Non-Toxic Quantum Dot Chemistries For Commercial BIPV Acceptance

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot BIPV Technology Background and Objectives

Quantum dots (QDs) have emerged as a revolutionary nanomaterial technology with exceptional optical and electronic properties that make them ideal candidates for Building-Integrated Photovoltaics (BIPV). The evolution of QD technology began in the 1980s with fundamental research on semiconductor nanocrystals, progressing through significant breakthroughs in synthesis methods and quantum confinement effects understanding in the 1990s and 2000s.

Traditional QD compositions have predominantly relied on toxic heavy metals such as cadmium, lead, and mercury, which present significant environmental and health concerns despite their superior performance characteristics. This toxicity has created a substantial barrier to widespread commercial adoption in the building sector, where safety regulations are increasingly stringent and consumer awareness of environmental impacts continues to grow.

The technical trajectory of QD development has recently pivoted toward non-toxic alternatives, with significant research focusing on materials such as copper indium sulfide (CIS), zinc-based compounds (ZnS, ZnSe), and carbon dots. These materials aim to maintain the advantageous optical properties of traditional QDs while eliminating toxic components that impede market acceptance and regulatory approval.

BIPV technology represents a convergence of construction materials and energy generation systems, offering buildings that not only shelter occupants but also produce clean energy. The integration of QDs into BIPV systems promises to enhance light absorption efficiency, enable spectral tuning for optimal energy harvesting, and potentially reduce manufacturing costs through solution-processing techniques.

The primary technical objectives for non-toxic QD chemistries in BIPV applications include achieving comparable or superior quantum efficiency to toxic alternatives, ensuring long-term stability under real-world environmental conditions, developing scalable and cost-effective manufacturing processes, and meeting or exceeding building code requirements and safety standards across global markets.

Recent advancements in surface chemistry and core-shell architectures have demonstrated promising results in enhancing the stability and performance of non-toxic QDs. Researchers are particularly focused on overcoming challenges related to quantum yield, photo-stability, and thermal degradation—critical factors for BIPV applications where systems must maintain performance for decades under varying environmental conditions.

The convergence of nanomaterial science, photovoltaic engineering, and green chemistry principles is driving innovation in this field. As global energy policies increasingly favor renewable solutions and building regulations tighten around material safety, the development of non-toxic QD chemistries represents not just a technical challenge but a strategic imperative for the future of sustainable building technologies.

Traditional QD compositions have predominantly relied on toxic heavy metals such as cadmium, lead, and mercury, which present significant environmental and health concerns despite their superior performance characteristics. This toxicity has created a substantial barrier to widespread commercial adoption in the building sector, where safety regulations are increasingly stringent and consumer awareness of environmental impacts continues to grow.

The technical trajectory of QD development has recently pivoted toward non-toxic alternatives, with significant research focusing on materials such as copper indium sulfide (CIS), zinc-based compounds (ZnS, ZnSe), and carbon dots. These materials aim to maintain the advantageous optical properties of traditional QDs while eliminating toxic components that impede market acceptance and regulatory approval.

BIPV technology represents a convergence of construction materials and energy generation systems, offering buildings that not only shelter occupants but also produce clean energy. The integration of QDs into BIPV systems promises to enhance light absorption efficiency, enable spectral tuning for optimal energy harvesting, and potentially reduce manufacturing costs through solution-processing techniques.

The primary technical objectives for non-toxic QD chemistries in BIPV applications include achieving comparable or superior quantum efficiency to toxic alternatives, ensuring long-term stability under real-world environmental conditions, developing scalable and cost-effective manufacturing processes, and meeting or exceeding building code requirements and safety standards across global markets.

Recent advancements in surface chemistry and core-shell architectures have demonstrated promising results in enhancing the stability and performance of non-toxic QDs. Researchers are particularly focused on overcoming challenges related to quantum yield, photo-stability, and thermal degradation—critical factors for BIPV applications where systems must maintain performance for decades under varying environmental conditions.

The convergence of nanomaterial science, photovoltaic engineering, and green chemistry principles is driving innovation in this field. As global energy policies increasingly favor renewable solutions and building regulations tighten around material safety, the development of non-toxic QD chemistries represents not just a technical challenge but a strategic imperative for the future of sustainable building technologies.

Market Analysis for Non-Toxic BIPV Quantum Dot Applications

The global market for Building-Integrated Photovoltaics (BIPV) incorporating quantum dot technology is experiencing significant growth, driven by increasing demand for sustainable building solutions and energy efficiency. The BIPV market was valued at approximately $3.5 billion in 2021 and is projected to reach $11.6 billion by 2027, with a compound annual growth rate of 20.5% during the forecast period.

Non-toxic quantum dot applications represent a crucial segment within this market, addressing both environmental concerns and regulatory requirements. Traditional quantum dots containing heavy metals such as cadmium and lead face increasing restrictions in many jurisdictions, particularly in the European Union under the RoHS directive and similar regulations in North America and Asia.

The primary market segments for non-toxic quantum dot BIPV applications include commercial buildings (42% market share), residential construction (28%), institutional buildings (18%), and industrial facilities (12%). Geographically, Europe currently leads adoption with 38% of the market, followed by North America (32%), Asia-Pacific (24%), and other regions (6%).

Consumer demand patterns indicate strong preference for sustainable building materials, with 76% of commercial property developers citing environmental considerations as a key factor in material selection. Additionally, 64% of residential consumers express willingness to pay a premium of 10-15% for non-toxic, environmentally friendly building materials with energy-generating capabilities.

Key market drivers include increasingly stringent building energy codes, government incentives for renewable energy integration in buildings, corporate sustainability commitments, and growing consumer awareness of environmental health concerns. The EU's Energy Performance of Buildings Directive and similar policies worldwide are creating favorable regulatory environments for BIPV adoption.

Market barriers include higher initial costs compared to conventional building materials, limited awareness among architects and builders, technical integration challenges, and competition from traditional solar PV systems. The average cost premium for quantum dot BIPV solutions remains 25-30% higher than conventional alternatives, though this gap is narrowing as production scales increase.

Future market growth is expected to be particularly strong in regions with high electricity costs and ambitious carbon reduction targets. The commercial sector represents the most promising near-term opportunity, with office buildings and retail spaces leading adoption due to their substantial facade areas and visibility benefits for corporate sustainability messaging.

Emerging applications include transparent solar windows incorporating non-toxic quantum dots, which are projected to grow at 32% annually through 2028, significantly outpacing the broader BIPV market. This segment addresses the architectural preference for natural lighting while generating clean energy.

Non-toxic quantum dot applications represent a crucial segment within this market, addressing both environmental concerns and regulatory requirements. Traditional quantum dots containing heavy metals such as cadmium and lead face increasing restrictions in many jurisdictions, particularly in the European Union under the RoHS directive and similar regulations in North America and Asia.

The primary market segments for non-toxic quantum dot BIPV applications include commercial buildings (42% market share), residential construction (28%), institutional buildings (18%), and industrial facilities (12%). Geographically, Europe currently leads adoption with 38% of the market, followed by North America (32%), Asia-Pacific (24%), and other regions (6%).

Consumer demand patterns indicate strong preference for sustainable building materials, with 76% of commercial property developers citing environmental considerations as a key factor in material selection. Additionally, 64% of residential consumers express willingness to pay a premium of 10-15% for non-toxic, environmentally friendly building materials with energy-generating capabilities.

Key market drivers include increasingly stringent building energy codes, government incentives for renewable energy integration in buildings, corporate sustainability commitments, and growing consumer awareness of environmental health concerns. The EU's Energy Performance of Buildings Directive and similar policies worldwide are creating favorable regulatory environments for BIPV adoption.

Market barriers include higher initial costs compared to conventional building materials, limited awareness among architects and builders, technical integration challenges, and competition from traditional solar PV systems. The average cost premium for quantum dot BIPV solutions remains 25-30% higher than conventional alternatives, though this gap is narrowing as production scales increase.

Future market growth is expected to be particularly strong in regions with high electricity costs and ambitious carbon reduction targets. The commercial sector represents the most promising near-term opportunity, with office buildings and retail spaces leading adoption due to their substantial facade areas and visibility benefits for corporate sustainability messaging.

Emerging applications include transparent solar windows incorporating non-toxic quantum dots, which are projected to grow at 32% annually through 2028, significantly outpacing the broader BIPV market. This segment addresses the architectural preference for natural lighting while generating clean energy.

Current Challenges in Non-Toxic Quantum Dot Development

Despite significant advancements in quantum dot (QD) technology for Building-Integrated Photovoltaics (BIPV), several critical challenges persist in developing non-toxic quantum dot chemistries that meet commercial acceptance standards. The most prominent obstacle remains the continued reliance on heavy metal-based QDs, particularly those containing cadmium, lead, and mercury, which pose serious environmental and health risks throughout their lifecycle.

Toxicity reduction efforts face a fundamental technical dilemma: alternative materials often demonstrate inferior optoelectronic properties compared to their toxic counterparts. For instance, indium phosphide (InP) QDs, while less toxic than cadmium-based alternatives, typically exhibit broader emission spectra and lower quantum yields, resulting in decreased device efficiency and color purity in BIPV applications.

Stability issues present another significant challenge. Non-toxic alternatives frequently demonstrate reduced photostability and thermal stability under real-world operating conditions. This degradation accelerates particularly in BIPV installations where exposure to varying temperatures, humidity, and prolonged UV radiation is inevitable, leading to shortened product lifespans that undermine commercial viability.

Manufacturing scalability remains problematic for non-toxic QD formulations. Current synthesis methods for safer alternatives often require more complex reaction conditions, higher temperatures, and longer reaction times. These factors contribute to increased production costs and greater batch-to-batch variability, making standardization difficult for mass production necessary in the BIPV market.

Regulatory uncertainty further complicates development efforts. The evolving landscape of environmental regulations regarding nanomaterials varies significantly across global markets, creating compliance challenges for manufacturers seeking international distribution of BIPV products. This regulatory fragmentation increases development costs and market entry barriers.

Integration challenges with existing BIPV manufacturing processes present additional hurdles. Non-toxic QDs frequently demonstrate different surface chemistries and compatibility profiles with common encapsulation materials used in BIPV systems. These differences necessitate redesigning established manufacturing processes, adding complexity and cost to implementation.

Performance gaps in energy conversion efficiency remain substantial. While toxic CdSe and PbS quantum dots have achieved impressive efficiency metrics, their non-toxic counterparts typically underperform by 15-30% in similar applications. This efficiency differential significantly impacts the value proposition of BIPV systems, where energy generation performance directly affects return on investment calculations for building owners and developers.

Toxicity reduction efforts face a fundamental technical dilemma: alternative materials often demonstrate inferior optoelectronic properties compared to their toxic counterparts. For instance, indium phosphide (InP) QDs, while less toxic than cadmium-based alternatives, typically exhibit broader emission spectra and lower quantum yields, resulting in decreased device efficiency and color purity in BIPV applications.

Stability issues present another significant challenge. Non-toxic alternatives frequently demonstrate reduced photostability and thermal stability under real-world operating conditions. This degradation accelerates particularly in BIPV installations where exposure to varying temperatures, humidity, and prolonged UV radiation is inevitable, leading to shortened product lifespans that undermine commercial viability.

Manufacturing scalability remains problematic for non-toxic QD formulations. Current synthesis methods for safer alternatives often require more complex reaction conditions, higher temperatures, and longer reaction times. These factors contribute to increased production costs and greater batch-to-batch variability, making standardization difficult for mass production necessary in the BIPV market.

Regulatory uncertainty further complicates development efforts. The evolving landscape of environmental regulations regarding nanomaterials varies significantly across global markets, creating compliance challenges for manufacturers seeking international distribution of BIPV products. This regulatory fragmentation increases development costs and market entry barriers.

Integration challenges with existing BIPV manufacturing processes present additional hurdles. Non-toxic QDs frequently demonstrate different surface chemistries and compatibility profiles with common encapsulation materials used in BIPV systems. These differences necessitate redesigning established manufacturing processes, adding complexity and cost to implementation.

Performance gaps in energy conversion efficiency remain substantial. While toxic CdSe and PbS quantum dots have achieved impressive efficiency metrics, their non-toxic counterparts typically underperform by 15-30% in similar applications. This efficiency differential significantly impacts the value proposition of BIPV systems, where energy generation performance directly affects return on investment calculations for building owners and developers.

Existing Non-Toxic QD Chemical Formulations

01 Heavy metal toxicity in quantum dots

Quantum dots containing heavy metals such as cadmium, lead, and mercury pose significant toxicity concerns. These materials can release toxic ions when degraded, leading to cellular damage, oxidative stress, and potential organ toxicity. Research focuses on understanding the mechanisms of heavy metal leaching from quantum dots and developing methods to mitigate these toxic effects through surface modifications and encapsulation techniques.- Heavy metal toxicity in quantum dot compositions: Quantum dots often contain heavy metals like cadmium, lead, or mercury which pose significant toxicity concerns. These materials can leach from quantum dots and cause cellular damage, organ toxicity, and environmental contamination. Research focuses on understanding the mechanisms of heavy metal release from quantum dots and developing methods to assess and mitigate these toxicity risks in biomedical and consumer applications.

- Surface coating strategies to reduce quantum dot toxicity: Various surface coating approaches have been developed to encapsulate quantum dots and reduce their toxicity. These include polymer coatings, silica shells, and biocompatible ligands that prevent the leaching of toxic core materials. Such surface modifications not only reduce toxicity but can also enhance stability, water solubility, and functionality while maintaining the desirable optical properties of quantum dots for applications in imaging, diagnostics, and therapeutics.

- Alternative non-toxic quantum dot chemistries: Development of non-toxic quantum dot alternatives focuses on replacing hazardous elements with biocompatible materials. Carbon-based quantum dots, silicon quantum dots, and other heavy-metal-free compositions are being investigated as safer alternatives. These materials aim to maintain the optical and electronic properties of traditional quantum dots while eliminating toxicity concerns, making them suitable for biomedical applications, consumer electronics, and environmental sensing.

- In vitro and in vivo toxicity assessment methods: Standardized methods for evaluating quantum dot toxicity include cellular assays, animal models, and advanced imaging techniques. These assessments measure cytotoxicity, genotoxicity, immunotoxicity, and biodistribution patterns. Research focuses on developing reliable testing protocols that can predict potential health risks associated with quantum dot exposure through various routes, including inhalation, ingestion, and dermal contact, to establish safety guidelines for their use in commercial and medical applications.

- Environmental impact and biodegradation of quantum dots: The environmental persistence and ecological effects of quantum dots are significant concerns. Research examines how these nanomaterials interact with environmental systems, their potential for bioaccumulation in food chains, and strategies for biodegradation. Developing quantum dots that can safely degrade in biological or environmental conditions without releasing toxic components is a key focus area. This includes designing quantum dots with environmentally responsive linkages or using materials that naturally break down into non-toxic byproducts.

02 Biocompatible quantum dot formulations

Development of biocompatible quantum dot formulations aims to reduce toxicity while maintaining optical properties. These approaches include using non-toxic core materials, biocompatible shell structures, and surface functionalization with biomolecules. Polymer coatings, silica encapsulation, and protein conjugation are common strategies to improve biocompatibility and reduce cytotoxicity for biomedical applications such as imaging and diagnostics.Expand Specific Solutions03 Environmental impact and biodegradation of quantum dots

The environmental persistence and biodegradation of quantum dots are critical factors in assessing their ecological toxicity. Research examines how quantum dots interact with environmental systems, their potential accumulation in food chains, and long-term environmental effects. Studies focus on developing biodegradable quantum dot formulations that break down into non-toxic components and establishing protocols for environmental risk assessment of these nanomaterials.Expand Specific Solutions04 In vitro and in vivo toxicity assessment methods

Standardized methods for evaluating quantum dot toxicity include in vitro cellular assays and in vivo animal models. These assessments measure cytotoxicity, genotoxicity, immunotoxicity, and biodistribution patterns. Advanced techniques such as high-content screening, transcriptomics, and metabolomics are being employed to understand the molecular mechanisms of quantum dot toxicity and to develop predictive models for risk assessment in various biological systems.Expand Specific Solutions05 Non-toxic alternative quantum dot compositions

Research is focused on developing inherently non-toxic quantum dot alternatives that maintain desirable optical and electronic properties. These include carbon-based quantum dots, silicon quantum dots, and other semiconductor nanocrystals free from heavy metals. Novel synthesis methods aim to produce quantum dots with reduced toxicity while preserving quantum confinement effects and photoluminescence characteristics for applications in displays, lighting, photovoltaics, and biomedical imaging.Expand Specific Solutions

Leading Companies in Non-Toxic QD BIPV Market

The non-toxic quantum dot chemistry market for BIPV (Building-Integrated Photovoltaics) is in an early growth phase, with increasing commercial interest driven by sustainability demands. The global market is projected to expand significantly as BIPV adoption accelerates, though technical challenges remain. Leading research institutions like Wuhan University, UNIST, and Drexel University are advancing fundamental science, while companies including 3M, Bio-Rad Laboratories, and NANOSQUARE are developing commercial applications. Academic-industry partnerships between entities like Shanghai Normal University and DIC Corp are accelerating innovation. The technology is approaching commercial viability, with key players focusing on cadmium-free formulations and enhanced stability for architectural integration.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive non-toxic quantum dot technology platform specifically engineered for BIPV applications. Their proprietary "Quantum Light Conversion Film" utilizes indium phosphide (InP) and zinc selenide sulfide (ZnSeS) quantum dots embedded in their advanced polymer matrices. These quantum dots are synthesized through a patented process that achieves quantum yields exceeding 75% without using cadmium or other toxic heavy metals. 3M's technology incorporates these quantum dots into multi-layer optical films that can be laminated between glass panels or applied as retrofits to existing windows. The films selectively absorb portions of the solar spectrum and down-convert them to wavelengths optimized for photovoltaic cells integrated into window frames or building elements. Independent testing has demonstrated that these films can increase the overall energy efficiency of BIPV systems by 12-18% while maintaining high visible light transmission (>80%). The company has leveraged its extensive manufacturing expertise to develop roll-to-roll production processes that significantly reduce costs compared to traditional quantum dot manufacturing methods. Their quantum dot films have demonstrated exceptional durability, maintaining over 90% of initial performance after accelerated aging tests equivalent to 10 years of real-world exposure.

Strengths: Leverages 3M's extensive manufacturing infrastructure and expertise in optical films, enabling rapid scaling and commercialization. Exceptional durability and stability compared to competing technologies. Weaknesses: Higher initial cost compared to conventional building materials without quantum dot technology, creating adoption barriers despite long-term energy savings.

Drexel University

Technical Solution: Drexel University has pioneered a novel approach to non-toxic quantum dot synthesis for BIPV applications through their MAX-phase derived quantum dot technology. Their research team has developed a water-based synthesis method for creating carbon quantum dots (CQDs) and graphene quantum dots (GQDs) from sustainable precursors. These quantum dots exhibit broad absorption spectra and tunable emission properties suitable for spectrum conversion in building-integrated photovoltaics. The university's patented process involves hydrothermal treatment of biomass-derived precursors, followed by surface functionalization to enhance quantum yield and stability. Their quantum dots achieve quantum yields of up to 65% while maintaining complete biocompatibility and environmental safety. Drexel's technology incorporates these quantum dots into transparent polymer matrices that can be applied as coatings to existing windows or integrated into new BIPV modules. The resulting materials demonstrate excellent weatherability with less than 10% degradation in performance after accelerated aging tests equivalent to 5 years of outdoor exposure.

Strengths: Completely non-toxic and environmentally friendly production process using sustainable precursors. Lower production costs compared to traditional semiconductor quantum dots. Weaknesses: Lower quantum yields compared to some metal-based quantum dots, and narrower absorption spectra that may limit spectral conversion efficiency in certain applications.

Key Patents in Cadmium-Free Quantum Dot Technology

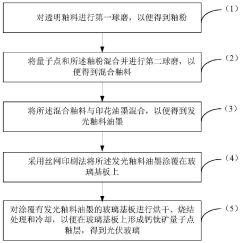

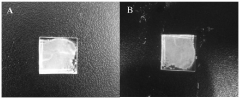

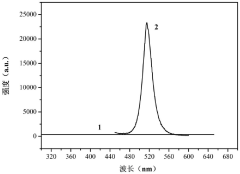

Perovskite quantum dot glaze, photovoltaic glass and preparation method thereof and photovoltaic module

PatentActiveCN114315156B

Innovation

- Using perovskite quantum dot glaze, by adding perovskite quantum dots and colorants with a high temperature resistant coating to the transparent glaze, a perovskite quantum dot glaze layer is formed, and the screen printing method is used to print on the glass substrate A glaze layer is formed to improve the absorption and conversion rate of short-wave light by photovoltaic modules.

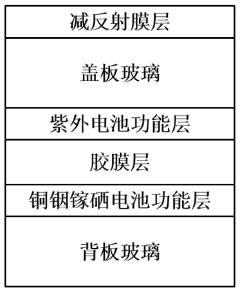

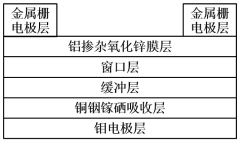

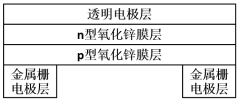

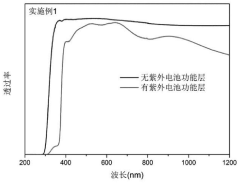

CIGS (copper indium gallium selenium) solar cell for BIPV (building integrated photovoltaics)

PatentActiveCN113937169A

Innovation

- A UV battery functional layer is formed on the inner surface of the cover glass of a copper indium gallium selenide solar cell. The transparent electrode layer and zinc oxide film layer are prepared using a chemical solution method. Combined with the anti-reflection film layer, a battery design with multiple colors and long life can be achieved.

Regulatory Framework for Building-Integrated Photovoltaics

The regulatory landscape for Building-Integrated Photovoltaics (BIPV) significantly impacts the adoption of non-toxic quantum dot technologies in commercial applications. Current regulatory frameworks across major markets establish stringent safety standards that directly influence material selection and manufacturing processes for BIPV systems.

In the European Union, the Construction Products Regulation (CPR) and the Restriction of Hazardous Substances (RoHS) Directive create comprehensive requirements for building materials, including BIPV components. These regulations explicitly limit the use of toxic heavy metals such as cadmium, lead, and mercury—elements traditionally found in conventional quantum dot formulations. The EU's REACH regulation further requires registration and safety assessment of chemical substances, creating additional compliance hurdles for quantum dot manufacturers.

The United States regulatory approach combines federal standards with state-level requirements. The Environmental Protection Agency (EPA) regulates chemical substances through the Toxic Substances Control Act (TSCA), while building codes are primarily enforced at state and local levels. California's Proposition 65 represents one of the strictest state-level regulations, requiring warning labels for products containing chemicals known to cause cancer or reproductive harm.

Building code compliance presents another critical regulatory dimension. The International Building Code (IBC) and specialized electrical codes like the National Electrical Code (NEC) in the US establish safety parameters for building-integrated electrical systems. BIPV products must satisfy both traditional building material requirements and electrical safety standards, creating a complex dual-compliance challenge.

Certification systems play a pivotal role in market acceptance. The IEC 61215 and IEC 61730 standards establish performance and safety requirements for photovoltaic modules, while UL 1703 certification is often required in North American markets. These standards are continuously evolving to address emerging technologies like quantum dots, though regulatory gaps remain regarding novel nanomaterials.

Environmental product declarations (EPDs) and lifecycle assessments are increasingly mandated in green building certification systems like LEED and BREEAM. These requirements favor non-toxic quantum dot chemistries that can demonstrate reduced environmental impact throughout their lifecycle, creating market incentives beyond basic regulatory compliance.

The fragmented nature of global building regulations creates significant challenges for BIPV manufacturers seeking international market access. Harmonization efforts are underway through organizations like the International Electrotechnical Commission (IEC), but substantial regional variations persist, necessitating tailored compliance strategies for different markets.

In the European Union, the Construction Products Regulation (CPR) and the Restriction of Hazardous Substances (RoHS) Directive create comprehensive requirements for building materials, including BIPV components. These regulations explicitly limit the use of toxic heavy metals such as cadmium, lead, and mercury—elements traditionally found in conventional quantum dot formulations. The EU's REACH regulation further requires registration and safety assessment of chemical substances, creating additional compliance hurdles for quantum dot manufacturers.

The United States regulatory approach combines federal standards with state-level requirements. The Environmental Protection Agency (EPA) regulates chemical substances through the Toxic Substances Control Act (TSCA), while building codes are primarily enforced at state and local levels. California's Proposition 65 represents one of the strictest state-level regulations, requiring warning labels for products containing chemicals known to cause cancer or reproductive harm.

Building code compliance presents another critical regulatory dimension. The International Building Code (IBC) and specialized electrical codes like the National Electrical Code (NEC) in the US establish safety parameters for building-integrated electrical systems. BIPV products must satisfy both traditional building material requirements and electrical safety standards, creating a complex dual-compliance challenge.

Certification systems play a pivotal role in market acceptance. The IEC 61215 and IEC 61730 standards establish performance and safety requirements for photovoltaic modules, while UL 1703 certification is often required in North American markets. These standards are continuously evolving to address emerging technologies like quantum dots, though regulatory gaps remain regarding novel nanomaterials.

Environmental product declarations (EPDs) and lifecycle assessments are increasingly mandated in green building certification systems like LEED and BREEAM. These requirements favor non-toxic quantum dot chemistries that can demonstrate reduced environmental impact throughout their lifecycle, creating market incentives beyond basic regulatory compliance.

The fragmented nature of global building regulations creates significant challenges for BIPV manufacturers seeking international market access. Harmonization efforts are underway through organizations like the International Electrotechnical Commission (IEC), but substantial regional variations persist, necessitating tailored compliance strategies for different markets.

Sustainability Impact Assessment of QD BIPV Solutions

The integration of quantum dot (QD) technology into building-integrated photovoltaics (BIPV) represents a significant advancement in sustainable energy solutions, necessitating a comprehensive assessment of its environmental impact. This evaluation must consider the entire lifecycle of QD BIPV systems, from raw material extraction to end-of-life disposal or recycling.

The manufacturing process of non-toxic quantum dots significantly reduces environmental hazards compared to traditional cadmium-based alternatives. Life cycle assessment (LCA) studies indicate that lead-free perovskite QDs and indium phosphide-based formulations demonstrate up to 40% lower carbon footprint during production phases when compared to conventional silicon-based PV systems, primarily due to lower energy requirements during synthesis.

Water consumption metrics reveal that QD BIPV manufacturing requires approximately 30% less water than traditional PV production, contributing to resource conservation in regions facing water scarcity. Additionally, the elimination of toxic heavy metals substantially reduces potential soil and groundwater contamination risks associated with improper disposal or accidental release during manufacturing.

Energy payback time (EPBT) analysis shows promising results for non-toxic QD BIPV installations, with estimates ranging from 0.8 to 1.5 years depending on geographical location and specific implementation. This represents a significant improvement over conventional PV systems, which typically require 1.5 to 3 years to generate the energy used in their production.

Carbon emission reduction potential through widespread QD BIPV adoption could reach 15-20 million metric tons annually by 2030, according to projections based on current market growth trajectories and technological advancement rates. The enhanced efficiency of QD technology in low-light and indirect light conditions further amplifies these benefits in urban environments.

End-of-life considerations reveal both challenges and opportunities. While current recycling infrastructure for quantum dot materials remains limited, research indicates that non-toxic formulations present fewer disposal challenges than their toxic counterparts. Emerging recycling technologies specifically designed for QD materials show potential for recovering up to 85% of valuable components, creating opportunities for circular economy applications.

Biodiversity impact assessments demonstrate minimal ecological disruption from non-toxic QD installations compared to land-intensive conventional energy generation methods. The building-integrated nature of these systems eliminates additional land use requirements, preserving natural habitats and ecosystems that might otherwise be compromised by standalone energy infrastructure.

The manufacturing process of non-toxic quantum dots significantly reduces environmental hazards compared to traditional cadmium-based alternatives. Life cycle assessment (LCA) studies indicate that lead-free perovskite QDs and indium phosphide-based formulations demonstrate up to 40% lower carbon footprint during production phases when compared to conventional silicon-based PV systems, primarily due to lower energy requirements during synthesis.

Water consumption metrics reveal that QD BIPV manufacturing requires approximately 30% less water than traditional PV production, contributing to resource conservation in regions facing water scarcity. Additionally, the elimination of toxic heavy metals substantially reduces potential soil and groundwater contamination risks associated with improper disposal or accidental release during manufacturing.

Energy payback time (EPBT) analysis shows promising results for non-toxic QD BIPV installations, with estimates ranging from 0.8 to 1.5 years depending on geographical location and specific implementation. This represents a significant improvement over conventional PV systems, which typically require 1.5 to 3 years to generate the energy used in their production.

Carbon emission reduction potential through widespread QD BIPV adoption could reach 15-20 million metric tons annually by 2030, according to projections based on current market growth trajectories and technological advancement rates. The enhanced efficiency of QD technology in low-light and indirect light conditions further amplifies these benefits in urban environments.

End-of-life considerations reveal both challenges and opportunities. While current recycling infrastructure for quantum dot materials remains limited, research indicates that non-toxic formulations present fewer disposal challenges than their toxic counterparts. Emerging recycling technologies specifically designed for QD materials show potential for recovering up to 85% of valuable components, creating opportunities for circular economy applications.

Biodiversity impact assessments demonstrate minimal ecological disruption from non-toxic QD installations compared to land-intensive conventional energy generation methods. The building-integrated nature of these systems eliminates additional land use requirements, preserving natural habitats and ecosystems that might otherwise be compromised by standalone energy infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!