Model Predictive Control In Advanced HVAC Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Evolution in HVAC Systems

Model Predictive Control (MPC) technology in HVAC systems has undergone significant evolution over the past three decades, transforming from theoretical concepts to practical implementations. The journey began in the 1980s with early mathematical formulations of predictive control algorithms, though these remained largely academic exercises due to computational limitations of the era.

The 1990s marked the first serious attempts to apply MPC to building climate control, with researchers developing simplified models that could run on the limited computing hardware available. These early implementations focused primarily on single-zone temperature control with relatively long prediction horizons of several hours.

A significant breakthrough occurred in the early 2000s when researchers began incorporating weather forecasts and occupancy predictions into MPC frameworks. This period also saw the development of more sophisticated thermal models capable of accounting for building thermal mass, solar gains, and other complex thermodynamic factors.

Between 2005-2010, the computational efficiency of MPC algorithms improved dramatically, enabling real-time implementation in more complex multi-zone buildings. During this phase, researchers began exploring economic MPC formulations that could optimize for energy costs while maintaining comfort constraints.

The 2010-2015 period witnessed the integration of MPC with building automation systems (BAS) and the emergence of cloud-based computing solutions that could handle the computational demands of complex predictive models. This era also saw the first commercial deployments of MPC in large commercial buildings, with documented energy savings typically ranging from 15-30%.

From 2015 onwards, MPC technology has increasingly incorporated machine learning techniques for model identification and adaptation. Deep learning approaches have enabled more accurate prediction of building thermal behavior without relying on first-principles physics models. This hybrid approach combining physics-based models with data-driven techniques has significantly improved prediction accuracy.

The most recent developments (2020 onwards) include distributed MPC architectures that can coordinate multiple HVAC subsystems, integration with renewable energy sources and energy storage systems, and the incorporation of occupant feedback loops. Edge computing implementations have reduced latency issues, while digital twin technology has enabled continuous model refinement.

Current state-of-the-art MPC systems feature hierarchical control structures that optimize across multiple time scales, from immediate comfort control to day-ahead energy planning, while incorporating uncertainty quantification to enhance robustness against prediction errors.

The 1990s marked the first serious attempts to apply MPC to building climate control, with researchers developing simplified models that could run on the limited computing hardware available. These early implementations focused primarily on single-zone temperature control with relatively long prediction horizons of several hours.

A significant breakthrough occurred in the early 2000s when researchers began incorporating weather forecasts and occupancy predictions into MPC frameworks. This period also saw the development of more sophisticated thermal models capable of accounting for building thermal mass, solar gains, and other complex thermodynamic factors.

Between 2005-2010, the computational efficiency of MPC algorithms improved dramatically, enabling real-time implementation in more complex multi-zone buildings. During this phase, researchers began exploring economic MPC formulations that could optimize for energy costs while maintaining comfort constraints.

The 2010-2015 period witnessed the integration of MPC with building automation systems (BAS) and the emergence of cloud-based computing solutions that could handle the computational demands of complex predictive models. This era also saw the first commercial deployments of MPC in large commercial buildings, with documented energy savings typically ranging from 15-30%.

From 2015 onwards, MPC technology has increasingly incorporated machine learning techniques for model identification and adaptation. Deep learning approaches have enabled more accurate prediction of building thermal behavior without relying on first-principles physics models. This hybrid approach combining physics-based models with data-driven techniques has significantly improved prediction accuracy.

The most recent developments (2020 onwards) include distributed MPC architectures that can coordinate multiple HVAC subsystems, integration with renewable energy sources and energy storage systems, and the incorporation of occupant feedback loops. Edge computing implementations have reduced latency issues, while digital twin technology has enabled continuous model refinement.

Current state-of-the-art MPC systems feature hierarchical control structures that optimize across multiple time scales, from immediate comfort control to day-ahead energy planning, while incorporating uncertainty quantification to enhance robustness against prediction errors.

Market Demand for Intelligent HVAC Control

The global market for intelligent HVAC control systems is experiencing robust growth, driven primarily by increasing energy efficiency requirements and the rising adoption of smart building technologies. According to recent market research, the intelligent HVAC control market was valued at approximately $12.8 billion in 2022 and is projected to reach $28.4 billion by 2030, representing a compound annual growth rate (CAGR) of 10.5% during the forecast period.

Energy conservation remains the primary driver for this market expansion. Commercial buildings account for nearly 40% of global energy consumption, with HVAC systems responsible for roughly 40-60% of that energy usage. This significant energy footprint has prompted stringent regulations worldwide, including the European Energy Performance of Buildings Directive and ASHRAE 90.1 standards in North America, which mandate improved HVAC efficiency.

The integration of Model Predictive Control (MPC) in advanced HVAC systems addresses this demand directly by offering potential energy savings of 15-30% compared to conventional control methods. This substantial efficiency improvement represents not only environmental benefits but also significant operational cost reductions for building owners and facility managers.

Beyond energy efficiency, market demand is being shaped by several concurrent trends. The growing implementation of IoT and smart building platforms has created an ecosystem where advanced control systems like MPC can leverage real-time data from multiple sources. Market research indicates that approximately 80% of new commercial construction projects now incorporate some form of building automation system, providing the infrastructure necessary for advanced control strategies.

Occupant comfort and health considerations have emerged as equally important market drivers, particularly following the COVID-19 pandemic. Studies show that optimal indoor environmental quality can improve worker productivity by 8-11%, representing substantial economic value for commercial enterprises. MPC's ability to balance multiple objectives simultaneously—including thermal comfort, air quality, and energy efficiency—positions it as an ideal solution for these complex requirements.

Regional market analysis reveals varying adoption rates and drivers. North America currently leads with approximately 35% market share, driven primarily by corporate sustainability initiatives and energy cost concerns. The Asia-Pacific region shows the fastest growth rate at 12.7% annually, fueled by rapid urbanization and new construction. European markets are particularly responsive to regulatory pressures, with the EU's carbon neutrality goals accelerating adoption of advanced control technologies.

The market is further segmented by building type, with commercial office spaces representing the largest segment (42%), followed by healthcare facilities (18%), educational institutions (15%), and retail establishments (12%). Each sector presents unique requirements and challenges for HVAC control implementation.

Energy conservation remains the primary driver for this market expansion. Commercial buildings account for nearly 40% of global energy consumption, with HVAC systems responsible for roughly 40-60% of that energy usage. This significant energy footprint has prompted stringent regulations worldwide, including the European Energy Performance of Buildings Directive and ASHRAE 90.1 standards in North America, which mandate improved HVAC efficiency.

The integration of Model Predictive Control (MPC) in advanced HVAC systems addresses this demand directly by offering potential energy savings of 15-30% compared to conventional control methods. This substantial efficiency improvement represents not only environmental benefits but also significant operational cost reductions for building owners and facility managers.

Beyond energy efficiency, market demand is being shaped by several concurrent trends. The growing implementation of IoT and smart building platforms has created an ecosystem where advanced control systems like MPC can leverage real-time data from multiple sources. Market research indicates that approximately 80% of new commercial construction projects now incorporate some form of building automation system, providing the infrastructure necessary for advanced control strategies.

Occupant comfort and health considerations have emerged as equally important market drivers, particularly following the COVID-19 pandemic. Studies show that optimal indoor environmental quality can improve worker productivity by 8-11%, representing substantial economic value for commercial enterprises. MPC's ability to balance multiple objectives simultaneously—including thermal comfort, air quality, and energy efficiency—positions it as an ideal solution for these complex requirements.

Regional market analysis reveals varying adoption rates and drivers. North America currently leads with approximately 35% market share, driven primarily by corporate sustainability initiatives and energy cost concerns. The Asia-Pacific region shows the fastest growth rate at 12.7% annually, fueled by rapid urbanization and new construction. European markets are particularly responsive to regulatory pressures, with the EU's carbon neutrality goals accelerating adoption of advanced control technologies.

The market is further segmented by building type, with commercial office spaces representing the largest segment (42%), followed by healthcare facilities (18%), educational institutions (15%), and retail establishments (12%). Each sector presents unique requirements and challenges for HVAC control implementation.

Current MPC Implementation Challenges in HVAC

Despite the promising potential of Model Predictive Control (MPC) in HVAC systems, several significant implementation challenges persist that hinder widespread adoption. One primary obstacle is the complexity of developing accurate building thermal models. These models must account for numerous variables including building envelope characteristics, occupancy patterns, equipment performance, and external weather conditions. The non-linear nature of building thermal dynamics further complicates model development, often requiring sophisticated system identification techniques that demand specialized expertise.

Computational burden represents another substantial challenge. MPC algorithms require solving optimization problems in real-time, which can be computationally intensive, especially for large commercial buildings with multiple zones and complex HVAC configurations. This computational demand often necessitates powerful hardware or cloud-based solutions, increasing implementation costs and potentially introducing latency issues in control responses.

The economic barrier to MPC implementation remains significant. Initial costs include hardware upgrades, software development, commissioning, and staff training. While long-term energy savings typically offset these investments, the extended payback periods (often 3-5 years) deter many facility managers from adoption, particularly in smaller buildings where the cost-benefit ratio is less favorable.

Technical integration challenges also impede MPC deployment. Many existing buildings operate with legacy Building Management Systems (BMS) that lack the necessary communication protocols or data handling capabilities to implement advanced control strategies. Retrofitting these systems requires substantial modifications to both hardware and software infrastructure, creating additional technical hurdles and costs.

Sensor limitations further constrain MPC effectiveness. Optimal control performance depends on accurate, real-time measurements of various parameters, yet many buildings have insufficient sensor networks or rely on sensors with inadequate accuracy or reliability. The cost of installing comprehensive sensor networks represents another financial barrier to implementation.

Uncertainty management remains an ongoing research challenge. MPC performance is highly dependent on the ability to handle uncertainties in weather forecasts, occupancy patterns, and equipment performance. Current approaches often struggle to balance robustness against uncertainty with control performance, particularly in highly variable environments.

Finally, the knowledge gap among building operators and facility managers presents a significant practical barrier. The complexity of MPC systems requires specialized knowledge for operation and maintenance that is often unavailable in typical building management teams, necessitating either extensive training programs or ongoing external technical support.

Computational burden represents another substantial challenge. MPC algorithms require solving optimization problems in real-time, which can be computationally intensive, especially for large commercial buildings with multiple zones and complex HVAC configurations. This computational demand often necessitates powerful hardware or cloud-based solutions, increasing implementation costs and potentially introducing latency issues in control responses.

The economic barrier to MPC implementation remains significant. Initial costs include hardware upgrades, software development, commissioning, and staff training. While long-term energy savings typically offset these investments, the extended payback periods (often 3-5 years) deter many facility managers from adoption, particularly in smaller buildings where the cost-benefit ratio is less favorable.

Technical integration challenges also impede MPC deployment. Many existing buildings operate with legacy Building Management Systems (BMS) that lack the necessary communication protocols or data handling capabilities to implement advanced control strategies. Retrofitting these systems requires substantial modifications to both hardware and software infrastructure, creating additional technical hurdles and costs.

Sensor limitations further constrain MPC effectiveness. Optimal control performance depends on accurate, real-time measurements of various parameters, yet many buildings have insufficient sensor networks or rely on sensors with inadequate accuracy or reliability. The cost of installing comprehensive sensor networks represents another financial barrier to implementation.

Uncertainty management remains an ongoing research challenge. MPC performance is highly dependent on the ability to handle uncertainties in weather forecasts, occupancy patterns, and equipment performance. Current approaches often struggle to balance robustness against uncertainty with control performance, particularly in highly variable environments.

Finally, the knowledge gap among building operators and facility managers presents a significant practical barrier. The complexity of MPC systems requires specialized knowledge for operation and maintenance that is often unavailable in typical building management teams, necessitating either extensive training programs or ongoing external technical support.

State-of-the-Art MPC Algorithms for HVAC

01 Advanced MPC algorithms for improved control efficiency

Advanced Model Predictive Control (MPC) algorithms can significantly improve control efficiency in various systems. These algorithms utilize mathematical models to predict future system behavior and optimize control actions accordingly. By incorporating techniques such as adaptive modeling, constraint handling, and multi-objective optimization, these advanced MPC implementations can achieve better performance with reduced computational overhead, leading to more efficient control systems in industrial applications.- Advanced MPC algorithms for improved control efficiency: Advanced Model Predictive Control (MPC) algorithms can significantly improve control efficiency in various systems. These algorithms incorporate optimization techniques to predict future system behavior and calculate optimal control actions. By considering constraints and multiple objectives simultaneously, these advanced algorithms can achieve better performance, faster response times, and reduced computational load compared to traditional control methods.

- Real-time adaptation and computational efficiency in MPC: Real-time adaptation mechanisms in Model Predictive Control systems enhance control efficiency by dynamically adjusting to changing conditions. These approaches focus on reducing computational complexity while maintaining control performance, enabling faster execution cycles and more responsive control. Techniques include efficient matrix computations, parallel processing, and simplified model representations that balance accuracy with computational demands.

- MPC integration with industrial processes and systems: The integration of Model Predictive Control with industrial processes and systems enhances operational efficiency across various applications. This approach involves tailoring MPC strategies to specific industrial requirements, such as manufacturing, energy systems, and chemical processes. By incorporating domain-specific constraints and objectives, these integrated solutions optimize resource utilization, improve product quality, and reduce energy consumption while maintaining stable operation.

- Robust MPC design for handling uncertainties and disturbances: Robust Model Predictive Control designs improve control efficiency by effectively handling system uncertainties and external disturbances. These approaches incorporate uncertainty models and disturbance rejection techniques to maintain stable and efficient operation under varying conditions. By accounting for potential variations in system parameters and external influences, robust MPC designs ensure consistent performance and prevent control degradation in challenging environments.

- Machine learning enhanced MPC for adaptive performance: Machine learning techniques can enhance Model Predictive Control efficiency through adaptive modeling and optimization. By incorporating learning algorithms, MPC systems can continuously improve their predictive models based on operational data, leading to better control decisions over time. These hybrid approaches combine the theoretical strengths of MPC with the adaptive capabilities of machine learning to handle complex, nonlinear systems and changing operating conditions more effectively.

02 Real-time optimization techniques in MPC

Real-time optimization techniques enhance the efficiency of Model Predictive Control systems by enabling faster computation and implementation of control strategies. These techniques include fast solving algorithms, parallel processing, and efficient model reduction methods that maintain prediction accuracy while decreasing computational load. Real-time optimization allows MPC to be applied in systems with strict timing requirements, improving overall control efficiency while maintaining robust performance.Expand Specific Solutions03 Integration of MPC with other control strategies

Integrating Model Predictive Control with complementary control strategies creates hybrid systems that leverage the strengths of each approach. These integrations may combine MPC with PID control, fuzzy logic, neural networks, or other control methodologies. Such hybrid approaches can enhance control efficiency by using MPC for complex, constrained optimization while employing simpler control methods for fast response requirements, resulting in more efficient overall system performance across various operating conditions.Expand Specific Solutions04 Distributed MPC architectures for complex systems

Distributed Model Predictive Control architectures improve control efficiency in large-scale and complex systems by dividing the control problem into smaller, more manageable sub-problems. These architectures enable parallel computation across multiple controllers while maintaining coordination through communication protocols. Distributed MPC reduces computational burden, improves scalability, and enhances fault tolerance, making it particularly effective for controlling interconnected systems such as power grids, chemical processes, and manufacturing facilities.Expand Specific Solutions05 Adaptive and learning-based MPC frameworks

Adaptive and learning-based Model Predictive Control frameworks continuously improve control efficiency through online model adaptation and performance learning. These frameworks incorporate techniques such as reinforcement learning, Bayesian optimization, and recursive model identification to adjust control parameters based on observed system behavior. By automatically adapting to changing system dynamics and disturbances, these advanced MPC implementations maintain optimal performance over time, reducing the need for manual retuning and improving long-term control efficiency.Expand Specific Solutions

Leading HVAC MPC Solution Providers

Model Predictive Control (MPC) in advanced HVAC systems is evolving rapidly in a growth market phase, with the global smart HVAC controls market expected to reach $28 billion by 2025. The technology is transitioning from early adoption to mainstream implementation, with varying levels of maturity across applications. Johnson Controls, Siemens, and Honeywell lead the market with comprehensive solutions integrating AI and IoT capabilities, while companies like Gree Electric and Azbil are advancing regional innovations. Emerging players such as Brain4energy and Xinzhi Energy are introducing specialized MPC solutions focusing on energy efficiency. Academic institutions including Syracuse University and Nanyang Technological University are contributing significant research to advance algorithmic approaches and implementation methodologies.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed an advanced Model Predictive Control framework specifically designed for variable refrigerant flow (VRF) HVAC systems, which they've integrated into their GMV series products. Their approach utilizes detailed compressor and heat exchanger models to optimize refrigerant flow rates and temperatures across multiple indoor units from a single outdoor condensing unit. Gree's MPC implementation features specialized algorithms that account for the nonlinear characteristics of refrigeration cycles, enabling more precise control than conventional methods. Their system employs a distributed control architecture where a central controller coordinates multiple zone-level controllers, each running localized predictive models. Gree has incorporated machine learning techniques to improve prediction accuracy over time, with their systems analyzing operational data to refine thermal response models. Field testing has demonstrated energy savings of 15-30% compared to conventional VRF control methods, with particularly strong performance in partial-load conditions. Their MPC technology includes specialized modes for humidity control and air quality management beyond simple temperature regulation.

Strengths: Specialized optimization for VRF systems; distributed control architecture improves reliability; strong performance in partial-load conditions common in commercial buildings. Weaknesses: Less comprehensive building-wide integration compared to building automation specialists; primarily focused on their own equipment rather than multi-vendor environments; more limited deployment in Western markets.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has developed a comprehensive Model Predictive Control framework for HVAC systems called OpenBlue, which integrates building automation with advanced analytics. Their solution employs physics-based models combined with machine learning algorithms to predict building thermal behavior and optimize HVAC operations. The system continuously collects data from sensors throughout buildings to create digital twins that simulate building performance under various conditions. Johnson Controls' MPC technology can forecast weather patterns, occupancy trends, and energy prices to proactively adjust HVAC settings 4-8 hours in advance, achieving 20-30% energy savings compared to conventional control systems. Their Enterprise Management platform provides centralized control across multiple buildings, allowing for fleet-wide optimization and demand response capabilities that can reduce peak loads by up to 40% during high-demand periods.

Strengths: Comprehensive integration with building management systems; proven energy savings of 20-30%; extensive sensor network and digital twin capabilities. Weaknesses: Implementation requires significant upfront investment; complex deployment requiring specialized expertise; potential challenges with retrofitting older HVAC systems.

Key Patents and Research in HVAC Predictive Control

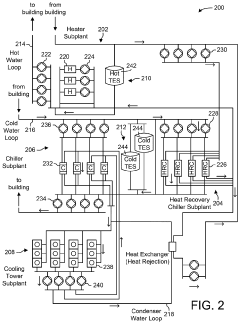

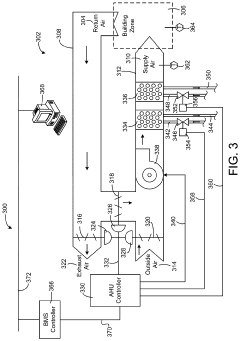

Building HVAC system with modular cascaded model

PatentActiveUS20210041127A1

Innovation

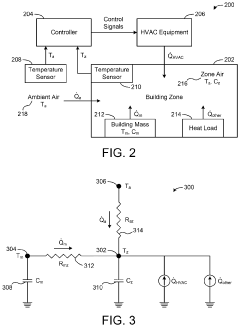

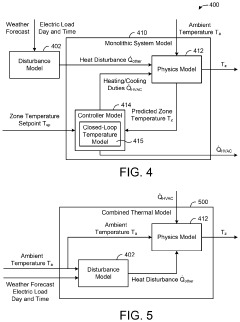

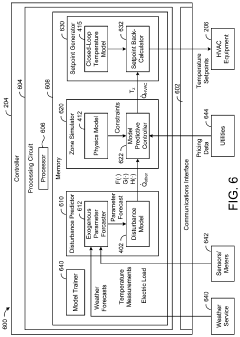

- A cascaded model comprising a disturbance model and a physics model is used, where the disturbance model predicts heat disturbances as a function of exogenous parameters, and the physics model predicts temperature based on these disturbances and HVAC actions, allowing for the generation of control signals to optimize heating or cooling without requiring direct measurement of heat disturbances.

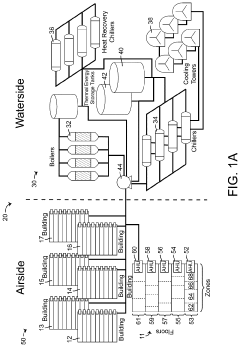

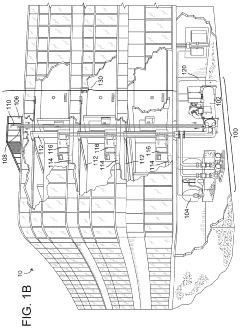

Building HVAC system with multi-level model predictive control

PatentActiveUS20210034024A1

Innovation

- A distributed MPC system is implemented, comprising a high-level MPC and multiple low-level MPCs for both airside and waterside systems, which generates optimal load profiles and setpoints to minimize total energy cost by considering both airside and waterside power consumption, allowing for simultaneous management of airside and waterside systems and decomposing the optimization problem into more manageable sub-problems.

Energy Efficiency and Sustainability Impact

The implementation of Model Predictive Control (MPC) in advanced HVAC systems represents a significant advancement in building energy management with profound implications for energy efficiency and sustainability. Studies indicate that MPC-based HVAC control strategies can reduce energy consumption by 15-30% compared to conventional control methods, directly contributing to lower carbon emissions and operational costs in commercial and residential buildings.

MPC's ability to anticipate future conditions and optimize system performance proactively creates substantial environmental benefits. By minimizing energy waste through precise load matching and optimal start-stop timing, these systems reduce the carbon footprint associated with building operations. This is particularly significant considering that buildings account for approximately 40% of global energy consumption and one-third of greenhouse gas emissions worldwide.

The sustainability impact extends beyond direct energy savings. MPC-enabled HVAC systems demonstrate enhanced ability to integrate with renewable energy sources, effectively managing the intermittent nature of solar and wind power. This integration capability facilitates higher renewable energy penetration in building operations, further reducing reliance on fossil fuels and associated emissions.

From a lifecycle perspective, the improved operational efficiency translates to reduced wear on HVAC equipment, extending system lifespan and decreasing the environmental impact associated with manufacturing and disposing of replacement components. The resulting reduction in maintenance requirements also contributes to resource conservation and waste reduction.

Economic sustainability benefits are equally compelling. Despite higher initial implementation costs, MPC systems typically achieve payback periods of 2-5 years through energy savings alone. This favorable return on investment makes the technology increasingly attractive to building owners and operators seeking both environmental and financial sustainability.

In regions with dynamic electricity pricing, MPC systems demonstrate exceptional capability to shift loads to off-peak periods, reducing strain on electrical grids during high-demand periods. This load-shifting capability not only reduces energy costs but also supports grid stability and resilience, contributing to broader energy system sustainability.

The data-driven nature of MPC systems also enables continuous performance monitoring and verification, supporting ongoing sustainability reporting and certification requirements. This aspect is increasingly valuable as regulatory frameworks and corporate sustainability commitments become more stringent regarding building energy performance and emissions.

MPC's ability to anticipate future conditions and optimize system performance proactively creates substantial environmental benefits. By minimizing energy waste through precise load matching and optimal start-stop timing, these systems reduce the carbon footprint associated with building operations. This is particularly significant considering that buildings account for approximately 40% of global energy consumption and one-third of greenhouse gas emissions worldwide.

The sustainability impact extends beyond direct energy savings. MPC-enabled HVAC systems demonstrate enhanced ability to integrate with renewable energy sources, effectively managing the intermittent nature of solar and wind power. This integration capability facilitates higher renewable energy penetration in building operations, further reducing reliance on fossil fuels and associated emissions.

From a lifecycle perspective, the improved operational efficiency translates to reduced wear on HVAC equipment, extending system lifespan and decreasing the environmental impact associated with manufacturing and disposing of replacement components. The resulting reduction in maintenance requirements also contributes to resource conservation and waste reduction.

Economic sustainability benefits are equally compelling. Despite higher initial implementation costs, MPC systems typically achieve payback periods of 2-5 years through energy savings alone. This favorable return on investment makes the technology increasingly attractive to building owners and operators seeking both environmental and financial sustainability.

In regions with dynamic electricity pricing, MPC systems demonstrate exceptional capability to shift loads to off-peak periods, reducing strain on electrical grids during high-demand periods. This load-shifting capability not only reduces energy costs but also supports grid stability and resilience, contributing to broader energy system sustainability.

The data-driven nature of MPC systems also enables continuous performance monitoring and verification, supporting ongoing sustainability reporting and certification requirements. This aspect is increasingly valuable as regulatory frameworks and corporate sustainability commitments become more stringent regarding building energy performance and emissions.

Building Code Compliance and Standards

The implementation of Model Predictive Control (MPC) in advanced HVAC systems must adhere to various building codes and standards that govern energy efficiency, indoor air quality, and system performance. These regulations vary significantly across different regions and jurisdictions, creating a complex regulatory landscape that manufacturers and system integrators must navigate.

In the United States, ASHRAE Standard 90.1 serves as a cornerstone for energy efficiency requirements in commercial buildings, establishing minimum performance standards for HVAC systems. The standard specifically addresses control strategies, with recent updates increasingly recognizing advanced control methodologies like MPC. Similarly, ASHRAE Standard 62.1 focuses on ventilation requirements for acceptable indoor air quality, which MPC algorithms must incorporate as constraints in their optimization frameworks.

The International Building Code (IBC) and International Energy Conservation Code (IECC) provide additional regulatory frameworks that influence the implementation of MPC in HVAC systems. These codes are updated on three-year cycles, requiring continuous adaptation of control strategies to remain compliant. Recent editions have begun to explicitly address predictive control technologies, acknowledging their potential for energy savings.

In the European context, the Energy Performance of Buildings Directive (EPBD) mandates nearly zero-energy buildings (nZEB) standards, creating strong incentives for advanced control strategies like MPC. The European Committee for Standardization (CEN) has developed standards such as EN 15232, which classifies building automation and control systems according to their energy efficiency potential, with predictive controls achieving the highest ratings.

Certification programs like LEED in North America and BREEAM in Europe award points for advanced HVAC control strategies that optimize energy performance. MPC implementations that demonstrate significant energy savings beyond code minimums can contribute substantially to achieving higher certification levels, driving adoption in premium building projects.

Safety standards also play a crucial role, with regulations like UL 60730 in the US and IEC 60730 internationally establishing requirements for automatic electrical controls. These standards address critical aspects such as software reliability and fault detection, which are particularly relevant for algorithmic control approaches like MPC.

The regulatory landscape continues to evolve, with emerging standards increasingly focusing on grid interaction capabilities. For instance, IEEE 2030.5 provides a standard for communications between utilities and customer energy management systems, enabling MPC algorithms to respond to demand response signals and participate in grid services while maintaining occupant comfort and adhering to building performance requirements.

In the United States, ASHRAE Standard 90.1 serves as a cornerstone for energy efficiency requirements in commercial buildings, establishing minimum performance standards for HVAC systems. The standard specifically addresses control strategies, with recent updates increasingly recognizing advanced control methodologies like MPC. Similarly, ASHRAE Standard 62.1 focuses on ventilation requirements for acceptable indoor air quality, which MPC algorithms must incorporate as constraints in their optimization frameworks.

The International Building Code (IBC) and International Energy Conservation Code (IECC) provide additional regulatory frameworks that influence the implementation of MPC in HVAC systems. These codes are updated on three-year cycles, requiring continuous adaptation of control strategies to remain compliant. Recent editions have begun to explicitly address predictive control technologies, acknowledging their potential for energy savings.

In the European context, the Energy Performance of Buildings Directive (EPBD) mandates nearly zero-energy buildings (nZEB) standards, creating strong incentives for advanced control strategies like MPC. The European Committee for Standardization (CEN) has developed standards such as EN 15232, which classifies building automation and control systems according to their energy efficiency potential, with predictive controls achieving the highest ratings.

Certification programs like LEED in North America and BREEAM in Europe award points for advanced HVAC control strategies that optimize energy performance. MPC implementations that demonstrate significant energy savings beyond code minimums can contribute substantially to achieving higher certification levels, driving adoption in premium building projects.

Safety standards also play a crucial role, with regulations like UL 60730 in the US and IEC 60730 internationally establishing requirements for automatic electrical controls. These standards address critical aspects such as software reliability and fault detection, which are particularly relevant for algorithmic control approaches like MPC.

The regulatory landscape continues to evolve, with emerging standards increasingly focusing on grid interaction capabilities. For instance, IEEE 2030.5 provides a standard for communications between utilities and customer energy management systems, enabling MPC algorithms to respond to demand response signals and participate in grid services while maintaining occupant comfort and adhering to building performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!