Nylon 66 vs Bronze: Frictional Analysis for Bushings

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 and Bronze Bushing Technology Background

Bushings, essential components in mechanical systems, have evolved significantly over the centuries. Initially crafted from wood and leather, the industrial revolution brought metal bushings, particularly bronze, which dominated the market for decades due to their excellent mechanical properties and durability. The mid-20th century witnessed a paradigm shift with the introduction of engineering polymers, notably Nylon 66, revolutionizing bushing technology by offering lightweight alternatives with unique tribological characteristics.

Bronze bushings, composed primarily of copper with tin and other elements, have established themselves as reliable components in high-load, high-temperature applications. Their excellent thermal conductivity, dimensional stability, and inherent self-lubricating properties when impregnated with oil have made them industry standards in heavy machinery, automotive applications, and industrial equipment. The technology behind bronze bushings has matured over decades, with various alloy compositions optimized for specific operational conditions.

Nylon 66, a synthetic polyamide developed by DuPont in 1935, emerged as a viable bushing material in the 1950s. Its introduction represented a significant technological advancement, offering substantial weight reduction, corrosion resistance, and noise dampening capabilities. The polymer's unique molecular structure provides inherent lubricity, reducing friction without additional lubricants in many applications. This self-lubricating property has positioned Nylon 66 as an increasingly popular choice in modern engineering designs.

The technological evolution of both materials has been driven by growing demands for energy efficiency, reduced maintenance, and extended component lifespan. Bronze bushing technology has advanced through metallurgical improvements and precision manufacturing techniques, while Nylon 66 has benefited from polymer science breakthroughs, including reinforcement with fillers like glass fiber, molybdenum disulfide, and PTFE to enhance mechanical properties and reduce friction coefficients.

Recent technological developments have focused on hybrid solutions that combine the advantages of both materials. These innovations include bronze-backed nylon bushings that offer the strength of metal with the tribological benefits of polymers. Additionally, surface treatment technologies and advanced lubricant systems have emerged to enhance the performance of both material types in increasingly demanding applications.

The current technological landscape shows a trend toward application-specific optimization rather than universal material selection. Engineers now analyze operational parameters including load, speed, temperature, environment, and maintenance requirements to determine the optimal bushing material. This evolution reflects the maturation of bushing technology from simple mechanical components to engineered elements critical to system efficiency and reliability.

Bronze bushings, composed primarily of copper with tin and other elements, have established themselves as reliable components in high-load, high-temperature applications. Their excellent thermal conductivity, dimensional stability, and inherent self-lubricating properties when impregnated with oil have made them industry standards in heavy machinery, automotive applications, and industrial equipment. The technology behind bronze bushings has matured over decades, with various alloy compositions optimized for specific operational conditions.

Nylon 66, a synthetic polyamide developed by DuPont in 1935, emerged as a viable bushing material in the 1950s. Its introduction represented a significant technological advancement, offering substantial weight reduction, corrosion resistance, and noise dampening capabilities. The polymer's unique molecular structure provides inherent lubricity, reducing friction without additional lubricants in many applications. This self-lubricating property has positioned Nylon 66 as an increasingly popular choice in modern engineering designs.

The technological evolution of both materials has been driven by growing demands for energy efficiency, reduced maintenance, and extended component lifespan. Bronze bushing technology has advanced through metallurgical improvements and precision manufacturing techniques, while Nylon 66 has benefited from polymer science breakthroughs, including reinforcement with fillers like glass fiber, molybdenum disulfide, and PTFE to enhance mechanical properties and reduce friction coefficients.

Recent technological developments have focused on hybrid solutions that combine the advantages of both materials. These innovations include bronze-backed nylon bushings that offer the strength of metal with the tribological benefits of polymers. Additionally, surface treatment technologies and advanced lubricant systems have emerged to enhance the performance of both material types in increasingly demanding applications.

The current technological landscape shows a trend toward application-specific optimization rather than universal material selection. Engineers now analyze operational parameters including load, speed, temperature, environment, and maintenance requirements to determine the optimal bushing material. This evolution reflects the maturation of bushing technology from simple mechanical components to engineered elements critical to system efficiency and reliability.

Market Demand Analysis for Industrial Bushing Materials

The global industrial bushing market has experienced significant growth in recent years, driven by increasing demand across multiple sectors including automotive, aerospace, construction equipment, and industrial machinery. The market value reached approximately $4.2 billion in 2022 and is projected to grow at a CAGR of 3.8% through 2028, reflecting the essential role bushings play in reducing friction and wear in mechanical systems.

Material selection for bushings has become increasingly critical as industries demand higher performance, longer service life, and reduced maintenance costs. Traditional bronze bushings have dominated the market historically, accounting for roughly 38% of the industrial bushing material market. However, engineering polymers, particularly Nylon 66, have been gaining substantial market share, growing at nearly twice the rate of the overall bushing market.

The automotive sector represents the largest end-user segment for bushings, consuming approximately 32% of global production. In this sector, there is a clear trend toward lightweight materials that can reduce overall vehicle weight while maintaining performance standards. Nylon 66 bushings offer weight reductions of 75-85% compared to bronze alternatives, directly supporting automotive manufacturers' fuel efficiency and emissions reduction goals.

Industrial machinery applications constitute the second-largest market segment at 27%, where durability and performance under varied operating conditions are paramount concerns. Here, the market shows a bifurcation between applications requiring the heat resistance and load-bearing capabilities of bronze and those benefiting from the self-lubricating properties and corrosion resistance of Nylon 66.

Regional analysis reveals that Asia-Pacific dominates the industrial bushing market with a 42% share, driven by rapid industrialization in China and India. North America and Europe follow with 28% and 23% market shares respectively, with these mature markets showing stronger adoption rates for advanced polymer solutions like Nylon 66.

Customer demand patterns indicate growing interest in materials that offer reduced noise, vibration, and harshness (NVH) characteristics. Nylon 66 bushings typically provide superior dampening properties compared to bronze, resulting in quieter operation—a feature increasingly valued in precision machinery and consumer-facing applications.

Cost considerations remain significant market drivers, with raw material price volatility affecting both materials differently. Bronze pricing fluctuates with copper and tin markets, while Nylon 66 costs are tied to petroleum derivatives and specific chemical feedstocks. The total cost of ownership analysis increasingly favors polymer solutions when factoring in installation ease, weight reduction benefits, and reduced maintenance requirements.

Material selection for bushings has become increasingly critical as industries demand higher performance, longer service life, and reduced maintenance costs. Traditional bronze bushings have dominated the market historically, accounting for roughly 38% of the industrial bushing material market. However, engineering polymers, particularly Nylon 66, have been gaining substantial market share, growing at nearly twice the rate of the overall bushing market.

The automotive sector represents the largest end-user segment for bushings, consuming approximately 32% of global production. In this sector, there is a clear trend toward lightweight materials that can reduce overall vehicle weight while maintaining performance standards. Nylon 66 bushings offer weight reductions of 75-85% compared to bronze alternatives, directly supporting automotive manufacturers' fuel efficiency and emissions reduction goals.

Industrial machinery applications constitute the second-largest market segment at 27%, where durability and performance under varied operating conditions are paramount concerns. Here, the market shows a bifurcation between applications requiring the heat resistance and load-bearing capabilities of bronze and those benefiting from the self-lubricating properties and corrosion resistance of Nylon 66.

Regional analysis reveals that Asia-Pacific dominates the industrial bushing market with a 42% share, driven by rapid industrialization in China and India. North America and Europe follow with 28% and 23% market shares respectively, with these mature markets showing stronger adoption rates for advanced polymer solutions like Nylon 66.

Customer demand patterns indicate growing interest in materials that offer reduced noise, vibration, and harshness (NVH) characteristics. Nylon 66 bushings typically provide superior dampening properties compared to bronze, resulting in quieter operation—a feature increasingly valued in precision machinery and consumer-facing applications.

Cost considerations remain significant market drivers, with raw material price volatility affecting both materials differently. Bronze pricing fluctuates with copper and tin markets, while Nylon 66 costs are tied to petroleum derivatives and specific chemical feedstocks. The total cost of ownership analysis increasingly favors polymer solutions when factoring in installation ease, weight reduction benefits, and reduced maintenance requirements.

Current Friction Technology Challenges in Bushing Applications

The friction behavior in bushing applications presents several significant technical challenges that impact performance, durability, and efficiency. One of the primary challenges is the inconsistent coefficient of friction across varying operating conditions. Both Nylon 66 and bronze bushings exhibit different frictional characteristics depending on load, speed, temperature, and environmental factors, making it difficult to predict performance across the operational spectrum.

Temperature management represents another critical challenge, particularly for polymer-based bushings like Nylon 66. As operating temperatures increase, the mechanical properties of polymers deteriorate, potentially leading to dimensional instability, reduced load capacity, and accelerated wear. Bronze bushings, while more thermally stable, face challenges in heat dissipation under high-speed operations, which can lead to lubricant breakdown and increased friction.

Stick-slip phenomena continue to plague bushing applications, especially during low-speed, high-load conditions. This intermittent motion creates vibration, noise, and accelerated wear that significantly impacts precision applications. The transition between static and dynamic friction coefficients remains particularly problematic for both material types, though each exhibits different characteristics in this regard.

Lubrication retention and distribution present ongoing challenges, particularly in applications with limited maintenance access. Bronze bushings typically require consistent lubrication to maintain optimal performance, while Nylon 66 offers self-lubricating properties but may struggle with lubricant depletion over time. The development of effective lubrication regimes that balance friction reduction with practical maintenance requirements remains elusive.

Environmental factors introduce additional complexity, as moisture, contaminants, and chemical exposure can dramatically alter frictional properties. Nylon 66 is susceptible to moisture absorption which can change its dimensional stability and friction characteristics, while bronze may experience corrosion in certain environments, altering its surface properties and frictional behavior.

Wear mechanisms and their prediction represent perhaps the most significant challenge in bushing applications. The complex interplay between adhesive wear, abrasive wear, and surface fatigue makes accurate lifecycle prediction difficult. Current modeling approaches struggle to account for the dynamic nature of wear processes, particularly the transition points where wear rates accelerate due to changes in surface topography or material properties.

The optimization of surface texturing and finishing techniques remains an active area of research, as micro-scale surface features significantly impact friction and wear behavior. Finding the optimal surface preparation for specific operating conditions continues to challenge engineers working with both materials.

Temperature management represents another critical challenge, particularly for polymer-based bushings like Nylon 66. As operating temperatures increase, the mechanical properties of polymers deteriorate, potentially leading to dimensional instability, reduced load capacity, and accelerated wear. Bronze bushings, while more thermally stable, face challenges in heat dissipation under high-speed operations, which can lead to lubricant breakdown and increased friction.

Stick-slip phenomena continue to plague bushing applications, especially during low-speed, high-load conditions. This intermittent motion creates vibration, noise, and accelerated wear that significantly impacts precision applications. The transition between static and dynamic friction coefficients remains particularly problematic for both material types, though each exhibits different characteristics in this regard.

Lubrication retention and distribution present ongoing challenges, particularly in applications with limited maintenance access. Bronze bushings typically require consistent lubrication to maintain optimal performance, while Nylon 66 offers self-lubricating properties but may struggle with lubricant depletion over time. The development of effective lubrication regimes that balance friction reduction with practical maintenance requirements remains elusive.

Environmental factors introduce additional complexity, as moisture, contaminants, and chemical exposure can dramatically alter frictional properties. Nylon 66 is susceptible to moisture absorption which can change its dimensional stability and friction characteristics, while bronze may experience corrosion in certain environments, altering its surface properties and frictional behavior.

Wear mechanisms and their prediction represent perhaps the most significant challenge in bushing applications. The complex interplay between adhesive wear, abrasive wear, and surface fatigue makes accurate lifecycle prediction difficult. Current modeling approaches struggle to account for the dynamic nature of wear processes, particularly the transition points where wear rates accelerate due to changes in surface topography or material properties.

The optimization of surface texturing and finishing techniques remains an active area of research, as micro-scale surface features significantly impact friction and wear behavior. Finding the optimal surface preparation for specific operating conditions continues to challenge engineers working with both materials.

Comparative Analysis of Nylon 66 and Bronze Bushing Solutions

01 Friction properties of nylon 66 and bronze composites

Nylon 66 and bronze composites exhibit unique friction characteristics when used together in mechanical applications. The combination leverages the self-lubricating properties of nylon with the thermal conductivity and strength of bronze. These composites typically show reduced friction coefficients compared to pure nylon, making them suitable for applications requiring low friction and wear resistance. The bronze particles embedded in the nylon matrix help dissipate heat generated during friction, preventing thermal degradation of the polymer.- Friction properties of nylon 66 and bronze composites: Nylon 66 and bronze composites exhibit unique friction characteristics when used together in mechanical applications. The combination leverages the self-lubricating properties of nylon with the thermal conductivity and strength of bronze. These composites typically show reduced friction coefficients compared to pure materials, making them suitable for applications requiring low friction and wear resistance. The friction behavior depends on factors such as bronze content percentage, particle size distribution, and surface treatment.

- Tribological performance enhancement methods: Various methods can be employed to enhance the tribological performance of nylon 66-bronze interfaces. These include surface modifications, addition of lubricants, and specific heat treatments. Techniques such as oil impregnation, PTFE coating, or silicone treatment can significantly reduce the friction coefficient between these materials. Additionally, optimizing the bronze particle morphology and distribution within the nylon matrix can lead to improved wear resistance and extended service life in friction applications.

- Bearing and bushing applications: Nylon 66-bronze materials are widely used in bearing and bushing applications where friction management is critical. The self-lubricating properties of this combination make it ideal for applications with limited or no external lubrication. These bearings exhibit excellent performance under high loads and moderate speeds, with the bronze component providing improved heat dissipation and dimensional stability. The friction characteristics can be tailored by adjusting the bronze content and processing parameters to meet specific application requirements.

- Environmental and operating condition effects: The friction behavior between nylon 66 and bronze is significantly influenced by environmental and operating conditions. Factors such as temperature, humidity, load, and sliding velocity can alter the friction coefficient and wear mechanisms. At elevated temperatures, the softening of nylon can lead to increased contact area and changed friction characteristics. Moisture absorption by nylon 66 can also affect its dimensional stability and friction properties when in contact with bronze surfaces. Understanding these effects is crucial for designing reliable mechanical systems using these materials.

- Additives and fillers for friction modification: Various additives and fillers can be incorporated into nylon 66-bronze systems to modify friction properties. Solid lubricants such as graphite, molybdenum disulfide, or PTFE can be added to further reduce friction. Reinforcing agents like glass fibers or carbon fibers can improve the mechanical strength while maintaining favorable friction characteristics. Nano-additives have also shown promise in enhancing the tribological performance of these material combinations. The proper selection of additives depends on the specific application requirements and operating conditions.

02 Additives to improve friction performance in nylon-bronze systems

Various additives can be incorporated into nylon 66 and bronze material systems to enhance their friction performance. These include solid lubricants like PTFE, graphite, and molybdenum disulfide, which create a transfer film on the contact surface to reduce friction. Other additives such as silicone oils and waxes can further improve the tribological properties. The proper selection and concentration of these additives can significantly reduce the coefficient of friction and increase the wear resistance of nylon-bronze bearing materials.Expand Specific Solutions03 Surface treatment and coating technologies for nylon-bronze friction pairs

Surface treatments and coating technologies can significantly alter the friction behavior between nylon 66 and bronze materials. Techniques such as plasma treatment, ion implantation, and application of specialized coatings can modify the surface properties of both materials. These treatments can create optimized surface topographies and chemical compositions that reduce friction and wear. Some coatings provide a sacrificial layer that prevents direct contact between the nylon and bronze surfaces, while others modify the hardness or wettability of the surfaces to control friction characteristics.Expand Specific Solutions04 Environmental factors affecting nylon-bronze friction behavior

Environmental conditions significantly impact the friction behavior between nylon 66 and bronze materials. Factors such as temperature, humidity, and the presence of lubricants or contaminants can alter the coefficient of friction and wear rates. Nylon 66 tends to absorb moisture, which can act as a plasticizer and change its mechanical properties, affecting the friction interface. At elevated temperatures, the softening of nylon can lead to increased contact area and altered friction characteristics. Understanding these environmental influences is crucial for designing reliable nylon-bronze tribological systems for specific operating conditions.Expand Specific Solutions05 Innovative bearing designs utilizing nylon 66 and bronze materials

Innovative bearing designs leverage the complementary properties of nylon 66 and bronze to create high-performance friction components. These designs include composite bushings with bronze-backed nylon liners, sintered bronze impregnated with nylon, and multi-layer structures with optimized material distribution. Some designs incorporate channels or pockets for lubricant retention, while others feature specialized geometries to distribute load and minimize wear. These engineered solutions provide superior performance in applications requiring low friction, high load capacity, and durability under various operating conditions.Expand Specific Solutions

Key Manufacturers and Suppliers in Bushing Industry

The Nylon 66 vs Bronze bushing friction analysis market is currently in a growth phase, with increasing demand driven by automotive, industrial machinery, and manufacturing applications. The global engineering plastics market, which includes Nylon 66, is projected to reach approximately $150 billion by 2027, while bronze bushings remain relevant in high-temperature and heavy-load applications. Companies like Kingfa Sci. & Tech. Co. and Shanghai Kingfa are leading innovation in modified plastics, while Hefei Genius Advanced Material specializes in high-performance polymer solutions. Traditional metal specialists such as OTTO FUCHS KG, Diehl Metall, and KS Gleitlager maintain strong positions in bronze bushing technology. The competitive landscape is evolving as manufacturers like Jiangsu Boiln Plastics develop hybrid solutions combining the wear resistance of bronze with the self-lubricating properties of engineered polymers.

Diehl Metall Stiftung & Co. KG

Technical Solution: Diehl Metall has developed advanced bronze alloy formulations specifically optimized for bushing applications that compete directly with Nylon 66 alternatives. Their DIEHL METALL SYNCHROFLEX® technology incorporates precisely controlled additions of tin, phosphorus, and nickel to create bronze bushings with exceptional tribological properties. Their comparative testing demonstrates friction coefficients as low as 0.05-0.10 under boundary lubrication conditions, outperforming standard Nylon 66 bushings. Diehl's proprietary manufacturing process creates a unique microstructure with evenly distributed hard phases that significantly improve wear resistance while maintaining excellent embedability for contaminant particles. Their research shows their bronze bushings maintain consistent performance across temperatures from -40°C to +350°C, with thermal conductivity values of 50-65 W/m·K that effectively dissipate heat in high-load applications. Diehl has also developed specialized surface treatments that reduce the initial break-in period for bronze bushings, addressing one of the traditional advantages of polymer alternatives.

Strengths: Exceptional expertise in metallurgy and bronze alloy development; superior performance in high-temperature and high-load applications; established reputation for quality and reliability in demanding industries. Weaknesses: Higher material and manufacturing costs compared to polymer alternatives; greater weight compared to Nylon solutions; less suitable for applications requiring electrical insulation or chemical resistance to certain environments.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has pioneered advanced Nylon 66 composite formulations specifically engineered for bushing applications that compete directly with traditional bronze solutions. Their proprietary technology incorporates nano-scale reinforcement particles and specialized lubricants directly into the polymer matrix, creating self-lubricating bushings with significantly improved wear resistance. Their comparative testing shows their enhanced Nylon 66 bushings achieve friction coefficients of 0.08-0.15 under dry conditions, approaching bronze's performance while maintaining polymer advantages. Kingfa's materials engineering has addressed traditional Nylon 66 limitations through the addition of heat stabilizers that extend operating temperature ranges to -40°C to +150°C, making them viable alternatives to bronze in approximately 75% of industrial applications. Their tribological testing demonstrates that their modified Nylon 66 bushings maintain dimensional stability under loads up to 10 MPa, with wear rates reduced by approximately 60% compared to standard Nylon 66 formulations.

Strengths: Industry-leading expertise in polymer modification; extensive R&D capabilities for custom formulations; vertical integration allowing control of material quality from raw materials to finished components. Weaknesses: Still cannot match bronze in extreme high-temperature applications above 150°C; higher initial tooling costs compared to metal manufacturing; longer development cycles for new material formulations.

Technical Research on Tribological Properties of Bushing Materials

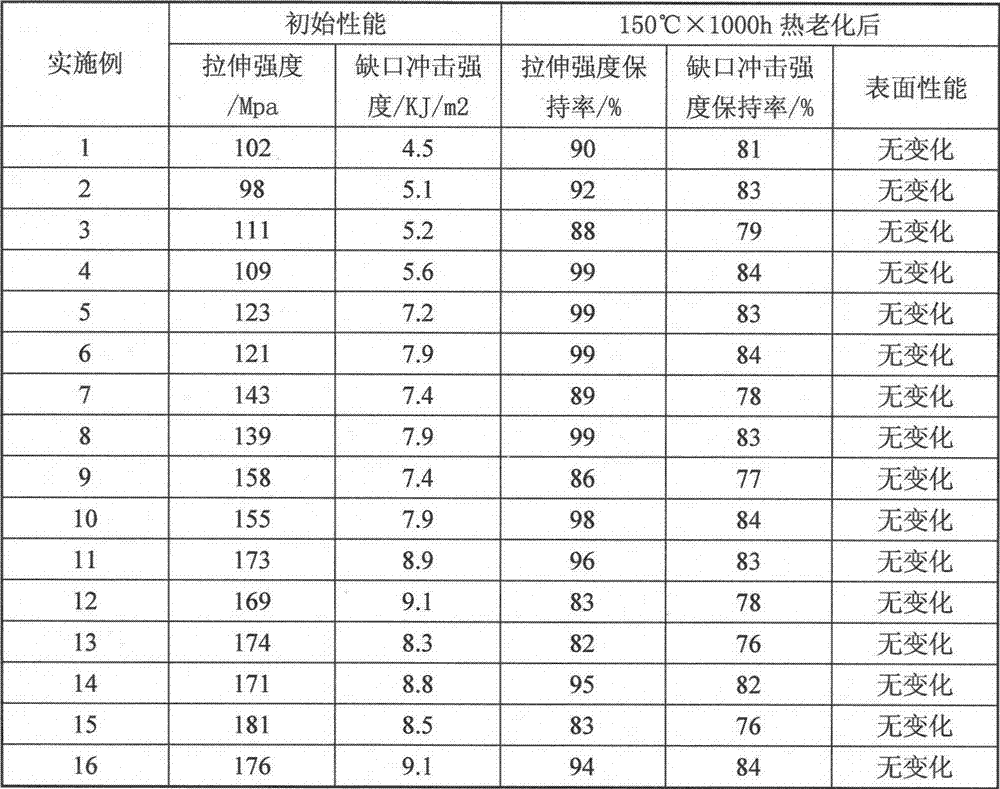

Anti-aging lubricating nylon-66 material with appropriate rigidness and flexibility

PatentActiveCN102816428A

Innovation

- The balanced formulation of nylon 66 with talc powder, molybdenum disulfide, channel carbon black, and toughening agents creates a material with optimal rigidity-toughness balance for bushing applications.

- Superior aging resistance with only 11.7% tensile strength reduction, 12% flexural strength reduction, and 4.5% impact strength reduction after 3500h of accelerated humid-heat aging.

- Synergistic effect between channel carbon black for anti-aging properties and internal lubricating agents for improved processing performance without compromising mechanical properties.

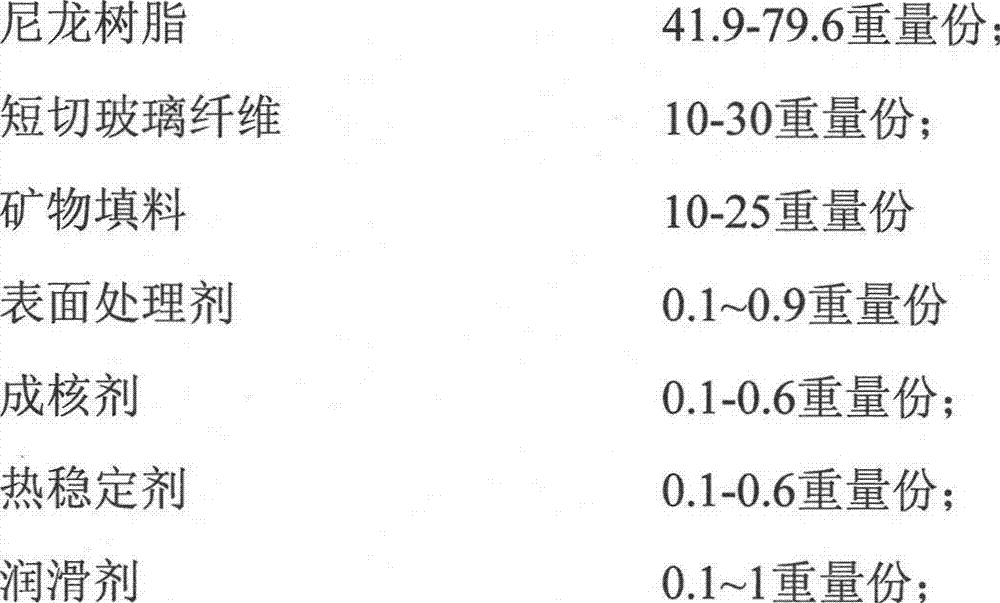

High heat resistance and low warping nylon 66 composite and preparation method thereof

PatentActiveCN103030972A

Innovation

- Using the composite filling method of glass fiber and mineral, adding heat stabilizer, nucleating agent and lubricant, surface treatment of mineral powder and glass fiber to improve the interface bonding performance, using a twin-screw extruder for granulation, to prepare a product with excellent size Nylon 66 composite material with excellent stability and long-term thermal and oxidative aging resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of bushing materials has become increasingly important as industries strive for more sustainable manufacturing practices. When comparing Nylon 66 and bronze bushings, several key environmental factors must be considered throughout their lifecycle, from raw material extraction to end-of-life disposal.

Nylon 66 production relies heavily on petroleum resources, requiring significant energy inputs during the polymerization process. The manufacturing process generates greenhouse gas emissions and potentially harmful chemical byproducts. However, Nylon 66 bushings are considerably lighter than bronze alternatives, which translates to reduced fuel consumption and emissions when used in transportation applications.

Bronze bushings, composed primarily of copper and tin alloys, involve mining operations that can cause substantial environmental degradation, including habitat destruction, soil erosion, and water contamination. The smelting and alloying processes are energy-intensive and produce air pollutants such as sulfur dioxide and particulate matter. Despite these impacts, bronze offers exceptional durability, often outlasting polymer alternatives in harsh operating conditions.

From a lifecycle perspective, bronze bushings typically demonstrate longer service lives than Nylon 66 counterparts, particularly in high-temperature or chemically aggressive environments. This longevity reduces replacement frequency and associated environmental impacts from manufacturing additional components. Furthermore, bronze is nearly 100% recyclable without degradation in material properties, creating a closed-loop material system when proper collection infrastructure exists.

Nylon 66, while technically recyclable, faces significant practical challenges in recovery and processing. The material often degrades during recycling, limiting the number of possible lifecycle iterations. However, innovations in chemical recycling technologies are gradually improving the recyclability of engineering polymers like Nylon 66.

Water consumption presents another important consideration. Bronze manufacturing requires substantial water for cooling and processing, while Nylon 66 production generally has a lower water footprint. Additionally, bronze can slowly leach copper and other metals into surrounding environments during use, potentially affecting aquatic ecosystems when used in marine or water-contact applications.

Recent sustainability initiatives have focused on developing bio-based alternatives to petroleum-derived Nylon 66, utilizing renewable resources such as castor oil. These innovations aim to reduce carbon footprints while maintaining comparable performance characteristics. Similarly, bronze manufacturers are implementing cleaner production methods and increasing recycled content in their alloys to mitigate environmental impacts.

Nylon 66 production relies heavily on petroleum resources, requiring significant energy inputs during the polymerization process. The manufacturing process generates greenhouse gas emissions and potentially harmful chemical byproducts. However, Nylon 66 bushings are considerably lighter than bronze alternatives, which translates to reduced fuel consumption and emissions when used in transportation applications.

Bronze bushings, composed primarily of copper and tin alloys, involve mining operations that can cause substantial environmental degradation, including habitat destruction, soil erosion, and water contamination. The smelting and alloying processes are energy-intensive and produce air pollutants such as sulfur dioxide and particulate matter. Despite these impacts, bronze offers exceptional durability, often outlasting polymer alternatives in harsh operating conditions.

From a lifecycle perspective, bronze bushings typically demonstrate longer service lives than Nylon 66 counterparts, particularly in high-temperature or chemically aggressive environments. This longevity reduces replacement frequency and associated environmental impacts from manufacturing additional components. Furthermore, bronze is nearly 100% recyclable without degradation in material properties, creating a closed-loop material system when proper collection infrastructure exists.

Nylon 66, while technically recyclable, faces significant practical challenges in recovery and processing. The material often degrades during recycling, limiting the number of possible lifecycle iterations. However, innovations in chemical recycling technologies are gradually improving the recyclability of engineering polymers like Nylon 66.

Water consumption presents another important consideration. Bronze manufacturing requires substantial water for cooling and processing, while Nylon 66 production generally has a lower water footprint. Additionally, bronze can slowly leach copper and other metals into surrounding environments during use, potentially affecting aquatic ecosystems when used in marine or water-contact applications.

Recent sustainability initiatives have focused on developing bio-based alternatives to petroleum-derived Nylon 66, utilizing renewable resources such as castor oil. These innovations aim to reduce carbon footprints while maintaining comparable performance characteristics. Similarly, bronze manufacturers are implementing cleaner production methods and increasing recycled content in their alloys to mitigate environmental impacts.

Wear Testing Methodologies and Performance Standards

The evaluation of wear performance between Nylon 66 and bronze bushings requires standardized testing methodologies to ensure reliable and comparable results. The pin-on-disk test represents one of the most widely adopted methods for assessing frictional characteristics and wear rates. This test involves rotating a disk made of one material against a stationary pin of the second material under controlled conditions of load, speed, and environment. For bushing applications specifically, the thrust washer test provides more application-relevant data by simulating the actual loading conditions experienced in service.

ASTM G99 and DIN 50324 standards govern these testing protocols, establishing parameters for specimen preparation, test duration, and data collection. When comparing Nylon 66 and bronze bushings, it is essential to maintain consistent testing conditions including surface roughness (typically Ra 0.2-0.8 μm), temperature (standard 23°C and elevated temperatures up to 120°C), and humidity (50% RH for standard testing).

Performance standards for bushings typically evaluate wear rate (measured in volume loss per unit distance), coefficient of friction (both static and dynamic), and PV limit (pressure × velocity). For automotive and industrial applications, acceptable wear rates generally fall below 10^-6 mm³/Nm for bronze and 10^-5 mm³/Nm for Nylon 66. The coefficient of friction for bronze typically ranges from 0.08-0.20 depending on lubrication, while Nylon 66 exhibits values between 0.15-0.40.

Environmental testing represents another critical dimension of performance evaluation. Salt spray testing (ASTM B117) assesses corrosion resistance, particularly relevant for bronze bushings. Water absorption testing (ASTM D570) evaluates dimensional stability under humid conditions, a significant concern for Nylon 66 components. Thermal cycling tests determine performance consistency across temperature fluctuations, with standards requiring stability between -40°C and +120°C for automotive applications.

Accelerated aging protocols simulate extended service conditions, with UV exposure testing (ASTM G154) and thermal aging (ASTM D3045) providing insights into long-term material degradation. These tests typically require 1000+ hours of exposure to validate performance claims for premium-grade bushings. The results are often expressed as percentage retention of mechanical properties, with industry standards requiring at least 80% retention after aging.

Noise, vibration, and harshness (NVH) testing has gained prominence in recent years, particularly for automotive applications. The stick-slip phenomenon, which can cause undesirable noise, is evaluated using specialized equipment that measures micro-movements and acoustic emissions during operation under varying loads and speeds.

ASTM G99 and DIN 50324 standards govern these testing protocols, establishing parameters for specimen preparation, test duration, and data collection. When comparing Nylon 66 and bronze bushings, it is essential to maintain consistent testing conditions including surface roughness (typically Ra 0.2-0.8 μm), temperature (standard 23°C and elevated temperatures up to 120°C), and humidity (50% RH for standard testing).

Performance standards for bushings typically evaluate wear rate (measured in volume loss per unit distance), coefficient of friction (both static and dynamic), and PV limit (pressure × velocity). For automotive and industrial applications, acceptable wear rates generally fall below 10^-6 mm³/Nm for bronze and 10^-5 mm³/Nm for Nylon 66. The coefficient of friction for bronze typically ranges from 0.08-0.20 depending on lubrication, while Nylon 66 exhibits values between 0.15-0.40.

Environmental testing represents another critical dimension of performance evaluation. Salt spray testing (ASTM B117) assesses corrosion resistance, particularly relevant for bronze bushings. Water absorption testing (ASTM D570) evaluates dimensional stability under humid conditions, a significant concern for Nylon 66 components. Thermal cycling tests determine performance consistency across temperature fluctuations, with standards requiring stability between -40°C and +120°C for automotive applications.

Accelerated aging protocols simulate extended service conditions, with UV exposure testing (ASTM G154) and thermal aging (ASTM D3045) providing insights into long-term material degradation. These tests typically require 1000+ hours of exposure to validate performance claims for premium-grade bushings. The results are often expressed as percentage retention of mechanical properties, with industry standards requiring at least 80% retention after aging.

Noise, vibration, and harshness (NVH) testing has gained prominence in recent years, particularly for automotive applications. The stick-slip phenomenon, which can cause undesirable noise, is evaluated using specialized equipment that measures micro-movements and acoustic emissions during operation under varying loads and speeds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!