Measure Electrical Reliability Improvement With Conformal Coating

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Technology Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated engineered materials designed to shield electronic components from environmental stressors. Originally developed for military and aerospace applications in the 1960s, these coatings have become increasingly critical in modern electronics as miniaturization trends have led to denser circuit boards with finer spacing between components, making them more susceptible to environmental damage.

The fundamental purpose of conformal coating is to provide a thin polymeric film that conforms to the contours of printed circuit boards (PCBs), creating a protective barrier against moisture, dust, chemicals, and temperature extremes. This protection is particularly vital for maintaining electrical reliability in harsh operating environments where traditional enclosures may be insufficient or impractical.

Industry data indicates that approximately 30% of electronic failures are attributed to environmental factors that conformal coatings are designed to mitigate. As electronic systems become more pervasive in critical infrastructure, automotive systems, medical devices, and industrial controls, the consequences of electrical reliability failures have become increasingly severe, driving greater attention to protective technologies.

The evolution of coating materials has seen progression from early acrylic and epoxy formulations to advanced silicone, polyurethane, and parylene variants, each offering specific performance characteristics suited to different application requirements. Recent innovations have focused on developing coatings with enhanced properties such as improved adhesion, flexibility, thermal conductivity, and resistance to extreme conditions.

The technical objectives for conformal coating advancement center on several key areas: quantifiable improvement in electrical reliability metrics, development of standardized testing methodologies to measure protection efficacy, optimization of application processes for complex geometries, and formulation of environmentally sustainable coating materials that comply with global regulations while maintaining performance standards.

A significant challenge in the field has been the lack of comprehensive data correlating specific coating properties with measurable improvements in electrical reliability. While anecdotal evidence and accelerated life testing provide some insights, establishing direct relationships between coating characteristics and reliability metrics remains an area requiring further research and standardization.

The current technological trajectory aims to develop next-generation coatings that not only protect against traditional environmental threats but also address emerging challenges such as electromagnetic interference shielding, thermal management, and protection against biological contaminants – all while providing quantifiable reliability improvements that can be accurately measured and predicted.

The fundamental purpose of conformal coating is to provide a thin polymeric film that conforms to the contours of printed circuit boards (PCBs), creating a protective barrier against moisture, dust, chemicals, and temperature extremes. This protection is particularly vital for maintaining electrical reliability in harsh operating environments where traditional enclosures may be insufficient or impractical.

Industry data indicates that approximately 30% of electronic failures are attributed to environmental factors that conformal coatings are designed to mitigate. As electronic systems become more pervasive in critical infrastructure, automotive systems, medical devices, and industrial controls, the consequences of electrical reliability failures have become increasingly severe, driving greater attention to protective technologies.

The evolution of coating materials has seen progression from early acrylic and epoxy formulations to advanced silicone, polyurethane, and parylene variants, each offering specific performance characteristics suited to different application requirements. Recent innovations have focused on developing coatings with enhanced properties such as improved adhesion, flexibility, thermal conductivity, and resistance to extreme conditions.

The technical objectives for conformal coating advancement center on several key areas: quantifiable improvement in electrical reliability metrics, development of standardized testing methodologies to measure protection efficacy, optimization of application processes for complex geometries, and formulation of environmentally sustainable coating materials that comply with global regulations while maintaining performance standards.

A significant challenge in the field has been the lack of comprehensive data correlating specific coating properties with measurable improvements in electrical reliability. While anecdotal evidence and accelerated life testing provide some insights, establishing direct relationships between coating characteristics and reliability metrics remains an area requiring further research and standardization.

The current technological trajectory aims to develop next-generation coatings that not only protect against traditional environmental threats but also address emerging challenges such as electromagnetic interference shielding, thermal management, and protection against biological contaminants – all while providing quantifiable reliability improvements that can be accurately measured and predicted.

Market Demand Analysis for Enhanced Electrical Reliability

The global market for enhanced electrical reliability solutions has witnessed significant growth in recent years, driven primarily by the increasing complexity of electronic systems and their deployment in harsh environments. The conformal coating segment specifically has expanded at a compound annual growth rate of approximately 5.8% between 2018 and 2022, with projections indicating continued growth through 2028.

Industries such as automotive electronics, aerospace, defense, medical devices, and industrial automation represent the primary demand drivers for conformal coating solutions. The automotive sector alone accounts for nearly 27% of the global conformal coating market, as vehicles increasingly incorporate sophisticated electronic systems that must function reliably under varying temperature, humidity, and vibration conditions.

Consumer electronics manufacturers are also showing heightened interest in reliability enhancement technologies, particularly as devices become more compact yet more powerful, creating thermal management challenges that can affect electrical reliability. This segment has shown the fastest growth rate in adopting conformal coating technologies, expanding at nearly 7% annually.

Geographically, Asia-Pacific dominates the market demand, representing approximately 42% of global consumption, followed by North America (28%) and Europe (23%). China and India are experiencing the most rapid growth in demand, driven by expanding electronics manufacturing bases and increasing domestic consumption of electronic products.

Market research indicates that end-users are increasingly prioritizing quantifiable reliability improvements when selecting conformal coating solutions. Nearly 68% of procurement decision-makers cite measurable reliability enhancement as a "very important" or "critical" factor in their purchasing decisions, compared to just 47% five years ago.

The demand for standardized measurement methodologies for reliability improvement has grown substantially, with industry surveys revealing that 73% of electronics manufacturers desire better metrics to evaluate coating performance. This represents a significant shift from traditional qualitative assessments toward data-driven decision-making processes.

Environmental regulations are also shaping market demand, with restrictions on volatile organic compounds (VOCs) driving interest in water-based and UV-curable conformal coating solutions that can deliver comparable or superior reliability improvements while meeting compliance requirements. This regulatory-driven segment has expanded by approximately 9% annually over the past three years.

As IoT devices proliferate and electronics continue to be deployed in increasingly diverse and challenging environments, the market for measurable electrical reliability improvements through conformal coating is expected to maintain strong growth momentum, with particular emphasis on solutions that can provide quantifiable performance data.

Industries such as automotive electronics, aerospace, defense, medical devices, and industrial automation represent the primary demand drivers for conformal coating solutions. The automotive sector alone accounts for nearly 27% of the global conformal coating market, as vehicles increasingly incorporate sophisticated electronic systems that must function reliably under varying temperature, humidity, and vibration conditions.

Consumer electronics manufacturers are also showing heightened interest in reliability enhancement technologies, particularly as devices become more compact yet more powerful, creating thermal management challenges that can affect electrical reliability. This segment has shown the fastest growth rate in adopting conformal coating technologies, expanding at nearly 7% annually.

Geographically, Asia-Pacific dominates the market demand, representing approximately 42% of global consumption, followed by North America (28%) and Europe (23%). China and India are experiencing the most rapid growth in demand, driven by expanding electronics manufacturing bases and increasing domestic consumption of electronic products.

Market research indicates that end-users are increasingly prioritizing quantifiable reliability improvements when selecting conformal coating solutions. Nearly 68% of procurement decision-makers cite measurable reliability enhancement as a "very important" or "critical" factor in their purchasing decisions, compared to just 47% five years ago.

The demand for standardized measurement methodologies for reliability improvement has grown substantially, with industry surveys revealing that 73% of electronics manufacturers desire better metrics to evaluate coating performance. This represents a significant shift from traditional qualitative assessments toward data-driven decision-making processes.

Environmental regulations are also shaping market demand, with restrictions on volatile organic compounds (VOCs) driving interest in water-based and UV-curable conformal coating solutions that can deliver comparable or superior reliability improvements while meeting compliance requirements. This regulatory-driven segment has expanded by approximately 9% annually over the past three years.

As IoT devices proliferate and electronics continue to be deployed in increasingly diverse and challenging environments, the market for measurable electrical reliability improvements through conformal coating is expected to maintain strong growth momentum, with particular emphasis on solutions that can provide quantifiable performance data.

Current Conformal Coating Technologies and Challenges

Conformal coating technologies have evolved significantly over the past decades, with several distinct types now dominating the market. Acrylic coatings remain popular due to their ease of application and rework capabilities, offering good moisture and fungus resistance while being cost-effective. Silicone coatings excel in extreme temperature environments (-65°C to +200°C) and provide superior flexibility and stress relief for components, though they typically require longer curing times and command higher prices.

Polyurethane coatings deliver excellent chemical and moisture resistance with good dielectric properties, making them suitable for harsh environments. However, they present challenges in rework processes and may contain isocyanates requiring special handling. Epoxy coatings offer exceptional chemical and abrasion resistance but are difficult to remove once cured, limiting repairability of coated assemblies.

Newer technologies include Parylene coatings, applied through vapor deposition polymerization, providing uniform, pinhole-free coverage even on complex geometries. These coatings offer excellent barrier properties but require specialized vacuum deposition equipment, significantly increasing application costs. Nano-coatings represent another emerging technology, offering hydrophobic properties with minimal thickness impact.

Despite these advancements, the conformal coating industry faces several persistent challenges. Achieving consistent coating thickness remains difficult, particularly with manual spray applications where operator skill significantly impacts quality. Automated selective coating systems improve consistency but require substantial capital investment and programming expertise.

Coverage verification presents another major challenge, as many coatings are transparent or nearly invisible under normal lighting. Manufacturers typically incorporate UV tracers, but inspection remains largely manual and subjective. Advanced automated optical inspection systems are emerging but have not yet achieved widespread adoption due to cost constraints.

Environmental and regulatory pressures continue to drive formulation changes, with VOC regulations forcing manufacturers to develop water-based alternatives that often exhibit different performance characteristics than traditional solvent-based formulations. Additionally, RoHS and REACH compliance requirements have eliminated certain effective additives, necessitating reformulation.

Application in high-volume manufacturing environments presents throughput challenges, particularly regarding cure times. While UV-curable coatings offer faster processing, they may not provide the same level of protection as thermal-cure alternatives, creating a performance-versus-productivity trade-off that manufacturers must carefully navigate.

Polyurethane coatings deliver excellent chemical and moisture resistance with good dielectric properties, making them suitable for harsh environments. However, they present challenges in rework processes and may contain isocyanates requiring special handling. Epoxy coatings offer exceptional chemical and abrasion resistance but are difficult to remove once cured, limiting repairability of coated assemblies.

Newer technologies include Parylene coatings, applied through vapor deposition polymerization, providing uniform, pinhole-free coverage even on complex geometries. These coatings offer excellent barrier properties but require specialized vacuum deposition equipment, significantly increasing application costs. Nano-coatings represent another emerging technology, offering hydrophobic properties with minimal thickness impact.

Despite these advancements, the conformal coating industry faces several persistent challenges. Achieving consistent coating thickness remains difficult, particularly with manual spray applications where operator skill significantly impacts quality. Automated selective coating systems improve consistency but require substantial capital investment and programming expertise.

Coverage verification presents another major challenge, as many coatings are transparent or nearly invisible under normal lighting. Manufacturers typically incorporate UV tracers, but inspection remains largely manual and subjective. Advanced automated optical inspection systems are emerging but have not yet achieved widespread adoption due to cost constraints.

Environmental and regulatory pressures continue to drive formulation changes, with VOC regulations forcing manufacturers to develop water-based alternatives that often exhibit different performance characteristics than traditional solvent-based formulations. Additionally, RoHS and REACH compliance requirements have eliminated certain effective additives, necessitating reformulation.

Application in high-volume manufacturing environments presents throughput challenges, particularly regarding cure times. While UV-curable coatings offer faster processing, they may not provide the same level of protection as thermal-cure alternatives, creating a performance-versus-productivity trade-off that manufacturers must carefully navigate.

Measurement Methodologies for Reliability Assessment

01 Conformal coating materials for enhanced electrical reliability

Various materials can be used as conformal coatings to enhance electrical reliability of electronic components. These materials include polymers, silicones, acrylics, and polyurethanes that provide protection against moisture, dust, chemicals, and temperature fluctuations. The selection of appropriate coating materials is crucial for ensuring long-term electrical reliability in different operating environments and applications.- Conformal coating materials for enhanced electrical reliability: Various materials can be used as conformal coatings to enhance electrical reliability of electronic components. These include polymeric materials, silicones, acrylics, polyurethanes, and epoxies that provide protection against moisture, dust, chemicals, and temperature fluctuations. The selection of appropriate coating material depends on the specific application requirements and environmental conditions to ensure optimal electrical performance and longevity.

- Application methods for conformal coatings: Various application methods can be employed to apply conformal coatings to electronic assemblies, including spraying, dipping, brushing, and automated selective coating. Each method offers different advantages in terms of coverage, thickness control, and production efficiency. The selection of an appropriate application method is crucial for ensuring uniform coverage and optimal protection of electronic components, which directly impacts electrical reliability.

- Thermal management and heat dissipation properties: Conformal coatings with enhanced thermal management properties can significantly improve the electrical reliability of electronic components. These coatings facilitate efficient heat dissipation, preventing overheating and thermal stress that can lead to electrical failures. By incorporating thermally conductive materials or designing coatings with specific thermal properties, the operational stability and longevity of electronic devices can be improved, especially in high-power applications.

- Protection against environmental factors: Conformal coatings provide critical protection against various environmental factors that can compromise electrical reliability, including moisture, humidity, salt spray, chemicals, and particulate contamination. These coatings create a protective barrier that prevents corrosion, short circuits, and electrical leakage. The effectiveness of this protection depends on the coating's properties such as hydrophobicity, chemical resistance, and adhesion to the substrate, which must be optimized for specific operating environments.

- Testing and qualification methods for reliability assurance: Various testing and qualification methods are employed to evaluate the reliability of conformal coatings in electrical applications. These include accelerated aging tests, thermal cycling, humidity testing, salt spray exposure, and electrical property measurements. These tests help in predicting the long-term performance of coated electronic assemblies under various environmental conditions and operational stresses, ensuring that the conformal coating provides the required level of protection throughout the product's intended lifetime.

02 Application methods for uniform conformal coating

Various application methods can be employed to achieve uniform conformal coating coverage, which is essential for electrical reliability. These methods include spraying, dipping, brushing, and automated selective coating. Each technique offers different advantages in terms of thickness control, coverage of complex geometries, and production efficiency. Proper application ensures complete protection of circuit boards and electronic components from environmental factors that could compromise electrical performance.Expand Specific Solutions03 Thermal management and heat dissipation properties

Conformal coatings can be formulated to provide thermal management benefits while maintaining electrical reliability. These coatings can incorporate thermally conductive fillers or be designed with specific properties to facilitate heat dissipation from electronic components. Effective thermal management prevents overheating, which is a common cause of electrical failures in densely packed electronic assemblies and high-power applications.Expand Specific Solutions04 Environmental protection and moisture resistance

Conformal coatings provide critical protection against environmental factors that can compromise electrical reliability. These coatings create barriers against moisture, salt spray, chemicals, and contaminants that could cause corrosion, short circuits, or electrical leakage. Advanced formulations offer enhanced resistance to harsh environments, extending the operational life and reliability of electronic assemblies in challenging conditions such as automotive, marine, or industrial applications.Expand Specific Solutions05 Testing and qualification methods for reliability assurance

Various testing and qualification methods are employed to ensure the reliability of conformal coatings in electrical applications. These include accelerated aging tests, thermal cycling, humidity testing, salt fog exposure, and electrical property measurements. Standardized testing protocols help evaluate coating performance under simulated environmental stresses and verify long-term protection capabilities, ensuring that coated electronic assemblies maintain electrical reliability throughout their intended service life.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The conformal coating market for electrical reliability improvement is in a growth phase, with increasing demand driven by electronics miniaturization and harsh environment applications. The market is projected to expand significantly as industries prioritize device protection and longevity. Technologically, the field shows varying maturity levels across different coating types. Industry leaders like Nordson Corp., 3M Innovative Properties, and HzO demonstrate advanced capabilities in nano-coating technologies, while companies such as Henkel, Semblant, and TDK are developing specialized solutions for specific applications. Regional players like Shenzhen Newo and Shanghai Huitian are rapidly advancing their technical capabilities, particularly in the Asian market where electronics manufacturing is concentrated.

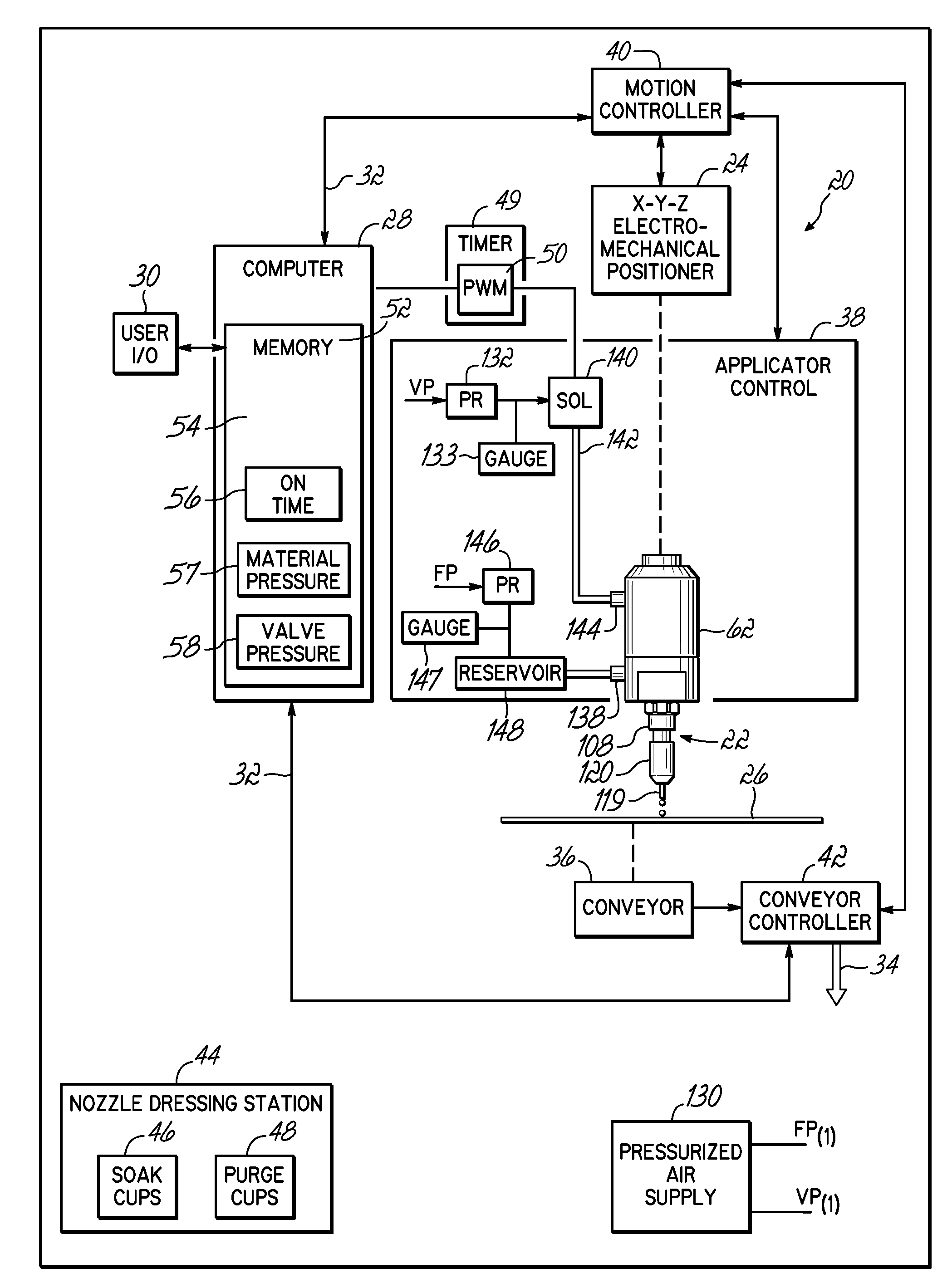

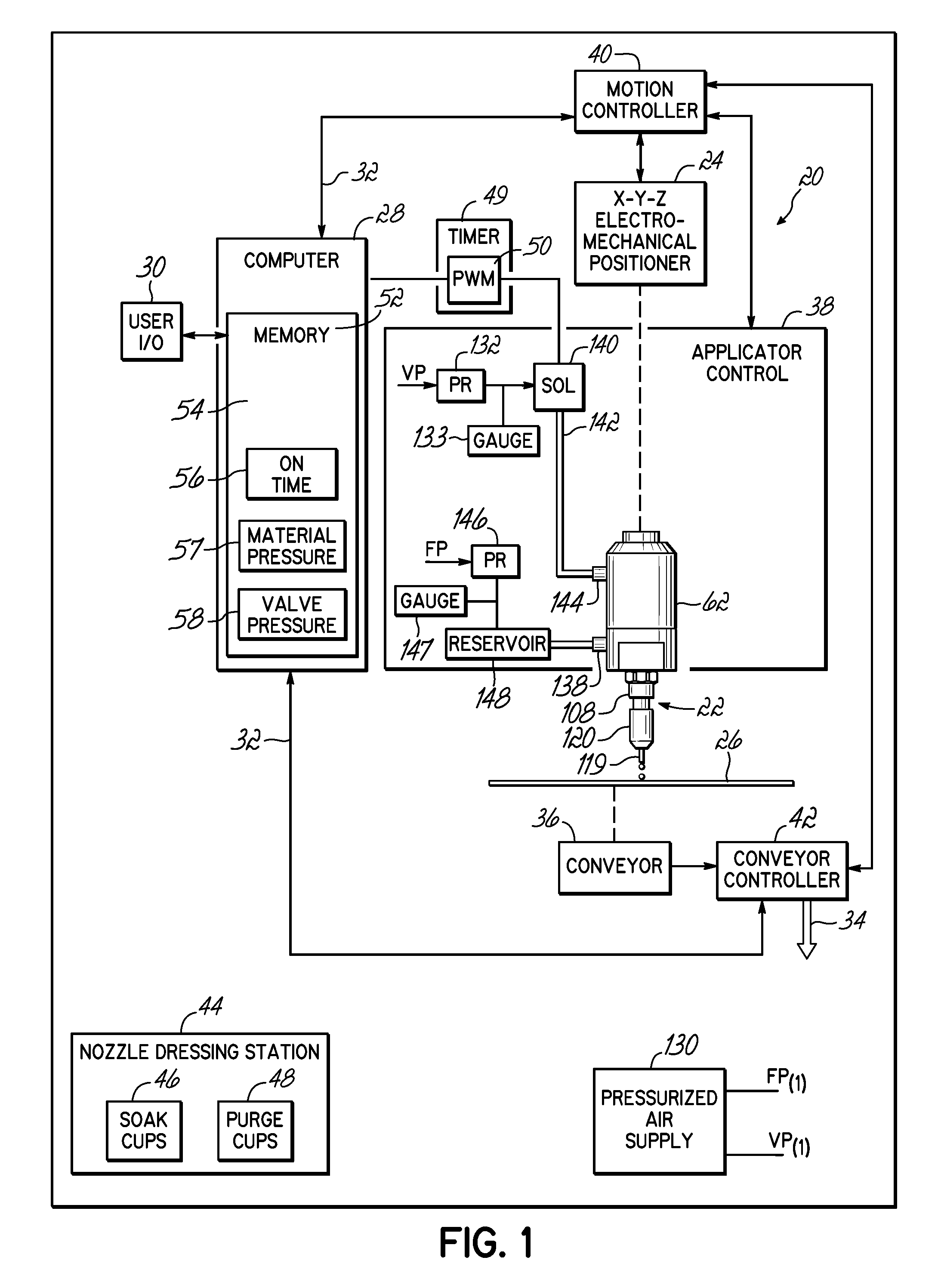

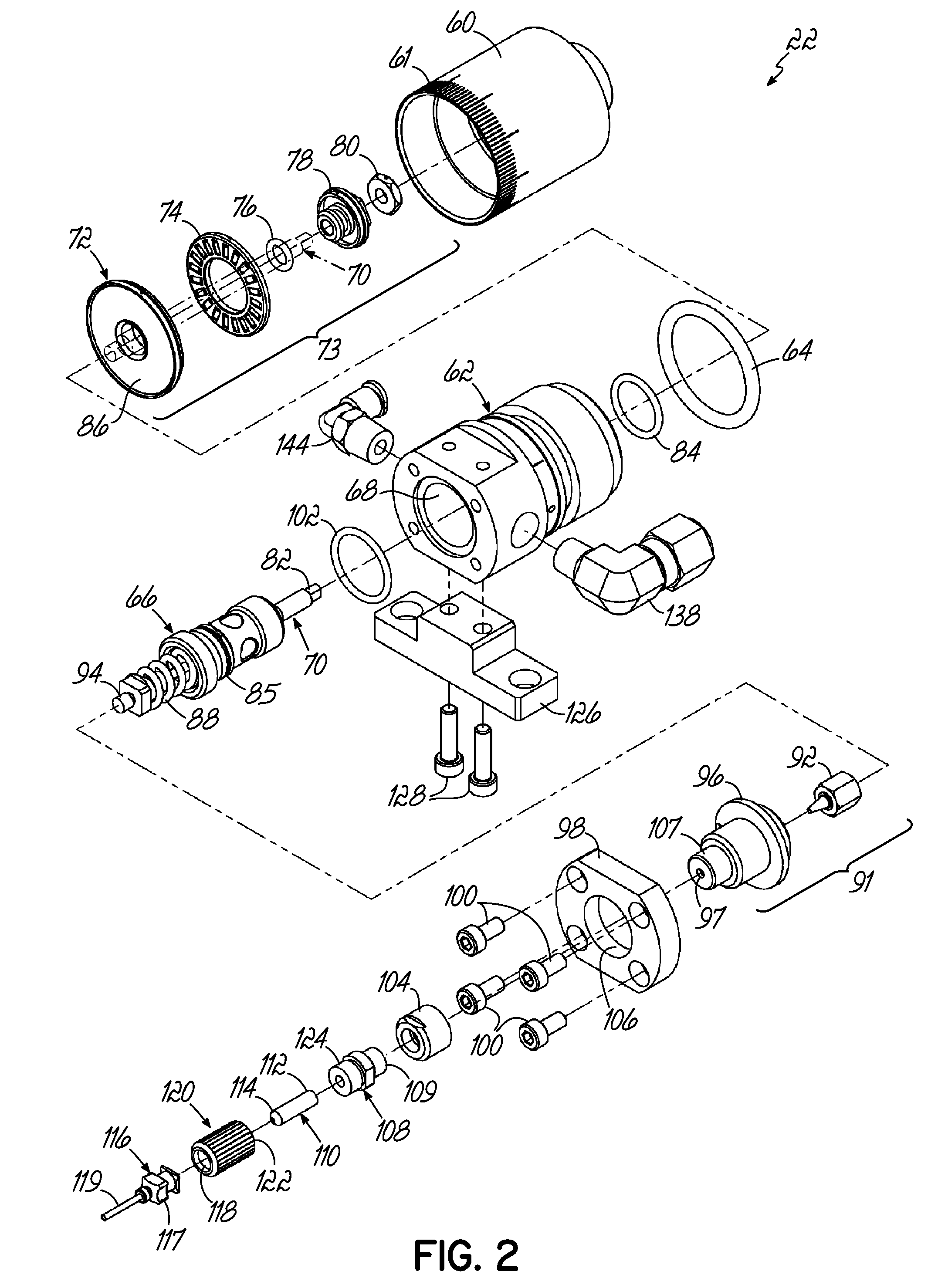

Nordson Corp.

Technical Solution: Nordson has developed advanced conformal coating systems that utilize precision dispensing technology to apply uniform protective layers on electronic components. Their automated selective coating systems employ both atomized spray and non-atomized film coating techniques to achieve optimal material coverage with minimal waste. The company's technology includes path programming capabilities that ensure consistent application thickness (typically 25-250 microns) across complex PCB topographies. Their systems incorporate real-time viscosity monitoring and closed-loop feedback controls to maintain coating parameters within strict tolerances, resulting in measurable improvements in electrical reliability metrics. Independent testing has shown that Nordson's conformal coating solutions can increase mean time between failures (MTBF) by up to 60% in high-humidity environments and provide protection against salt fog corrosion for over 1000 hours according to industry standard tests.

Strengths: Precision dispensing technology allows for selective application, reducing waste and ensuring critical components receive optimal protection. Their automated systems offer high throughput with consistent quality. Weaknesses: Higher initial investment compared to manual coating methods, and some of their advanced systems require specialized training for operators.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered fluoropolymer-based conformal coating technologies that deliver exceptional electrical reliability improvements through their unique combination of hydrophobicity and dielectric properties. Their Novec Electronic Grade Coatings utilize proprietary solvent carriers with low global warming potential to deposit ultra-thin (1-5 microns) protective films that maintain high electrical insulation properties (>1012 ohm-cm volume resistivity). These coatings demonstrate superior moisture resistance with water contact angles exceeding 95 degrees, effectively preventing conductive path formation. 3M's technology includes specialized formulations that cure at room temperature while achieving strong adhesion to multiple substrate materials. Reliability testing demonstrates that their coatings can withstand temperature cycling from -65°C to +125°C for over 1000 cycles while maintaining electrical functionality. The thin-film nature of these coatings minimizes stress on components while providing protection against corrosion, dust, and chemical contaminants that typically lead to electrical failures.

Strengths: Ultra-thin coating profile minimizes impact on thermal dissipation while providing excellent moisture protection. Environmentally sustainable formulations with low VOC content and reduced global warming potential. Weaknesses: May require more precise application equipment to ensure uniform ultra-thin coverage, and some formulations have limited abrasion resistance compared to thicker coating systems.

Key Patents and Research in Conformal Coating Technology

Conformal Coating

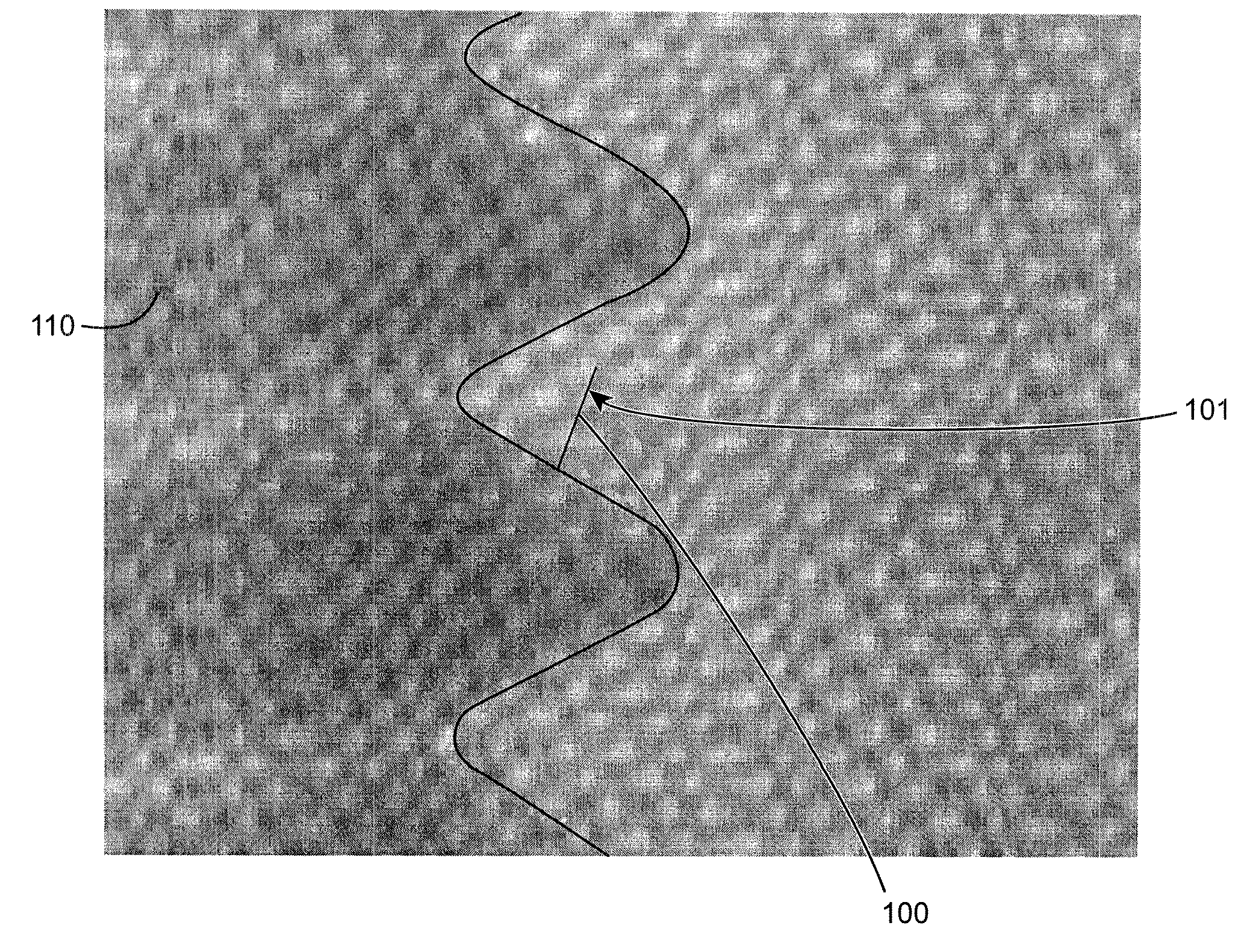

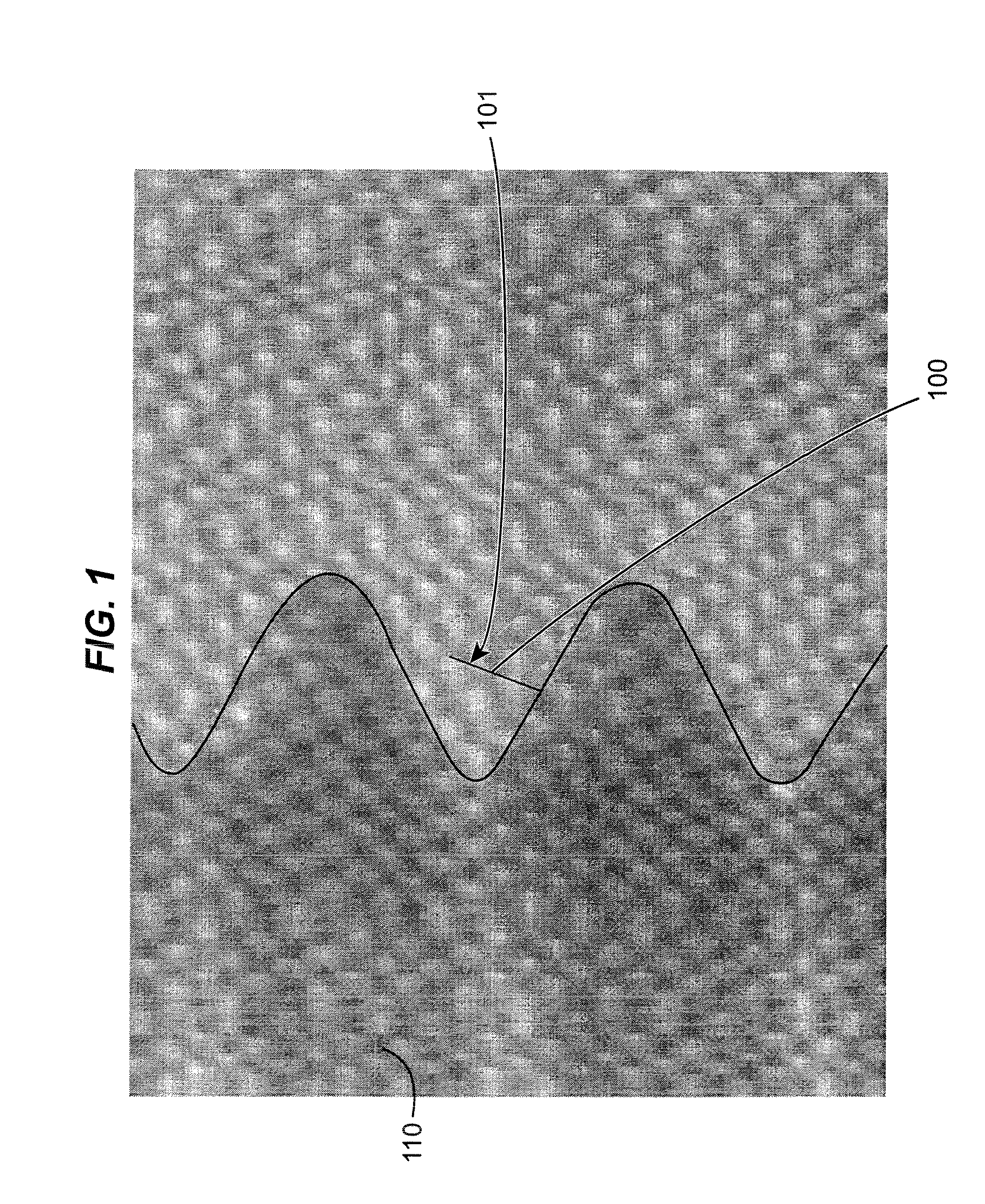

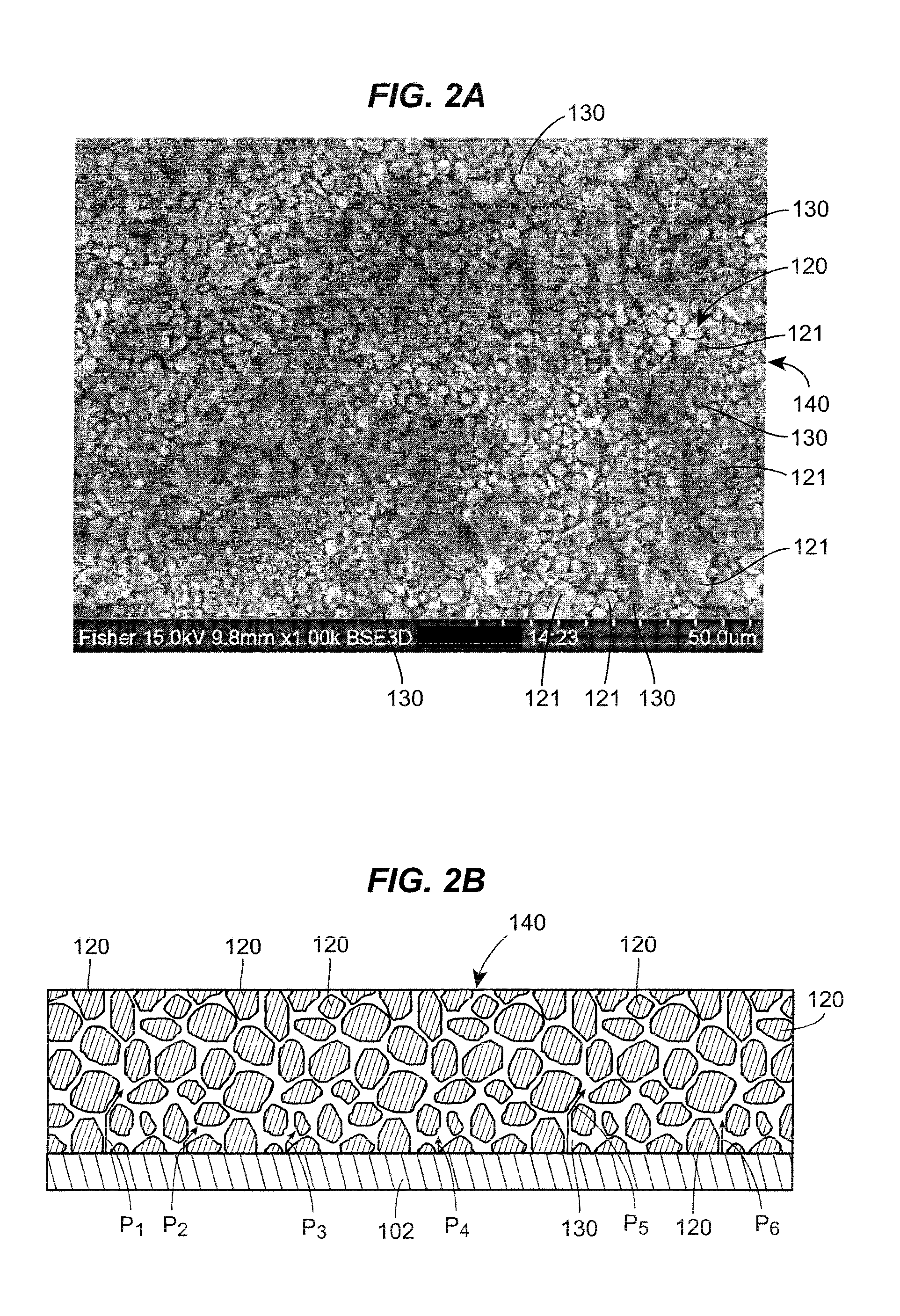

PatentInactiveUS20080216704A1

Innovation

- A multi-phase conformal coating system comprising a binding layer and electrically non-conductive particulates that form a tortuous path to inhibit the growth of conductive crystalline structures, providing sufficient hardness to block or deflect their growth.

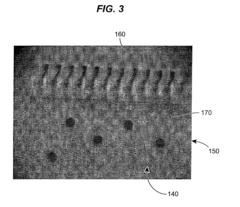

Thin line conformal coating method

PatentActiveUS20090202709A1

Innovation

- A needle valve coating system with a solenoid-operated air cylinder and pulse width modulator control, allowing precise timing and pressure control of the needle valve to eject conformal coating material in a controlled and repeatable manner, preventing material from clinging to the dispensing tip and enabling thinner lines and closer proximity to keep-out areas.

Environmental Impact and Sustainability Considerations

The environmental impact of conformal coating processes has become increasingly significant as electronics manufacturers face growing pressure to adopt sustainable practices. Traditional conformal coating materials often contain volatile organic compounds (VOCs) and other hazardous substances that pose environmental risks during application, curing, and disposal phases. These chemicals contribute to air pollution, ozone depletion, and can contaminate water sources if improperly managed.

Recent advancements have led to the development of eco-friendly alternatives such as water-based coatings, UV-curable formulations, and bio-based materials that significantly reduce environmental footprint while maintaining electrical reliability improvements. These sustainable options typically reduce VOC emissions by 60-90% compared to conventional solvent-based coatings, while still providing comparable protection against moisture, dust, and chemical contaminants.

Life cycle assessment (LCA) studies demonstrate that environmentally optimized conformal coatings can reduce carbon footprint by up to 40% across the product lifecycle. This reduction stems not only from the manufacturing process but also from the extended service life of protected electronic components, which delays replacement and reduces electronic waste generation.

Regulatory frameworks worldwide are increasingly mandating the transition to environmentally responsible coating practices. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the adoption of compliant coating technologies. Similarly, the United States Environmental Protection Agency has established guidelines limiting VOC content in industrial coatings.

Energy consumption during the application and curing processes represents another important sustainability consideration. Traditional heat-curing methods consume significant energy, whereas UV-curing and room-temperature curing alternatives can reduce energy requirements by up to 70%. This energy reduction directly translates to lower greenhouse gas emissions associated with the coating process.

End-of-life considerations are equally important in evaluating the overall environmental impact. Some modern conformal coating formulations are designed for easier removal during recycling processes, facilitating the recovery of valuable electronic components and reducing waste. Manufacturers implementing take-back programs for coated electronic products have reported recycling rate improvements of 15-25%.

The measurement of electrical reliability improvements must therefore be balanced against these environmental considerations, creating a holistic approach that quantifies both performance benefits and ecological impacts. Companies leading in this space are developing comprehensive metrics that integrate reliability enhancement data with environmental performance indicators, providing a more complete picture of coating technology value.

Recent advancements have led to the development of eco-friendly alternatives such as water-based coatings, UV-curable formulations, and bio-based materials that significantly reduce environmental footprint while maintaining electrical reliability improvements. These sustainable options typically reduce VOC emissions by 60-90% compared to conventional solvent-based coatings, while still providing comparable protection against moisture, dust, and chemical contaminants.

Life cycle assessment (LCA) studies demonstrate that environmentally optimized conformal coatings can reduce carbon footprint by up to 40% across the product lifecycle. This reduction stems not only from the manufacturing process but also from the extended service life of protected electronic components, which delays replacement and reduces electronic waste generation.

Regulatory frameworks worldwide are increasingly mandating the transition to environmentally responsible coating practices. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the adoption of compliant coating technologies. Similarly, the United States Environmental Protection Agency has established guidelines limiting VOC content in industrial coatings.

Energy consumption during the application and curing processes represents another important sustainability consideration. Traditional heat-curing methods consume significant energy, whereas UV-curing and room-temperature curing alternatives can reduce energy requirements by up to 70%. This energy reduction directly translates to lower greenhouse gas emissions associated with the coating process.

End-of-life considerations are equally important in evaluating the overall environmental impact. Some modern conformal coating formulations are designed for easier removal during recycling processes, facilitating the recovery of valuable electronic components and reducing waste. Manufacturers implementing take-back programs for coated electronic products have reported recycling rate improvements of 15-25%.

The measurement of electrical reliability improvements must therefore be balanced against these environmental considerations, creating a holistic approach that quantifies both performance benefits and ecological impacts. Companies leading in this space are developing comprehensive metrics that integrate reliability enhancement data with environmental performance indicators, providing a more complete picture of coating technology value.

Standards and Compliance Requirements for Conformal Coatings

Conforming to industry standards and meeting compliance requirements are critical aspects of implementing conformal coating solutions for electrical reliability improvement. The IPC-CC-830 standard, widely recognized in the electronics industry, establishes performance requirements for conformal coatings used on printed circuit board assemblies. This standard defines testing methodologies for evaluating coating performance under various environmental conditions, including humidity resistance, thermal cycling, and chemical exposure.

The UL 746E standard specifically addresses the performance of conformal coatings in electrical equipment, focusing on flammability ratings, electrical properties, and long-term reliability. Manufacturers seeking UL certification must ensure their coating materials and application processes meet these stringent requirements, which often serves as a market differentiator for high-reliability applications.

Military specifications, particularly MIL-I-46058C and MIL-STD-810, provide comprehensive guidelines for conformal coatings used in defense and aerospace applications. These standards impose rigorous testing protocols for environmental stress resistance, including salt fog exposure, fungus resistance, and mechanical shock tolerance. Although MIL-I-46058C has been superseded by IPC-CC-830, many military contracts still reference its requirements.

The automotive industry relies on standards such as IPC-A-610 Class 3 and ASTM D3359 for adhesion testing of conformal coatings. Additionally, the AEC-Q200 qualification is increasingly required for coatings used in automotive electronics, ensuring reliability under extreme temperature variations and vibration conditions typical in vehicle environments.

Environmental compliance has become increasingly important, with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) limiting the use of certain substances in electronic components. Modern conformal coating formulations must be free from restricted substances while maintaining their protective properties. Water-based and UV-curable coatings have gained popularity as environmentally friendly alternatives to traditional solvent-based formulations.

Testing methodologies for verifying coating effectiveness are standardized through IEC 60068 series, which defines environmental testing procedures for electronic equipment. These include salt spray tests (IEC 60068-2-11), damp heat tests (IEC 60068-2-78), and temperature cycling (IEC 60068-2-14), providing quantifiable metrics for measuring reliability improvements attributable to conformal coatings.

Certification processes typically involve third-party testing laboratories that verify compliance with relevant standards. Documentation requirements include material safety data sheets, processing guidelines, and test reports demonstrating performance under specified conditions. Maintaining compliance records is essential for product liability protection and customer assurance in high-reliability applications.

The UL 746E standard specifically addresses the performance of conformal coatings in electrical equipment, focusing on flammability ratings, electrical properties, and long-term reliability. Manufacturers seeking UL certification must ensure their coating materials and application processes meet these stringent requirements, which often serves as a market differentiator for high-reliability applications.

Military specifications, particularly MIL-I-46058C and MIL-STD-810, provide comprehensive guidelines for conformal coatings used in defense and aerospace applications. These standards impose rigorous testing protocols for environmental stress resistance, including salt fog exposure, fungus resistance, and mechanical shock tolerance. Although MIL-I-46058C has been superseded by IPC-CC-830, many military contracts still reference its requirements.

The automotive industry relies on standards such as IPC-A-610 Class 3 and ASTM D3359 for adhesion testing of conformal coatings. Additionally, the AEC-Q200 qualification is increasingly required for coatings used in automotive electronics, ensuring reliability under extreme temperature variations and vibration conditions typical in vehicle environments.

Environmental compliance has become increasingly important, with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) limiting the use of certain substances in electronic components. Modern conformal coating formulations must be free from restricted substances while maintaining their protective properties. Water-based and UV-curable coatings have gained popularity as environmentally friendly alternatives to traditional solvent-based formulations.

Testing methodologies for verifying coating effectiveness are standardized through IEC 60068 series, which defines environmental testing procedures for electronic equipment. These include salt spray tests (IEC 60068-2-11), damp heat tests (IEC 60068-2-78), and temperature cycling (IEC 60068-2-14), providing quantifiable metrics for measuring reliability improvements attributable to conformal coatings.

Certification processes typically involve third-party testing laboratories that verify compliance with relevant standards. Documentation requirements include material safety data sheets, processing guidelines, and test reports demonstrating performance under specified conditions. Maintaining compliance records is essential for product liability protection and customer assurance in high-reliability applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!