Measure Adhesion Strength in Conformal Coating Applications

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Adhesion Technology Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated engineered materials with specific performance characteristics. Initially developed for military and aerospace applications in the 1960s, these coatings were designed to protect electronic assemblies from harsh environmental conditions. The evolution of conformal coatings has been driven by the miniaturization of electronic components, increased circuit density, and the expansion of electronics into more demanding environments.

Adhesion strength measurement in conformal coating applications represents a critical quality control parameter that directly impacts product reliability and longevity. Historically, adhesion testing methods were primarily qualitative and subjective, relying on visual inspection after tape or scratch tests. The industry has progressively moved toward more quantitative and reproducible measurement techniques to meet the increasingly stringent requirements of modern electronics.

The primary technical objective in this field is to develop standardized, reliable, and non-destructive methods for measuring adhesion strength that correlate with real-world performance. This includes addressing the challenges of measuring adhesion on complex geometries, different substrate materials, and various coating formulations. Additionally, there is a growing need for in-line measurement techniques that can be integrated into production processes for real-time quality control.

Recent technological advancements have introduced new coating materials with enhanced adhesion properties, including nano-modified formulations and hybrid organic-inorganic systems. These innovations necessitate corresponding advancements in adhesion measurement methodologies to accurately characterize their performance. The industry is witnessing a shift toward multi-parameter assessment approaches that consider not only the absolute adhesion strength but also factors such as adhesion durability under thermal cycling, humidity exposure, and mechanical stress.

The convergence of computational modeling and experimental techniques is emerging as a promising direction for predicting adhesion behavior and optimizing coating formulations. Machine learning algorithms are increasingly being applied to correlate surface preparation parameters, coating properties, and environmental factors with adhesion performance, enabling more precise control over the coating process.

Global standards organizations, including IPC, ASTM, and ISO, are actively working to establish unified testing protocols and acceptance criteria for adhesion strength in conformal coatings. These efforts aim to harmonize measurement methodologies across the industry and facilitate meaningful comparisons between different coating systems and application techniques.

Adhesion strength measurement in conformal coating applications represents a critical quality control parameter that directly impacts product reliability and longevity. Historically, adhesion testing methods were primarily qualitative and subjective, relying on visual inspection after tape or scratch tests. The industry has progressively moved toward more quantitative and reproducible measurement techniques to meet the increasingly stringent requirements of modern electronics.

The primary technical objective in this field is to develop standardized, reliable, and non-destructive methods for measuring adhesion strength that correlate with real-world performance. This includes addressing the challenges of measuring adhesion on complex geometries, different substrate materials, and various coating formulations. Additionally, there is a growing need for in-line measurement techniques that can be integrated into production processes for real-time quality control.

Recent technological advancements have introduced new coating materials with enhanced adhesion properties, including nano-modified formulations and hybrid organic-inorganic systems. These innovations necessitate corresponding advancements in adhesion measurement methodologies to accurately characterize their performance. The industry is witnessing a shift toward multi-parameter assessment approaches that consider not only the absolute adhesion strength but also factors such as adhesion durability under thermal cycling, humidity exposure, and mechanical stress.

The convergence of computational modeling and experimental techniques is emerging as a promising direction for predicting adhesion behavior and optimizing coating formulations. Machine learning algorithms are increasingly being applied to correlate surface preparation parameters, coating properties, and environmental factors with adhesion performance, enabling more precise control over the coating process.

Global standards organizations, including IPC, ASTM, and ISO, are actively working to establish unified testing protocols and acceptance criteria for adhesion strength in conformal coatings. These efforts aim to harmonize measurement methodologies across the industry and facilitate meaningful comparisons between different coating systems and application techniques.

Market Demand Analysis for Adhesion Testing Solutions

The global market for adhesion testing solutions in conformal coating applications has witnessed substantial growth in recent years, driven primarily by the increasing complexity of electronic components and the growing demand for reliable protection in harsh environments. The conformal coating market, valued at approximately 2.1 billion USD in 2022, is projected to expand at a compound annual growth rate of 5.8% through 2028, with adhesion testing solutions representing a critical segment within this ecosystem.

Industries such as automotive electronics, aerospace, medical devices, and consumer electronics are the primary drivers of this market growth. The automotive sector, in particular, has emerged as a significant consumer of adhesion testing solutions due to the proliferation of electronic control units and sensors that require protection from moisture, chemicals, and temperature fluctuations. The transition toward electric vehicles has further accelerated this demand, as battery management systems and power electronics require robust conformal coating with verifiable adhesion properties.

Market research indicates that approximately 65% of electronics manufacturers consider adhesion strength as a critical quality parameter in their production processes. However, only about 40% currently employ standardized, quantitative testing methods, revealing a substantial gap between recognized importance and implemented solutions. This discrepancy represents a significant market opportunity for advanced adhesion testing technologies.

Regional analysis shows North America and Europe leading the market adoption of sophisticated adhesion testing solutions, with Asia-Pacific regions demonstrating the fastest growth rate. This growth is attributed to the rapid expansion of electronics manufacturing facilities in countries like China, Taiwan, and Vietnam, coupled with increasing quality standards to meet international export requirements.

Customer needs analysis reveals several key market demands: non-destructive testing capabilities, integration with automated production lines, real-time monitoring solutions, and testing methods that can accommodate increasingly miniaturized components. Additionally, there is growing interest in testing solutions that can predict long-term adhesion performance rather than merely measuring initial bond strength.

The regulatory landscape is also influencing market demand, with standards such as IPC-CC-830, MIL-I-46058C, and IEC 60068 driving the need for more precise and reliable adhesion testing methodologies. Compliance with these standards is becoming a competitive necessity rather than an optional feature, particularly for manufacturers serving military, aerospace, and medical markets.

From a pricing perspective, the market shows willingness to invest in premium solutions that offer demonstrable improvements in production yield and long-term product reliability. The total cost of ownership, including reduced failure rates and warranty claims, is increasingly recognized as the relevant metric rather than initial equipment cost alone.

Industries such as automotive electronics, aerospace, medical devices, and consumer electronics are the primary drivers of this market growth. The automotive sector, in particular, has emerged as a significant consumer of adhesion testing solutions due to the proliferation of electronic control units and sensors that require protection from moisture, chemicals, and temperature fluctuations. The transition toward electric vehicles has further accelerated this demand, as battery management systems and power electronics require robust conformal coating with verifiable adhesion properties.

Market research indicates that approximately 65% of electronics manufacturers consider adhesion strength as a critical quality parameter in their production processes. However, only about 40% currently employ standardized, quantitative testing methods, revealing a substantial gap between recognized importance and implemented solutions. This discrepancy represents a significant market opportunity for advanced adhesion testing technologies.

Regional analysis shows North America and Europe leading the market adoption of sophisticated adhesion testing solutions, with Asia-Pacific regions demonstrating the fastest growth rate. This growth is attributed to the rapid expansion of electronics manufacturing facilities in countries like China, Taiwan, and Vietnam, coupled with increasing quality standards to meet international export requirements.

Customer needs analysis reveals several key market demands: non-destructive testing capabilities, integration with automated production lines, real-time monitoring solutions, and testing methods that can accommodate increasingly miniaturized components. Additionally, there is growing interest in testing solutions that can predict long-term adhesion performance rather than merely measuring initial bond strength.

The regulatory landscape is also influencing market demand, with standards such as IPC-CC-830, MIL-I-46058C, and IEC 60068 driving the need for more precise and reliable adhesion testing methodologies. Compliance with these standards is becoming a competitive necessity rather than an optional feature, particularly for manufacturers serving military, aerospace, and medical markets.

From a pricing perspective, the market shows willingness to invest in premium solutions that offer demonstrable improvements in production yield and long-term product reliability. The total cost of ownership, including reduced failure rates and warranty claims, is increasingly recognized as the relevant metric rather than initial equipment cost alone.

Current Adhesion Measurement Challenges and Limitations

Despite significant advancements in conformal coating technologies, the measurement of adhesion strength remains one of the most challenging aspects in quality control and reliability assessment. Current methodologies face substantial limitations that impede accurate, reproducible, and standardized evaluation of coating adhesion performance. Traditional testing methods such as cross-hatch, pull-off, and tape tests often yield qualitative rather than quantitative results, making objective comparison between different coating systems difficult.

The geometric complexity of modern electronic assemblies presents a significant challenge for adhesion testing. Components with varying heights, densities, and surface characteristics create inconsistent coating thicknesses and adhesion profiles across a single assembly. This non-uniformity makes it nearly impossible to apply standard adhesion tests uniformly across all areas of interest, resulting in incomplete assessment of overall coating reliability.

Environmental factors introduce another layer of complexity to adhesion measurement. Temperature fluctuations, humidity variations, and aging effects can dramatically alter adhesion properties over time. Current testing methodologies struggle to account for these dynamic changes, as most tests provide only a static snapshot of adhesion strength at a specific moment under laboratory conditions, failing to predict long-term performance in real-world applications.

Miniaturization trends in electronics have further complicated adhesion testing. As component sizes decrease and packing densities increase, the physical space available for conventional adhesion testing becomes severely limited. Many established test methods require minimum surface areas that exceed what is available on modern high-density assemblies, rendering these techniques impractical for contemporary applications.

Non-destructive testing remains an elusive goal in adhesion measurement. Most current methods damage the coating and underlying substrate, making them unsuitable for in-process quality control or field evaluation of deployed products. This destructive nature necessitates testing on representative samples rather than actual production units, introducing sampling errors and reducing confidence in overall quality assessment.

Quantification challenges persist across all measurement techniques. The correlation between test results and actual field performance remains poorly understood, with limited scientific literature establishing clear relationships between laboratory measurements and real-world reliability. This knowledge gap makes it difficult for manufacturers to establish meaningful acceptance criteria or predict product longevity based on adhesion test results.

Automation compatibility represents another significant limitation. Many current adhesion test methods rely heavily on operator skill and judgment, introducing variability and subjectivity into the results. As manufacturing processes become increasingly automated, the lack of machine-compatible adhesion testing methods creates a bottleneck in production and quality control workflows, hampering efficiency and consistency.

The geometric complexity of modern electronic assemblies presents a significant challenge for adhesion testing. Components with varying heights, densities, and surface characteristics create inconsistent coating thicknesses and adhesion profiles across a single assembly. This non-uniformity makes it nearly impossible to apply standard adhesion tests uniformly across all areas of interest, resulting in incomplete assessment of overall coating reliability.

Environmental factors introduce another layer of complexity to adhesion measurement. Temperature fluctuations, humidity variations, and aging effects can dramatically alter adhesion properties over time. Current testing methodologies struggle to account for these dynamic changes, as most tests provide only a static snapshot of adhesion strength at a specific moment under laboratory conditions, failing to predict long-term performance in real-world applications.

Miniaturization trends in electronics have further complicated adhesion testing. As component sizes decrease and packing densities increase, the physical space available for conventional adhesion testing becomes severely limited. Many established test methods require minimum surface areas that exceed what is available on modern high-density assemblies, rendering these techniques impractical for contemporary applications.

Non-destructive testing remains an elusive goal in adhesion measurement. Most current methods damage the coating and underlying substrate, making them unsuitable for in-process quality control or field evaluation of deployed products. This destructive nature necessitates testing on representative samples rather than actual production units, introducing sampling errors and reducing confidence in overall quality assessment.

Quantification challenges persist across all measurement techniques. The correlation between test results and actual field performance remains poorly understood, with limited scientific literature establishing clear relationships between laboratory measurements and real-world reliability. This knowledge gap makes it difficult for manufacturers to establish meaningful acceptance criteria or predict product longevity based on adhesion test results.

Automation compatibility represents another significant limitation. Many current adhesion test methods rely heavily on operator skill and judgment, introducing variability and subjectivity into the results. As manufacturing processes become increasingly automated, the lack of machine-compatible adhesion testing methods creates a bottleneck in production and quality control workflows, hampering efficiency and consistency.

Current Adhesion Strength Measurement Techniques

01 Surface preparation techniques for improved adhesion

Proper surface preparation is crucial for enhancing the adhesion strength of conformal coatings. This includes cleaning methods to remove contaminants, oils, and particulates that can interfere with coating adhesion. Surface treatments such as plasma cleaning, chemical etching, or mechanical abrasion can increase surface energy and create better mechanical bonding opportunities. These preparation techniques create optimal conditions for conformal coating adhesion by ensuring a clean, receptive substrate surface.- Surface preparation techniques for improved adhesion: Proper surface preparation is crucial for enhancing the adhesion strength of conformal coatings. Techniques such as plasma treatment, chemical cleaning, and mechanical abrasion can remove contaminants and modify surface properties to improve wetting and bonding. These preparation methods create optimal surface conditions that allow the conformal coating to form stronger chemical and physical bonds with the substrate, resulting in superior adhesion strength and durability.

- Adhesion promoters and coupling agents: Incorporating adhesion promoters or coupling agents into conformal coating formulations significantly enhances bonding strength between the coating and substrate. These specialized compounds create chemical bridges between dissimilar materials, improving interfacial adhesion. Silane coupling agents, titanates, and other adhesion promoters can be added directly to coating formulations or applied as primers before the main coating application, resulting in stronger bonds and reduced risk of delamination under environmental stress.

- Coating formulation optimization for adhesion strength: The composition of conformal coating formulations significantly impacts adhesion performance. Optimizing the balance of resins, solvents, and additives can enhance wetting properties and chemical compatibility with substrates. Formulations can be tailored with specific polymer chemistries that match substrate characteristics, while controlling viscosity and surface tension ensures proper flow and coverage. Advanced formulations may incorporate cross-linking agents or reactive components that form stronger chemical bonds with substrate materials.

- Curing processes and parameters affecting adhesion: The curing process significantly influences the adhesion strength of conformal coatings. Parameters such as temperature, humidity, cure time, and curing method (thermal, UV, moisture) must be optimized for specific coating chemistries. Proper curing ensures complete polymerization and cross-linking, which maximizes adhesion strength by allowing the coating to form strong chemical bonds with the substrate. Controlled curing profiles can reduce internal stresses that might otherwise compromise adhesion performance over time.

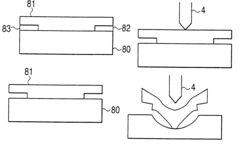

- Testing and measurement methods for adhesion strength: Various testing methodologies are employed to evaluate the adhesion strength of conformal coatings. Cross-hatch adhesion tests, pull-off tests, and peel strength measurements provide quantitative data on coating performance. Environmental stress testing, including thermal cycling, humidity exposure, and chemical resistance tests, helps predict long-term adhesion reliability. These standardized testing protocols enable objective comparison between different coating formulations and application methods, facilitating quality control and product development.

02 Adhesion promoters and coupling agents

Chemical additives known as adhesion promoters or coupling agents can significantly enhance the bond between conformal coatings and substrates. These compounds typically contain functional groups that can interact with both the substrate surface and the coating material, creating a chemical bridge. Silane coupling agents, titanates, and other specialty chemicals can be incorporated either as primers applied before coating or as additives within the coating formulation itself. These materials improve wet-out characteristics and form stronger chemical bonds at the interface.Expand Specific Solutions03 Coating formulation optimization

The chemical composition of conformal coatings can be optimized to enhance adhesion strength. This includes selecting appropriate base polymers (acrylics, polyurethanes, silicones, epoxies) based on substrate compatibility, adjusting viscosity for proper flow and coverage, and incorporating specialized additives that improve wetting and adhesion. Formulation parameters such as solids content, solvent selection, and curing mechanisms all impact the coating's ability to form strong bonds with the substrate. Balancing these factors leads to coatings with superior adhesion properties.Expand Specific Solutions04 Application methods and process control

The method of applying conformal coatings significantly impacts adhesion strength. Techniques such as spraying, dipping, brushing, and selective coating each offer different advantages for coverage and adhesion. Process parameters including application thickness, temperature, humidity control, and curing conditions must be carefully controlled to optimize adhesion. Multi-layer approaches with appropriate drying times between coats can also enhance overall adhesion performance. Proper process control ensures consistent coating quality and maximizes adhesion strength across production runs.Expand Specific Solutions05 Testing and evaluation methods for adhesion strength

Various testing methodologies are employed to evaluate the adhesion strength of conformal coatings. These include cross-hatch adhesion tests, pull-off tests, tape tests, and environmental stress testing. Advanced analytical techniques such as scanning electron microscopy and surface analysis help identify failure mechanisms at the coating-substrate interface. Accelerated aging tests involving thermal cycling, humidity exposure, and chemical resistance provide insights into long-term adhesion performance. These evaluation methods are essential for validating coating performance and optimizing adhesion strength for specific applications.Expand Specific Solutions

Key Industry Players in Conformal Coating Measurement

The adhesion strength measurement in conformal coating applications market is in a growth phase, driven by increasing demand for reliable electronic protection in harsh environments. The market size is expanding due to the proliferation of electronics in automotive, aerospace, and consumer sectors. Technologically, the field shows varying maturity levels, with established players like PPG Industries and AKZO Nobel Coatings offering traditional solutions, while companies such as Bruker Nano and KLA Corp. are advancing measurement precision through innovative instrumentation. Aerospace leaders including Airbus, Rolls-Royce, and Safran are driving requirements for high-performance coatings, while chemical specialists like Dow Corning Toray, LINTEC, and BASF Coatings are developing advanced formulations with enhanced adhesion properties for next-generation applications.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed a comprehensive adhesion strength measurement system specifically for conformal coatings that combines multiple testing methodologies. Their approach integrates cross-hatch testing with pull-off adhesion testing using specialized equipment that can measure forces from 0-2000 psi. The system employs environmental conditioning chambers to evaluate coating performance under various temperature and humidity conditions, simulating real-world environments. PPG's proprietary software analyzes adhesion data across multiple substrates simultaneously, providing statistical analysis of coating performance. Their technology includes non-destructive evaluation methods using acoustic microscopy to detect delamination before visible failure occurs. The company has also developed substrate-specific pretreatment processes that enhance adhesion properties for different materials including metals, plastics, and composite surfaces commonly used in aerospace and automotive applications.

Strengths: Comprehensive multi-method approach allows for more accurate adhesion characterization across diverse substrates and environmental conditions. Integration of non-destructive testing methods enables early detection of adhesion failures. Weaknesses: System requires significant capital investment and specialized training. Testing methodology may be overly complex for simple applications where basic adhesion testing would suffice.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has pioneered advanced nanomechanical testing solutions for conformal coating adhesion measurement through their Hysitron nanoindentation technology. Their system utilizes controlled scratch testing at the micro and nano scales, allowing precise quantification of adhesion strength between conformal coatings and substrates. The technology employs a diamond probe that applies progressively increasing lateral forces while monitoring the critical load at which coating delamination occurs. Bruker's system incorporates acoustic emission sensors that detect the exact moment of adhesion failure, even when not visually apparent. Their PeakForce QNM (Quantitative Nanomechanical Mapping) technology enables simultaneous mapping of adhesion properties across sample surfaces with nanometer resolution, identifying weak spots in coating adhesion before catastrophic failure. The system can operate in controlled environmental chambers to simulate various temperature, humidity, and chemical exposure conditions, providing real-time adhesion data during environmental cycling tests.

Strengths: Provides quantitative adhesion measurements at nano and micro scales with exceptional precision and repeatability. Capable of mapping adhesion variations across surfaces to identify potential failure points. Weaknesses: High equipment cost and complexity limit accessibility for smaller manufacturers. Requires significant expertise to properly interpret data and translate results to practical applications.

Critical Patents and Research in Adhesion Testing

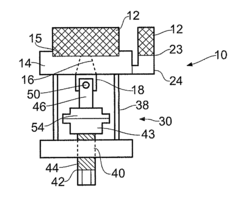

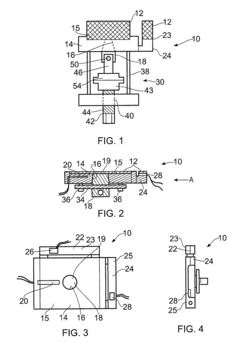

Apparatus and a method of testing the adhesion strength and/or cohesive strength of a coating

PatentActiveUS20110214497A1

Innovation

- An apparatus comprising a first member with an aperture, a second member that can be located within, temperature and strain gauges to measure thermal and residual stresses, and a device to apply a tensile load, allowing for the measurement of adhesive and cohesive strength without adhesive contamination, while analyzing the relationship between temperature, strain, and strength to optimize coating deposition parameters.

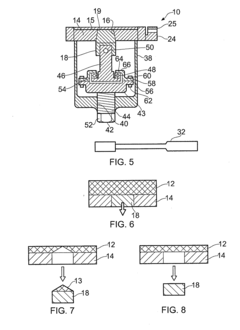

Adhesion strength testing using a depth-sensing indentation technique

PatentInactiveUS6339958B1

Innovation

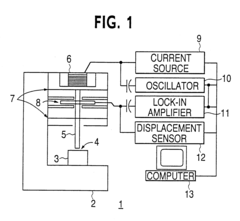

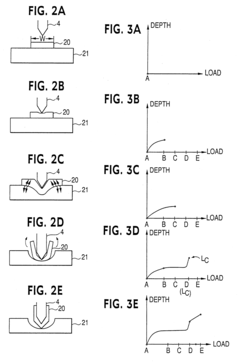

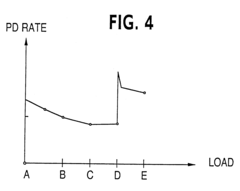

- A nondestructive depth sensing indentation technique using a nanoindentation apparatus with a variable load to measure adhesion strength by detecting the critical load and penetration depth rate, allowing for in-situ testing of thin films on substrates without damaging the film, and calculating adhesion strength through critical stress and shear force calculations.

Standards and Regulatory Requirements for Coating Adhesion

Adherence to established standards and regulatory requirements is paramount in conformal coating applications, particularly in industries where reliability and safety are critical. The IPC-CC-830 standard, widely recognized in the electronics industry, provides comprehensive guidelines for testing and evaluating conformal coating adhesion strength. This standard outlines specific methodologies for cross-hatch adhesion testing, tape testing procedures, and acceptable performance criteria that manufacturers must meet to ensure compliance.

Beyond IPC standards, the military specification MIL-I-46058C remains influential, especially for defense and aerospace applications. This specification establishes rigorous requirements for coating adhesion under extreme environmental conditions, including thermal cycling, humidity exposure, and mechanical stress. Manufacturers serving military markets must demonstrate adherence to these standards through documented testing protocols and quality assurance measures.

In the automotive sector, the USCAR-2 standard addresses conformal coating adhesion requirements specifically for electronic components in vehicles. This standard incorporates accelerated aging tests to simulate the harsh conditions electronic assemblies face throughout a vehicle's lifecycle. Similarly, the AEC-Q200 qualification provides guidelines for passive components, including requirements for coating adhesion strength in automotive applications.

International standards such as IEC 60068-2-X series provide test methods for environmental testing of electronic equipment, including adhesion performance after exposure to various environmental stressors. These standards are particularly relevant for products intended for global markets where diverse environmental conditions must be considered.

Medical device manufacturers must comply with ISO 10993 standards for biocompatibility, which includes requirements for coating adhesion in implantable and patient-contact devices. The FDA has established additional guidance documents that reference these standards and provide specific requirements for coating adhesion testing in medical applications.

Regulatory bodies increasingly focus on environmental compliance, with standards like RoHS and REACH affecting the formulation of conformal coatings. These regulations limit the use of certain hazardous substances that might otherwise enhance adhesion properties, driving innovation in environmentally friendly coating technologies that maintain strong adhesion characteristics.

Certification bodies like UL and CSA have developed their own testing protocols for evaluating coating adhesion in safety-critical applications. UL 746E specifically addresses the performance of coatings and encapsulants used on printed circuit boards, including adhesion requirements that must be met for product certification.

Beyond IPC standards, the military specification MIL-I-46058C remains influential, especially for defense and aerospace applications. This specification establishes rigorous requirements for coating adhesion under extreme environmental conditions, including thermal cycling, humidity exposure, and mechanical stress. Manufacturers serving military markets must demonstrate adherence to these standards through documented testing protocols and quality assurance measures.

In the automotive sector, the USCAR-2 standard addresses conformal coating adhesion requirements specifically for electronic components in vehicles. This standard incorporates accelerated aging tests to simulate the harsh conditions electronic assemblies face throughout a vehicle's lifecycle. Similarly, the AEC-Q200 qualification provides guidelines for passive components, including requirements for coating adhesion strength in automotive applications.

International standards such as IEC 60068-2-X series provide test methods for environmental testing of electronic equipment, including adhesion performance after exposure to various environmental stressors. These standards are particularly relevant for products intended for global markets where diverse environmental conditions must be considered.

Medical device manufacturers must comply with ISO 10993 standards for biocompatibility, which includes requirements for coating adhesion in implantable and patient-contact devices. The FDA has established additional guidance documents that reference these standards and provide specific requirements for coating adhesion testing in medical applications.

Regulatory bodies increasingly focus on environmental compliance, with standards like RoHS and REACH affecting the formulation of conformal coatings. These regulations limit the use of certain hazardous substances that might otherwise enhance adhesion properties, driving innovation in environmentally friendly coating technologies that maintain strong adhesion characteristics.

Certification bodies like UL and CSA have developed their own testing protocols for evaluating coating adhesion in safety-critical applications. UL 746E specifically addresses the performance of coatings and encapsulants used on printed circuit boards, including adhesion requirements that must be met for product certification.

Environmental Factors Affecting Coating Adhesion Performance

Environmental factors play a critical role in determining the long-term performance and reliability of conformal coating adhesion. Temperature fluctuations represent one of the most significant challenges, as thermal cycling can induce mechanical stress at the coating-substrate interface due to differences in thermal expansion coefficients. When substrates and coatings expand and contract at different rates, shear forces develop that may compromise adhesion integrity over time, particularly at temperature extremes ranging from -65°C to 150°C commonly encountered in aerospace and automotive applications.

Humidity and moisture exposure constitute another major environmental factor affecting adhesion performance. Water molecules can penetrate the coating-substrate interface through various mechanisms, including diffusion through the coating itself or capillary action along microscopic defects. This moisture intrusion can lead to hydrolysis reactions that degrade chemical bonds at the interface, resulting in progressive delamination. Studies have shown that relative humidity levels above 75% significantly accelerate adhesion degradation, especially when combined with elevated temperatures.

Chemical exposure presents additional challenges to coating adhesion stability. Industrial environments often contain airborne contaminants, cleaning agents, and process chemicals that may interact with the coating system. Particularly problematic are polar solvents, acids, and alkaline solutions that can penetrate the coating matrix and disrupt the interfacial bonding mechanisms. The chemical resistance profile of a conformal coating must therefore be carefully matched to the expected environmental exposure conditions.

Ultraviolet radiation exposure represents a significant degradation mechanism for many polymer-based conformal coatings. UV radiation can break chemical bonds within the coating structure, leading to embrittlement, discoloration, and reduced adhesion strength. This photodegradation process is particularly relevant for outdoor electronic applications or those exposed to high-intensity lighting conditions. UV-stabilized coating formulations have been developed to mitigate these effects, but complete immunity remains challenging.

Mechanical vibration and shock loading can also compromise coating adhesion over time. Continuous vibration, particularly at resonant frequencies, can induce fatigue at the coating-substrate interface, gradually weakening adhesive bonds. Impact events may cause instantaneous adhesion failure if the energy absorption capacity of the interface is exceeded. These mechanical factors are especially relevant in automotive, aerospace, and industrial applications where equipment is subjected to constant movement and occasional impact events.

Atmospheric pressure variations, while less commonly considered, can affect coating adhesion in specialized applications such as aerospace electronics or deep-sea equipment. Rapid pressure changes can create stress at the coating-substrate interface due to trapped gas expansion or contraction, potentially leading to delamination or bubble formation that compromises protective functions.

Humidity and moisture exposure constitute another major environmental factor affecting adhesion performance. Water molecules can penetrate the coating-substrate interface through various mechanisms, including diffusion through the coating itself or capillary action along microscopic defects. This moisture intrusion can lead to hydrolysis reactions that degrade chemical bonds at the interface, resulting in progressive delamination. Studies have shown that relative humidity levels above 75% significantly accelerate adhesion degradation, especially when combined with elevated temperatures.

Chemical exposure presents additional challenges to coating adhesion stability. Industrial environments often contain airborne contaminants, cleaning agents, and process chemicals that may interact with the coating system. Particularly problematic are polar solvents, acids, and alkaline solutions that can penetrate the coating matrix and disrupt the interfacial bonding mechanisms. The chemical resistance profile of a conformal coating must therefore be carefully matched to the expected environmental exposure conditions.

Ultraviolet radiation exposure represents a significant degradation mechanism for many polymer-based conformal coatings. UV radiation can break chemical bonds within the coating structure, leading to embrittlement, discoloration, and reduced adhesion strength. This photodegradation process is particularly relevant for outdoor electronic applications or those exposed to high-intensity lighting conditions. UV-stabilized coating formulations have been developed to mitigate these effects, but complete immunity remains challenging.

Mechanical vibration and shock loading can also compromise coating adhesion over time. Continuous vibration, particularly at resonant frequencies, can induce fatigue at the coating-substrate interface, gradually weakening adhesive bonds. Impact events may cause instantaneous adhesion failure if the energy absorption capacity of the interface is exceeded. These mechanical factors are especially relevant in automotive, aerospace, and industrial applications where equipment is subjected to constant movement and occasional impact events.

Atmospheric pressure variations, while less commonly considered, can affect coating adhesion in specialized applications such as aerospace electronics or deep-sea equipment. Rapid pressure changes can create stress at the coating-substrate interface due to trapped gas expansion or contraction, potentially leading to delamination or bubble formation that compromises protective functions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!