniques, and emergency procedures. This includes instruction on the use of PPE, spill cleanup, and first aid measures in case of exposure.

Medical surveillance programs are another key aspect of isocyanate safety regulations. Workers who are potentially exposed to isocyanates must undergo regular health assessments, including pulmonary function tests, to monitor for any adverse health effects. Early detection of sensitization or other health issues is crucial for preventing long-term health consequences.

As isocyanate synthesis technologies continue to advance, safety regulations are continuously updated to address new challenges. This includes the development of safer handling methods, improved containment systems, and more sensitive detection technologies. Regulatory bodies work closely with industry stakeholders to ensure that safety standards keep pace with technological advancements in isocyanate production and use.

The implementation of these safety regulations has significantly reduced the incidence of isocyanate-related occupational illnesses and accidents. However, ongoing vigilance and continuous improvement in safety practices remain essential as the industry continues to grow and evolve.

One of the primary focuses of these regulations is exposure control. Workers are required to use appropriate personal protective equipment (PPE), including respiratory protection, chemical-resistant gloves, and protective clothing. Ventilation systems in production facilities must meet specific standards to minimize airborne concentrations of isocyanate vapors. Regular air monitoring is mandated to ensure that exposure levels remain below permissible limits.

Storage and transportation of isocyanates are also heavily regulated. Containers must be properly labeled with hazard information and stored in cool, dry areas away from incompatible materials. Spill containment measures and emergency response plans are required to be in place. Transportation of isocyanates is governed by strict packaging and documentation requirements to prevent accidents during transit.

Training and education form a crucial component of isocyanate safety regulations. Employers are required to provide comprehensive training to workers on the hazards of isocyanates, proper handling techniques, and emergency procedures. This includes instruction on the use of PPE, spill cleanup, and first aid measures in case of exposure.

Medical surveillance programs are another key aspect of isocyanate safety regulations. Workers who are potentially exposed to isocyanates must undergo regular health assessments, including pulmonary function tests, to monitor for any adverse health effects. Early detection of sensitization or other health issues is crucial for preventing long-term health consequences.

As isocyanate synthesis technologies continue to advance, safety regulations are continuously updated to address new challenges. This includes the development of safer handling methods, improved containment systems, and more sensitive detection technologies. Regulatory bodies work closely with industry stakeholders to ensure that safety standards keep pace with technological advancements in isocyanate production and use.

The implementation of these safety regulations has significantly reduced the incidence of isocyanate-related occupational illnesses and accidents. However, ongoing vigilance and continuous improvement in safety practices remain essential as the industry continues to grow and evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!