Measure Effectiveness of Conformal Coating Against Tropical Conditions

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Technology Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated engineered materials designed to shield electronic components from harsh environmental conditions. Originally developed for military and aerospace applications in the 1960s, these coatings have become increasingly important in commercial electronics as miniaturization trends expose sensitive components to environmental threats. The fundamental purpose of conformal coating remains consistent: to provide a thin polymeric film that conforms to circuit board topography, creating a protective barrier against moisture, dust, chemicals, and temperature fluctuations.

In tropical environments, electronic devices face particularly severe challenges including extreme humidity (often exceeding 90%), elevated temperatures (regularly above 35°C), condensation cycles, salt spray in coastal areas, and accelerated fungal and microbial growth. These conditions significantly accelerate corrosion processes and electrical failures, making effective protection critical for maintaining operational reliability.

The technological evolution of conformal coatings has progressed through several generations, from early solvent-based acrylics to modern hybrid formulations. Current coating technologies include acrylics, silicones, polyurethanes, epoxies, and parylene, each offering distinct performance characteristics suited to different application requirements. Recent innovations have focused on developing nano-enhanced coatings that provide superior moisture resistance while maintaining breathability to prevent pressure-induced delamination.

The primary objectives of this technical research are multifaceted. First, to establish standardized methodologies for quantitatively measuring coating effectiveness specifically against tropical conditions, addressing the current gap in industry standards that often fail to replicate real-world tropical exposure. Second, to identify optimal coating formulations and application techniques that maximize protection in high-humidity, high-temperature environments while minimizing production costs and environmental impact.

Additionally, this research aims to develop accelerated testing protocols that can reliably predict long-term coating performance in tropical conditions within reasonable timeframes, enabling faster product development cycles. The ultimate goal is to establish clear correlations between laboratory measurements and actual field performance, providing manufacturers with actionable data for material selection and application processes.

As electronics continue to penetrate developing markets in tropical regions and climate change intensifies weather extremes globally, the importance of effective conformal coating solutions is becoming increasingly critical across industries ranging from consumer electronics to automotive systems, medical devices, and industrial controls.

In tropical environments, electronic devices face particularly severe challenges including extreme humidity (often exceeding 90%), elevated temperatures (regularly above 35°C), condensation cycles, salt spray in coastal areas, and accelerated fungal and microbial growth. These conditions significantly accelerate corrosion processes and electrical failures, making effective protection critical for maintaining operational reliability.

The technological evolution of conformal coatings has progressed through several generations, from early solvent-based acrylics to modern hybrid formulations. Current coating technologies include acrylics, silicones, polyurethanes, epoxies, and parylene, each offering distinct performance characteristics suited to different application requirements. Recent innovations have focused on developing nano-enhanced coatings that provide superior moisture resistance while maintaining breathability to prevent pressure-induced delamination.

The primary objectives of this technical research are multifaceted. First, to establish standardized methodologies for quantitatively measuring coating effectiveness specifically against tropical conditions, addressing the current gap in industry standards that often fail to replicate real-world tropical exposure. Second, to identify optimal coating formulations and application techniques that maximize protection in high-humidity, high-temperature environments while minimizing production costs and environmental impact.

Additionally, this research aims to develop accelerated testing protocols that can reliably predict long-term coating performance in tropical conditions within reasonable timeframes, enabling faster product development cycles. The ultimate goal is to establish clear correlations between laboratory measurements and actual field performance, providing manufacturers with actionable data for material selection and application processes.

As electronics continue to penetrate developing markets in tropical regions and climate change intensifies weather extremes globally, the importance of effective conformal coating solutions is becoming increasingly critical across industries ranging from consumer electronics to automotive systems, medical devices, and industrial controls.

Market Demand Analysis for Tropical Environment Protection

The global market for conformal coating solutions specifically designed for tropical environment protection has been experiencing significant growth, driven primarily by the increasing deployment of electronic devices in harsh climatic conditions. Tropical regions, characterized by high humidity, elevated temperatures, and increased risk of fungal and microbial growth, present unique challenges for electronic equipment reliability and longevity.

Market research indicates that the conformal coating market for tropical protection is expected to grow at a compound annual growth rate of 5.7% through 2028, with the Asia-Pacific region leading this expansion due to its large tropical areas and rapidly growing electronics manufacturing base. Industries such as telecommunications, aerospace, defense, and automotive are the primary consumers of these specialized protective solutions.

The demand is particularly strong in countries with tropical climates such as Indonesia, Malaysia, Singapore, Brazil, and parts of India, where the combination of high humidity (often exceeding 80%) and temperatures above 30°C creates an aggressive environment for electronic components. These conditions accelerate corrosion rates by 2-3 times compared to temperate climates, significantly reducing equipment lifespan without adequate protection.

Consumer electronics manufacturers are increasingly recognizing the need for tropical-grade protection as warranty claims from tropical regions show 40% higher failure rates for unprotected devices. This has created a growing segment within the broader conformal coating market specifically targeting tropical condition resistance.

Military and defense applications represent another substantial market segment, with requirements for equipment that can withstand extreme tropical conditions during deployment. These applications demand coatings that not only protect against humidity but also resist fungal growth, salt spray, and chemical exposure while maintaining operational integrity.

The offshore oil and gas industry has emerged as a significant consumer of tropical-resistant conformal coatings, with platforms in regions like the Gulf of Mexico and Southeast Asia requiring electronics that can withstand both marine and tropical conditions simultaneously. This dual-protection requirement has spurred innovation in multi-functional coating formulations.

Market analysis reveals a shift toward environmentally friendly coating solutions, with water-based and UV-curable formulations gaining market share as regulations on volatile organic compounds (VOCs) become more stringent globally. This trend is particularly evident in European companies operating in tropical markets, where environmental compliance is increasingly becoming a competitive advantage.

The aftermarket for conformal coating services targeting existing installations in tropical environments is also expanding, offering retrofitting solutions for critical infrastructure that was not initially designed with tropical conditions in mind. This segment is growing at nearly 7% annually, outpacing the overall market.

Market research indicates that the conformal coating market for tropical protection is expected to grow at a compound annual growth rate of 5.7% through 2028, with the Asia-Pacific region leading this expansion due to its large tropical areas and rapidly growing electronics manufacturing base. Industries such as telecommunications, aerospace, defense, and automotive are the primary consumers of these specialized protective solutions.

The demand is particularly strong in countries with tropical climates such as Indonesia, Malaysia, Singapore, Brazil, and parts of India, where the combination of high humidity (often exceeding 80%) and temperatures above 30°C creates an aggressive environment for electronic components. These conditions accelerate corrosion rates by 2-3 times compared to temperate climates, significantly reducing equipment lifespan without adequate protection.

Consumer electronics manufacturers are increasingly recognizing the need for tropical-grade protection as warranty claims from tropical regions show 40% higher failure rates for unprotected devices. This has created a growing segment within the broader conformal coating market specifically targeting tropical condition resistance.

Military and defense applications represent another substantial market segment, with requirements for equipment that can withstand extreme tropical conditions during deployment. These applications demand coatings that not only protect against humidity but also resist fungal growth, salt spray, and chemical exposure while maintaining operational integrity.

The offshore oil and gas industry has emerged as a significant consumer of tropical-resistant conformal coatings, with platforms in regions like the Gulf of Mexico and Southeast Asia requiring electronics that can withstand both marine and tropical conditions simultaneously. This dual-protection requirement has spurred innovation in multi-functional coating formulations.

Market analysis reveals a shift toward environmentally friendly coating solutions, with water-based and UV-curable formulations gaining market share as regulations on volatile organic compounds (VOCs) become more stringent globally. This trend is particularly evident in European companies operating in tropical markets, where environmental compliance is increasingly becoming a competitive advantage.

The aftermarket for conformal coating services targeting existing installations in tropical environments is also expanding, offering retrofitting solutions for critical infrastructure that was not initially designed with tropical conditions in mind. This segment is growing at nearly 7% annually, outpacing the overall market.

Current State and Challenges in Conformal Coating Technology

Conformal coating technology has evolved significantly over the past decades, with current solutions offering varying degrees of protection against tropical conditions. The global market features several established coating types including acrylic, silicone, polyurethane, epoxy, and parylene, each with distinct properties and protection capabilities. Despite widespread adoption across electronics manufacturing, significant challenges persist in measuring and ensuring consistent performance in extreme tropical environments.

The primary technical challenge lies in developing standardized testing methodologies that accurately simulate the complex combination of high humidity, temperature fluctuations, salt spray, and fungal growth characteristic of tropical conditions. Current testing standards such as IPC-CC-830, MIL-I-46058C, and IEC 60068 provide baseline parameters but often fail to replicate the dynamic nature of tropical environments where multiple stressors operate simultaneously.

Material limitations represent another significant hurdle. While existing coatings offer reasonable protection, they frequently demonstrate compromised performance when exposed to prolonged tropical conditions. Silicone coatings, though excellent for moisture resistance, may experience adhesion degradation over time. Acrylic coatings, despite their reworkability advantages, show vulnerability to chemical exposure common in tropical regions. Polyurethane coatings offer good chemical resistance but may yellow and degrade under intense UV exposure typical in equatorial regions.

Application precision presents ongoing technical difficulties. Conventional application methods including dipping, spraying, and selective coating often result in inconsistent coating thickness, which directly impacts protection effectiveness. The industry still struggles with achieving uniform coverage over complex PCB topographies featuring high-density components and fine-pitch connections. This inconsistency creates vulnerable points where tropical conditions can penetrate and initiate corrosion or electrical failures.

Measurement and verification technologies remain inadequate for real-time assessment of coating integrity. Current inspection methods primarily rely on visual inspection under UV light, thickness measurements, and destructive testing. These approaches provide limited insight into how coatings perform over extended periods in tropical environments and fail to detect microscopic breaches that may develop over time.

Sustainability concerns are emerging as significant challenges as environmental regulations become more stringent. Many traditional conformal coating formulations contain volatile organic compounds (VOCs) and other environmentally harmful substances. The industry faces increasing pressure to develop eco-friendly alternatives that maintain or exceed current protection standards while reducing environmental impact.

Geographical distribution of conformal coating technology shows concentration in North America, Europe, and East Asia, with limited specialized research focused specifically on tropical applications despite the growing electronics manufacturing presence in tropical regions like Southeast Asia and parts of Latin America.

The primary technical challenge lies in developing standardized testing methodologies that accurately simulate the complex combination of high humidity, temperature fluctuations, salt spray, and fungal growth characteristic of tropical conditions. Current testing standards such as IPC-CC-830, MIL-I-46058C, and IEC 60068 provide baseline parameters but often fail to replicate the dynamic nature of tropical environments where multiple stressors operate simultaneously.

Material limitations represent another significant hurdle. While existing coatings offer reasonable protection, they frequently demonstrate compromised performance when exposed to prolonged tropical conditions. Silicone coatings, though excellent for moisture resistance, may experience adhesion degradation over time. Acrylic coatings, despite their reworkability advantages, show vulnerability to chemical exposure common in tropical regions. Polyurethane coatings offer good chemical resistance but may yellow and degrade under intense UV exposure typical in equatorial regions.

Application precision presents ongoing technical difficulties. Conventional application methods including dipping, spraying, and selective coating often result in inconsistent coating thickness, which directly impacts protection effectiveness. The industry still struggles with achieving uniform coverage over complex PCB topographies featuring high-density components and fine-pitch connections. This inconsistency creates vulnerable points where tropical conditions can penetrate and initiate corrosion or electrical failures.

Measurement and verification technologies remain inadequate for real-time assessment of coating integrity. Current inspection methods primarily rely on visual inspection under UV light, thickness measurements, and destructive testing. These approaches provide limited insight into how coatings perform over extended periods in tropical environments and fail to detect microscopic breaches that may develop over time.

Sustainability concerns are emerging as significant challenges as environmental regulations become more stringent. Many traditional conformal coating formulations contain volatile organic compounds (VOCs) and other environmentally harmful substances. The industry faces increasing pressure to develop eco-friendly alternatives that maintain or exceed current protection standards while reducing environmental impact.

Geographical distribution of conformal coating technology shows concentration in North America, Europe, and East Asia, with limited specialized research focused specifically on tropical applications despite the growing electronics manufacturing presence in tropical regions like Southeast Asia and parts of Latin America.

Existing Measurement Methods for Coating Effectiveness

01 Protection against environmental factors

Conformal coatings provide effective protection for electronic components against various environmental factors such as moisture, dust, chemicals, and temperature fluctuations. These coatings form a protective barrier that prevents contaminants from reaching sensitive electronic parts, thereby extending the lifespan of the components and ensuring reliable operation in harsh environments.- Protection against environmental factors: Conformal coatings provide effective protection for electronic components against various environmental factors such as moisture, dust, chemicals, and temperature fluctuations. These coatings form a protective barrier that prevents corrosion, electrical shorts, and other damage that can occur when electronic assemblies are exposed to harsh conditions. The effectiveness of this protection depends on the coating material properties and application method, with proper coverage ensuring extended component life and reliability.

- Coating materials and their properties: Different conformal coating materials offer varying levels of effectiveness based on their inherent properties. Common materials include acrylics, silicones, polyurethanes, epoxies, and parylene, each with specific advantages for different applications. Silicones typically offer excellent temperature resistance and flexibility, while parylene provides superior moisture barrier properties. Polyurethanes balance good moisture resistance with mechanical strength, and acrylics offer ease of application and rework. The selection of coating material significantly impacts the overall protection effectiveness for specific environmental challenges.

- Application methods and coverage quality: The effectiveness of conformal coatings is highly dependent on the application method and resulting coverage quality. Common application techniques include dipping, spraying, brushing, and automated selective coating. Each method offers different advantages in terms of thickness control, uniformity, and ability to coat complex geometries. Proper application ensures complete coverage without voids, bubbles, or thin spots that could compromise protection. Advanced application technologies can optimize coating thickness and uniformity, particularly for high-density circuit boards with fine-pitch components.

- Testing and qualification of coating effectiveness: Evaluating conformal coating effectiveness requires comprehensive testing and qualification procedures. Standard tests include salt spray exposure, humidity aging, thermal cycling, and electrical insulation resistance measurements. These tests verify the coating's ability to maintain protection under various environmental stresses. Advanced analytical techniques such as cross-sectional analysis and impedance spectroscopy can quantify coating integrity and performance over time. Establishing proper test protocols ensures that the selected coating will provide the required level of protection for the intended application environment.

- Enhanced functionality through specialized coatings: Beyond basic environmental protection, specialized conformal coatings can provide enhanced functionality and effectiveness for specific applications. These include coatings with electromagnetic interference (EMI) shielding properties, thermally conductive formulations for heat dissipation, optically clear coatings for LED applications, and hydrophobic coatings for extreme moisture resistance. Some advanced formulations incorporate self-healing capabilities or antimicrobial properties. These specialized coatings extend the traditional protective function to address specific performance requirements in demanding applications.

02 Coating materials and their properties

Different conformal coating materials offer varying levels of effectiveness based on their specific properties. Common materials include acrylics, silicones, polyurethanes, epoxies, and parylene. Each material has distinct characteristics regarding flexibility, chemical resistance, dielectric strength, temperature tolerance, and adhesion properties that determine their suitability for specific applications and environments.Expand Specific Solutions03 Application methods and coverage quality

The effectiveness of conformal coatings is significantly influenced by the application method used. Techniques such as dipping, spraying, selective coating, and vapor deposition each provide different levels of coverage and thickness control. The quality of coverage, including uniformity and absence of defects like bubbles or voids, directly impacts the protective performance of the coating.Expand Specific Solutions04 Thermal management and heat dissipation

Conformal coatings can affect the thermal properties of electronic assemblies. Some specialized coatings are designed to enhance heat dissipation while maintaining protection against environmental factors. The thermal conductivity of the coating material and its thickness play crucial roles in managing heat generated by electronic components, which is essential for preventing overheating and ensuring long-term reliability.Expand Specific Solutions05 Testing and qualification methods

The effectiveness of conformal coatings is evaluated through various testing and qualification methods. These include environmental stress tests, thermal cycling, humidity testing, salt spray exposure, and electrical property measurements. Advanced analytical techniques such as cross-sectional analysis and accelerated aging tests help determine the long-term protection capabilities and reliability of different coating solutions under specific operating conditions.Expand Specific Solutions

Key Industry Players in Conformal Coating Manufacturing

The conformal coating market for tropical condition protection is in a growth phase, with increasing demand driven by electronics manufacturing in humid environments. The market size is expanding as industries like aerospace (Boeing, Eastman Kodak), electronics (Seiko Epson, HzO), and automotive sectors require more reliable protection solutions. Technology maturity varies across players, with established chemical companies (3M, BASF, Wacker Chemie) offering advanced solutions, while specialized coating manufacturers (SDC Technologies, Kansai Paint) focus on performance optimization. Research institutions (Beihang University, Georgia Tech) are developing next-generation coatings with enhanced humidity resistance. Companies like HzO and Sundew Technologies represent innovative approaches with nano-coating technologies specifically designed for extreme environmental protection.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced conformal coating measurement systems specifically designed for tropical condition testing. Their technology incorporates multi-parameter environmental chambers that simultaneously control temperature (up to 85°C), humidity (up to 95% RH), and UV exposure to simulate accelerated tropical aging. 3M's proprietary fluorescent tracers embedded in their coatings allow for non-destructive optical inspection using specialized UV imaging systems that quantify coating thickness variations and detect microscopic defects. Their measurement protocol includes impedance spectroscopy to evaluate moisture ingress resistance over time, with automated data collection systems that generate comprehensive coating performance metrics. The company has established industry-standard test protocols that correlate accelerated testing with real-world performance data collected from tropical field stations in Southeast Asia.

Strengths: Industry-leading measurement precision (±2μm thickness accuracy), comprehensive multi-parameter testing capabilities, and extensive historical performance database for comparative analysis. Weaknesses: Proprietary measurement systems require specialized training and calibration, and testing protocols can be time-intensive (typically 1000+ hours for complete evaluation).

Nordson Corp.

Technical Solution: Nordson has pioneered automated measurement systems for conformal coating effectiveness in tropical environments. Their approach centers on their Tropical Environment Simulation Technology (TEST) chambers that precisely replicate tropical conditions including temperature cycling (25-65°C), humidity oscillation (65-95%), salt fog exposure, and fungal resistance testing. Nordson's measurement technology incorporates multi-point impedance analysis that maps coating protection across entire PCB surfaces rather than isolated test points. Their proprietary optical coherence tomography system provides non-destructive 3D visualization of coating layer integrity before, during, and after tropical exposure. Nordson's measurement protocol includes automated cyclic condensation testing that evaluates how coatings perform during the rapid temperature changes characteristic of tropical environments. Their data analytics platform correlates coating performance metrics with specific environmental parameters to identify critical failure thresholds.

Strengths: High-throughput automated testing capabilities, exceptional measurement resolution (sub-micron detection of coating anomalies), and sophisticated data analytics for predictive performance modeling. Weaknesses: High capital investment required for comprehensive measurement systems and limited correlation data for newer coating formulations.

Core Technical Innovations in Tropical Resistance Testing

Low stress conformal coatings of reliability without hermeticity for microelectromechanical system based multichip module encapsulation

PatentInactiveUS6989433B2

Innovation

- Development of low stress conformal coatings using elastomer-modified epoxy and silicone compositions with specific weight percentages of elastomers, diluents, catalysts, and fillers to achieve low viscosity, room temperature curability, and improved contamination resistance, featuring a storage modulus less than 65 MPa and a glass transition temperature below -60°C.

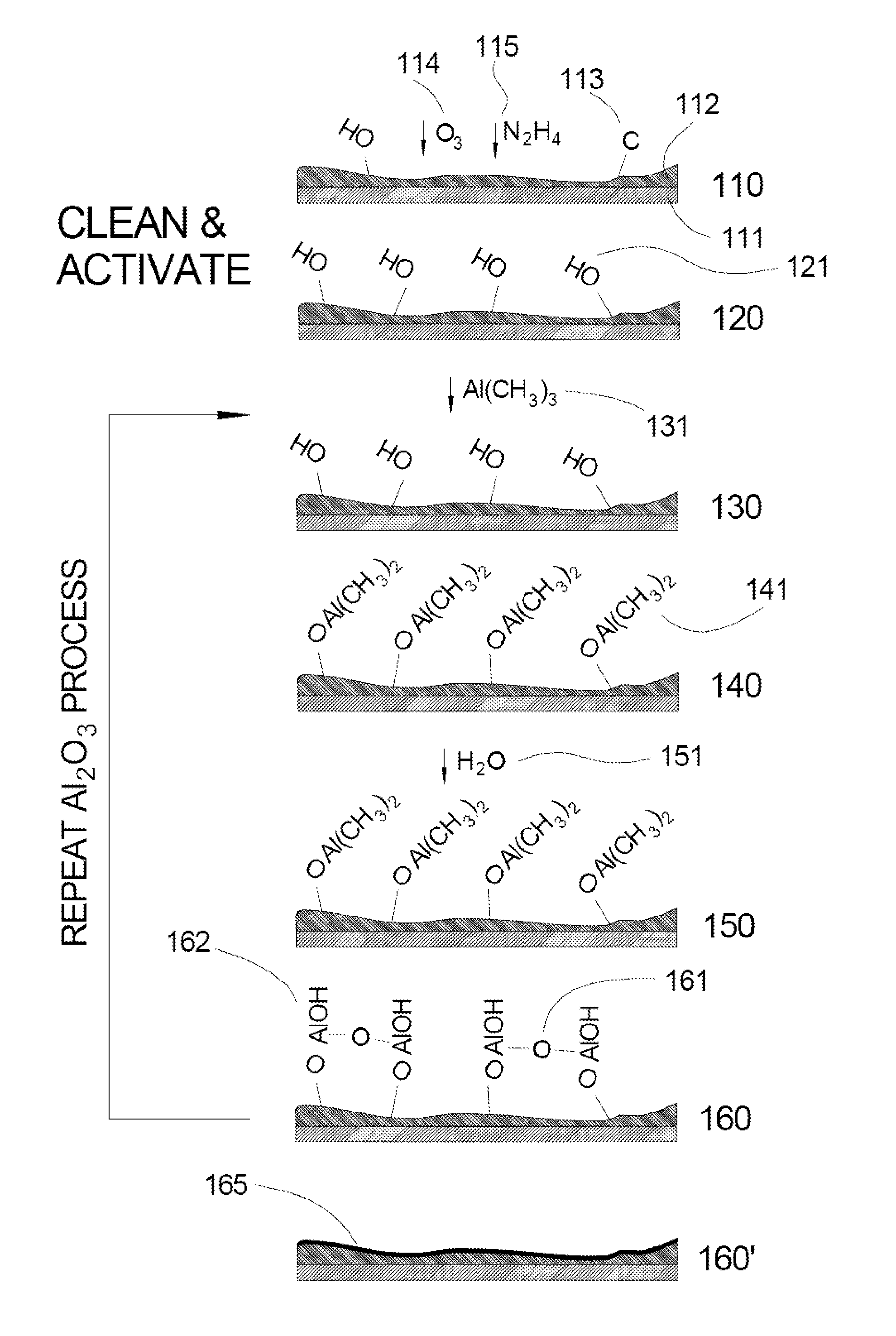

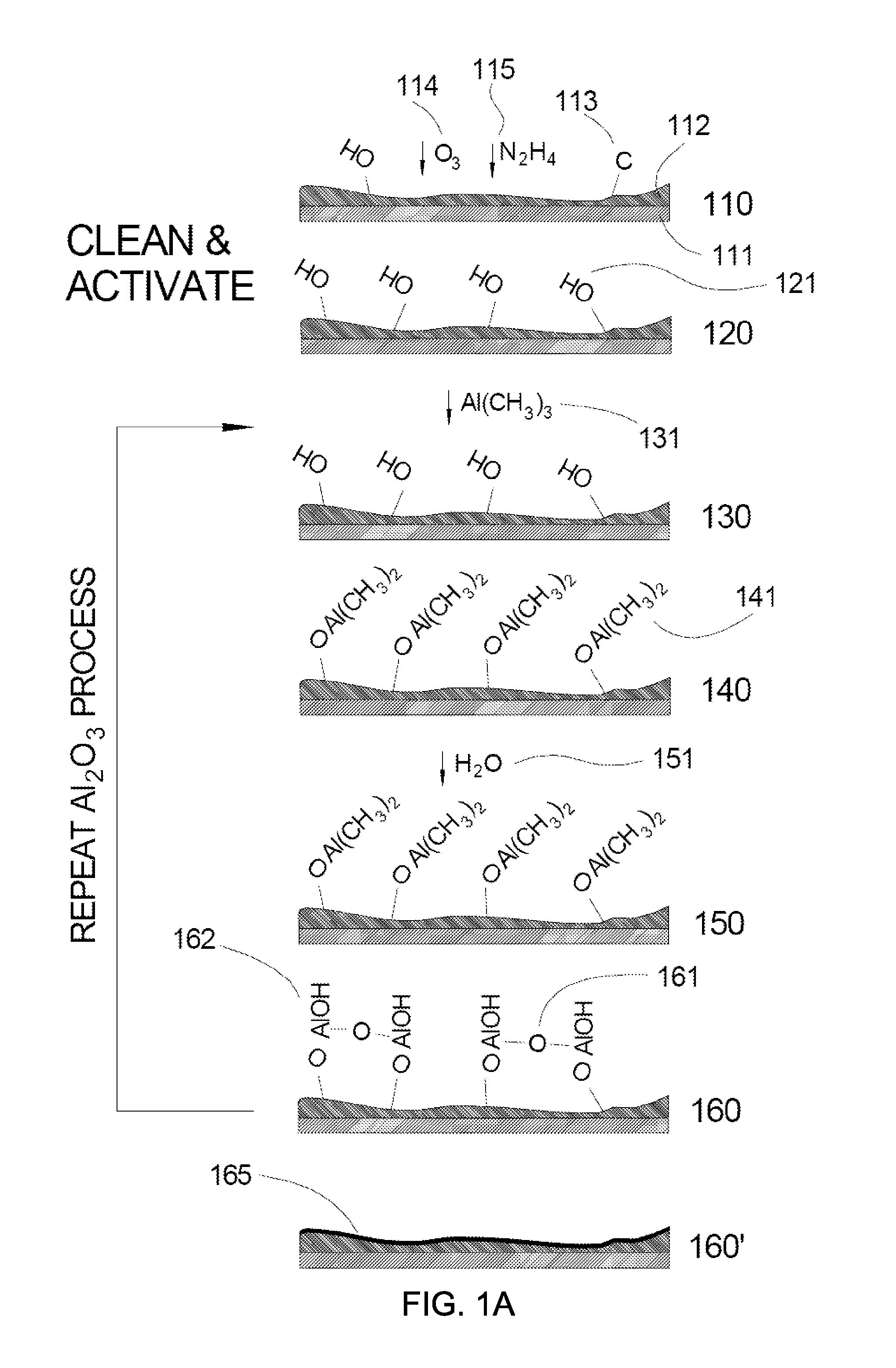

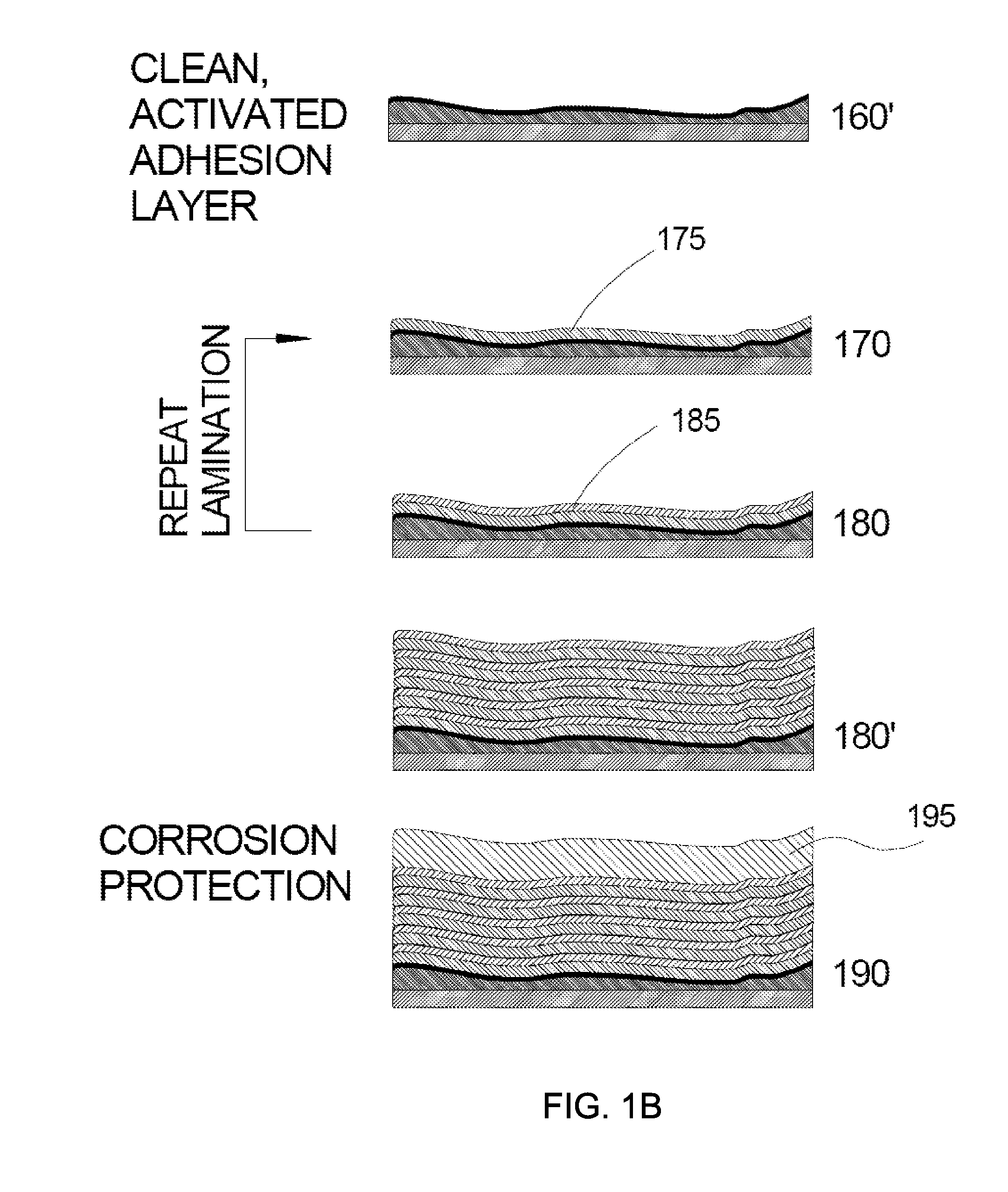

Coatings for suppressing metallic whiskers

PatentInactiveUS20110206909A1

Innovation

- The development of Whisker-Cap coatings (WCCs) that induce tensile stress on metallic features, comprising a laminate structure with an adhesion layer, alternating middle layers, and an outermost cap layer, deposited using atomic layer deposition (ALD), which creates sufficient tensile stress to suppress whisker growth and prevent tin pest phase transition.

Environmental Compliance and Sustainability Considerations

Environmental regulations and sustainability practices are increasingly shaping the conformal coating industry, particularly for applications in tropical conditions. Manufacturers must navigate a complex landscape of global and regional compliance requirements. The EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have significantly impacted coating formulations, driving the transition away from solvent-based coatings containing high levels of Volatile Organic Compounds (VOCs).

In tropical environments, where coating effectiveness is critical, compliance challenges are magnified. Traditional high-performance coatings often contained chemicals now restricted under various environmental protocols. This has necessitated reformulation while maintaining performance standards against humidity, fungal growth, and corrosion prevalent in tropical conditions.

Water-based and UV-curable conformal coatings represent the industry's response to sustainability demands. These alternatives offer reduced environmental impact while providing adequate protection in tropical settings. Recent testing protocols have demonstrated that some water-based formulations can achieve comparable performance to traditional solvent-based coatings when properly applied and cured, with humidity resistance ratings within 5-10% of conventional solutions.

Life Cycle Assessment (LCA) has become a standard practice for evaluating coating sustainability. Studies indicate that while eco-friendly coatings may require more frequent reapplication in extreme tropical conditions, their overall environmental footprint remains significantly lower. A comprehensive LCA conducted in 2022 showed that water-based acrylic coatings reduced carbon emissions by approximately 65% compared to traditional solvent-based alternatives when considering manufacturing, application, and disposal phases.

Waste management considerations are particularly relevant for tropical applications, where increased coating degradation may occur. Closed-loop recycling systems for coating application equipment and proper disposal protocols for removed coatings are becoming industry standards. Some manufacturers have implemented take-back programs for coating containers and waste materials, reducing environmental impact in sensitive tropical ecosystems.

Energy consumption during application and curing processes represents another sustainability consideration. Traditional heat-curing methods consume significant energy, whereas UV-curable coatings require less energy but specialized equipment. Recent innovations in ambient-cure formulations specifically designed for tropical conditions offer promising energy efficiency improvements while maintaining necessary protection levels.

The measurement of coating effectiveness must now incorporate sustainability metrics alongside traditional performance indicators. Standardized testing protocols are evolving to include environmental impact assessments, creating a more holistic evaluation framework for conformal coatings in tropical applications. This integrated approach ensures that protection against tropical conditions doesn't come at an unsustainable environmental cost.

In tropical environments, where coating effectiveness is critical, compliance challenges are magnified. Traditional high-performance coatings often contained chemicals now restricted under various environmental protocols. This has necessitated reformulation while maintaining performance standards against humidity, fungal growth, and corrosion prevalent in tropical conditions.

Water-based and UV-curable conformal coatings represent the industry's response to sustainability demands. These alternatives offer reduced environmental impact while providing adequate protection in tropical settings. Recent testing protocols have demonstrated that some water-based formulations can achieve comparable performance to traditional solvent-based coatings when properly applied and cured, with humidity resistance ratings within 5-10% of conventional solutions.

Life Cycle Assessment (LCA) has become a standard practice for evaluating coating sustainability. Studies indicate that while eco-friendly coatings may require more frequent reapplication in extreme tropical conditions, their overall environmental footprint remains significantly lower. A comprehensive LCA conducted in 2022 showed that water-based acrylic coatings reduced carbon emissions by approximately 65% compared to traditional solvent-based alternatives when considering manufacturing, application, and disposal phases.

Waste management considerations are particularly relevant for tropical applications, where increased coating degradation may occur. Closed-loop recycling systems for coating application equipment and proper disposal protocols for removed coatings are becoming industry standards. Some manufacturers have implemented take-back programs for coating containers and waste materials, reducing environmental impact in sensitive tropical ecosystems.

Energy consumption during application and curing processes represents another sustainability consideration. Traditional heat-curing methods consume significant energy, whereas UV-curable coatings require less energy but specialized equipment. Recent innovations in ambient-cure formulations specifically designed for tropical conditions offer promising energy efficiency improvements while maintaining necessary protection levels.

The measurement of coating effectiveness must now incorporate sustainability metrics alongside traditional performance indicators. Standardized testing protocols are evolving to include environmental impact assessments, creating a more holistic evaluation framework for conformal coatings in tropical applications. This integrated approach ensures that protection against tropical conditions doesn't come at an unsustainable environmental cost.

Cost-Benefit Analysis of Advanced Coating Technologies

When evaluating the economic viability of implementing advanced conformal coating technologies for tropical condition protection, a comprehensive cost-benefit analysis reveals significant considerations across multiple dimensions. Initial investment costs for advanced coating technologies such as nano-enhanced acrylics, parylene, and silicone-based solutions range from $3-15 per square inch depending on application complexity and volume requirements. These costs encompass specialized equipment acquisition, facility modifications for controlled application environments, and staff training.

Operational expenditures must account for ongoing material costs, maintenance of application equipment, quality control processes, and potential production line adjustments. Advanced coating technologies typically add 5-12% to unit production costs but can reduce field failure rates by 35-60% in tropical environments characterized by high humidity, temperature fluctuations, and biological contaminants.

The benefit side of the equation demonstrates compelling long-term advantages. Extended product lifespan in tropical conditions shows a 2.5-4x improvement compared to uncoated electronics, with advanced coatings outperforming standard options by approximately 40%. This translates directly to reduced warranty claims, with data from electronics manufacturers operating in Southeast Asian markets indicating a 45-70% decrease in moisture-related failures.

Customer satisfaction metrics reveal that products with advanced coatings maintain performance specifications 3-5 times longer in tropical environments, significantly enhancing brand reputation and customer loyalty. Market analysis indicates consumers in tropical regions are willing to pay a 15-25% premium for demonstrably resilient electronics.

Return on investment calculations suggest that despite higher initial costs, advanced coating technologies typically achieve break-even within 12-18 months in tropical market applications. The total cost of ownership over a five-year product lifecycle shows a 30-45% reduction compared to standard protection methods when accounting for reduced maintenance, fewer replacements, and decreased service calls.

Environmental considerations also factor into the cost-benefit equation, with newer coating technologies offering reduced VOC emissions and improved recyclability. Regulatory compliance costs are lower with advanced solutions that meet stringent environmental standards in emerging markets, avoiding potential penalties and market access restrictions that could impact revenue streams.

Operational expenditures must account for ongoing material costs, maintenance of application equipment, quality control processes, and potential production line adjustments. Advanced coating technologies typically add 5-12% to unit production costs but can reduce field failure rates by 35-60% in tropical environments characterized by high humidity, temperature fluctuations, and biological contaminants.

The benefit side of the equation demonstrates compelling long-term advantages. Extended product lifespan in tropical conditions shows a 2.5-4x improvement compared to uncoated electronics, with advanced coatings outperforming standard options by approximately 40%. This translates directly to reduced warranty claims, with data from electronics manufacturers operating in Southeast Asian markets indicating a 45-70% decrease in moisture-related failures.

Customer satisfaction metrics reveal that products with advanced coatings maintain performance specifications 3-5 times longer in tropical environments, significantly enhancing brand reputation and customer loyalty. Market analysis indicates consumers in tropical regions are willing to pay a 15-25% premium for demonstrably resilient electronics.

Return on investment calculations suggest that despite higher initial costs, advanced coating technologies typically achieve break-even within 12-18 months in tropical market applications. The total cost of ownership over a five-year product lifecycle shows a 30-45% reduction compared to standard protection methods when accounting for reduced maintenance, fewer replacements, and decreased service calls.

Environmental considerations also factor into the cost-benefit equation, with newer coating technologies offering reduced VOC emissions and improved recyclability. Regulatory compliance costs are lower with advanced solutions that meet stringent environmental standards in emerging markets, avoiding potential penalties and market access restrictions that could impact revenue streams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!