Oleoresin Efficiency: Pressure vs Solvent Systems

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Extraction Technology Background and Objectives

Oleoresin extraction technology has evolved significantly over the past century, transitioning from rudimentary mechanical methods to sophisticated industrial processes. Initially developed in the early 20th century for essential oil production, oleoresin extraction has become a critical technology in pharmaceutical, food, cosmetic, and chemical industries. The fundamental principle involves separating valuable compounds from plant materials through various extraction mechanisms, with efficiency and product quality serving as primary metrics of technological advancement.

The evolution of extraction methodologies has followed distinct technological waves. Traditional methods relied on mechanical pressing and water distillation, which yielded limited extraction efficiency and often degraded heat-sensitive compounds. The mid-20th century saw the introduction of solvent-based extraction systems, predominantly utilizing organic solvents like hexane, acetone, and ethanol, which significantly improved yield but introduced concerns regarding solvent residues and environmental impact.

Recent decades have witnessed a paradigm shift toward pressure-based systems, particularly supercritical fluid extraction (SFE) using CO2. This technology leverages the unique properties of supercritical fluids to achieve high extraction efficiency while minimizing environmental footprint. Parallel to this development, subcritical water extraction and pulsed electric field technologies have emerged as promising alternatives, especially for heat-sensitive compounds.

The current technological landscape presents a dichotomy between pressure-based and solvent-based systems, each with distinct advantages and limitations. Pressure-based systems offer superior selectivity and environmental benefits but require significant capital investment and technical expertise. Conversely, solvent-based systems provide cost-effective scalability but face increasing regulatory scrutiny regarding residual solvents and waste management.

The primary objective of current research in oleoresin extraction technology is to optimize the efficiency-cost ratio while addressing sustainability concerns. Specific goals include developing hybrid systems that combine the advantages of both pressure and solvent methodologies, reducing energy consumption during extraction processes, enhancing selectivity for target compounds, and minimizing environmental impact through solvent recovery and waste reduction strategies.

Additionally, there is growing interest in developing extraction technologies specifically tailored for emerging bioactive compounds with pharmaceutical potential, particularly from underutilized plant species. This requires advancements in analytical techniques to identify and quantify novel compounds, as well as extraction methodologies capable of selectively isolating these compounds without degradation.

The trajectory of oleoresin extraction technology is increasingly influenced by sustainability imperatives, regulatory requirements for product purity, and market demand for natural ingredients with verifiable provenance and consistent bioactive profiles.

The evolution of extraction methodologies has followed distinct technological waves. Traditional methods relied on mechanical pressing and water distillation, which yielded limited extraction efficiency and often degraded heat-sensitive compounds. The mid-20th century saw the introduction of solvent-based extraction systems, predominantly utilizing organic solvents like hexane, acetone, and ethanol, which significantly improved yield but introduced concerns regarding solvent residues and environmental impact.

Recent decades have witnessed a paradigm shift toward pressure-based systems, particularly supercritical fluid extraction (SFE) using CO2. This technology leverages the unique properties of supercritical fluids to achieve high extraction efficiency while minimizing environmental footprint. Parallel to this development, subcritical water extraction and pulsed electric field technologies have emerged as promising alternatives, especially for heat-sensitive compounds.

The current technological landscape presents a dichotomy between pressure-based and solvent-based systems, each with distinct advantages and limitations. Pressure-based systems offer superior selectivity and environmental benefits but require significant capital investment and technical expertise. Conversely, solvent-based systems provide cost-effective scalability but face increasing regulatory scrutiny regarding residual solvents and waste management.

The primary objective of current research in oleoresin extraction technology is to optimize the efficiency-cost ratio while addressing sustainability concerns. Specific goals include developing hybrid systems that combine the advantages of both pressure and solvent methodologies, reducing energy consumption during extraction processes, enhancing selectivity for target compounds, and minimizing environmental impact through solvent recovery and waste reduction strategies.

Additionally, there is growing interest in developing extraction technologies specifically tailored for emerging bioactive compounds with pharmaceutical potential, particularly from underutilized plant species. This requires advancements in analytical techniques to identify and quantify novel compounds, as well as extraction methodologies capable of selectively isolating these compounds without degradation.

The trajectory of oleoresin extraction technology is increasingly influenced by sustainability imperatives, regulatory requirements for product purity, and market demand for natural ingredients with verifiable provenance and consistent bioactive profiles.

Market Analysis of Oleoresin Products and Applications

The global oleoresin market has demonstrated robust growth, valued at approximately $1.7 billion in 2022 and projected to reach $2.8 billion by 2030, growing at a CAGR of 6.5%. This expansion is primarily driven by increasing consumer preference for natural food additives and flavoring agents across various industries including food and beverage, pharmaceuticals, and cosmetics.

Food and beverage remains the dominant application sector, accounting for over 45% of the total market share. Within this sector, spice oleoresins such as paprika, black pepper, and turmeric are experiencing particularly high demand due to their consistent flavor profiles, extended shelf life, and ease of standardization compared to raw spices. The pharmaceutical segment is the fastest-growing application area, with a growth rate exceeding 7% annually, driven by the increasing incorporation of oleoresins in nutraceuticals and traditional medicine formulations.

Geographically, Asia-Pacific represents the largest market for oleoresins, contributing approximately 40% of global revenue. This dominance is attributed to the region's position as a major producer of spices and the presence of traditional extraction knowledge. North America and Europe follow, with growing demand for natural food ingredients and increasing consumer awareness about clean-label products fueling market expansion.

The market structure reveals a fragmentation pattern with several medium to large-scale players controlling about 60% of the market share. Key industry participants include Synthite Industries Ltd., Kancor Ingredients Ltd., Universal Oleoresins, and Naturex S.A., who have established strong supply chain networks and proprietary extraction technologies.

Consumer trends significantly influencing the oleoresin market include the growing preference for clean-label products, increasing demand for natural preservatives, and rising awareness about the health benefits of plant-based extracts. The food industry's shift toward replacing synthetic additives with natural alternatives has particularly benefited oleoresin suppliers who can demonstrate superior extraction efficiency and product purity.

Price sensitivity remains a critical factor in market dynamics, with extraction efficiency directly impacting production costs and final product pricing. Notably, markets utilizing oleoresins for pharmaceutical and cosmetic applications demonstrate less price sensitivity compared to the food sector, prioritizing quality and bioactive compound preservation over cost considerations.

Recent market disruptions include supply chain challenges due to climate change affecting spice cultivation, increasing regulatory scrutiny regarding extraction solvents, and growing competition from synthetic flavor alternatives in price-sensitive segments. These factors collectively underscore the importance of developing more efficient extraction technologies that can optimize yield while maintaining the integrity of bioactive compounds.

Food and beverage remains the dominant application sector, accounting for over 45% of the total market share. Within this sector, spice oleoresins such as paprika, black pepper, and turmeric are experiencing particularly high demand due to their consistent flavor profiles, extended shelf life, and ease of standardization compared to raw spices. The pharmaceutical segment is the fastest-growing application area, with a growth rate exceeding 7% annually, driven by the increasing incorporation of oleoresins in nutraceuticals and traditional medicine formulations.

Geographically, Asia-Pacific represents the largest market for oleoresins, contributing approximately 40% of global revenue. This dominance is attributed to the region's position as a major producer of spices and the presence of traditional extraction knowledge. North America and Europe follow, with growing demand for natural food ingredients and increasing consumer awareness about clean-label products fueling market expansion.

The market structure reveals a fragmentation pattern with several medium to large-scale players controlling about 60% of the market share. Key industry participants include Synthite Industries Ltd., Kancor Ingredients Ltd., Universal Oleoresins, and Naturex S.A., who have established strong supply chain networks and proprietary extraction technologies.

Consumer trends significantly influencing the oleoresin market include the growing preference for clean-label products, increasing demand for natural preservatives, and rising awareness about the health benefits of plant-based extracts. The food industry's shift toward replacing synthetic additives with natural alternatives has particularly benefited oleoresin suppliers who can demonstrate superior extraction efficiency and product purity.

Price sensitivity remains a critical factor in market dynamics, with extraction efficiency directly impacting production costs and final product pricing. Notably, markets utilizing oleoresins for pharmaceutical and cosmetic applications demonstrate less price sensitivity compared to the food sector, prioritizing quality and bioactive compound preservation over cost considerations.

Recent market disruptions include supply chain challenges due to climate change affecting spice cultivation, increasing regulatory scrutiny regarding extraction solvents, and growing competition from synthetic flavor alternatives in price-sensitive segments. These factors collectively underscore the importance of developing more efficient extraction technologies that can optimize yield while maintaining the integrity of bioactive compounds.

Current Extraction Methods and Technical Challenges

The extraction of oleoresins from plant materials has evolved significantly over the past decades, with various methods developed to optimize yield, quality, and efficiency. Currently, the industry employs several established extraction techniques, each with distinct advantages and limitations when considering the pressure versus solvent paradigm.

Conventional solvent extraction remains the most widely implemented method globally, utilizing organic solvents such as hexane, ethanol, and acetone. This approach operates at atmospheric pressure and moderate temperatures, making it accessible for small to medium-scale operations. However, it faces significant challenges including lengthy extraction times (often 6-12 hours), substantial solvent consumption, and environmental concerns related to volatile organic compound emissions.

Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a premium alternative that balances pressure and solvent considerations. Operating at pressures between 100-400 bar and temperatures of 35-60°C, SFE offers superior selectivity and produces solvent-free extracts. The technical challenges include high initial capital investment (typically 3-5 times that of conventional systems), complex pressure management systems, and energy-intensive operation.

Pressurized liquid extraction (PLE), also known as accelerated solvent extraction, represents a hybrid approach that employs elevated pressures (100-200 bar) while maintaining the solvent in liquid state. This method significantly reduces extraction time to 15-30 minutes but requires sophisticated equipment for pressure maintenance and temperature control.

Ultrasound-assisted extraction (UAE) and microwave-assisted extraction (MAE) have gained traction as energy-efficient alternatives that enhance extraction rates through mechanical effects rather than extreme pressure conditions. These techniques reduce solvent consumption by 30-50% compared to conventional methods but face scalability challenges and potential degradation of heat-sensitive compounds.

The industry currently grapples with several technical challenges across these methods. Foremost is the energy-efficiency dilemma—high-pressure systems deliver superior extraction efficiency but at significant energy costs. Equipment design faces the challenge of pressure vessel safety and material compatibility with diverse solvents and plant matrices.

Selectivity remains a persistent challenge, as most current methods extract a broad spectrum of compounds rather than targeting specific high-value oleoresins. This necessitates additional downstream processing steps, reducing overall process efficiency. Furthermore, the industry faces regulatory hurdles regarding solvent residues in final products, particularly for food and pharmaceutical applications where limits are increasingly stringent.

Scale-up challenges present significant barriers, as laboratory-optimized parameters often fail to translate directly to industrial-scale operations, particularly in pressure-based systems where fluid dynamics change substantially with increased vessel dimensions.

Conventional solvent extraction remains the most widely implemented method globally, utilizing organic solvents such as hexane, ethanol, and acetone. This approach operates at atmospheric pressure and moderate temperatures, making it accessible for small to medium-scale operations. However, it faces significant challenges including lengthy extraction times (often 6-12 hours), substantial solvent consumption, and environmental concerns related to volatile organic compound emissions.

Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a premium alternative that balances pressure and solvent considerations. Operating at pressures between 100-400 bar and temperatures of 35-60°C, SFE offers superior selectivity and produces solvent-free extracts. The technical challenges include high initial capital investment (typically 3-5 times that of conventional systems), complex pressure management systems, and energy-intensive operation.

Pressurized liquid extraction (PLE), also known as accelerated solvent extraction, represents a hybrid approach that employs elevated pressures (100-200 bar) while maintaining the solvent in liquid state. This method significantly reduces extraction time to 15-30 minutes but requires sophisticated equipment for pressure maintenance and temperature control.

Ultrasound-assisted extraction (UAE) and microwave-assisted extraction (MAE) have gained traction as energy-efficient alternatives that enhance extraction rates through mechanical effects rather than extreme pressure conditions. These techniques reduce solvent consumption by 30-50% compared to conventional methods but face scalability challenges and potential degradation of heat-sensitive compounds.

The industry currently grapples with several technical challenges across these methods. Foremost is the energy-efficiency dilemma—high-pressure systems deliver superior extraction efficiency but at significant energy costs. Equipment design faces the challenge of pressure vessel safety and material compatibility with diverse solvents and plant matrices.

Selectivity remains a persistent challenge, as most current methods extract a broad spectrum of compounds rather than targeting specific high-value oleoresins. This necessitates additional downstream processing steps, reducing overall process efficiency. Furthermore, the industry faces regulatory hurdles regarding solvent residues in final products, particularly for food and pharmaceutical applications where limits are increasingly stringent.

Scale-up challenges present significant barriers, as laboratory-optimized parameters often fail to translate directly to industrial-scale operations, particularly in pressure-based systems where fluid dynamics change substantially with increased vessel dimensions.

Comparative Analysis of Pressure and Solvent Extraction Systems

01 Solvent-based extraction methods for oleoresins

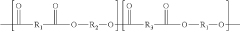

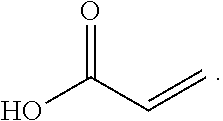

Various solvents can be used for efficient extraction of oleoresins from plant materials. These methods typically involve using organic solvents such as hexane, ethanol, or acetone to dissolve and extract the oleoresin compounds. The efficiency of these extraction systems depends on solvent selection, extraction time, temperature, and the ratio of solvent to plant material. Solvent-based methods are widely used due to their relatively high yield and ability to extract a broad spectrum of compounds from the plant material.- Solvent-based extraction methods for oleoresins: Various solvents can be used for efficient extraction of oleoresins from plant materials. These methods typically involve using organic solvents such as hexane, ethanol, or supercritical CO2 to dissolve and extract the desired compounds from the plant material. The choice of solvent affects the extraction efficiency, yield, and quality of the oleoresin. Solvent-based methods often provide higher yields compared to traditional methods and can be optimized for specific oleoresin types.

- Supercritical fluid extraction technology: Supercritical fluid extraction, particularly using CO2, has emerged as an efficient and environmentally friendly method for oleoresin extraction. This technology utilizes the unique properties of supercritical fluids to penetrate plant materials and selectively extract desired compounds. The process operates at controlled temperature and pressure conditions, allowing for precise tuning of extraction parameters. Supercritical fluid extraction typically results in high-quality oleoresins with minimal solvent residues and preserves heat-sensitive compounds.

- Mechanical extraction systems and equipment design: Specialized equipment designs can significantly improve oleoresin extraction efficiency. These include optimized pressing mechanisms, grinding systems, and continuous extraction apparatus. Modern mechanical extraction systems incorporate features such as precise temperature control, automated operation, and energy recovery systems. Equipment innovations focus on increasing yield while reducing processing time and energy consumption. The design of extraction vessels, material handling systems, and separation units all contribute to overall system efficiency.

- Process optimization techniques for improved efficiency: Various process optimization techniques can enhance oleoresin extraction efficiency. These include pre-treatment of raw materials, optimization of extraction parameters (time, temperature, pressure), and multi-stage extraction processes. Statistical experimental design methods help identify optimal operating conditions. Process monitoring and control systems ensure consistent quality and yield. Techniques such as ultrasonic assistance, microwave pre-treatment, and pulsed electric field application can also improve extraction efficiency by enhancing mass transfer and cell disruption.

- Sustainable and eco-friendly extraction approaches: Environmentally sustainable approaches to oleoresin extraction focus on reducing energy consumption, minimizing waste, and eliminating harmful solvents. These methods include water-based extraction, enzyme-assisted extraction, and green solvent utilization. Closed-loop systems that recycle solvents and energy contribute to sustainability. Some innovations incorporate renewable energy sources to power extraction processes. These eco-friendly approaches not only reduce environmental impact but can also improve product quality and meet increasing consumer demand for sustainably produced ingredients.

02 Supercritical fluid extraction technology

Supercritical fluid extraction, particularly using CO2, has emerged as an efficient and environmentally friendly method for oleoresin extraction. This technology utilizes the unique properties of supercritical fluids that can penetrate plant materials like a gas while dissolving compounds like a liquid. The process operates at controlled temperature and pressure conditions to optimize extraction efficiency. Supercritical fluid extraction offers advantages including solvent-free products, selective extraction capabilities, and preservation of heat-sensitive compounds in the oleoresin.Expand Specific Solutions03 Continuous extraction systems for improved efficiency

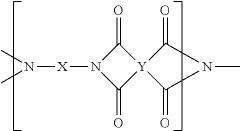

Continuous extraction systems have been developed to enhance the efficiency of oleoresin extraction processes. These systems allow for uninterrupted operation, reducing processing time and increasing throughput compared to batch extraction methods. Continuous systems often incorporate features such as counter-current extraction, automated material handling, and integrated solvent recovery mechanisms. These innovations result in higher extraction yields, more consistent product quality, and reduced operating costs for commercial oleoresin production.Expand Specific Solutions04 Enzymatic and bio-catalytic extraction methods

Enzymatic and bio-catalytic approaches offer innovative solutions for enhancing oleoresin extraction efficiency. These methods utilize specific enzymes or biological catalysts to break down plant cell walls, facilitating the release of oleoresins. The enzymatic pre-treatment of plant materials can significantly improve extraction yields when combined with conventional extraction techniques. These bio-based methods operate under mild conditions, reducing energy requirements and preserving the quality of heat-sensitive compounds in the final oleoresin product.Expand Specific Solutions05 Process optimization and equipment design for extraction efficiency

Optimization of process parameters and specialized equipment design play crucial roles in maximizing oleoresin extraction efficiency. This includes innovations in extraction vessel design, agitation systems, heat transfer mechanisms, and separation technologies. Advanced process control systems enable precise management of critical parameters such as temperature, pressure, and flow rates. Equipment features such as ultrasonic assistance, microwave enhancement, or pulsed electric field technology can further improve extraction efficiency by enhancing mass transfer and reducing extraction time.Expand Specific Solutions

Leading Companies and Research Institutions in Oleoresin Industry

The oleoresin extraction technology market is currently in a growth phase, with increasing demand driven by pharmaceutical, food, and cosmetic applications. The market is characterized by competition between traditional solvent-based systems and newer pressure-based technologies, with an estimated global market size of $1.5-2 billion. Major petroleum companies like China Petroleum & Chemical Corp., PetroChina, and ExxonMobil are leveraging their expertise in extraction technologies, while specialty chemical firms such as Air Products & Chemicals, Wacker Chemical, and BASF are developing innovative solvent systems. Academic institutions including Southwest Petroleum University and Fudan University are contributing significant research to improve extraction efficiency. The technology is approaching maturity with continuous innovations focused on sustainability, yield optimization, and reduced environmental impact.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced supercritical CO2 extraction technology for oleoresin processing that operates at pressures of 100-400 bar and temperatures between 35-60°C. Their system incorporates a multi-stage separation process that allows for fractional extraction of different oleoresin components based on their solubility parameters. The technology utilizes specialized pressure vessels with proprietary internal designs that enhance mass transfer efficiency by up to 30% compared to conventional systems. Sinopec has also implemented energy recovery systems that reduce operational costs by recycling thermal energy and recapturing CO2, achieving approximately 85% solvent recovery rates while maintaining extract purity above 98%.

Strengths: Superior energy efficiency with 25-30% lower energy consumption than conventional methods; excellent extract purity; high automation level reducing labor costs. Weaknesses: High initial capital investment; requires specialized maintenance expertise; system complexity can lead to longer downtime during technical issues.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has pioneered a hybrid pressure-solvent system for oleoresin extraction that combines modified atmosphere processing with specialized solvent formulations. Their technology utilizes proprietary gas mixtures at moderate pressures (50-150 bar) alongside carefully selected co-solvents that enhance extraction selectivity. The system features patented membrane separation technology that allows for continuous operation while maintaining solvent integrity. Air Products' approach incorporates real-time monitoring systems that adjust pressure and solvent ratios dynamically based on feedstock characteristics, achieving extraction efficiencies of up to 95% while reducing processing time by approximately 40% compared to traditional methods. Their closed-loop design minimizes environmental impact through near-complete solvent recovery.

Strengths: Exceptional extraction selectivity allowing for targeted compound isolation; reduced processing time; lower energy requirements than pure pressure systems. Weaknesses: Complex control systems requiring specialized operator training; higher operational costs due to solvent replacement needs; more challenging regulatory compliance due to solvent usage.

Key Patents and Innovations in Oleoresin Extraction

Solvent systems containing a high proportion of diluent for pressure-sensitive copying systems

PatentInactiveGB2106529B

Innovation

- A solvent system comprising 15-70% by weight of alkylated diphenyl ethers as dye solvents and 30-85% by weight of a diluent, which allows for improved print speed and intensity, even at higher diluent ratios, using alkylated diphenyl ethers and biodegradable diluents like monoalkylbenzenes and mineral oils.

Polymer aerogels fabricated without solvent exchange

PatentInactiveUS20210115214A1

Innovation

- The production of polymeric aerogels is achieved without solvent exchange by using an organic solvent with high vapor pressure and low boiling point, allowing for ambient or subcritical drying to prevent pore collapse and enhance mechanical strength.

Environmental Impact and Sustainability Considerations

The environmental impact of oleoresin extraction processes represents a critical consideration in today's sustainability-focused industrial landscape. Traditional solvent-based extraction methods, while effective for yield, often employ volatile organic compounds (VOCs) such as hexane, acetone, and petroleum ether that pose significant environmental hazards. These solvents contribute to air pollution through VOC emissions, potentially contaminate water systems through improper disposal, and require substantial energy for recovery processes.

Pressure-based extraction systems, particularly supercritical CO2 extraction, offer compelling environmental advantages. Carbon dioxide is non-toxic, non-flammable, and leaves no harmful residues in the final product. Furthermore, CO2 is readily available as a by-product from industrial processes, potentially allowing for carbon capture utilization when integrated into extraction operations. The closed-loop nature of these systems significantly reduces emissions compared to conventional solvent methods.

Energy consumption patterns differ markedly between the two approaches. Solvent systems typically require extensive heating for solvent recovery, contributing to higher carbon footprints. Pressure-based systems, while requiring initial energy investment for compression, often demonstrate superior energy efficiency over complete operational cycles, particularly in facilities utilizing renewable energy sources.

Water usage represents another critical sustainability metric. Conventional solvent systems frequently demand substantial water volumes for cooling and separation processes. Pressure-based extraction typically requires significantly less water, reducing strain on local water resources and minimizing wastewater generation requiring treatment.

Waste generation profiles also differ substantially. Solvent-based methods produce hazardous waste streams requiring specialized disposal protocols, while pressure systems generate minimal waste products. The potential for solvent residues in final products also raises concerns regarding downstream environmental impacts when these products enter consumer use cycles.

Regulatory frameworks increasingly reflect these environmental considerations, with stricter controls on solvent use and emissions driving industry innovation. Many regions have implemented graduated regulatory approaches that incentivize transitions to greener extraction technologies through tax benefits, expedited permitting, or market access advantages.

Life cycle assessment (LCA) studies consistently demonstrate that pressure-based systems, despite higher initial capital investments, typically offer superior environmental performance across multiple impact categories including global warming potential, acidification, and ecotoxicity. These sustainability advantages increasingly translate to market benefits as consumers and downstream industries prioritize environmentally responsible production methods.

Pressure-based extraction systems, particularly supercritical CO2 extraction, offer compelling environmental advantages. Carbon dioxide is non-toxic, non-flammable, and leaves no harmful residues in the final product. Furthermore, CO2 is readily available as a by-product from industrial processes, potentially allowing for carbon capture utilization when integrated into extraction operations. The closed-loop nature of these systems significantly reduces emissions compared to conventional solvent methods.

Energy consumption patterns differ markedly between the two approaches. Solvent systems typically require extensive heating for solvent recovery, contributing to higher carbon footprints. Pressure-based systems, while requiring initial energy investment for compression, often demonstrate superior energy efficiency over complete operational cycles, particularly in facilities utilizing renewable energy sources.

Water usage represents another critical sustainability metric. Conventional solvent systems frequently demand substantial water volumes for cooling and separation processes. Pressure-based extraction typically requires significantly less water, reducing strain on local water resources and minimizing wastewater generation requiring treatment.

Waste generation profiles also differ substantially. Solvent-based methods produce hazardous waste streams requiring specialized disposal protocols, while pressure systems generate minimal waste products. The potential for solvent residues in final products also raises concerns regarding downstream environmental impacts when these products enter consumer use cycles.

Regulatory frameworks increasingly reflect these environmental considerations, with stricter controls on solvent use and emissions driving industry innovation. Many regions have implemented graduated regulatory approaches that incentivize transitions to greener extraction technologies through tax benefits, expedited permitting, or market access advantages.

Life cycle assessment (LCA) studies consistently demonstrate that pressure-based systems, despite higher initial capital investments, typically offer superior environmental performance across multiple impact categories including global warming potential, acidification, and ecotoxicity. These sustainability advantages increasingly translate to market benefits as consumers and downstream industries prioritize environmentally responsible production methods.

Cost-Benefit Analysis of Different Extraction Methodologies

When evaluating oleoresin extraction methodologies, a comprehensive cost-benefit analysis reveals significant economic and operational differences between pressure-based and solvent-based systems. Initial capital investment varies substantially, with high-pressure systems (such as supercritical CO2 extraction) requiring investments of $500,000-2,000,000 for industrial-scale equipment, compared to $150,000-600,000 for conventional solvent extraction systems. This substantial difference in upfront costs creates a significant barrier to entry for smaller producers considering pressure-based technologies.

Operational expenses follow a different pattern. Solvent-based systems incur recurring costs for chemical solvents (approximately $2-5 per kg of oleoresin produced), solvent recovery (70-95% efficiency depending on system sophistication), and waste disposal. Conversely, pressure-based systems have higher energy consumption costs (typically 30-50% more than solvent systems) but minimal consumable expenses, with CO2 being recyclable at 95-99% efficiency in closed-loop systems.

Extraction efficiency metrics demonstrate that supercritical CO2 systems achieve 92-98% extraction rates for most oleoresins, compared to 85-95% for optimized solvent systems. This efficiency differential translates to approximately 5-10% higher yield per unit of raw material, creating long-term economic advantages despite higher initial investments.

Product quality considerations significantly impact market value. Pressure-extracted oleoresins command premium prices (15-30% higher) due to solvent-free status, preservation of thermolabile compounds, and reduced processing steps. This quality differential creates substantial revenue enhancement opportunities that offset higher operational costs over time.

Regulatory compliance costs vary dramatically between methodologies. Solvent-based systems face increasingly stringent regulations regarding solvent residues (typically limited to 20-30 ppm), worker exposure, and environmental discharge. These compliance requirements add approximately 5-15% to operational costs annually. Pressure-based systems, particularly those using CO2, face fewer regulatory hurdles and associated costs.

Return on investment calculations indicate that pressure-based systems typically achieve ROI in 3-5 years for high-volume operations, while solvent systems reach ROI in 1.5-3 years. However, this calculation shifts significantly based on production volume, target compounds, and market positioning. For premium oleoresin products with high market values, pressure-based systems demonstrate superior long-term economic performance despite higher initial investments.

Operational expenses follow a different pattern. Solvent-based systems incur recurring costs for chemical solvents (approximately $2-5 per kg of oleoresin produced), solvent recovery (70-95% efficiency depending on system sophistication), and waste disposal. Conversely, pressure-based systems have higher energy consumption costs (typically 30-50% more than solvent systems) but minimal consumable expenses, with CO2 being recyclable at 95-99% efficiency in closed-loop systems.

Extraction efficiency metrics demonstrate that supercritical CO2 systems achieve 92-98% extraction rates for most oleoresins, compared to 85-95% for optimized solvent systems. This efficiency differential translates to approximately 5-10% higher yield per unit of raw material, creating long-term economic advantages despite higher initial investments.

Product quality considerations significantly impact market value. Pressure-extracted oleoresins command premium prices (15-30% higher) due to solvent-free status, preservation of thermolabile compounds, and reduced processing steps. This quality differential creates substantial revenue enhancement opportunities that offset higher operational costs over time.

Regulatory compliance costs vary dramatically between methodologies. Solvent-based systems face increasingly stringent regulations regarding solvent residues (typically limited to 20-30 ppm), worker exposure, and environmental discharge. These compliance requirements add approximately 5-15% to operational costs annually. Pressure-based systems, particularly those using CO2, face fewer regulatory hurdles and associated costs.

Return on investment calculations indicate that pressure-based systems typically achieve ROI in 3-5 years for high-volume operations, while solvent systems reach ROI in 1.5-3 years. However, this calculation shifts significantly based on production volume, target compounds, and market positioning. For premium oleoresin products with high market values, pressure-based systems demonstrate superior long-term economic performance despite higher initial investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!