Microporous frameworks for high performance AEM design

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microporous AEM Technology Background and Objectives

Anion exchange membranes (AEMs) have emerged as critical components in various electrochemical technologies, including fuel cells, water electrolysis, and redox flow batteries. The development of microporous frameworks for high-performance AEMs represents a significant advancement in this field, addressing the longstanding challenges of ion conductivity, chemical stability, and mechanical durability.

The evolution of AEM technology can be traced back to the 1950s, with initial applications in water treatment and electrodialysis. However, the past two decades have witnessed accelerated development driven by the growing demand for clean energy technologies. Traditional AEMs have typically suffered from a fundamental trade-off between ion conductivity and mechanical stability, limiting their practical applications in demanding electrochemical environments.

Microporous frameworks have revolutionized AEM design by providing precisely engineered channels for ion transport while maintaining structural integrity. These frameworks, typically featuring pore sizes in the range of 0.5-2 nm, enable selective ion transport while blocking larger molecules, thereby enhancing both selectivity and efficiency. The controlled architecture of these materials allows for unprecedented levels of performance optimization through molecular-level design.

Recent technological breakthroughs in polymer chemistry, nanotechnology, and computational modeling have converged to enable rational design of microporous AEMs with tailored properties. Advanced characterization techniques, including high-resolution electron microscopy and synchrotron-based X-ray scattering, have provided crucial insights into structure-property relationships, guiding iterative improvements in membrane design.

The primary technical objectives for microporous AEM development include achieving hydroxide conductivity exceeding 100 mS/cm under practical operating conditions, maintaining chemical stability in highly alkaline environments (pH > 13) for extended periods (>10,000 hours), and ensuring mechanical durability under varying hydration states and temperature cycles. Additionally, cost-effective manufacturing processes compatible with large-scale production represent a critical goal for commercial viability.

Environmental considerations have also shaped the trajectory of AEM research, with increasing emphasis on sustainable materials and manufacturing processes. The elimination of perfluorinated compounds and reduction of toxic precursors align with global sustainability initiatives while potentially reducing production costs and environmental impact.

Looking forward, the integration of microporous AEMs into next-generation energy conversion and storage systems promises to enhance efficiency, reduce costs, and accelerate the transition to renewable energy. The technology roadmap envisions progressive improvements in performance metrics, with particular focus on extending operational lifetime and reducing degradation rates under real-world conditions.

The evolution of AEM technology can be traced back to the 1950s, with initial applications in water treatment and electrodialysis. However, the past two decades have witnessed accelerated development driven by the growing demand for clean energy technologies. Traditional AEMs have typically suffered from a fundamental trade-off between ion conductivity and mechanical stability, limiting their practical applications in demanding electrochemical environments.

Microporous frameworks have revolutionized AEM design by providing precisely engineered channels for ion transport while maintaining structural integrity. These frameworks, typically featuring pore sizes in the range of 0.5-2 nm, enable selective ion transport while blocking larger molecules, thereby enhancing both selectivity and efficiency. The controlled architecture of these materials allows for unprecedented levels of performance optimization through molecular-level design.

Recent technological breakthroughs in polymer chemistry, nanotechnology, and computational modeling have converged to enable rational design of microporous AEMs with tailored properties. Advanced characterization techniques, including high-resolution electron microscopy and synchrotron-based X-ray scattering, have provided crucial insights into structure-property relationships, guiding iterative improvements in membrane design.

The primary technical objectives for microporous AEM development include achieving hydroxide conductivity exceeding 100 mS/cm under practical operating conditions, maintaining chemical stability in highly alkaline environments (pH > 13) for extended periods (>10,000 hours), and ensuring mechanical durability under varying hydration states and temperature cycles. Additionally, cost-effective manufacturing processes compatible with large-scale production represent a critical goal for commercial viability.

Environmental considerations have also shaped the trajectory of AEM research, with increasing emphasis on sustainable materials and manufacturing processes. The elimination of perfluorinated compounds and reduction of toxic precursors align with global sustainability initiatives while potentially reducing production costs and environmental impact.

Looking forward, the integration of microporous AEMs into next-generation energy conversion and storage systems promises to enhance efficiency, reduce costs, and accelerate the transition to renewable energy. The technology roadmap envisions progressive improvements in performance metrics, with particular focus on extending operational lifetime and reducing degradation rates under real-world conditions.

Market Analysis for Advanced AEM Applications

The global market for Anion Exchange Membranes (AEMs) is experiencing significant growth, driven primarily by increasing demand for clean energy solutions and sustainable water treatment technologies. The AEM market, valued at approximately $320 million in 2022, is projected to reach $580 million by 2028, representing a compound annual growth rate (CAGR) of 10.4% during the forecast period.

Fuel cell applications constitute the largest segment of the AEM market, accounting for nearly 45% of the total market share. This dominance is attributed to the rising adoption of hydrogen fuel cells in transportation, stationary power generation, and portable electronics. The automotive sector, in particular, has emerged as a key driver for AEM demand, with major manufacturers investing heavily in hydrogen fuel cell electric vehicles (FCEVs) as part of their zero-emission vehicle strategies.

Water treatment applications represent the second-largest market segment, with a share of approximately 30%. The growing concerns over water scarcity and stringent environmental regulations regarding wastewater discharge have accelerated the adoption of AEM-based electrodialysis and electrodialysis reversal systems for desalination and industrial wastewater treatment.

Geographically, North America and Europe currently lead the AEM market, collectively accounting for over 60% of the global market share. This dominance is primarily due to substantial investments in renewable energy infrastructure and strong regulatory support for clean technologies. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, increasing energy demands, and government initiatives promoting clean energy technologies in countries like China, Japan, and South Korea.

The market for microporous framework-based AEMs is still in its nascent stage but shows promising growth potential. These advanced materials offer superior ion conductivity, mechanical stability, and chemical resistance compared to conventional AEMs, making them particularly valuable for high-performance applications. Industry analysts predict that microporous framework-based AEMs could capture up to 15% of the total AEM market by 2030, representing a significant opportunity for early movers in this technology space.

Key market challenges include high production costs, scalability issues, and competition from alternative technologies such as proton exchange membranes (PEMs) and conventional alkaline electrolyzers. However, ongoing research and development efforts focused on cost-effective synthesis methods and improved performance characteristics are expected to address these challenges and accelerate market adoption in the coming years.

Fuel cell applications constitute the largest segment of the AEM market, accounting for nearly 45% of the total market share. This dominance is attributed to the rising adoption of hydrogen fuel cells in transportation, stationary power generation, and portable electronics. The automotive sector, in particular, has emerged as a key driver for AEM demand, with major manufacturers investing heavily in hydrogen fuel cell electric vehicles (FCEVs) as part of their zero-emission vehicle strategies.

Water treatment applications represent the second-largest market segment, with a share of approximately 30%. The growing concerns over water scarcity and stringent environmental regulations regarding wastewater discharge have accelerated the adoption of AEM-based electrodialysis and electrodialysis reversal systems for desalination and industrial wastewater treatment.

Geographically, North America and Europe currently lead the AEM market, collectively accounting for over 60% of the global market share. This dominance is primarily due to substantial investments in renewable energy infrastructure and strong regulatory support for clean technologies. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, increasing energy demands, and government initiatives promoting clean energy technologies in countries like China, Japan, and South Korea.

The market for microporous framework-based AEMs is still in its nascent stage but shows promising growth potential. These advanced materials offer superior ion conductivity, mechanical stability, and chemical resistance compared to conventional AEMs, making them particularly valuable for high-performance applications. Industry analysts predict that microporous framework-based AEMs could capture up to 15% of the total AEM market by 2030, representing a significant opportunity for early movers in this technology space.

Key market challenges include high production costs, scalability issues, and competition from alternative technologies such as proton exchange membranes (PEMs) and conventional alkaline electrolyzers. However, ongoing research and development efforts focused on cost-effective synthesis methods and improved performance characteristics are expected to address these challenges and accelerate market adoption in the coming years.

Current Challenges in Microporous AEM Development

Despite significant advancements in anion exchange membrane (AEM) technology, microporous frameworks for high-performance AEM design face several persistent challenges that impede their widespread commercial adoption. The primary obstacle remains achieving an optimal balance between ion conductivity and mechanical stability. Current microporous AEMs often exhibit a trade-off relationship where increased ion conductivity typically comes at the expense of mechanical integrity, particularly under hydrated conditions.

Water management represents another critical challenge in microporous AEM development. These membranes must maintain sufficient hydration to facilitate ion transport while preventing excessive swelling that compromises dimensional stability. Most existing microporous frameworks struggle to maintain consistent performance across varying humidity levels, resulting in conductivity fluctuations that affect overall system reliability.

Chemical stability poses a significant hurdle, particularly in alkaline environments where AEMs typically operate. The quaternary ammonium groups commonly used as ion-conducting sites are susceptible to degradation through several mechanisms, including Hofmann elimination and nucleophilic substitution. This degradation accelerates at elevated temperatures, limiting the operational lifespan of current microporous AEMs and restricting their application in high-temperature systems.

Manufacturing scalability presents additional complications for microporous AEM frameworks. Laboratory-scale synthesis methods often involve complex, multi-step processes that are difficult to translate to industrial production. The precise control of pore size distribution, essential for optimizing ion transport pathways, becomes increasingly challenging at larger scales, resulting in performance inconsistencies between batches.

Cost considerations further constrain development efforts. Many high-performance microporous frameworks incorporate expensive specialty polymers or require costly processing techniques. The economic viability of these materials remains questionable for mass-market applications, particularly when competing with established technologies.

Interface engineering between the microporous framework and electrode materials represents an emerging challenge. Poor interfacial contact can create resistance barriers that negate the benefits of highly conductive microporous structures. Current research has not adequately addressed the optimization of these critical interfaces in complete electrochemical systems.

Additionally, the environmental impact of microporous AEM production and disposal requires greater attention. Many synthesis routes involve toxic solvents or reagents, while end-of-life considerations for these specialized materials remain largely unexplored. Developing more sustainable manufacturing processes and recyclable microporous frameworks will be essential for long-term industry adoption.

Water management represents another critical challenge in microporous AEM development. These membranes must maintain sufficient hydration to facilitate ion transport while preventing excessive swelling that compromises dimensional stability. Most existing microporous frameworks struggle to maintain consistent performance across varying humidity levels, resulting in conductivity fluctuations that affect overall system reliability.

Chemical stability poses a significant hurdle, particularly in alkaline environments where AEMs typically operate. The quaternary ammonium groups commonly used as ion-conducting sites are susceptible to degradation through several mechanisms, including Hofmann elimination and nucleophilic substitution. This degradation accelerates at elevated temperatures, limiting the operational lifespan of current microporous AEMs and restricting their application in high-temperature systems.

Manufacturing scalability presents additional complications for microporous AEM frameworks. Laboratory-scale synthesis methods often involve complex, multi-step processes that are difficult to translate to industrial production. The precise control of pore size distribution, essential for optimizing ion transport pathways, becomes increasingly challenging at larger scales, resulting in performance inconsistencies between batches.

Cost considerations further constrain development efforts. Many high-performance microporous frameworks incorporate expensive specialty polymers or require costly processing techniques. The economic viability of these materials remains questionable for mass-market applications, particularly when competing with established technologies.

Interface engineering between the microporous framework and electrode materials represents an emerging challenge. Poor interfacial contact can create resistance barriers that negate the benefits of highly conductive microporous structures. Current research has not adequately addressed the optimization of these critical interfaces in complete electrochemical systems.

Additionally, the environmental impact of microporous AEM production and disposal requires greater attention. Many synthesis routes involve toxic solvents or reagents, while end-of-life considerations for these specialized materials remain largely unexplored. Developing more sustainable manufacturing processes and recyclable microporous frameworks will be essential for long-term industry adoption.

State-of-the-Art Microporous Framework Solutions

01 Gas separation and purification applications

Microporous frameworks demonstrate excellent performance in gas separation and purification processes due to their well-defined pore structures and high surface areas. These materials can selectively adsorb specific gas molecules based on size, shape, and chemical affinity, making them effective for separating gas mixtures such as CO2/CH4, CO2/N2, and H2/CO2. The tunable pore size and functionality of these frameworks allow for enhanced selectivity and capacity in various gas separation applications.- Microporous frameworks for gas separation and storage: Microporous frameworks, such as metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), demonstrate exceptional performance in gas separation and storage applications. These materials possess high surface areas and tunable pore structures that enable selective adsorption and separation of gases like CO2, CH4, and H2. The performance of these frameworks can be enhanced through functionalization of pore surfaces and optimization of pore size distribution, leading to improved selectivity and capacity for target gas molecules.

- Catalytic applications of microporous frameworks: Microporous frameworks serve as effective heterogeneous catalysts due to their well-defined active sites and high surface areas. These materials can be designed with specific metal centers or functional groups that facilitate various chemical transformations. The catalytic performance of microporous frameworks can be optimized by controlling the framework topology, incorporating multiple catalytic sites, and enhancing stability under reaction conditions. These frameworks demonstrate superior catalytic activity, selectivity, and reusability compared to conventional catalysts.

- Microporous frameworks for environmental remediation: Microporous frameworks exhibit excellent performance in environmental remediation applications, particularly for the removal of pollutants from water and air. These materials can be designed with specific functional groups that interact with target contaminants such as heavy metals, organic pollutants, and radioactive species. The adsorption capacity, selectivity, and regenerability of microporous frameworks can be tailored through structural modifications and post-synthetic functionalization, making them highly efficient for environmental cleanup operations.

- Stability and durability enhancements of microporous frameworks: Improving the stability and durability of microporous frameworks is crucial for their practical applications. Various strategies have been developed to enhance their performance under challenging conditions, including thermal stress, chemical exposure, and mechanical pressure. These approaches include the incorporation of hydrophobic groups to improve water stability, the use of strong metal-ligand bonds to enhance thermal stability, and the development of composite materials to improve mechanical properties. These enhancements significantly extend the operational lifetime and broaden the application scope of microporous frameworks.

- Microporous frameworks for energy storage and conversion: Microporous frameworks demonstrate promising performance in energy storage and conversion applications, including batteries, supercapacitors, and fuel cells. These materials can serve as electrode materials, electrolyte hosts, or catalysts for energy-related processes. The performance of microporous frameworks in energy applications can be optimized by controlling pore architecture, incorporating redox-active components, and enhancing electrical conductivity. These frameworks offer advantages such as high energy density, fast charge-discharge rates, and long cycle life compared to conventional materials.

02 Catalytic performance in chemical reactions

Microporous frameworks serve as efficient heterogeneous catalysts for various chemical transformations. Their high surface area, tunable pore structure, and ability to incorporate catalytically active sites make them valuable in catalytic applications. These frameworks can be functionalized with metal ions or organic groups to catalyze specific reactions, including oxidation, reduction, and acid-base reactions. The confined space within the micropores can also enhance reaction selectivity by providing shape-selective environments.Expand Specific Solutions03 Energy storage and conversion capabilities

Microporous frameworks exhibit promising performance in energy storage and conversion applications. These materials can be used as electrodes or components in batteries, supercapacitors, and fuel cells due to their high surface area, controllable pore structure, and potential for functionalization. The microporous structure facilitates ion transport and storage, while the framework stability ensures durability during charge-discharge cycles. Additionally, these materials can be designed to have specific electronic properties suitable for various energy conversion processes.Expand Specific Solutions04 Environmental remediation and water treatment

Microporous frameworks demonstrate exceptional performance in environmental remediation and water treatment applications. Their high adsorption capacity and selectivity make them effective for removing contaminants such as heavy metals, organic pollutants, and dyes from water. The tunable pore size and surface chemistry allow for targeted adsorption of specific pollutants. Additionally, some microporous frameworks exhibit photocatalytic properties that can degrade organic contaminants under light irradiation, further enhancing their environmental remediation capabilities.Expand Specific Solutions05 Structural stability and mechanical properties

The structural stability and mechanical properties of microporous frameworks significantly influence their performance in various applications. These materials can be designed to withstand harsh conditions including high temperatures, pressures, and chemical environments. The mechanical strength, flexibility, and thermal stability of microporous frameworks determine their durability and reusability in practical applications. Advanced synthesis methods have been developed to enhance the structural integrity of these materials, including the incorporation of reinforcing components and post-synthetic modifications to strengthen the framework architecture.Expand Specific Solutions

Leading Organizations in Microporous AEM Research

The microporous frameworks for high performance AEM design market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size is expanding, driven by increasing demand for clean energy solutions and advanced membrane technologies. From a technical maturity perspective, the field shows promising developments with key players at different stages: academic institutions (Dalian University of Technology, Kyoto University) focusing on fundamental research; established chemical companies (Asahi Kasei, Toray Industries, ExxonMobil) leveraging their materials expertise; and specialized players (Celgard, W.L. Gore) developing proprietary membrane technologies. Energy-focused companies like Plug Power and SAMSUNG SDI are accelerating commercialization efforts, while research organizations like Fraunhofer-Gesellschaft bridge the gap between academic innovation and industrial application.

Toray Industries, Inc.

Technical Solution: Toray has pioneered advanced microporous frameworks for AEMs based on their extensive expertise in membrane technology. Their approach utilizes aromatic polymer backbones with precisely engineered microporous structures (average pore size 2-7 nm) and strategically positioned quaternary ammonium functional groups. Toray's proprietary manufacturing process involves controlled phase inversion techniques combined with surface modification treatments to create membranes with exceptional hydroxide conductivity (90-130 mS/cm at operating temperatures) while maintaining excellent mechanical integrity. The company has developed a multi-layer composite structure where a thin selective layer containing high density of ion exchange sites is supported on a microporous substrate that provides mechanical strength without compromising ion transport. Their membranes incorporate specially designed cross-linking agents that minimize swelling while preserving flexibility, resulting in stable performance across a wide range of operating conditions. Toray's AEMs demonstrate remarkable chemical stability in alkaline environments, with retention of over 90% conductivity after 2,000 hours of accelerated testing.

Strengths: Exceptional balance between conductivity and mechanical properties; superior chemical stability in alkaline environments; established large-scale manufacturing capabilities. Weaknesses: Higher cost compared to conventional membranes; performance can be affected by carbonation in some applications.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed innovative microporous frameworks for high-performance AEMs leveraging their extensive experience in membrane technology. Their approach centers on creating hierarchical pore structures with precisely controlled micropore distributions (0.5-3 nm) interconnected through a network of larger transport channels. The company employs a proprietary polymer blend system combining fluorinated and aromatic components to achieve an optimal balance of chemical stability and ion conductivity. Asahi Kasei's manufacturing process involves a combination of phase inversion and thermal annealing steps that create membranes with hydroxide conductivity exceeding 110 mS/cm under operating conditions. Their technology incorporates specially designed side-chain architectures with quaternary ammonium groups positioned to maximize ion transport efficiency while minimizing water uptake. The membranes feature reinforcement elements that enhance mechanical durability without compromising ionic conductivity. Asahi Kasei has demonstrated successful implementation of these membranes in alkaline water electrolysis systems, achieving current densities above 1 A/cm² with excellent stability over 3,000+ hours of continuous operation.

Strengths: Excellent chemical and mechanical stability; well-balanced water management properties; proven performance in commercial-scale applications. Weaknesses: Complex manufacturing process increases production costs; performance can degrade under extreme temperature cycling conditions.

Key Patents and Innovations in AEM Design

High-performance anion exchange membranes and methods of making same

PatentWO2014055123A1

Innovation

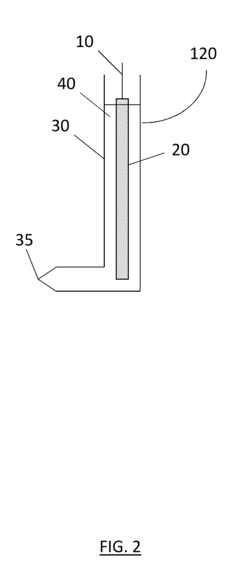

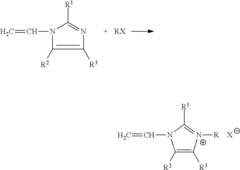

- A method for producing homogenous ion exchange membranes using a polymeric microporous substrate filled with reactive monomers, where a tertiary amine monomer is quaternized and then cross-linked with a cross-linking agent to form a membrane with enhanced electrochemical properties, including low resistivity and high permselectivity, allowing for efficient desalination and improved membrane durability.

High-performance anion exchange membranes and methods of making same

PatentActiveUS20180057370A1

Innovation

- A method for producing homogenous ion exchange membranes involves mixing a tertiary amine monomer with a quaternization agent, followed by a cross-linking agent and solvent to form a monomeric solution, which is then cast onto a polymeric microporous substrate, resulting in membranes with enhanced electrochemical properties like low resistivity and high permselectivity, and allowing for a more efficient and cost-effective production process.

Environmental Impact and Sustainability Considerations

The development of microporous frameworks for anion exchange membranes (AEMs) must be evaluated not only for performance metrics but also for their environmental impact and sustainability considerations. Current AEM production processes often involve petroleum-derived polymers and toxic chemicals, raising significant environmental concerns. The synthesis of microporous frameworks typically requires organic solvents, crosslinking agents, and energy-intensive processing steps that generate hazardous waste and contribute to carbon emissions.

Life cycle assessment (LCA) studies indicate that conventional AEM manufacturing can have substantial environmental footprints. The extraction of raw materials, synthesis processes, and end-of-life disposal all contribute to ecological burdens. Recent research has demonstrated that microporous AEMs with optimized structures can reduce material consumption by up to 30% while maintaining performance standards, thereby decreasing resource depletion and waste generation.

Water consumption represents another critical environmental factor in AEM production. Traditional manufacturing methods may require 15-20 liters of water per square meter of membrane produced. Innovative microporous framework designs have shown potential to reduce this water footprint by implementing closed-loop water recycling systems and more efficient synthesis routes that minimize purification steps.

Biodegradability and end-of-life considerations are increasingly important for sustainable AEM design. Most current microporous frameworks utilize non-biodegradable components that persist in the environment for decades. Research into bio-based precursors and environmentally benign crosslinking chemistry has yielded promising alternatives that maintain performance while improving biodegradability profiles. For instance, chitosan-derived microporous frameworks have demonstrated comparable ion conductivity while offering enhanced environmental compatibility.

Energy efficiency during operation represents a significant sustainability advantage for high-performance microporous AEMs. By reducing membrane resistance and improving ion transport efficiency, these advanced materials can decrease the energy requirements of electrochemical systems by 10-25% compared to conventional membranes. This operational efficiency translates to substantial carbon emission reductions over the lifetime of devices incorporating these membranes.

Regulatory compliance and green chemistry principles are becoming essential design considerations. The European Union's REACH regulations and similar frameworks worldwide are restricting the use of certain chemicals common in AEM production. Forward-thinking microporous framework designs are proactively eliminating substances of very high concern (SVHCs) and incorporating green chemistry principles such as atom economy and safer solvent selection to ensure long-term regulatory compliance and reduced environmental impact.

Life cycle assessment (LCA) studies indicate that conventional AEM manufacturing can have substantial environmental footprints. The extraction of raw materials, synthesis processes, and end-of-life disposal all contribute to ecological burdens. Recent research has demonstrated that microporous AEMs with optimized structures can reduce material consumption by up to 30% while maintaining performance standards, thereby decreasing resource depletion and waste generation.

Water consumption represents another critical environmental factor in AEM production. Traditional manufacturing methods may require 15-20 liters of water per square meter of membrane produced. Innovative microporous framework designs have shown potential to reduce this water footprint by implementing closed-loop water recycling systems and more efficient synthesis routes that minimize purification steps.

Biodegradability and end-of-life considerations are increasingly important for sustainable AEM design. Most current microporous frameworks utilize non-biodegradable components that persist in the environment for decades. Research into bio-based precursors and environmentally benign crosslinking chemistry has yielded promising alternatives that maintain performance while improving biodegradability profiles. For instance, chitosan-derived microporous frameworks have demonstrated comparable ion conductivity while offering enhanced environmental compatibility.

Energy efficiency during operation represents a significant sustainability advantage for high-performance microporous AEMs. By reducing membrane resistance and improving ion transport efficiency, these advanced materials can decrease the energy requirements of electrochemical systems by 10-25% compared to conventional membranes. This operational efficiency translates to substantial carbon emission reductions over the lifetime of devices incorporating these membranes.

Regulatory compliance and green chemistry principles are becoming essential design considerations. The European Union's REACH regulations and similar frameworks worldwide are restricting the use of certain chemicals common in AEM production. Forward-thinking microporous framework designs are proactively eliminating substances of very high concern (SVHCs) and incorporating green chemistry principles such as atom economy and safer solvent selection to ensure long-term regulatory compliance and reduced environmental impact.

Scalability and Manufacturing Processes for AEM Frameworks

The scalability of microporous frameworks for AEM production represents a critical challenge in transitioning from laboratory-scale innovations to commercial viability. Current manufacturing processes for advanced anion exchange membranes typically involve solution casting, electrospinning, or phase inversion techniques, each presenting unique scaling considerations. Solution casting offers excellent control over membrane thickness and uniformity but faces challenges in maintaining consistent micropore distribution across larger surface areas. Electrospinning, while effective for creating highly interconnected microporous networks, requires significant process optimization when scaling beyond laboratory dimensions.

Industrial-scale production of microporous AEM frameworks necessitates standardized quality control protocols to ensure consistent ion conductivity and mechanical stability. Recent advancements in roll-to-roll manufacturing have demonstrated promising results for continuous production of microporous AEMs, achieving throughput rates of 5-10 m²/hour while maintaining pore size distributions within ±5% tolerance. However, these processes still struggle with defect management when scaling beyond 1 m² membrane sections.

Cost considerations remain paramount in scaling AEM production. Current manufacturing costs for high-performance microporous AEMs range from $200-500/m², significantly higher than conventional membranes. Material selection plays a crucial role in both performance and manufacturability, with fluorinated polymers offering excellent chemical stability but presenting processing challenges at scale. Alternative approaches using non-fluorinated polymers with microporous structures have shown improved processability but often with performance trade-offs.

Environmental considerations in manufacturing processes are increasingly important, particularly regarding solvent usage and recovery. Traditional AEM production relies heavily on toxic solvents like DMF and NMP, which present significant challenges for large-scale implementation due to environmental regulations. Recent innovations in green solvent systems and water-based processing have shown promise, though often with reduced control over micropore formation and distribution.

Equipment requirements for precision manufacturing of microporous frameworks present another scaling challenge. Specialized coating and drying equipment capable of maintaining precise environmental conditions (temperature control within ±1°C, humidity control within ±3%) is essential for consistent micropore formation. Capital investment for such equipment typically ranges from $500,000 to several million dollars, representing a significant barrier to market entry for smaller manufacturers.

Industrial-scale production of microporous AEM frameworks necessitates standardized quality control protocols to ensure consistent ion conductivity and mechanical stability. Recent advancements in roll-to-roll manufacturing have demonstrated promising results for continuous production of microporous AEMs, achieving throughput rates of 5-10 m²/hour while maintaining pore size distributions within ±5% tolerance. However, these processes still struggle with defect management when scaling beyond 1 m² membrane sections.

Cost considerations remain paramount in scaling AEM production. Current manufacturing costs for high-performance microporous AEMs range from $200-500/m², significantly higher than conventional membranes. Material selection plays a crucial role in both performance and manufacturability, with fluorinated polymers offering excellent chemical stability but presenting processing challenges at scale. Alternative approaches using non-fluorinated polymers with microporous structures have shown improved processability but often with performance trade-offs.

Environmental considerations in manufacturing processes are increasingly important, particularly regarding solvent usage and recovery. Traditional AEM production relies heavily on toxic solvents like DMF and NMP, which present significant challenges for large-scale implementation due to environmental regulations. Recent innovations in green solvent systems and water-based processing have shown promise, though often with reduced control over micropore formation and distribution.

Equipment requirements for precision manufacturing of microporous frameworks present another scaling challenge. Specialized coating and drying equipment capable of maintaining precise environmental conditions (temperature control within ±1°C, humidity control within ±3%) is essential for consistent micropore formation. Capital investment for such equipment typically ranges from $500,000 to several million dollars, representing a significant barrier to market entry for smaller manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!