Microstructure control for efficient ion migration

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microstructure Control Background and Objectives

Microstructure control for efficient ion migration has emerged as a critical frontier in materials science and electrochemistry over the past three decades. The evolution of this field traces back to the 1990s when researchers first recognized the profound impact of material microstructure on ionic conductivity in solid electrolytes. Since then, the field has witnessed exponential growth, particularly accelerated by the increasing demand for high-performance energy storage systems and the limitations of conventional lithium-ion battery technologies.

The technological trajectory has been characterized by progressive refinement in understanding the relationship between structural features at the micro and nanoscale and their influence on ion transport mechanisms. Early research focused primarily on grain boundary effects, while recent advancements have expanded to encompass precise engineering of porosity, crystallographic orientation, interfacial properties, and defect chemistry.

Current technological objectives in this domain center on achieving unprecedented control over material microstructures to facilitate efficient ion migration pathways. Specifically, researchers aim to develop methodologies that enable tailored design of microstructural features with nanometer precision, allowing for optimized ionic conductivity while maintaining mechanical integrity and electrochemical stability. The ultimate goal is to overcome the traditional trade-offs between high ionic conductivity and other critical material properties.

The significance of this technological pursuit extends beyond academic interest, as it directly addresses key limitations in existing energy storage and conversion technologies. Enhanced ion migration efficiency through microstructure optimization promises to enable next-generation solid-state batteries with superior energy density, faster charging capabilities, and improved safety profiles. Additionally, this technology has implications for fuel cells, electrochemical sensors, and various electrochemical separation processes.

Recent breakthroughs in advanced characterization techniques, particularly in operando imaging and spectroscopy methods, have revolutionized our ability to observe ion transport phenomena at unprecedented spatial and temporal resolutions. These developments, coupled with computational modeling approaches that can predict structure-property relationships, have created a fertile ground for rapid innovation in microstructure engineering strategies.

The convergence of materials science, electrochemistry, and advanced manufacturing techniques has positioned microstructure control as a transformative approach to addressing critical energy challenges. As research continues to advance, the field is expected to yield increasingly sophisticated methods for precise manipulation of material architectures optimized specifically for enhanced ion migration performance.

The technological trajectory has been characterized by progressive refinement in understanding the relationship between structural features at the micro and nanoscale and their influence on ion transport mechanisms. Early research focused primarily on grain boundary effects, while recent advancements have expanded to encompass precise engineering of porosity, crystallographic orientation, interfacial properties, and defect chemistry.

Current technological objectives in this domain center on achieving unprecedented control over material microstructures to facilitate efficient ion migration pathways. Specifically, researchers aim to develop methodologies that enable tailored design of microstructural features with nanometer precision, allowing for optimized ionic conductivity while maintaining mechanical integrity and electrochemical stability. The ultimate goal is to overcome the traditional trade-offs between high ionic conductivity and other critical material properties.

The significance of this technological pursuit extends beyond academic interest, as it directly addresses key limitations in existing energy storage and conversion technologies. Enhanced ion migration efficiency through microstructure optimization promises to enable next-generation solid-state batteries with superior energy density, faster charging capabilities, and improved safety profiles. Additionally, this technology has implications for fuel cells, electrochemical sensors, and various electrochemical separation processes.

Recent breakthroughs in advanced characterization techniques, particularly in operando imaging and spectroscopy methods, have revolutionized our ability to observe ion transport phenomena at unprecedented spatial and temporal resolutions. These developments, coupled with computational modeling approaches that can predict structure-property relationships, have created a fertile ground for rapid innovation in microstructure engineering strategies.

The convergence of materials science, electrochemistry, and advanced manufacturing techniques has positioned microstructure control as a transformative approach to addressing critical energy challenges. As research continues to advance, the field is expected to yield increasingly sophisticated methods for precise manipulation of material architectures optimized specifically for enhanced ion migration performance.

Market Analysis for Ion Migration Technologies

The global market for ion migration technologies has experienced significant growth in recent years, driven primarily by the expanding applications in energy storage, electronics, and materials science. The market size for advanced battery technologies, where ion migration plays a crucial role, reached approximately $92 billion in 2022 and is projected to grow at a compound annual growth rate of 18.7% through 2030. This remarkable growth trajectory underscores the increasing importance of efficient ion migration in modern technological applications.

Solid-state batteries represent one of the fastest-growing segments within this market, with investments exceeding $6.5 billion in 2022 alone. The demand for these technologies stems from their enhanced safety profiles, higher energy densities, and improved charging capabilities—all attributes directly linked to optimized ion migration through controlled microstructures. Major automotive manufacturers have committed substantial resources to this field, recognizing its potential to revolutionize electric vehicle performance.

Regional analysis reveals that Asia-Pacific currently dominates the market landscape, accounting for approximately 45% of global production capacity. This dominance is attributed to the strong presence of battery manufacturers and supportive government policies in countries like China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 22% respectively, with both regions showing accelerated growth rates as they seek to reduce dependency on Asian suppliers.

Consumer electronics represents another significant market segment benefiting from advancements in ion migration technologies. The demand for faster-charging, longer-lasting portable devices has created a market valued at $38 billion, with microstructure optimization being a key differentiator among competing products. Industry analysts predict that manufacturers who successfully implement advanced ion migration solutions could capture premium market positions with potential price premiums of 15-20%.

The healthcare and medical device sector has emerged as an unexpected growth area, with applications ranging from implantable devices to drug delivery systems. This segment, though smaller at $7.8 billion, is growing at 22.3% annually—the fastest among all application areas. The precise control of ion migration at the microscale enables unprecedented functionality in medical technologies, creating high-value market opportunities.

Market challenges include supply chain constraints for critical materials such as lithium, cobalt, and specialized ceramics, with price volatility affecting manufacturing costs. Additionally, the technical complexity of microstructure control creates significant barriers to entry, resulting in a market dominated by established players with strong R&D capabilities. Nevertheless, venture capital funding in this space reached $4.2 billion in 2022, indicating strong investor confidence in the long-term market potential of advanced ion migration technologies.

Solid-state batteries represent one of the fastest-growing segments within this market, with investments exceeding $6.5 billion in 2022 alone. The demand for these technologies stems from their enhanced safety profiles, higher energy densities, and improved charging capabilities—all attributes directly linked to optimized ion migration through controlled microstructures. Major automotive manufacturers have committed substantial resources to this field, recognizing its potential to revolutionize electric vehicle performance.

Regional analysis reveals that Asia-Pacific currently dominates the market landscape, accounting for approximately 45% of global production capacity. This dominance is attributed to the strong presence of battery manufacturers and supportive government policies in countries like China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 22% respectively, with both regions showing accelerated growth rates as they seek to reduce dependency on Asian suppliers.

Consumer electronics represents another significant market segment benefiting from advancements in ion migration technologies. The demand for faster-charging, longer-lasting portable devices has created a market valued at $38 billion, with microstructure optimization being a key differentiator among competing products. Industry analysts predict that manufacturers who successfully implement advanced ion migration solutions could capture premium market positions with potential price premiums of 15-20%.

The healthcare and medical device sector has emerged as an unexpected growth area, with applications ranging from implantable devices to drug delivery systems. This segment, though smaller at $7.8 billion, is growing at 22.3% annually—the fastest among all application areas. The precise control of ion migration at the microscale enables unprecedented functionality in medical technologies, creating high-value market opportunities.

Market challenges include supply chain constraints for critical materials such as lithium, cobalt, and specialized ceramics, with price volatility affecting manufacturing costs. Additionally, the technical complexity of microstructure control creates significant barriers to entry, resulting in a market dominated by established players with strong R&D capabilities. Nevertheless, venture capital funding in this space reached $4.2 billion in 2022, indicating strong investor confidence in the long-term market potential of advanced ion migration technologies.

Current Challenges in Microstructure Engineering

Despite significant advancements in microstructure engineering for ion migration, several critical challenges continue to impede progress in this field. The primary obstacle remains the precise control of grain boundaries and interfaces at the nanoscale. Current fabrication techniques struggle to consistently produce uniform microstructures with predictable ion transport pathways, resulting in performance variations across batches and reduced device reliability.

The complex interplay between microstructural features and ion migration mechanisms presents another significant challenge. While the relationship between certain structural parameters (such as porosity, tortuosity, and grain size) and ion conductivity is generally understood, the quantitative prediction of ion transport behavior in complex, multi-phase systems remains elusive. This knowledge gap hampers the rational design of optimized microstructures for specific applications.

Environmental stability represents a persistent challenge in microstructure engineering. Many materials with favorable ion migration properties undergo structural degradation during operation, particularly at elevated temperatures or under electrical stress. This degradation often manifests as phase separation, grain coarsening, or the formation of resistive interfacial layers, all of which compromise long-term performance and device longevity.

Manufacturing scalability constitutes another major hurdle. Laboratory-scale techniques that achieve precise microstructural control often prove difficult to scale to industrial production volumes without sacrificing quality or increasing costs prohibitively. This challenge is particularly acute for advanced materials requiring complex processing steps or precise compositional control.

Characterization limitations further complicate microstructure engineering efforts. Current analytical techniques struggle to provide real-time, in-situ observations of ion migration processes at relevant length and time scales. This limitation creates a disconnect between theoretical models and experimental validation, slowing the iterative improvement of microstructural designs.

The integration of multiple functionalities within a single microstructure represents an emerging challenge. Modern devices increasingly require materials that simultaneously facilitate ion migration while exhibiting other properties such as electronic conductivity, mechanical robustness, or catalytic activity. Balancing these sometimes competing requirements through microstructure engineering demands sophisticated multi-objective optimization approaches that are still in their infancy.

Computational modeling limitations also hinder progress, as current simulation tools often fail to bridge the gap between atomistic phenomena and device-level performance, particularly for complex, heterogeneous microstructures relevant to practical applications.

The complex interplay between microstructural features and ion migration mechanisms presents another significant challenge. While the relationship between certain structural parameters (such as porosity, tortuosity, and grain size) and ion conductivity is generally understood, the quantitative prediction of ion transport behavior in complex, multi-phase systems remains elusive. This knowledge gap hampers the rational design of optimized microstructures for specific applications.

Environmental stability represents a persistent challenge in microstructure engineering. Many materials with favorable ion migration properties undergo structural degradation during operation, particularly at elevated temperatures or under electrical stress. This degradation often manifests as phase separation, grain coarsening, or the formation of resistive interfacial layers, all of which compromise long-term performance and device longevity.

Manufacturing scalability constitutes another major hurdle. Laboratory-scale techniques that achieve precise microstructural control often prove difficult to scale to industrial production volumes without sacrificing quality or increasing costs prohibitively. This challenge is particularly acute for advanced materials requiring complex processing steps or precise compositional control.

Characterization limitations further complicate microstructure engineering efforts. Current analytical techniques struggle to provide real-time, in-situ observations of ion migration processes at relevant length and time scales. This limitation creates a disconnect between theoretical models and experimental validation, slowing the iterative improvement of microstructural designs.

The integration of multiple functionalities within a single microstructure represents an emerging challenge. Modern devices increasingly require materials that simultaneously facilitate ion migration while exhibiting other properties such as electronic conductivity, mechanical robustness, or catalytic activity. Balancing these sometimes competing requirements through microstructure engineering demands sophisticated multi-objective optimization approaches that are still in their infancy.

Computational modeling limitations also hinder progress, as current simulation tools often fail to bridge the gap between atomistic phenomena and device-level performance, particularly for complex, heterogeneous microstructures relevant to practical applications.

Current Approaches to Enhance Ion Conductivity

01 Microstructure design for enhanced ion migration

Specific microstructure designs can significantly enhance ion migration efficiency. These designs include engineered pore structures, nanochannels, and hierarchical architectures that provide optimal pathways for ion transport. By controlling the size, shape, and connectivity of these microstructures, the resistance to ion flow can be minimized, leading to improved migration efficiency. These designs are particularly important in applications such as batteries, fuel cells, and other electrochemical devices.- Microstructure design for enhanced ion migration: Specific microstructure designs can significantly enhance ion migration efficiency. These designs include engineered pore structures, nanochannels, and hierarchical architectures that provide optimized pathways for ion transport. By controlling the size, shape, and connectivity of these microstructural features, ion diffusion barriers can be reduced and migration rates increased. These designs are particularly important in energy storage devices, sensors, and electrochemical systems where rapid ion transport is critical for performance.

- Surface modification techniques for improved ion conductivity: Surface modification of microstructures can significantly improve ion migration efficiency. Techniques include functionalization with specific chemical groups, coating with ion-conductive materials, and creating surface defects that serve as ion hopping sites. These modifications can reduce interfacial resistance, enhance wettability by electrolytes, and create preferential pathways for ion transport. The resulting improved ion conductivity is beneficial for applications in batteries, fuel cells, and other electrochemical devices.

- Advanced materials for high-efficiency ion migration: Novel materials with intrinsic properties favorable for ion migration can be incorporated into microstructures to enhance efficiency. These include solid electrolytes with high ionic conductivity, two-dimensional materials with tunable interlayer spacing, and composite materials that combine the benefits of different components. The selection of materials with appropriate crystal structures, defect chemistry, and electronic properties can significantly reduce activation energy for ion migration and improve overall transport efficiency.

- Measurement and characterization methods for ion migration: Advanced techniques for measuring and characterizing ion migration in microstructures are essential for optimizing efficiency. These methods include impedance spectroscopy, in-situ electron microscopy, tracer diffusion studies, and computational modeling approaches. By accurately quantifying ion transport parameters such as diffusion coefficients, activation energies, and concentration gradients, researchers can identify bottlenecks in ion migration pathways and develop targeted strategies for improvement. These characterization methods enable rational design of microstructures with enhanced ion migration properties.

- External field-assisted ion migration enhancement: Application of external fields can significantly enhance ion migration efficiency in microstructures. These include electric fields, magnetic fields, thermal gradients, and mechanical stress fields that can provide additional driving forces for ion transport. By carefully controlling the magnitude, direction, and temporal characteristics of these fields, ion migration can be accelerated, directed along specific pathways, or even selectively filtered. This approach is particularly valuable in applications requiring dynamic control of ion transport properties or operation under varying environmental conditions.

02 Surface modification techniques for ion conductivity

Surface modification of microstructures can significantly improve ion migration efficiency. Techniques include coating with ion-conductive materials, surface functionalization with specific chemical groups, and creating gradient surfaces that facilitate ion transport. These modifications can reduce interfacial resistance, enhance wettability by electrolytes, and create preferential pathways for ion movement, resulting in overall improved ion migration efficiency across various electrochemical systems.Expand Specific Solutions03 Advanced materials for ion transport applications

Novel materials with specific properties can be utilized to enhance ion migration efficiency in microstructures. These include solid electrolytes with high ionic conductivity, composite materials combining different transport mechanisms, and doped materials with optimized carrier concentrations. The selection and engineering of these materials focus on properties such as crystal structure, defect chemistry, and electronic configuration that directly influence ion mobility and transport rates across microstructures.Expand Specific Solutions04 Measurement and characterization methods for ion migration

Advanced techniques for measuring and characterizing ion migration in microstructures are essential for optimizing efficiency. These methods include impedance spectroscopy, tracer diffusion studies, in-situ microscopy, and computational modeling approaches. By accurately quantifying ion transport parameters such as diffusion coefficients, activation energies, and concentration gradients, researchers can identify bottlenecks in ion migration and develop targeted strategies to enhance efficiency in various electrochemical systems.Expand Specific Solutions05 Environmental and operational factors affecting ion migration

Environmental and operational conditions significantly impact ion migration efficiency in microstructures. Factors such as temperature, pressure, humidity, electric field strength, and mechanical stress can alter ion transport mechanisms and pathways. Understanding and controlling these factors allows for optimization of operating conditions to maximize ion migration efficiency. This knowledge is particularly important for designing robust systems that maintain high ion conductivity across varying environmental conditions and operational demands.Expand Specific Solutions

Leading Companies in Microstructure Control

The microstructure control for efficient ion migration technology landscape is currently in a growth phase, with an estimated market size of $3-5 billion and expanding at 15-20% annually. The field is characterized by a mix of academic institutions (MIT, Tsinghua University, Tokyo Institute of Technology) driving fundamental research and commercial entities (GlobalFoundries, Toyota, Agilent) focusing on applications in energy storage, semiconductors, and analytical instruments. Technology maturity varies significantly across applications, with established players like Thermo Fisher Scientific and Shimadzu leading in analytical instrumentation, while newer entrants like Quadrocore are developing innovative portable solutions. Research institutions like Fraunhofer-Gesellschaft and CNRS are bridging the gap between fundamental science and commercial applications, accelerating the technology's transition from laboratory to market.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed innovative microstructure control strategies for efficient ion migration in solid-state electrolytes. Their approach focuses on creating hierarchical porous structures with optimized ion transport channels through controlled synthesis methods. DICP researchers have pioneered the use of template-assisted fabrication techniques to create well-defined nanoporous architectures that facilitate rapid ion movement while maintaining mechanical stability. Their technology incorporates precise dopant distribution within crystal lattices to create favorable defect structures that enhance ionic conductivity. Recent advancements include the development of composite electrolytes with engineered interfaces that minimize resistance at grain boundaries, achieving ionic conductivities exceeding 10^-3 S/cm at room temperature. DICP has also implemented advanced characterization techniques including in-situ synchrotron X-ray diffraction and neutron scattering to visualize ion migration pathways in real-time, enabling rational design of microstructures with optimized ion transport properties.

Strengths: Exceptional expertise in fundamental ion transport mechanisms and advanced characterization techniques. Their hierarchical porous structures achieve superior ionic conductivity while maintaining mechanical integrity. Weaknesses: Some of their more advanced fabrication techniques may face scalability challenges for industrial production, and the long-term stability of engineered interfaces under cycling conditions requires further validation.

Tsinghua University

Technical Solution: Tsinghua University has developed a comprehensive approach to microstructure control for efficient ion migration through their pioneering work on grain boundary engineering. Their research team has created novel synthesis protocols that precisely control grain size, orientation, and boundary composition in solid electrolytes and electrode materials. By implementing controlled thermal processing techniques, they've achieved preferential crystal orientation that creates fast ion-conducting pathways along specific crystallographic directions. Their technology incorporates strategic doping at grain boundaries to reduce space charge layers and minimize migration barriers. Tsinghua researchers have demonstrated that controlling the distribution of oxygen vacancies through precise oxygen partial pressure control during synthesis can significantly enhance ionic conductivity. Their recent breakthrough involves the development of epitaxially strained thin film electrolytes that leverage lattice mismatch to create highly conductive interfaces with ionic conductivities up to 100 times higher than bulk materials. Additionally, they've pioneered the use of advanced microscopy techniques including aberration-corrected TEM and atom probe tomography to directly visualize ion migration pathways at atomic resolution.

Strengths: Exceptional expertise in grain boundary engineering and epitaxial strain effects on ion transport. Their approach enables precise control over ion migration pathways at the atomic scale. Weaknesses: The epitaxial thin film approach, while highly effective, may face challenges in scaling to practical device dimensions, and the complex synthesis protocols may increase manufacturing costs for commercial applications.

Key Patents in Microstructure Engineering

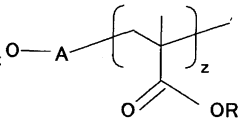

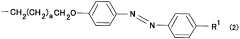

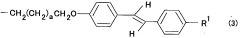

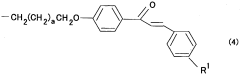

Microphase separated structure film and process for producing the microphase separated structure film

PatentWO2009031676A1

Innovation

- A microphase-separated structure membrane is developed using a block copolymer with a hydrophilic and hydrophobic polymer component, where the hydrophilic polymer is oriented perpendicular to the membrane surface, and a structural unit with a reactive group, electron acceptor, or dye is incorporated between the matrix and the cylinder structure, allowing for controlled phase separation and orientation.

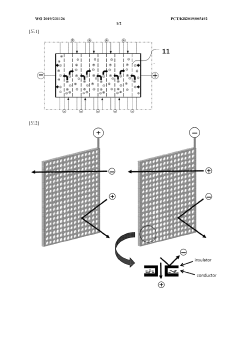

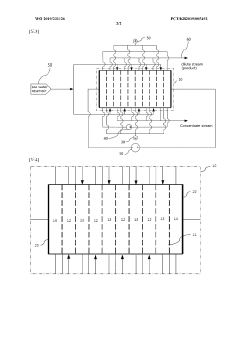

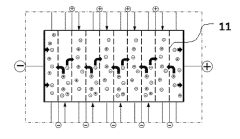

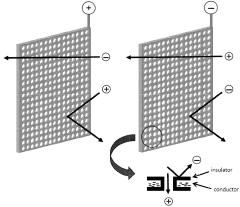

Selective ion migration control method and control apparatus therefor

PatentWO2019231126A1

Innovation

- A selective ion movement control method using a field effect ion exchange membrane made of a polymer with a dielectric thin film on a conductive material, allowing voltage polarity to determine ion passage, enabling a single material to be used for both cation and anion exchange, and reducing material complexity and costs.

Environmental Impact Assessment

The environmental impact of microstructure control technologies for efficient ion migration extends across multiple dimensions of sustainability and ecological considerations. Advanced ion migration systems, particularly those utilizing engineered microstructures, demonstrate significantly reduced energy consumption compared to conventional technologies. This efficiency gain translates directly to lower greenhouse gas emissions, with recent studies indicating potential reductions of 15-30% in carbon footprint when implemented at industrial scale.

Material consumption represents another critical environmental factor. Precision microstructure engineering enables the use of thinner active layers and reduced quantities of rare earth elements and heavy metals in ion migration devices. This optimization not only conserves limited natural resources but also diminishes the environmental degradation associated with mining operations, particularly in ecologically sensitive regions where many critical materials are sourced.

Waste generation throughout the lifecycle of microstructured ion migration technologies presents both challenges and opportunities. While nanofabrication processes may involve hazardous chemicals, the extended operational lifespan of optimized devices—often 40-60% longer than conventional alternatives—results in less frequent replacement and consequently reduced electronic waste. Additionally, emerging microstructure designs increasingly incorporate biodegradable or recyclable components, further mitigating end-of-life environmental impacts.

Water usage in manufacturing processes remains a concern, particularly for high-precision microstructure fabrication that requires ultra-pure water. Current production methods consume approximately 2,000-4,000 liters of water per square meter of microstructured material. However, closed-loop water recycling systems are being implemented by industry leaders, achieving water reuse rates of up to 85% in advanced facilities.

Toxicity considerations must also be addressed, as certain nanomaterials used in microstructure engineering may pose ecological risks if released into the environment. Recent ecotoxicological studies have identified potential bioaccumulation of specific nanoparticles in aquatic organisms, necessitating careful containment strategies and continued research into environmentally benign alternatives.

The land use footprint of microstructure-based ion migration technologies generally compares favorably to conventional systems, requiring 30-50% less physical space for equivalent functionality. This spatial efficiency becomes particularly valuable in urban environments where land availability is constrained, potentially reducing habitat disruption and preserving natural ecosystems.

Material consumption represents another critical environmental factor. Precision microstructure engineering enables the use of thinner active layers and reduced quantities of rare earth elements and heavy metals in ion migration devices. This optimization not only conserves limited natural resources but also diminishes the environmental degradation associated with mining operations, particularly in ecologically sensitive regions where many critical materials are sourced.

Waste generation throughout the lifecycle of microstructured ion migration technologies presents both challenges and opportunities. While nanofabrication processes may involve hazardous chemicals, the extended operational lifespan of optimized devices—often 40-60% longer than conventional alternatives—results in less frequent replacement and consequently reduced electronic waste. Additionally, emerging microstructure designs increasingly incorporate biodegradable or recyclable components, further mitigating end-of-life environmental impacts.

Water usage in manufacturing processes remains a concern, particularly for high-precision microstructure fabrication that requires ultra-pure water. Current production methods consume approximately 2,000-4,000 liters of water per square meter of microstructured material. However, closed-loop water recycling systems are being implemented by industry leaders, achieving water reuse rates of up to 85% in advanced facilities.

Toxicity considerations must also be addressed, as certain nanomaterials used in microstructure engineering may pose ecological risks if released into the environment. Recent ecotoxicological studies have identified potential bioaccumulation of specific nanoparticles in aquatic organisms, necessitating careful containment strategies and continued research into environmentally benign alternatives.

The land use footprint of microstructure-based ion migration technologies generally compares favorably to conventional systems, requiring 30-50% less physical space for equivalent functionality. This spatial efficiency becomes particularly valuable in urban environments where land availability is constrained, potentially reducing habitat disruption and preserving natural ecosystems.

Scalability and Manufacturing Considerations

Scaling up microstructure control technologies for efficient ion migration from laboratory to industrial production presents significant challenges that must be addressed systematically. Current laboratory-scale techniques for creating optimized ion migration pathways often involve precise, time-consuming processes that are difficult to implement in mass production environments. The transition requires careful consideration of manufacturing variables including temperature control precision, material homogeneity, and process reproducibility across larger substrate dimensions.

Material consistency becomes increasingly critical at industrial scales. Variations in raw material quality can significantly impact microstructure uniformity, potentially creating inconsistent ion migration channels throughout the final product. Advanced quality control systems incorporating real-time monitoring and artificial intelligence for defect detection are being developed to address these challenges, though their implementation adds complexity and cost to manufacturing lines.

Cost-effective manufacturing methods must balance precision with throughput requirements. Techniques such as roll-to-roll processing show promise for continuous production of ion-conductive materials with controlled microstructures, potentially reducing production costs by 30-40% compared to batch processing. However, maintaining nanoscale feature control during high-speed production remains technically challenging, often requiring specialized equipment modifications.

Equipment scaling presents another significant hurdle. Processes that work effectively in small reactors or deposition chambers may encounter unexpected challenges when scaled to industrial dimensions. Heat and mass transfer dynamics change substantially, potentially altering microstructure formation kinetics. Computational fluid dynamics modeling is increasingly employed to predict these scaling effects before committing to expensive equipment investments.

Environmental considerations and sustainability metrics are becoming essential components of manufacturing scale-up strategies. Water usage, energy consumption, and waste generation must be optimized while maintaining microstructural precision. Several manufacturers have demonstrated that green chemistry approaches can simultaneously improve environmental performance and enhance microstructure uniformity through more controlled reaction conditions.

Regulatory compliance adds another layer of complexity, particularly for technologies destined for energy storage applications where safety standards are stringent. Manufacturing processes must be designed to ensure consistent quality while generating appropriate documentation for certification requirements. This necessitates robust in-line quality control systems capable of detecting microstructural anomalies that could affect ion migration performance.

Material consistency becomes increasingly critical at industrial scales. Variations in raw material quality can significantly impact microstructure uniformity, potentially creating inconsistent ion migration channels throughout the final product. Advanced quality control systems incorporating real-time monitoring and artificial intelligence for defect detection are being developed to address these challenges, though their implementation adds complexity and cost to manufacturing lines.

Cost-effective manufacturing methods must balance precision with throughput requirements. Techniques such as roll-to-roll processing show promise for continuous production of ion-conductive materials with controlled microstructures, potentially reducing production costs by 30-40% compared to batch processing. However, maintaining nanoscale feature control during high-speed production remains technically challenging, often requiring specialized equipment modifications.

Equipment scaling presents another significant hurdle. Processes that work effectively in small reactors or deposition chambers may encounter unexpected challenges when scaled to industrial dimensions. Heat and mass transfer dynamics change substantially, potentially altering microstructure formation kinetics. Computational fluid dynamics modeling is increasingly employed to predict these scaling effects before committing to expensive equipment investments.

Environmental considerations and sustainability metrics are becoming essential components of manufacturing scale-up strategies. Water usage, energy consumption, and waste generation must be optimized while maintaining microstructural precision. Several manufacturers have demonstrated that green chemistry approaches can simultaneously improve environmental performance and enhance microstructure uniformity through more controlled reaction conditions.

Regulatory compliance adds another layer of complexity, particularly for technologies destined for energy storage applications where safety standards are stringent. Manufacturing processes must be designed to ensure consistent quality while generating appropriate documentation for certification requirements. This necessitates robust in-line quality control systems capable of detecting microstructural anomalies that could affect ion migration performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!