Optimal Conformal Coating Dispersion Techniques for Uniform Coverage

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Evolution and Objectives

Conformal coating technology has evolved significantly since its inception in the 1960s, initially developed for military and aerospace applications where electronic components required protection from harsh environmental conditions. The progression from simple acrylic and silicone-based formulations to today's advanced nano-engineered coatings represents a remarkable technological journey driven by increasingly demanding performance requirements in electronics manufacturing.

The 1980s marked a pivotal shift as consumer electronics proliferated, necessitating more cost-effective and efficient coating solutions. This period saw the introduction of automated dispensing systems, though coverage uniformity remained challenging. By the 1990s, environmental concerns prompted the development of low-VOC and water-based formulations, addressing regulatory pressures while maintaining protective properties.

The miniaturization trend in electronics during the 2000s created new technical challenges, as coating materials needed to provide adequate protection without interfering with component functionality in increasingly dense circuit boards. This led to innovations in selective coating techniques and precision dispensing technologies. The emergence of IoT devices and wearable technology in the 2010s further accelerated the need for conformal coatings that could protect electronics in diverse operating environments while maintaining dimensional tolerances.

Current technological objectives focus on achieving optimal uniformity in coating application, which directly impacts product reliability and longevity. Uniform coverage ensures consistent protection against moisture, chemicals, temperature fluctuations, and mechanical stress across the entire substrate. Non-uniform coating can create vulnerable areas prone to failure or excessive buildup that may cause thermal management issues or mechanical stress.

The industry aims to develop dispensing techniques that can adapt to complex geometries and high-density component arrangements while maintaining precise thickness control. Additional objectives include reducing application time and material waste, enhancing adhesion properties across diverse substrate materials, and improving coating performance in extreme environments.

Looking forward, the integration of real-time monitoring and feedback systems represents a significant goal, enabling adaptive dispensing that responds to substrate variations. There is also growing interest in developing coatings with self-healing properties and enhanced thermal conductivity to address emerging challenges in high-performance electronics. As electronics continue to penetrate new application domains, the evolution of conformal coating technology remains critical to ensuring reliability and longevity across diverse operating conditions.

The 1980s marked a pivotal shift as consumer electronics proliferated, necessitating more cost-effective and efficient coating solutions. This period saw the introduction of automated dispensing systems, though coverage uniformity remained challenging. By the 1990s, environmental concerns prompted the development of low-VOC and water-based formulations, addressing regulatory pressures while maintaining protective properties.

The miniaturization trend in electronics during the 2000s created new technical challenges, as coating materials needed to provide adequate protection without interfering with component functionality in increasingly dense circuit boards. This led to innovations in selective coating techniques and precision dispensing technologies. The emergence of IoT devices and wearable technology in the 2010s further accelerated the need for conformal coatings that could protect electronics in diverse operating environments while maintaining dimensional tolerances.

Current technological objectives focus on achieving optimal uniformity in coating application, which directly impacts product reliability and longevity. Uniform coverage ensures consistent protection against moisture, chemicals, temperature fluctuations, and mechanical stress across the entire substrate. Non-uniform coating can create vulnerable areas prone to failure or excessive buildup that may cause thermal management issues or mechanical stress.

The industry aims to develop dispensing techniques that can adapt to complex geometries and high-density component arrangements while maintaining precise thickness control. Additional objectives include reducing application time and material waste, enhancing adhesion properties across diverse substrate materials, and improving coating performance in extreme environments.

Looking forward, the integration of real-time monitoring and feedback systems represents a significant goal, enabling adaptive dispensing that responds to substrate variations. There is also growing interest in developing coatings with self-healing properties and enhanced thermal conductivity to address emerging challenges in high-performance electronics. As electronics continue to penetrate new application domains, the evolution of conformal coating technology remains critical to ensuring reliability and longevity across diverse operating conditions.

Market Requirements for Precision Coating Applications

The conformal coating market is experiencing significant growth driven by increasing demand for precision electronics protection across multiple industries. Current market analysis indicates that the global conformal coating market is projected to reach $15.2 billion by 2027, growing at a CAGR of 5.8% from 2022. This growth is primarily fueled by the expanding electronics industry, particularly in automotive, aerospace, defense, medical devices, and consumer electronics sectors where component reliability under harsh environmental conditions is critical.

In the automotive industry, the transition toward electric vehicles and advanced driver-assistance systems (ADAS) has created heightened demand for conformal coatings that can protect sensitive electronic components from moisture, dust, and chemical contaminants. These applications require coatings with exceptional uniformity to ensure consistent protection across complex circuit board geometries.

The aerospace and defense sectors represent premium market segments where coating quality directly impacts mission-critical systems. These industries demand coatings that can withstand extreme temperature fluctuations, vibration, and exposure to various chemicals while maintaining perfect coverage on intricate assemblies. Market research indicates that aerospace applications alone account for approximately 18% of the total conformal coating market value.

Medical device manufacturers constitute another rapidly growing segment, with increasingly stringent requirements for biocompatibility, sterilization resistance, and long-term reliability. The medical electronics market demands coatings that can be applied with precision to maintain functionality of miniaturized components while meeting strict regulatory standards including ISO 10993 and FDA requirements.

Consumer electronics manufacturers seek cost-effective coating solutions that can be applied at high volumes while maintaining quality standards. This segment is particularly sensitive to production efficiency and is driving innovation in automated dispensing systems that can deliver uniform coverage at accelerated speeds.

Across all industries, there is a clear market shift toward environmentally friendly coating formulations with reduced volatile organic compounds (VOCs). This trend is particularly pronounced in European and North American markets where environmental regulations are becoming increasingly stringent. Water-based and UV-curable coatings are gaining market share, growing at nearly twice the rate of traditional solvent-based systems.

The geographical distribution of market demand shows Asia-Pacific leading with approximately 42% market share, followed by North America and Europe. China and South Korea represent the fastest-growing markets due to their expanding electronics manufacturing base, while established markets in Japan, Germany, and the United States continue to drive innovation in high-precision applications.

In the automotive industry, the transition toward electric vehicles and advanced driver-assistance systems (ADAS) has created heightened demand for conformal coatings that can protect sensitive electronic components from moisture, dust, and chemical contaminants. These applications require coatings with exceptional uniformity to ensure consistent protection across complex circuit board geometries.

The aerospace and defense sectors represent premium market segments where coating quality directly impacts mission-critical systems. These industries demand coatings that can withstand extreme temperature fluctuations, vibration, and exposure to various chemicals while maintaining perfect coverage on intricate assemblies. Market research indicates that aerospace applications alone account for approximately 18% of the total conformal coating market value.

Medical device manufacturers constitute another rapidly growing segment, with increasingly stringent requirements for biocompatibility, sterilization resistance, and long-term reliability. The medical electronics market demands coatings that can be applied with precision to maintain functionality of miniaturized components while meeting strict regulatory standards including ISO 10993 and FDA requirements.

Consumer electronics manufacturers seek cost-effective coating solutions that can be applied at high volumes while maintaining quality standards. This segment is particularly sensitive to production efficiency and is driving innovation in automated dispensing systems that can deliver uniform coverage at accelerated speeds.

Across all industries, there is a clear market shift toward environmentally friendly coating formulations with reduced volatile organic compounds (VOCs). This trend is particularly pronounced in European and North American markets where environmental regulations are becoming increasingly stringent. Water-based and UV-curable coatings are gaining market share, growing at nearly twice the rate of traditional solvent-based systems.

The geographical distribution of market demand shows Asia-Pacific leading with approximately 42% market share, followed by North America and Europe. China and South Korea represent the fastest-growing markets due to their expanding electronics manufacturing base, while established markets in Japan, Germany, and the United States continue to drive innovation in high-precision applications.

Current Dispersion Technologies and Limitations

The conformal coating industry currently employs several dispersion technologies, each with distinct advantages and limitations. Selective coating systems represent the most widely adopted approach, utilizing robotic arms equipped with precision nozzles to apply coating materials along programmed paths. These systems excel in targeted application scenarios but struggle with complex geometries and often require extensive programming for new board designs. The precision achieved by selective coating typically ranges from ±0.5mm to ±1.5mm depending on the system quality and calibration frequency.

Spray coating technologies, including both conventional air spray and airless systems, offer broader coverage capabilities. Air spray systems atomize coating materials using compressed air, creating fine particles that provide excellent uniformity but suffer from overspray and material waste (typically 30-40%). Airless spray systems operate at higher pressures (2000-3000 psi) to force coating through small orifices, reducing waste but often creating thicker, less uniform coatings with potential for "orange peel" texture defects.

Dip coating represents the oldest dispersion method, immersing entire boards in coating material. While offering complete coverage and process simplicity, this approach faces significant challenges including material pooling, inconsistent thickness, and difficulty in achieving selective application. Modern dip systems incorporate controlled withdrawal rates (typically 5-25 cm/minute) to improve thickness consistency but cannot overcome inherent limitations for complex assemblies.

Emerging technologies include ultrasonic spray systems that utilize high-frequency vibrations (20-100 kHz) to produce exceptionally fine droplets (10-50 microns), significantly improving transfer efficiency to 80-90%. However, these systems require substantial capital investment and specialized maintenance protocols. Automated brush coating systems offer another alternative, using precision-controlled mechanical brushes to apply coatings, though they struggle with consistent material distribution across varied topographies.

Material formulation presents another critical limitation across all dispersion methods. Viscosity variations due to temperature fluctuations (±5°C can alter viscosity by 15-25%) significantly impact coating uniformity. Solvent-based coatings provide excellent flow characteristics but present environmental and workplace safety concerns, while water-based alternatives offer improved safety profiles but demonstrate inferior wetting properties on many substrate materials.

Environmental control during application represents a persistent challenge, with humidity variations beyond ±10% RH potentially causing adhesion issues, cloudiness, or improper curing. Airborne particulate contamination remains problematic even in controlled environments, with particles as small as 5 microns capable of creating coating defects and potential reliability issues.

Spray coating technologies, including both conventional air spray and airless systems, offer broader coverage capabilities. Air spray systems atomize coating materials using compressed air, creating fine particles that provide excellent uniformity but suffer from overspray and material waste (typically 30-40%). Airless spray systems operate at higher pressures (2000-3000 psi) to force coating through small orifices, reducing waste but often creating thicker, less uniform coatings with potential for "orange peel" texture defects.

Dip coating represents the oldest dispersion method, immersing entire boards in coating material. While offering complete coverage and process simplicity, this approach faces significant challenges including material pooling, inconsistent thickness, and difficulty in achieving selective application. Modern dip systems incorporate controlled withdrawal rates (typically 5-25 cm/minute) to improve thickness consistency but cannot overcome inherent limitations for complex assemblies.

Emerging technologies include ultrasonic spray systems that utilize high-frequency vibrations (20-100 kHz) to produce exceptionally fine droplets (10-50 microns), significantly improving transfer efficiency to 80-90%. However, these systems require substantial capital investment and specialized maintenance protocols. Automated brush coating systems offer another alternative, using precision-controlled mechanical brushes to apply coatings, though they struggle with consistent material distribution across varied topographies.

Material formulation presents another critical limitation across all dispersion methods. Viscosity variations due to temperature fluctuations (±5°C can alter viscosity by 15-25%) significantly impact coating uniformity. Solvent-based coatings provide excellent flow characteristics but present environmental and workplace safety concerns, while water-based alternatives offer improved safety profiles but demonstrate inferior wetting properties on many substrate materials.

Environmental control during application represents a persistent challenge, with humidity variations beyond ±10% RH potentially causing adhesion issues, cloudiness, or improper curing. Airborne particulate contamination remains problematic even in controlled environments, with particles as small as 5 microns capable of creating coating defects and potential reliability issues.

Contemporary Uniform Coverage Solutions

01 Spray coating techniques for uniform conformal coverage

Spray coating is a widely used technique for applying conformal coatings to achieve uniform coverage. This method involves atomizing the coating material and directing it onto the substrate surface. Various spray technologies, including ultrasonic spray, automated spray systems, and precision spray nozzles, can be employed to control droplet size, spray pattern, and coating thickness. These techniques help minimize overspray, reduce material waste, and ensure consistent coverage even on complex geometries and hard-to-reach areas.- Spray coating techniques for uniform conformal coverage: Spray coating is a widely used technique for applying conformal coatings to achieve uniform coverage. This method involves atomizing the coating material and directing it onto the substrate surface. Various spray technologies, including ultrasonic spray, air-assisted spray, and electrostatic spray, can be employed to control droplet size and distribution, ensuring even coating thickness across complex geometries. Spray parameters such as pressure, distance, and angle can be optimized to minimize overspray and achieve consistent coverage.

- Dip coating methods for comprehensive coverage: Dip coating involves immersing the substrate into a bath of conformal coating material and then withdrawing it at a controlled rate. This technique provides comprehensive coverage, including hard-to-reach areas and complex geometries. The withdrawal speed, viscosity of the coating material, and temperature control are critical parameters that affect the uniformity and thickness of the coating. Multiple dipping cycles may be employed to achieve desired thickness while maintaining uniformity. This method is particularly effective for batch processing of multiple components.

- Automated dispensing systems for precision coating: Automated dispensing systems utilize robotic arms or programmable equipment to apply conformal coatings with high precision. These systems can follow pre-programmed paths to ensure consistent application across specific areas of the substrate. They often incorporate vision systems for alignment and quality control, allowing real-time adjustments to dispensing parameters. Automated systems can combine multiple dispensing techniques, such as needle dispensing, jetting, or selective spraying, to optimize coverage based on substrate geometry. This approach is particularly valuable for high-volume production requiring repeatable coating quality.

- Material formulation for enhanced flow and leveling: The formulation of conformal coating materials plays a crucial role in achieving uniform coverage. Additives such as flow modifiers, leveling agents, and viscosity controllers can be incorporated to improve the coating's ability to spread evenly across surfaces. Solvent selection and concentration affect the drying behavior and final film formation. Some formulations include self-leveling properties that help eliminate thickness variations after application. Advanced polymer systems may incorporate thixotropic properties, allowing the material to flow during application but resist sagging or running afterward.

- Post-application treatments for coating uniformity: Various post-application treatments can enhance the uniformity of conformal coatings. These include controlled heating or curing processes that promote even flow and leveling before solidification. Vacuum techniques may be employed to remove entrapped air bubbles that could compromise coating integrity. UV exposure systems can provide precise curing control for photosensitive coatings. Centrifugal force application through spinning or rotation can redistribute excess coating material to achieve consistent thickness. These post-application methods help compensate for initial application irregularities and optimize the protective properties of the conformal coating.

02 Dip coating methods for comprehensive coverage

Dip coating involves immersing the substrate into a bath of conformal coating material and then withdrawing it at a controlled rate. This technique provides comprehensive coverage, including hard-to-reach areas and complex geometries. The withdrawal speed, viscosity of the coating material, and temperature control are critical parameters that affect the uniformity and thickness of the coating. Various modifications to traditional dip coating, such as controlled atmosphere dipping and multi-layer dipping, can be employed to enhance coating quality and ensure uniform coverage across the entire substrate.Expand Specific Solutions03 Selective coating application technologies

Selective coating technologies allow for precise application of conformal coatings to specific areas while keeping other areas coating-free. These techniques include automated dispensing systems, robotic application, and masking methods. Programmable dispensing paths, vision systems for alignment, and precision fluid control enable accurate coating placement. These selective application methods are particularly valuable for electronic assemblies where certain components or connectors must remain uncoated, while still ensuring uniform coverage in the protected areas.Expand Specific Solutions04 Advanced material formulations for improved dispersion

The formulation of conformal coating materials plays a crucial role in achieving uniform coverage. Advanced formulations incorporate flow modifiers, leveling agents, and viscosity controllers to improve material dispersion across surfaces. Some formulations include self-leveling properties that help eliminate pinholes and voids. Nano-modified coatings and specialized polymer blends can enhance surface wetting and adhesion properties, resulting in more uniform coating layers. The selection of solvents and curing agents also impacts the coating's ability to form consistent protective films.Expand Specific Solutions05 Process control and environmental factors for coating uniformity

Achieving uniform conformal coating coverage requires careful control of process parameters and environmental conditions. Factors such as temperature, humidity, air flow, and substrate preparation significantly impact coating quality. Advanced monitoring systems, including real-time viscosity measurement, environmental chambers, and automated inspection technologies, help maintain optimal coating conditions. Pre-coating treatments like plasma cleaning or surface activation can improve coating adhesion and uniformity. Post-application processes, such as controlled curing profiles and inspection techniques, further ensure coating consistency and performance.Expand Specific Solutions

Industry Leaders in Coating Dispersion Equipment

The conformal coating dispersion technology market is currently in a growth phase, characterized by increasing demand for uniform coverage solutions across electronics manufacturing. The market size is expanding due to the rising need for protection against environmental factors in various industries. Technologically, the field is moderately mature but continues to evolve with innovations in application methods and materials. Leading players include Nordson Corp., which dominates with comprehensive dispensing systems, HzO offering specialized nano-coating solutions, and 3M Innovative Properties contributing significant intellectual property. Other notable competitors include Wacker Chemie AG and Kaneka Corp. developing advanced chemical formulations, while equipment manufacturers like Tokyo Electron and Seiko Epson focus on precision application technologies. The market shows a trend toward more environmentally sustainable coating solutions with improved performance characteristics.

Nordson Corp.

Technical Solution: Nordson has developed advanced selective coating systems utilizing precision dispensing technology for conformal coating applications. Their Asymtek series employs programmable robotic systems with multi-axis motion control that can accurately apply conformal coatings to specific areas of circuit boards. The technology incorporates advanced vision alignment systems to ensure precise positioning and coating thickness control. Nordson's Film-Coater technology utilizes a film coating applicator that creates a uniform film of material which is transferred to the substrate, ensuring consistent thickness across complex topographies. Their systems also feature closed-loop feedback mechanisms that continuously monitor and adjust dispensing parameters such as pressure, temperature, and flow rate to maintain optimal viscosity and application consistency even during extended production runs.

Strengths: Industry-leading precision in selective coating applications; integrated vision systems for quality control; extensive material compatibility with various coating formulations. Weaknesses: Higher initial capital investment compared to manual systems; requires specialized technical expertise for programming and maintenance.

HzO, Inc.

Technical Solution: HzO has revolutionized conformal coating technology with their Parylene-based thin-film deposition system that creates ultra-uniform protective barriers at the molecular level. Their vacuum deposition process enables the coating to penetrate and protect even the most complex electronic assemblies with 100% coverage. The company's proprietary Plasma Enhanced Chemical Vapor Deposition (PECVD) technology creates pinhole-free barriers that provide exceptional protection against moisture, chemicals, and environmental contaminants. HzO's coating system features precise thickness control capabilities, allowing for application of protective layers as thin as 0.5 microns without compromising protection. Their process incorporates specialized masking techniques that protect sensitive areas like connectors and test points while ensuring complete coverage of critical components. The technology enables conformal coating application at lower temperatures than traditional methods, making it suitable for temperature-sensitive components and assemblies.

Strengths: Exceptional uniformity and coverage even in extremely complex geometries; superior moisture and chemical resistance; minimal impact on component dimensions and weight. Weaknesses: Higher processing costs compared to liquid application methods; requires specialized equipment and controlled environment; longer processing times for thicker coatings.

Critical Patents in Precision Dispensing Technology

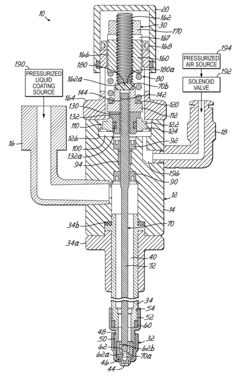

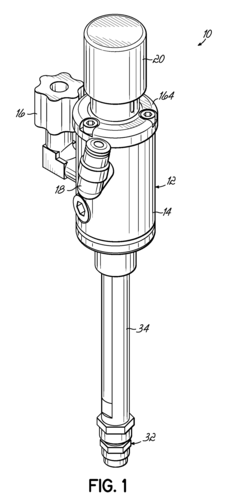

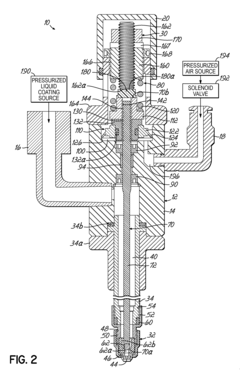

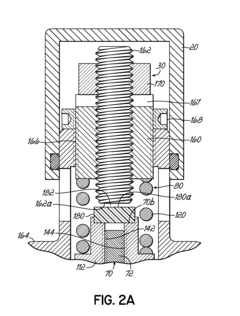

Conformal coating applicator and method

PatentActiveUS20120061426A1

Innovation

- Incorporating a resilient dampening element, such as an elastomeric material, between the valve stem and the hard stop element to provide a biasing force and reduce rebounding movement, ensuring a cleaner and sharper leading edge of the applied coating pattern.

Dyed fluoropolymers

PatentInactiveUS6894105B2

Innovation

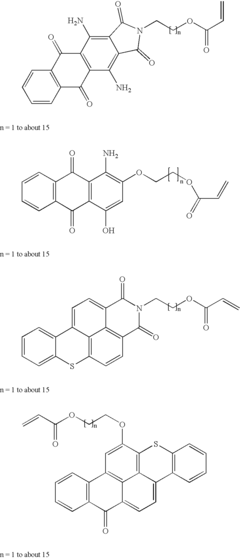

- Development of dyed fluoropolymers where the dye is covalently bonded to the polymer, using fluorochemical (meth)acrylate monomers and (meth)acrylate functional dyes, providing improved thermal stability, adhesion, and resistance to leaching, without the need for a cure mechanism.

Environmental Compliance in Coating Processes

Environmental regulations governing conformal coating processes have become increasingly stringent worldwide, necessitating comprehensive compliance strategies for manufacturers. The VOC (Volatile Organic Compound) emissions from traditional solvent-based conformal coatings face particularly strict limitations under frameworks such as the EU's RoHS and REACH regulations, the U.S. Clean Air Act, and China's VOC emission standards. These regulations have accelerated the industry shift toward water-based and UV-curable coating formulations with lower environmental impact.

Material Safety Data Sheets (MSDS) compliance represents a critical aspect of environmental management in conformal coating operations. Manufacturers must maintain detailed documentation of all chemical components, potential hazards, and proper handling procedures. This documentation must be readily accessible to employees and regulatory authorities, with regular updates to reflect any formulation changes or new regulatory requirements.

Waste management protocols for conformal coating processes require specialized handling procedures for both liquid waste and emissions. Spent solvents, excess coating materials, and cleaning solutions must undergo proper treatment before disposal. Many facilities have implemented closed-loop recycling systems for solvents and coating materials, significantly reducing waste generation while achieving cost savings through material recovery.

Air quality management systems have evolved substantially to address the particulate and gaseous emissions from coating operations. Modern facilities typically employ activated carbon filtration, thermal oxidizers, or catalytic converters to capture and neutralize airborne contaminants before release. Continuous emissions monitoring systems provide real-time data on air quality parameters, enabling immediate corrective actions when deviations occur.

Energy efficiency initiatives have become integral to environmental compliance strategies in coating processes. The transition to UV-LED curing systems from traditional thermal curing methods has reduced energy consumption by up to 80% in some applications. Additionally, heat recovery systems capture and repurpose thermal energy from curing operations, further reducing the carbon footprint of coating processes.

Water conservation measures have gained prominence in conformal coating operations, particularly for facilities using water-based formulations or aqueous cleaning systems. Closed-loop water recycling systems, often incorporating advanced filtration and purification technologies, minimize freshwater consumption and wastewater discharge. These systems typically achieve water reuse rates exceeding 90%, substantially reducing both environmental impact and operational costs.

Certification programs such as ISO 14001 provide standardized frameworks for environmental management systems in coating operations. These certifications require documented procedures, regular audits, and continuous improvement initiatives focused on reducing environmental impact. Many manufacturers have found that achieving and maintaining such certifications delivers competitive advantages through improved regulatory compliance, operational efficiency, and market access.

Material Safety Data Sheets (MSDS) compliance represents a critical aspect of environmental management in conformal coating operations. Manufacturers must maintain detailed documentation of all chemical components, potential hazards, and proper handling procedures. This documentation must be readily accessible to employees and regulatory authorities, with regular updates to reflect any formulation changes or new regulatory requirements.

Waste management protocols for conformal coating processes require specialized handling procedures for both liquid waste and emissions. Spent solvents, excess coating materials, and cleaning solutions must undergo proper treatment before disposal. Many facilities have implemented closed-loop recycling systems for solvents and coating materials, significantly reducing waste generation while achieving cost savings through material recovery.

Air quality management systems have evolved substantially to address the particulate and gaseous emissions from coating operations. Modern facilities typically employ activated carbon filtration, thermal oxidizers, or catalytic converters to capture and neutralize airborne contaminants before release. Continuous emissions monitoring systems provide real-time data on air quality parameters, enabling immediate corrective actions when deviations occur.

Energy efficiency initiatives have become integral to environmental compliance strategies in coating processes. The transition to UV-LED curing systems from traditional thermal curing methods has reduced energy consumption by up to 80% in some applications. Additionally, heat recovery systems capture and repurpose thermal energy from curing operations, further reducing the carbon footprint of coating processes.

Water conservation measures have gained prominence in conformal coating operations, particularly for facilities using water-based formulations or aqueous cleaning systems. Closed-loop water recycling systems, often incorporating advanced filtration and purification technologies, minimize freshwater consumption and wastewater discharge. These systems typically achieve water reuse rates exceeding 90%, substantially reducing both environmental impact and operational costs.

Certification programs such as ISO 14001 provide standardized frameworks for environmental management systems in coating operations. These certifications require documented procedures, regular audits, and continuous improvement initiatives focused on reducing environmental impact. Many manufacturers have found that achieving and maintaining such certifications delivers competitive advantages through improved regulatory compliance, operational efficiency, and market access.

Quality Assurance Metrics for Coating Performance

Quality assurance metrics serve as essential benchmarks for evaluating the effectiveness and reliability of conformal coating applications. The implementation of comprehensive measurement protocols ensures that coating performance meets industry standards and specific application requirements. These metrics typically encompass thickness uniformity, adhesion strength, dielectric properties, and environmental resistance parameters.

Thickness measurement represents a fundamental quality metric, with techniques including optical microscopy, eddy current testing, and ultrasonic gauging providing quantitative data on coating distribution. Statistical process control methods such as Cpk and Ppk indices offer valuable insights into process capability and stability, enabling manufacturers to maintain consistent coating quality across production batches.

Adhesion testing protocols, including cross-hatch, pull-off, and tape tests, quantify the mechanical bond between the coating and substrate. These measurements correlate directly with long-term reliability and resistance to environmental stressors. Modern quality systems increasingly incorporate automated visual inspection systems that utilize machine learning algorithms to detect defects such as bubbles, pinholes, and delamination with greater precision than traditional manual inspection methods.

Environmental stress testing constitutes another critical dimension of quality assurance. Accelerated aging tests simulating temperature cycling, humidity exposure, and salt spray conditions provide predictive metrics for coating durability. The IPC-CC-830B standard establishes minimum performance requirements for conformal coatings, including resistance to moisture, thermal shock, and chemical exposure, serving as a baseline for quality assessment.

Electrical performance metrics evaluate the coating's ability to maintain insulation resistance and prevent current leakage under various environmental conditions. These measurements typically include surface insulation resistance (SIR) testing and dielectric breakdown voltage assessment, which are particularly relevant for high-reliability electronic applications in automotive, aerospace, and medical device sectors.

Advanced analytical techniques such as Fourier Transform Infrared Spectroscopy (FTIR) and Differential Scanning Calorimetry (DSC) provide insights into chemical composition and cure completeness, enabling manufacturers to verify material properties and process consistency. These methods help identify potential issues before they manifest as field failures.

Real-time monitoring systems incorporating in-line viscosity measurement, temperature profiling, and cure verification represent the cutting edge of quality assurance technology. These systems enable immediate process adjustments to maintain optimal coating parameters, reducing variability and enhancing overall product reliability. The integration of these metrics into digital manufacturing platforms facilitates comprehensive data analysis and continuous process improvement.

Thickness measurement represents a fundamental quality metric, with techniques including optical microscopy, eddy current testing, and ultrasonic gauging providing quantitative data on coating distribution. Statistical process control methods such as Cpk and Ppk indices offer valuable insights into process capability and stability, enabling manufacturers to maintain consistent coating quality across production batches.

Adhesion testing protocols, including cross-hatch, pull-off, and tape tests, quantify the mechanical bond between the coating and substrate. These measurements correlate directly with long-term reliability and resistance to environmental stressors. Modern quality systems increasingly incorporate automated visual inspection systems that utilize machine learning algorithms to detect defects such as bubbles, pinholes, and delamination with greater precision than traditional manual inspection methods.

Environmental stress testing constitutes another critical dimension of quality assurance. Accelerated aging tests simulating temperature cycling, humidity exposure, and salt spray conditions provide predictive metrics for coating durability. The IPC-CC-830B standard establishes minimum performance requirements for conformal coatings, including resistance to moisture, thermal shock, and chemical exposure, serving as a baseline for quality assessment.

Electrical performance metrics evaluate the coating's ability to maintain insulation resistance and prevent current leakage under various environmental conditions. These measurements typically include surface insulation resistance (SIR) testing and dielectric breakdown voltage assessment, which are particularly relevant for high-reliability electronic applications in automotive, aerospace, and medical device sectors.

Advanced analytical techniques such as Fourier Transform Infrared Spectroscopy (FTIR) and Differential Scanning Calorimetry (DSC) provide insights into chemical composition and cure completeness, enabling manufacturers to verify material properties and process consistency. These methods help identify potential issues before they manifest as field failures.

Real-time monitoring systems incorporating in-line viscosity measurement, temperature profiling, and cure verification represent the cutting edge of quality assurance technology. These systems enable immediate process adjustments to maintain optimal coating parameters, reducing variability and enhancing overall product reliability. The integration of these metrics into digital manufacturing platforms facilitates comprehensive data analysis and continuous process improvement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!