Measure Dielectric Properties of Conformal Coating in RF Devices

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RF Conformal Coating Background and Objectives

Conformal coatings have been utilized in electronic manufacturing since the 1970s, primarily to protect printed circuit boards (PCBs) from environmental factors such as moisture, dust, chemicals, and temperature fluctuations. As radio frequency (RF) devices have evolved from simple communication equipment to complex systems operating at increasingly higher frequencies, the impact of conformal coatings on RF performance has become a critical consideration in design and manufacturing processes.

The dielectric properties of conformal coatings—specifically their permittivity and loss tangent—directly influence the electrical performance of RF circuits. Historically, these properties were often overlooked or approximated, leading to unpredictable performance variations in RF devices. The growing deployment of millimeter-wave applications for 5G, automotive radar, and aerospace systems has heightened the need for precise characterization of coating materials at higher frequencies.

Traditional measurement techniques for dielectric properties, such as parallel plate capacitors and resonant cavities, face significant limitations when applied to thin conformal coatings in their applied state. These methods typically require sample preparation that alters the material's properties from its as-applied condition on actual devices, creating discrepancies between measured values and real-world performance.

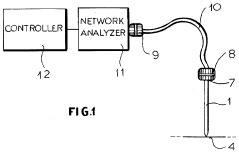

Recent technological advancements in vector network analyzers, material characterization software, and non-destructive testing have opened new possibilities for more accurate measurement approaches. The industry trend is moving toward in-situ measurement techniques that can characterize coatings directly on substrates and components, providing more relevant data for RF engineers.

The primary objective of this technical research is to evaluate existing and emerging methodologies for measuring the dielectric properties of conformal coatings specifically in RF applications. We aim to identify techniques that offer the optimal balance of accuracy, repeatability, frequency range coverage, and practical implementation in production environments.

Secondary objectives include mapping the relationship between coating application parameters (thickness, curing conditions, environmental aging) and resulting dielectric properties, as well as establishing standardized measurement protocols that can be adopted across the industry. This research also seeks to quantify how variations in dielectric properties translate to performance impacts in different RF device categories, from low-frequency communication equipment to millimeter-wave systems.

By achieving these objectives, we anticipate enabling more precise RF device modeling, improved performance prediction, and ultimately more reliable products with consistent RF characteristics despite the protective conformal coating layer.

The dielectric properties of conformal coatings—specifically their permittivity and loss tangent—directly influence the electrical performance of RF circuits. Historically, these properties were often overlooked or approximated, leading to unpredictable performance variations in RF devices. The growing deployment of millimeter-wave applications for 5G, automotive radar, and aerospace systems has heightened the need for precise characterization of coating materials at higher frequencies.

Traditional measurement techniques for dielectric properties, such as parallel plate capacitors and resonant cavities, face significant limitations when applied to thin conformal coatings in their applied state. These methods typically require sample preparation that alters the material's properties from its as-applied condition on actual devices, creating discrepancies between measured values and real-world performance.

Recent technological advancements in vector network analyzers, material characterization software, and non-destructive testing have opened new possibilities for more accurate measurement approaches. The industry trend is moving toward in-situ measurement techniques that can characterize coatings directly on substrates and components, providing more relevant data for RF engineers.

The primary objective of this technical research is to evaluate existing and emerging methodologies for measuring the dielectric properties of conformal coatings specifically in RF applications. We aim to identify techniques that offer the optimal balance of accuracy, repeatability, frequency range coverage, and practical implementation in production environments.

Secondary objectives include mapping the relationship between coating application parameters (thickness, curing conditions, environmental aging) and resulting dielectric properties, as well as establishing standardized measurement protocols that can be adopted across the industry. This research also seeks to quantify how variations in dielectric properties translate to performance impacts in different RF device categories, from low-frequency communication equipment to millimeter-wave systems.

By achieving these objectives, we anticipate enabling more precise RF device modeling, improved performance prediction, and ultimately more reliable products with consistent RF characteristics despite the protective conformal coating layer.

Market Demand for Dielectric Property Measurement

The market for dielectric property measurement in conformal coatings for RF devices has experienced significant growth driven by the expanding telecommunications sector, particularly with the global rollout of 5G networks. Industry analysts project the RF conformal coating market to reach $2.3 billion by 2027, with a compound annual growth rate of 6.8% from 2022. This growth is primarily fueled by increasing demand for reliable electronic components in harsh environments across aerospace, defense, automotive, and consumer electronics industries.

Telecommunications equipment manufacturers represent the largest market segment, accounting for approximately 34% of the total demand for dielectric measurement solutions. These manufacturers require precise characterization of conformal coating materials to ensure optimal RF performance, minimize signal loss, and maintain device reliability. The aerospace and defense sectors follow closely, contributing about 28% of market demand, where high-performance requirements and extreme operating conditions necessitate advanced dielectric property control.

Consumer electronics manufacturers have emerged as a rapidly growing segment, with demand increasing by 12% annually as devices become more compact while incorporating multiple antennas and RF components. This miniaturization trend has intensified the need for accurate dielectric property measurement to maintain signal integrity in densely packed electronic assemblies.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region demonstrates the fastest growth rate at 9.2% annually, driven by expanding electronics manufacturing capabilities and increasing adoption of 5G technology in countries like China, South Korea, and Taiwan.

Key market drivers include the growing complexity of RF devices operating at higher frequencies, stricter reliability requirements for electronics in autonomous vehicles and medical devices, and the need for materials that can maintain consistent dielectric properties across varying environmental conditions. Industry surveys indicate that 76% of electronics manufacturers consider accurate dielectric property measurement critical for product development and quality control.

The market also shows increasing demand for non-destructive testing methods that can measure dielectric properties in situ, without damaging the coated components. This trend is particularly pronounced in high-value electronics manufacturing, where post-production testing of assembled devices is preferred over sample-based quality control approaches.

Telecommunications equipment manufacturers represent the largest market segment, accounting for approximately 34% of the total demand for dielectric measurement solutions. These manufacturers require precise characterization of conformal coating materials to ensure optimal RF performance, minimize signal loss, and maintain device reliability. The aerospace and defense sectors follow closely, contributing about 28% of market demand, where high-performance requirements and extreme operating conditions necessitate advanced dielectric property control.

Consumer electronics manufacturers have emerged as a rapidly growing segment, with demand increasing by 12% annually as devices become more compact while incorporating multiple antennas and RF components. This miniaturization trend has intensified the need for accurate dielectric property measurement to maintain signal integrity in densely packed electronic assemblies.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region demonstrates the fastest growth rate at 9.2% annually, driven by expanding electronics manufacturing capabilities and increasing adoption of 5G technology in countries like China, South Korea, and Taiwan.

Key market drivers include the growing complexity of RF devices operating at higher frequencies, stricter reliability requirements for electronics in autonomous vehicles and medical devices, and the need for materials that can maintain consistent dielectric properties across varying environmental conditions. Industry surveys indicate that 76% of electronics manufacturers consider accurate dielectric property measurement critical for product development and quality control.

The market also shows increasing demand for non-destructive testing methods that can measure dielectric properties in situ, without damaging the coated components. This trend is particularly pronounced in high-value electronics manufacturing, where post-production testing of assembled devices is preferred over sample-based quality control approaches.

Current Challenges in RF Coating Characterization

The characterization of dielectric properties in conformal coatings presents significant challenges for RF device manufacturers and researchers. Traditional measurement techniques often fail to accurately capture the complex permittivity and loss tangent of thin conformal coatings when applied to irregular RF component geometries. This limitation stems from the inherent difficulty in isolating the coating's properties from the underlying substrate and surrounding materials.

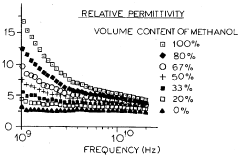

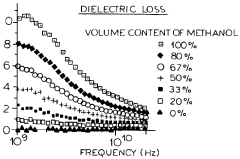

One major challenge is the frequency-dependent nature of dielectric properties. As RF devices operate across increasingly wider frequency bands (from sub-GHz to mmWave), the dielectric response of conformal coatings varies substantially. Current measurement systems struggle to provide consistent characterization across these broad frequency ranges, leading to incomplete material profiles that compromise simulation accuracy.

Sample preparation represents another significant hurdle. The thickness of conformal coatings typically ranges from 25 to 250 microns, making it extremely difficult to prepare uniform, defect-free samples for standard measurement techniques such as split-cavity resonators or transmission/reflection methods. The coating's thickness variation across a single component can exceed 15%, introducing substantial measurement uncertainties.

Environmental factors further complicate characterization efforts. Humidity, temperature, and aging all affect the dielectric properties of conformal coatings, yet current measurement protocols rarely account for these variables in a systematic manner. This leads to discrepancies between laboratory measurements and real-world performance, particularly in harsh operating environments.

The interface between the coating and substrate introduces additional complexity. Surface roughness, adhesion quality, and chemical interactions at the interface can significantly alter the effective dielectric properties. Current measurement techniques generally assume ideal interfaces, which rarely exist in practical applications.

Non-destructive testing remains elusive for in-situ characterization. Most reliable dielectric measurement methods require specialized sample preparation that damages the device under test. This prevents manufacturers from implementing comprehensive quality control procedures on production units without sacrificing yield.

Calibration standards specific to conformal coating measurements are notably absent in the industry. While calibration techniques exist for bulk materials and thin films on planar substrates, the irregular geometries typical of RF components coated with conformal materials lack standardized reference materials and procedures.

The combined effect of these challenges has led to an over-reliance on empirical approaches and iterative design processes, significantly increasing development time and cost for RF devices utilizing conformal coatings. Addressing these measurement limitations would enable more accurate electromagnetic simulations, improved material selection, and ultimately superior RF device performance.

One major challenge is the frequency-dependent nature of dielectric properties. As RF devices operate across increasingly wider frequency bands (from sub-GHz to mmWave), the dielectric response of conformal coatings varies substantially. Current measurement systems struggle to provide consistent characterization across these broad frequency ranges, leading to incomplete material profiles that compromise simulation accuracy.

Sample preparation represents another significant hurdle. The thickness of conformal coatings typically ranges from 25 to 250 microns, making it extremely difficult to prepare uniform, defect-free samples for standard measurement techniques such as split-cavity resonators or transmission/reflection methods. The coating's thickness variation across a single component can exceed 15%, introducing substantial measurement uncertainties.

Environmental factors further complicate characterization efforts. Humidity, temperature, and aging all affect the dielectric properties of conformal coatings, yet current measurement protocols rarely account for these variables in a systematic manner. This leads to discrepancies between laboratory measurements and real-world performance, particularly in harsh operating environments.

The interface between the coating and substrate introduces additional complexity. Surface roughness, adhesion quality, and chemical interactions at the interface can significantly alter the effective dielectric properties. Current measurement techniques generally assume ideal interfaces, which rarely exist in practical applications.

Non-destructive testing remains elusive for in-situ characterization. Most reliable dielectric measurement methods require specialized sample preparation that damages the device under test. This prevents manufacturers from implementing comprehensive quality control procedures on production units without sacrificing yield.

Calibration standards specific to conformal coating measurements are notably absent in the industry. While calibration techniques exist for bulk materials and thin films on planar substrates, the irregular geometries typical of RF components coated with conformal materials lack standardized reference materials and procedures.

The combined effect of these challenges has led to an over-reliance on empirical approaches and iterative design processes, significantly increasing development time and cost for RF devices utilizing conformal coatings. Addressing these measurement limitations would enable more accurate electromagnetic simulations, improved material selection, and ultimately superior RF device performance.

Existing Dielectric Measurement Methodologies

01 Dielectric properties of conformal coating materials

Conformal coatings with specific dielectric properties are essential for electronic applications. These coatings provide electrical insulation while maintaining desired dielectric constants and breakdown voltages. Materials such as parylene, silicone, acrylic, and epoxy resins are commonly used due to their excellent dielectric properties. The dielectric constant and dissipation factor of these materials can be tailored to meet specific application requirements, providing protection against electrical leakage and short circuits.- Dielectric properties of conformal coating materials: Conformal coatings with specific dielectric properties are essential for protecting electronic components while maintaining electrical performance. These coatings provide electrical insulation with controlled dielectric constants and breakdown voltages. Materials such as parylene, silicone, acrylic, and epoxy offer different dielectric strengths suitable for various applications, allowing designers to balance protection needs with signal integrity requirements.

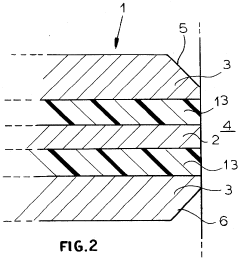

- Application methods for conformal coatings: Various application techniques are used to apply conformal coatings with consistent dielectric properties. These methods include spray coating, dip coating, vapor deposition, and selective coating. Each technique offers different advantages in terms of thickness control, coverage uniformity, and penetration into complex geometries, which directly impact the resulting dielectric performance of the coating layer.

- Environmental protection and dielectric stability: Conformal coatings provide environmental protection while maintaining dielectric stability under various conditions. These coatings shield electronic components from moisture, chemicals, dust, and temperature fluctuations that could otherwise compromise dielectric performance. Advanced formulations ensure that dielectric properties remain stable across wide temperature ranges and humidity levels, extending the operational life of electronic devices.

- Novel materials and composites for enhanced dielectric performance: Research into novel conformal coating materials focuses on enhancing dielectric properties through composite formulations and nanomaterials. These advanced materials incorporate fillers, nanoparticles, or specialized polymers to achieve customized dielectric constants, reduced signal loss, and improved thermal conductivity. Such innovations enable thinner coating layers while maintaining or improving dielectric strength and protection capabilities.

- Integration with semiconductor and PCB manufacturing: Conformal coatings with specific dielectric properties are increasingly integrated into semiconductor and printed circuit board manufacturing processes. These coatings are designed to be compatible with existing fabrication techniques while providing the necessary dielectric isolation between components. Advanced formulations address challenges such as adhesion to various substrates, curing compatibility, and maintaining consistent dielectric properties across complex three-dimensional structures.

02 Application methods for conformal coatings

Various application methods are employed to achieve optimal dielectric performance in conformal coatings. These include spray coating, dip coating, vapor deposition, and selective coating techniques. Each method offers different advantages in terms of coating uniformity, thickness control, and penetration into complex geometries. The application method significantly impacts the final dielectric properties of the coating, with vapor deposition methods like Parylene coating providing particularly uniform dielectric characteristics across complex substrate topographies.Expand Specific Solutions03 Enhanced dielectric performance through additives and fillers

The dielectric properties of conformal coatings can be enhanced through the incorporation of specific additives and fillers. Ceramic particles, metal oxides, and specialized polymers can be added to base coating formulations to modify dielectric constants, improve breakdown voltage, and enhance thermal conductivity. These additives allow for customization of the coating's electrical properties while maintaining essential protective characteristics such as moisture resistance and flexibility.Expand Specific Solutions04 Thermal management and dielectric stability

Conformal coatings must maintain stable dielectric properties across a wide temperature range. Advanced formulations incorporate thermal management features that prevent degradation of dielectric performance under thermal stress. These coatings provide reliable electrical insulation while dissipating heat from electronic components. The thermal stability of the dielectric properties is crucial for applications in harsh environments where temperature fluctuations could otherwise compromise the coating's insulative capabilities.Expand Specific Solutions05 Environmental protection and dielectric reliability

Conformal coatings provide environmental protection while maintaining reliable dielectric properties. These coatings shield electronic assemblies from moisture, chemicals, dust, and mechanical stress that could compromise dielectric performance. The coatings must balance dielectric strength with other protective properties such as hydrophobicity, chemical resistance, and flexibility. Long-term reliability of dielectric properties under various environmental conditions is a key consideration in coating selection for critical electronic applications.Expand Specific Solutions

Leading Companies in RF Coating Technology

The RF dielectric property measurement market for conformal coatings is in a growth phase, driven by increasing demand for precise characterization in high-frequency applications. The market is expanding with the miniaturization of RF devices and growing complexity of electronic systems. Leading players include established semiconductor equipment manufacturers like Applied Materials and Lam Research, who bring advanced metrology expertise, alongside specialized measurement solution providers such as Keysight Technologies and Micro-Epsilon. The technology landscape shows varying maturity levels, with companies like TDK, Sony, and 3M focusing on material development, while Onto Innovation and OMICRON electronics concentrate on specialized measurement systems. Research institutions like Forschungszentrum Jülich and Harbin Institute of Technology contribute to advancing fundamental measurement methodologies in this technically challenging field.

OMICRON electronics GmbH

Technical Solution: OMICRON has developed specialized dielectric response analysis (DRA) systems for characterizing conformal coatings in RF applications. Their technology employs frequency domain spectroscopy from 1 mHz to 5 GHz combined with time domain reflectometry to provide comprehensive dielectric property measurements. The system features proprietary electrode configurations that minimize fringing field effects, enabling accurate measurements of thin conformal coatings with thickness variations. OMICRON's solution incorporates multi-parameter fitting algorithms that can separate the dielectric response of coating layers from substrate and environmental effects. Their DielectricLab software provides advanced modeling capabilities that correlate dielectric properties with coating performance metrics such as moisture resistance, thermal stability, and RF signal integrity. The system also includes environmental chambers for testing under controlled humidity and temperature conditions.

Strengths: Comprehensive frequency range coverage; advanced algorithms for separating material responses; integrated environmental testing capabilities. Weaknesses: Complex calibration requirements; longer measurement times at lower frequencies; requires specialized sample preparation for some measurement modes.

3M Innovative Properties Co.

Technical Solution: 3M has developed proprietary measurement technologies specifically designed for characterizing the dielectric properties of their advanced conformal coating materials used in RF applications. Their approach combines parallel plate capacitance measurements with microstrip resonator techniques to characterize dielectric constant and loss tangent across frequencies from 100 MHz to 40 GHz. The system incorporates specialized sample preparation protocols that ensure consistent coating thickness and uniformity for accurate measurements. 3M's technology utilizes reference material calibration methods that achieve measurement accuracy of ±1% for dielectric constant and ±0.0005 for loss tangent. Their integrated measurement platform includes environmental conditioning capabilities that allow characterization of moisture absorption effects and temperature coefficient of dielectric properties. The system also features accelerated aging protocols to predict long-term stability of dielectric properties under various environmental stresses.

Strengths: Comprehensive material characterization capabilities; excellent measurement repeatability; integrated aging and environmental testing. Weaknesses: Primarily optimized for 3M's own coating materials; requires specialized sample preparation; limited flexibility for unusual sample geometries.

Key Innovations in RF Material Characterization

Device and apparatus for measuring dielectric properties of materials

PatentInactiveUS5744971A

Innovation

- A coaxial dielectric probe with an inner and outer conductor, having an outside diameter of less than 1 mm, allowing for real-time measurement of dielectric properties by transmitting and analyzing electromagnetic radiation, enabling spatial resolution for distinguishing between adjoining regions and allowing insertion into semi-rigid materials for depth profiling.

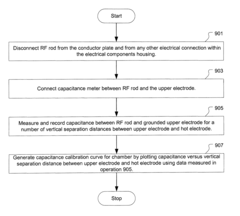

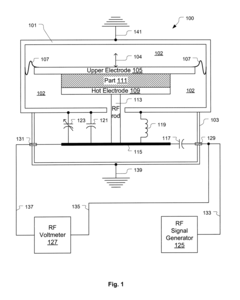

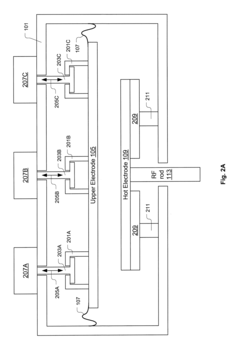

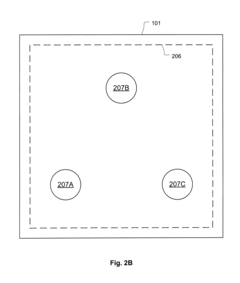

Methods for measuring dielectric properties of parts

PatentActiveUS7973539B1

Innovation

- A method involving an apparatus with an electrically grounded chamber, a lower electrode connected to an RF transmission rod, and an upper electrode, which uses a capacitance meter to measure capacitance between the RF rod and the upper electrode at various separation distances, allowing for the determination of dielectric constant and loss tangent by simulating the resonance frequency and calculating the capacitance of the part.

Environmental Impact of RF Coating Materials

The environmental impact of RF coating materials has become increasingly significant as the electronics industry continues to expand globally. Conformal coatings used in RF devices contain various chemical compounds that can have substantial ecological footprints throughout their lifecycle. Traditional coating materials often include acrylic, silicone, polyurethane, and epoxy-based formulations, many of which contain volatile organic compounds (VOCs) that contribute to air pollution and potential health hazards during application and curing processes.

Manufacturing processes for these coatings typically require significant energy consumption and may generate hazardous waste streams. The extraction of raw materials for these coatings, particularly for silicone-based formulations, involves mining operations that can lead to habitat destruction and soil degradation. Additionally, the refinement processes for these materials often produce greenhouse gas emissions that contribute to climate change.

During the operational lifetime of RF devices, the environmental impact of coating materials continues through potential leaching of chemicals into soil and water systems when devices are exposed to environmental conditions. Some coating formulations contain persistent organic pollutants that resist environmental degradation and can bioaccumulate in ecosystems, potentially affecting wildlife and human health through food chains.

End-of-life considerations present perhaps the most significant environmental challenge. Many RF devices with conformal coatings are difficult to recycle due to the complex mixture of materials. The coatings often prevent efficient separation of valuable components, leading to increased electronic waste. When improperly disposed of, these coatings can release harmful substances into landfills, potentially contaminating groundwater.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, have driven innovation toward more environmentally friendly coating alternatives. Water-based formulations and bio-based coatings derived from renewable resources are emerging as promising alternatives with reduced environmental impacts.

Life cycle assessment (LCA) studies indicate that newer coating technologies can reduce carbon footprints by up to 65% compared to traditional solvent-based systems. However, these environmentally friendly alternatives often present trade-offs in terms of RF performance characteristics, highlighting the need for continued research to optimize both environmental sustainability and technical performance in next-generation coating materials.

Manufacturing processes for these coatings typically require significant energy consumption and may generate hazardous waste streams. The extraction of raw materials for these coatings, particularly for silicone-based formulations, involves mining operations that can lead to habitat destruction and soil degradation. Additionally, the refinement processes for these materials often produce greenhouse gas emissions that contribute to climate change.

During the operational lifetime of RF devices, the environmental impact of coating materials continues through potential leaching of chemicals into soil and water systems when devices are exposed to environmental conditions. Some coating formulations contain persistent organic pollutants that resist environmental degradation and can bioaccumulate in ecosystems, potentially affecting wildlife and human health through food chains.

End-of-life considerations present perhaps the most significant environmental challenge. Many RF devices with conformal coatings are difficult to recycle due to the complex mixture of materials. The coatings often prevent efficient separation of valuable components, leading to increased electronic waste. When improperly disposed of, these coatings can release harmful substances into landfills, potentially contaminating groundwater.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, have driven innovation toward more environmentally friendly coating alternatives. Water-based formulations and bio-based coatings derived from renewable resources are emerging as promising alternatives with reduced environmental impacts.

Life cycle assessment (LCA) studies indicate that newer coating technologies can reduce carbon footprints by up to 65% compared to traditional solvent-based systems. However, these environmentally friendly alternatives often present trade-offs in terms of RF performance characteristics, highlighting the need for continued research to optimize both environmental sustainability and technical performance in next-generation coating materials.

Reliability Testing Standards for RF Coatings

Reliability testing standards for RF coatings have evolved significantly over the past decades to address the unique challenges posed by radio frequency environments. These standards encompass comprehensive methodologies for evaluating the performance and durability of conformal coatings used in RF devices under various environmental stressors. The primary standards organizations governing this domain include IPC (Association Connecting Electronics Industries), IEC (International Electrotechnical Commission), and MIL-STD (Military Standards).

IPC-CC-830C represents one of the foundational standards specifically addressing conformal coating requirements. This standard outlines testing procedures for evaluating coating resistance to moisture, temperature cycling, and chemical exposure—all critical factors affecting dielectric properties in RF applications. Complementing this, IEC 60068 provides a series of environmental testing procedures applicable to RF coating evaluation, with particular emphasis on temperature and humidity cycling tests that can reveal changes in dielectric constant and loss tangent over time.

For military and aerospace applications, MIL-STD-810G offers rigorous testing protocols for environmental stressors, while MIL-PRF-46058 specifically addresses electrical and environmental requirements for conformal coatings. These standards incorporate RF-specific considerations including dielectric withstanding voltage tests and insulation resistance measurements under extreme conditions.

ASTM D150 has emerged as a particularly relevant standard for measuring dielectric properties, providing detailed procedures for determining dielectric constant and dissipation factor across various frequencies. This standard is often referenced when characterizing RF coating materials before and after environmental exposure to quantify performance degradation.

Recent developments in reliability standards have increasingly focused on high-frequency performance metrics. The IPC-TM-650 test methods now include procedures specifically designed for evaluating material properties at RF and microwave frequencies, addressing the growing demand for coatings suitable for 5G and other advanced communications technologies.

Accelerated aging tests have become standardized components of reliability evaluation, with protocols typically involving exposure to elevated temperatures (85°C to 125°C) and high humidity (85% to 95% RH) for periods ranging from 500 to 1000 hours. These conditions effectively simulate years of operational stress in compressed timeframes, allowing for meaningful predictions of long-term dielectric stability.

Industry-specific standards have also emerged, with automotive standards like AEC-Q200 incorporating specialized testing for RF components used in vehicle communications systems. Similarly, telecommunications standards from ETSI (European Telecommunications Standards Institute) provide guidance on coating reliability requirements for base station equipment and other RF infrastructure components.

IPC-CC-830C represents one of the foundational standards specifically addressing conformal coating requirements. This standard outlines testing procedures for evaluating coating resistance to moisture, temperature cycling, and chemical exposure—all critical factors affecting dielectric properties in RF applications. Complementing this, IEC 60068 provides a series of environmental testing procedures applicable to RF coating evaluation, with particular emphasis on temperature and humidity cycling tests that can reveal changes in dielectric constant and loss tangent over time.

For military and aerospace applications, MIL-STD-810G offers rigorous testing protocols for environmental stressors, while MIL-PRF-46058 specifically addresses electrical and environmental requirements for conformal coatings. These standards incorporate RF-specific considerations including dielectric withstanding voltage tests and insulation resistance measurements under extreme conditions.

ASTM D150 has emerged as a particularly relevant standard for measuring dielectric properties, providing detailed procedures for determining dielectric constant and dissipation factor across various frequencies. This standard is often referenced when characterizing RF coating materials before and after environmental exposure to quantify performance degradation.

Recent developments in reliability standards have increasingly focused on high-frequency performance metrics. The IPC-TM-650 test methods now include procedures specifically designed for evaluating material properties at RF and microwave frequencies, addressing the growing demand for coatings suitable for 5G and other advanced communications technologies.

Accelerated aging tests have become standardized components of reliability evaluation, with protocols typically involving exposure to elevated temperatures (85°C to 125°C) and high humidity (85% to 95% RH) for periods ranging from 500 to 1000 hours. These conditions effectively simulate years of operational stress in compressed timeframes, allowing for meaningful predictions of long-term dielectric stability.

Industry-specific standards have also emerged, with automotive standards like AEC-Q200 incorporating specialized testing for RF components used in vehicle communications systems. Similarly, telecommunications standards from ETSI (European Telecommunications Standards Institute) provide guidance on coating reliability requirements for base station equipment and other RF infrastructure components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!