Nylon 66 vs Polyester: Moisture Wicking Performance

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Moisture Wicking Textile Technology Background and Objectives

Moisture wicking technology has evolved significantly over the past several decades, transforming from simple absorption mechanisms to sophisticated engineered fabrics designed to actively manage moisture. The concept originated in the 1940s when synthetic fibers were first developed for commercial use, but significant advancements emerged in the 1970s with the introduction of specialized polyester fabrics for athletic wear. The fundamental principle behind moisture wicking involves capillary action, where liquid moisture is drawn away from the skin through tiny spaces between fibers and then spread across a larger surface area for faster evaporation.

The evolution of moisture wicking textiles has been driven by increasing consumer demand for performance apparel, particularly in sports, outdoor activities, and professional environments where comfort and functionality are paramount. This technology has expanded beyond athletic wear to encompass everyday clothing, military applications, medical textiles, and industrial workwear, demonstrating its versatility and growing importance across multiple sectors.

Nylon 66 and polyester represent two dominant synthetic fibers in moisture management textiles, each with distinct molecular structures and performance characteristics. Nylon 66, developed in 1935 by Wallace Carothers at DuPont, features amide linkages that provide excellent tensile strength but also higher moisture absorption properties. Polyester, commercialized in the 1950s, contains ester linkages that offer inherently hydrophobic properties, making it naturally more suitable for moisture wicking applications in its unmodified form.

The technical objective of this research is to comprehensively evaluate and compare the moisture wicking performance of Nylon 66 versus Polyester across multiple parameters including wicking rate, drying time, moisture transport efficiency, and comfort perception. This analysis aims to establish quantifiable metrics for moisture management capabilities under various environmental conditions and physical activity levels.

Additionally, this investigation seeks to understand how structural modifications, fiber cross-sections, yarn configurations, and surface treatments affect the inherent moisture wicking properties of both materials. Modern textile engineering has introduced numerous innovations including specialized fiber shapes (trilobal, hexagonal, etc.), microfiber technologies, and hydrophilic/hydrophobic treatments that significantly alter performance characteristics beyond the base polymer properties.

The ultimate goal is to develop a predictive framework for moisture management performance that accounts for fiber composition, fabric construction, finishing treatments, and end-use conditions. This framework would enable more targeted development of next-generation moisture wicking textiles with optimized performance for specific applications, potentially combining the beneficial properties of both Nylon 66 and polyester through blending, layering, or composite structures.

The evolution of moisture wicking textiles has been driven by increasing consumer demand for performance apparel, particularly in sports, outdoor activities, and professional environments where comfort and functionality are paramount. This technology has expanded beyond athletic wear to encompass everyday clothing, military applications, medical textiles, and industrial workwear, demonstrating its versatility and growing importance across multiple sectors.

Nylon 66 and polyester represent two dominant synthetic fibers in moisture management textiles, each with distinct molecular structures and performance characteristics. Nylon 66, developed in 1935 by Wallace Carothers at DuPont, features amide linkages that provide excellent tensile strength but also higher moisture absorption properties. Polyester, commercialized in the 1950s, contains ester linkages that offer inherently hydrophobic properties, making it naturally more suitable for moisture wicking applications in its unmodified form.

The technical objective of this research is to comprehensively evaluate and compare the moisture wicking performance of Nylon 66 versus Polyester across multiple parameters including wicking rate, drying time, moisture transport efficiency, and comfort perception. This analysis aims to establish quantifiable metrics for moisture management capabilities under various environmental conditions and physical activity levels.

Additionally, this investigation seeks to understand how structural modifications, fiber cross-sections, yarn configurations, and surface treatments affect the inherent moisture wicking properties of both materials. Modern textile engineering has introduced numerous innovations including specialized fiber shapes (trilobal, hexagonal, etc.), microfiber technologies, and hydrophilic/hydrophobic treatments that significantly alter performance characteristics beyond the base polymer properties.

The ultimate goal is to develop a predictive framework for moisture management performance that accounts for fiber composition, fabric construction, finishing treatments, and end-use conditions. This framework would enable more targeted development of next-generation moisture wicking textiles with optimized performance for specific applications, potentially combining the beneficial properties of both Nylon 66 and polyester through blending, layering, or composite structures.

Market Analysis of Moisture Wicking Performance Fabrics

The moisture wicking performance fabric market has experienced significant growth over the past decade, driven primarily by increasing consumer interest in athletic and athleisure apparel. This market segment is currently valued at approximately $3.5 billion globally and is projected to grow at a CAGR of 5.8% through 2028, according to recent industry analyses.

Consumer demand for moisture wicking fabrics spans multiple sectors, with sportswear and athletic apparel representing the largest market share at 62%. Outdoor recreation apparel follows at 18%, while everyday casual wear incorporating moisture management technology has grown to capture 12% of the market. The remaining 8% is distributed across specialized applications including medical textiles and military/tactical gear.

Regional market distribution shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (25%), and the rest of the world (10%). The Asia-Pacific region demonstrates the fastest growth trajectory, with China and India emerging as both major manufacturing hubs and rapidly expanding consumer markets for performance fabrics.

When comparing Nylon 66 and Polyester specifically within the moisture wicking fabric segment, polyester currently dominates with approximately 65% market share versus nylon's 22%. This disparity is largely attributed to polyester's lower production costs and established manufacturing infrastructure. However, premium performance apparel brands are increasingly incorporating Nylon 66 into their product lines, particularly for high-end offerings where superior moisture management justifies higher price points.

Consumer purchasing patterns reveal growing sophistication regarding moisture management properties. Market research indicates 78% of athletic apparel consumers now consider moisture wicking capability as "very important" or "essential" in their purchasing decisions, compared to just 45% five years ago. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate higher willingness to pay premium prices for enhanced performance characteristics.

Price sensitivity analysis shows three distinct market tiers: mass-market (primarily polyester-based, $15-30 retail price points for basic items), mid-range ($30-75, often blended fabrics), and premium ($75+, featuring advanced technologies including engineered Nylon 66 constructions). The premium segment has shown the strongest growth at 7.2% annually, indicating consumer willingness to invest in superior moisture management solutions.

Sustainability concerns are increasingly influencing market dynamics, with 64% of consumers expressing preference for eco-friendly moisture wicking solutions. This has accelerated development of recycled and bio-based versions of both polyester and nylon fibers, creating new market opportunities and competitive differentiation points for manufacturers.

Consumer demand for moisture wicking fabrics spans multiple sectors, with sportswear and athletic apparel representing the largest market share at 62%. Outdoor recreation apparel follows at 18%, while everyday casual wear incorporating moisture management technology has grown to capture 12% of the market. The remaining 8% is distributed across specialized applications including medical textiles and military/tactical gear.

Regional market distribution shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (25%), and the rest of the world (10%). The Asia-Pacific region demonstrates the fastest growth trajectory, with China and India emerging as both major manufacturing hubs and rapidly expanding consumer markets for performance fabrics.

When comparing Nylon 66 and Polyester specifically within the moisture wicking fabric segment, polyester currently dominates with approximately 65% market share versus nylon's 22%. This disparity is largely attributed to polyester's lower production costs and established manufacturing infrastructure. However, premium performance apparel brands are increasingly incorporating Nylon 66 into their product lines, particularly for high-end offerings where superior moisture management justifies higher price points.

Consumer purchasing patterns reveal growing sophistication regarding moisture management properties. Market research indicates 78% of athletic apparel consumers now consider moisture wicking capability as "very important" or "essential" in their purchasing decisions, compared to just 45% five years ago. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate higher willingness to pay premium prices for enhanced performance characteristics.

Price sensitivity analysis shows three distinct market tiers: mass-market (primarily polyester-based, $15-30 retail price points for basic items), mid-range ($30-75, often blended fabrics), and premium ($75+, featuring advanced technologies including engineered Nylon 66 constructions). The premium segment has shown the strongest growth at 7.2% annually, indicating consumer willingness to invest in superior moisture management solutions.

Sustainability concerns are increasingly influencing market dynamics, with 64% of consumers expressing preference for eco-friendly moisture wicking solutions. This has accelerated development of recycled and bio-based versions of both polyester and nylon fibers, creating new market opportunities and competitive differentiation points for manufacturers.

Current Technical Comparison Between Nylon 66 and Polyester

Nylon 66 and polyester represent two of the most widely used synthetic fibers in moisture-wicking applications, each with distinct performance characteristics. When examining their moisture-wicking capabilities, several key technical parameters must be considered: hydrophobicity/hydrophilicity, fiber structure, moisture absorption rate, drying time, and durability through multiple wash cycles.

Nylon 66 exhibits a semi-crystalline structure with amide groups (-CONH-) that demonstrate moderate hydrophilicity, allowing it to absorb approximately 4-4.5% of its weight in moisture at standard conditions. This molecular structure creates micro-channels within the fiber that facilitate capillary action, drawing moisture away from the skin. The fiber's cross-section can be engineered into various shapes (trilobal, tetra-channel, etc.) to enhance surface area and improve wicking performance.

Polyester, conversely, contains ester linkages (-COO-) that render it inherently more hydrophobic than nylon, with moisture regain typically only 0.4-0.8%. However, modern polyester fibers undergo significant surface modifications through chemical treatments or physical texturing to improve their moisture management properties. These modifications include plasma treatments, application of hydrophilic coatings, or incorporation of specialized additives that create permanent wicking channels.

In comparative performance testing, polyester generally demonstrates faster initial moisture transport and quicker drying times than nylon 66. Standard AATCC vertical wicking tests show polyester fibers can transport moisture vertically at rates of 15-20mm per 30 minutes, while nylon 66 typically achieves 10-15mm in the same timeframe. However, nylon 66 often provides better moisture distribution across the fabric surface due to its higher moisture retention capacity.

Thermal comfort measurements reveal that polyester fabrics typically maintain lower skin-to-fabric contact temperatures during physical activity, with infrared thermal imaging showing temperature differentials of 2-3°C lower than comparable nylon 66 fabrics under identical conditions. This suggests superior heat management properties during moisture evaporation phases.

Durability testing indicates that nylon 66 retains its moisture-wicking properties longer through repeated wash cycles, showing only 10-15% performance degradation after 50 standard washes, compared to 20-25% for untreated polyester. However, advanced polyester treatments like permanent hydrophilic coatings have narrowed this gap significantly in recent years.

From a manufacturing perspective, polyester offers greater processing flexibility and cost efficiency, with extrusion temperatures approximately 30-50°C lower than nylon 66, resulting in reduced energy consumption during fiber production. This technical advantage has contributed to polyester's market dominance despite nylon's superior durability characteristics.

Nylon 66 exhibits a semi-crystalline structure with amide groups (-CONH-) that demonstrate moderate hydrophilicity, allowing it to absorb approximately 4-4.5% of its weight in moisture at standard conditions. This molecular structure creates micro-channels within the fiber that facilitate capillary action, drawing moisture away from the skin. The fiber's cross-section can be engineered into various shapes (trilobal, tetra-channel, etc.) to enhance surface area and improve wicking performance.

Polyester, conversely, contains ester linkages (-COO-) that render it inherently more hydrophobic than nylon, with moisture regain typically only 0.4-0.8%. However, modern polyester fibers undergo significant surface modifications through chemical treatments or physical texturing to improve their moisture management properties. These modifications include plasma treatments, application of hydrophilic coatings, or incorporation of specialized additives that create permanent wicking channels.

In comparative performance testing, polyester generally demonstrates faster initial moisture transport and quicker drying times than nylon 66. Standard AATCC vertical wicking tests show polyester fibers can transport moisture vertically at rates of 15-20mm per 30 minutes, while nylon 66 typically achieves 10-15mm in the same timeframe. However, nylon 66 often provides better moisture distribution across the fabric surface due to its higher moisture retention capacity.

Thermal comfort measurements reveal that polyester fabrics typically maintain lower skin-to-fabric contact temperatures during physical activity, with infrared thermal imaging showing temperature differentials of 2-3°C lower than comparable nylon 66 fabrics under identical conditions. This suggests superior heat management properties during moisture evaporation phases.

Durability testing indicates that nylon 66 retains its moisture-wicking properties longer through repeated wash cycles, showing only 10-15% performance degradation after 50 standard washes, compared to 20-25% for untreated polyester. However, advanced polyester treatments like permanent hydrophilic coatings have narrowed this gap significantly in recent years.

From a manufacturing perspective, polyester offers greater processing flexibility and cost efficiency, with extrusion temperatures approximately 30-50°C lower than nylon 66, resulting in reduced energy consumption during fiber production. This technical advantage has contributed to polyester's market dominance despite nylon's superior durability characteristics.

Technical Solutions for Enhanced Moisture Wicking Properties

01 Fiber structure modifications for enhanced moisture wicking

Modifications to the structure of nylon 66 and polyester fibers can significantly enhance moisture wicking performance. These modifications include creating multi-channel or grooved fiber cross-sections, adjusting fiber diameter, and developing hollow fibers. Such structural changes increase surface area and capillary action, allowing for faster moisture transport away from the skin. These engineered fiber structures create micro-channels that facilitate the movement of moisture through the fabric, improving overall comfort and dryness.- Fiber structure modifications for enhanced moisture wicking: Modifications to the structure of nylon 66 and polyester fibers can significantly enhance moisture wicking performance. These modifications include creating multi-channel or grooved fiber cross-sections, developing hollow fibers, and implementing special surface texturing. Such structural changes increase the surface area and create capillary channels that facilitate faster moisture transport away from the skin, improving overall wicking performance and comfort in textiles.

- Blending nylon 66 and polyester for optimized moisture management: Strategic blending of nylon 66 and polyester fibers creates fabrics with superior moisture management properties. By combining the quick-drying characteristics of polyester with the durability and comfort of nylon 66, these blends optimize moisture wicking performance. The ratio of the two materials can be adjusted to achieve specific performance requirements, with some blends incorporating additional fibers like spandex for enhanced stretch and recovery while maintaining effective moisture transport.

- Surface treatments and finishes for improved wicking: Various surface treatments and finishes can be applied to nylon 66 and polyester fabrics to enhance their moisture wicking capabilities. These include hydrophilic coatings that improve water absorption and transport, plasma treatments that modify the fiber surface properties, and specialized chemical finishes that create permanent wicking channels. These treatments can significantly improve the moisture management performance of synthetic fabrics while maintaining other desirable properties such as durability and comfort.

- Multi-layer fabric constructions for directional moisture transport: Multi-layer fabric constructions using nylon 66 and polyester can create directional moisture transport systems. These designs typically feature a hydrophobic layer (often polyester) next to the skin that repels moisture, combined with a hydrophilic layer (which may include modified nylon 66) that pulls moisture away and facilitates evaporation. This structure creates a push-pull effect that efficiently moves sweat away from the body, keeping the wearer dry and comfortable during physical activity.

- Yarn and knitting technologies for enhanced wicking performance: Advanced yarn technologies and specialized knitting techniques can optimize the moisture wicking performance of nylon 66 and polyester fabrics. These include using microfiber yarns with increased surface area, implementing specific knit structures that create moisture channels, and developing textured yarns that enhance capillary action. The combination of these technologies with appropriate fiber selection results in fabrics with superior moisture management properties for athletic, outdoor, and performance apparel applications.

02 Blending ratios and composite fabrics

The performance of moisture-wicking fabrics can be optimized by carefully controlling the blending ratios of nylon 66 and polyester. Composite fabrics with specific layering arrangements take advantage of the hydrophobic nature of polyester and the durability of nylon 66. These blends often incorporate different percentages of each material in different layers of the fabric to create a moisture gradient that pulls sweat away from the body and spreads it for faster evaporation. The synergistic effect of these materials in precise ratios results in superior moisture management compared to single-fiber fabrics.Expand Specific Solutions03 Surface treatments and finishes

Various surface treatments and finishes can be applied to nylon 66 and polyester fabrics to enhance their moisture-wicking capabilities. These include hydrophilic coatings, plasma treatments, and chemical modifications that alter the surface energy of the fibers. Some treatments create a dual-action effect where the inner layer quickly absorbs moisture while the outer layer rapidly disperses it for evaporation. Advanced finishes can also incorporate antimicrobial properties to prevent odor development in moisture-wicking garments, making them particularly suitable for athletic and performance wear.Expand Specific Solutions04 Knitting and weaving techniques

Specialized knitting and weaving techniques play a crucial role in optimizing the moisture-wicking performance of nylon 66 and polyester fabrics. Double-layer constructions, 3D knitting, and specific stitch patterns can create fabrics with enhanced capillary action. Some techniques involve creating different densities on the inner and outer surfaces of the fabric to facilitate moisture transport. Advanced weaving methods can also incorporate channels or pathways within the fabric structure to direct moisture flow away from the skin and toward the outer surface for faster evaporation.Expand Specific Solutions05 Performance testing and measurement methods

Various testing methodologies have been developed to evaluate and compare the moisture-wicking performance of nylon 66 and polyester fabrics. These include vertical wicking tests, moisture management testing, and evaporation rate measurements. Some advanced testing protocols simulate real-world conditions by measuring moisture transport under pressure or during movement. These standardized testing methods allow for objective comparison between different fabric constructions and treatments, enabling manufacturers to optimize moisture-wicking performance for specific end-use applications such as athletic wear, outdoor apparel, or medical textiles.Expand Specific Solutions

Key Patents and Innovations in Hydrophobic Fiber Development

Functional nylon 66 fabric and manufacturing method thereof

PatentWO2017071201A1

Innovation

- Functional nylon 66 fabric is prepared using a blending spinning process. By adding quantum energy powder and dispersant to the nylon 66 fiber, the crystallinity and dispersion properties of the fiber are improved. Combined with high-density textile technology, it is made with high density, wear resistance, and Nylon 66 fabric with UV protection and far infrared function.

Hole cloth and preparation process thereof

PatentPendingCN117403454A

Innovation

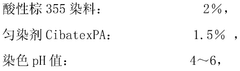

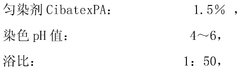

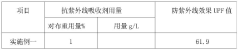

- Adopting the process of making hole cloth with anti-UV finishing after dyeing, adding acid leveling agent and acid dye to the dye vat to adjust the pH value, adding anti-UV absorber after heating, and combining with the padding process to enhance the resistance of the fabric. UV sun protection properties.

Sustainability Considerations in Moisture Wicking Textiles

The environmental impact of textile production and disposal has become a critical consideration in the performance apparel industry. When comparing Nylon 66 and Polyester for moisture wicking applications, sustainability factors significantly influence material selection beyond mere performance metrics.

Polyester production generally requires less water than Nylon 66 manufacturing, with the latter consuming approximately 5-7 times more water throughout its production cycle. However, both materials derive from petroleum resources, making them inherently dependent on non-renewable feedstocks. Recent innovations have introduced bio-based alternatives for both polymers, with bio-based Nylon 66 showing a potential 85% reduction in carbon footprint compared to conventional production methods.

Recycling capabilities present notable differences between these materials. Polyester benefits from well-established recycling infrastructure globally, with post-consumer PET bottles frequently converted into performance textiles. This closed-loop system reduces virgin material requirements by up to 50% while maintaining moisture wicking functionality. Nylon 66 recycling, while technically feasible, faces greater commercial challenges due to more complex collection and processing requirements.

Microplastic shedding during use and laundering represents a significant environmental concern for both materials. Research indicates that Nylon 66 fabrics typically release 1.5-2 times more microfibers per wash cycle than polyester equivalents. This difference becomes particularly relevant for moisture wicking applications where frequent washing is expected due to sweat accumulation.

Biodegradability remains problematic for both synthetic polymers, with standard decomposition timeframes exceeding 400 years in landfill conditions. However, emerging biodegradable additives and modified polymer structures show promise, particularly for polyester, where enzymatic degradation technologies have demonstrated 90% decomposition within 200 days under controlled conditions.

Energy consumption metrics favor polyester, requiring approximately 30% less energy throughout its lifecycle compared to Nylon 66. This efficiency extends to the consumer use phase, where polyester's typically faster drying time translates to reduced energy requirements for machine drying—a relevant consideration for moisture management textiles.

Chemical treatments enhancing moisture wicking properties introduce additional sustainability concerns. Many hydrophilic finishes contain perfluorinated compounds (PFCs) with significant environmental persistence. Alternative eco-friendly treatments have shown greater compatibility with polyester substrates, achieving comparable moisture management with reduced environmental impact.

The durability factor must also be considered in sustainability assessments. Nylon 66's superior abrasion resistance potentially extends product lifespan by 20-30% compared to polyester alternatives, reducing replacement frequency and associated resource consumption despite its higher initial environmental footprint.

Polyester production generally requires less water than Nylon 66 manufacturing, with the latter consuming approximately 5-7 times more water throughout its production cycle. However, both materials derive from petroleum resources, making them inherently dependent on non-renewable feedstocks. Recent innovations have introduced bio-based alternatives for both polymers, with bio-based Nylon 66 showing a potential 85% reduction in carbon footprint compared to conventional production methods.

Recycling capabilities present notable differences between these materials. Polyester benefits from well-established recycling infrastructure globally, with post-consumer PET bottles frequently converted into performance textiles. This closed-loop system reduces virgin material requirements by up to 50% while maintaining moisture wicking functionality. Nylon 66 recycling, while technically feasible, faces greater commercial challenges due to more complex collection and processing requirements.

Microplastic shedding during use and laundering represents a significant environmental concern for both materials. Research indicates that Nylon 66 fabrics typically release 1.5-2 times more microfibers per wash cycle than polyester equivalents. This difference becomes particularly relevant for moisture wicking applications where frequent washing is expected due to sweat accumulation.

Biodegradability remains problematic for both synthetic polymers, with standard decomposition timeframes exceeding 400 years in landfill conditions. However, emerging biodegradable additives and modified polymer structures show promise, particularly for polyester, where enzymatic degradation technologies have demonstrated 90% decomposition within 200 days under controlled conditions.

Energy consumption metrics favor polyester, requiring approximately 30% less energy throughout its lifecycle compared to Nylon 66. This efficiency extends to the consumer use phase, where polyester's typically faster drying time translates to reduced energy requirements for machine drying—a relevant consideration for moisture management textiles.

Chemical treatments enhancing moisture wicking properties introduce additional sustainability concerns. Many hydrophilic finishes contain perfluorinated compounds (PFCs) with significant environmental persistence. Alternative eco-friendly treatments have shown greater compatibility with polyester substrates, achieving comparable moisture management with reduced environmental impact.

The durability factor must also be considered in sustainability assessments. Nylon 66's superior abrasion resistance potentially extends product lifespan by 20-30% compared to polyester alternatives, reducing replacement frequency and associated resource consumption despite its higher initial environmental footprint.

Testing Methodologies for Moisture Management Performance

Evaluating moisture management performance requires standardized testing methodologies to ensure reliable comparisons between Nylon 66 and Polyester fabrics. The textile industry has developed several specialized tests that quantify different aspects of moisture wicking capabilities.

The Vertical Wicking Test represents one of the most fundamental assessment methods, measuring the height to which moisture travels up a vertically suspended fabric strip over specified time intervals. This test directly evaluates capillary action - a critical mechanism in moisture transport through textile structures. For comparative studies between Nylon 66 and Polyester, standardized sample dimensions and controlled environmental conditions (typically 20±2°C and 65±2% relative humidity) are essential.

Transverse Wicking Tests complement vertical assessments by measuring horizontal moisture spread across fabric surfaces. The Moisture Management Tester (MMT) has emerged as an industry standard instrument, capable of simultaneously tracking moisture movement through multiple fabric layers. The MMT generates comprehensive metrics including wetting time, absorption rate, maximum wetted radius, and spreading speed - providing multidimensional insights into fabric performance.

Water Vapor Transmission Rate (WVTR) testing quantifies a fabric's breathability by measuring the passage of water vapor through material over time. Higher WVTR values generally indicate superior moisture management properties. The upright cup method (ASTM E96) and the inverted cup method offer standardized approaches for these measurements, with the latter better simulating actual wearing conditions where perspiration pushes outward from the body.

Drying rate tests evaluate how quickly fabrics return to dry state after moisture exposure. These tests typically involve saturating fabric samples with precise water quantities, then measuring weight reduction over time under controlled temperature and humidity conditions. The resulting drying curves reveal crucial performance differences between Nylon 66 and Polyester fabrics.

Advanced instrumental techniques include Differential Scanning Calorimetry (DSC) for analyzing moisture absorption thermodynamics and Infrared Thermography for visualizing moisture distribution patterns. These methods provide deeper insights into the molecular-level interactions between fiber surfaces and water molecules.

For comprehensive performance evaluation, wear trials with human subjects represent the ultimate validation method. These trials typically employ moisture sensors placed between skin and fabric, combined with subjective comfort assessments. While more complex to standardize, wear trials bridge the gap between laboratory measurements and real-world performance, validating findings from controlled testing environments.

The Vertical Wicking Test represents one of the most fundamental assessment methods, measuring the height to which moisture travels up a vertically suspended fabric strip over specified time intervals. This test directly evaluates capillary action - a critical mechanism in moisture transport through textile structures. For comparative studies between Nylon 66 and Polyester, standardized sample dimensions and controlled environmental conditions (typically 20±2°C and 65±2% relative humidity) are essential.

Transverse Wicking Tests complement vertical assessments by measuring horizontal moisture spread across fabric surfaces. The Moisture Management Tester (MMT) has emerged as an industry standard instrument, capable of simultaneously tracking moisture movement through multiple fabric layers. The MMT generates comprehensive metrics including wetting time, absorption rate, maximum wetted radius, and spreading speed - providing multidimensional insights into fabric performance.

Water Vapor Transmission Rate (WVTR) testing quantifies a fabric's breathability by measuring the passage of water vapor through material over time. Higher WVTR values generally indicate superior moisture management properties. The upright cup method (ASTM E96) and the inverted cup method offer standardized approaches for these measurements, with the latter better simulating actual wearing conditions where perspiration pushes outward from the body.

Drying rate tests evaluate how quickly fabrics return to dry state after moisture exposure. These tests typically involve saturating fabric samples with precise water quantities, then measuring weight reduction over time under controlled temperature and humidity conditions. The resulting drying curves reveal crucial performance differences between Nylon 66 and Polyester fabrics.

Advanced instrumental techniques include Differential Scanning Calorimetry (DSC) for analyzing moisture absorption thermodynamics and Infrared Thermography for visualizing moisture distribution patterns. These methods provide deeper insights into the molecular-level interactions between fiber surfaces and water molecules.

For comprehensive performance evaluation, wear trials with human subjects represent the ultimate validation method. These trials typically employ moisture sensors placed between skin and fabric, combined with subjective comfort assessments. While more complex to standardize, wear trials bridge the gap between laboratory measurements and real-world performance, validating findings from controlled testing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!