Optimize Oleoresin Processing Methods for Eco-Friendly Production

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Processing Evolution and Objectives

Oleoresin extraction and processing has evolved significantly since its inception in ancient civilizations, where it was primarily used for medicinal purposes, adhesives, and waterproofing materials. The historical trajectory shows a transition from rudimentary collection methods involving tree tapping and natural exudation to increasingly sophisticated industrial processes. By the mid-20th century, solvent extraction emerged as the dominant technique, enabling higher yields and standardized quality, albeit with substantial environmental concerns due to chemical usage and waste generation.

The current technological landscape of oleoresin processing is characterized by a growing tension between production efficiency and environmental sustainability. Traditional methods utilizing petroleum-based solvents like hexane and acetone have proven effective for commercial-scale extraction but pose significant ecological hazards including groundwater contamination, air pollution, and high energy consumption. These environmental drawbacks have catalyzed research into alternative processing methodologies that maintain yield quality while reducing ecological impact.

Recent technological advancements have focused on developing greener extraction techniques such as supercritical CO2 extraction, microwave-assisted extraction, and enzyme-assisted processes. These innovations represent promising steps toward more sustainable practices but face challenges in scalability, cost-effectiveness, and integration with existing industrial infrastructure. The industry stands at a critical juncture where technological evolution must accelerate to meet both commercial demands and environmental imperatives.

The primary objective of optimizing oleoresin processing methods for eco-friendly production encompasses several interconnected goals. First, reducing or eliminating toxic solvent usage while maintaining extraction efficiency represents the most immediate challenge. Second, minimizing energy consumption throughout the processing chain would significantly lower the carbon footprint of operations. Third, developing closed-loop systems that recycle water and processing materials would address waste management concerns inherent in current methodologies.

Additionally, the optimization efforts aim to preserve or enhance the bioactive compounds in oleoresins that give them their commercial value. This requires precise control over processing parameters such as temperature, pressure, and extraction time to prevent degradation of sensitive compounds. The ultimate technological goal is to establish processing protocols that balance economic viability with environmental responsibility, potentially creating new industry standards that could influence regulatory frameworks globally.

The trajectory of oleoresin processing technology indicates a shift toward bio-based solvents, intensified extraction processes, and hybrid technologies that combine multiple approaches to maximize efficiency while minimizing environmental impact. These developments align with broader industry trends toward sustainable manufacturing and circular economy principles, positioning eco-friendly oleoresin processing as both a technical necessity and a market differentiator in the evolving natural products landscape.

The current technological landscape of oleoresin processing is characterized by a growing tension between production efficiency and environmental sustainability. Traditional methods utilizing petroleum-based solvents like hexane and acetone have proven effective for commercial-scale extraction but pose significant ecological hazards including groundwater contamination, air pollution, and high energy consumption. These environmental drawbacks have catalyzed research into alternative processing methodologies that maintain yield quality while reducing ecological impact.

Recent technological advancements have focused on developing greener extraction techniques such as supercritical CO2 extraction, microwave-assisted extraction, and enzyme-assisted processes. These innovations represent promising steps toward more sustainable practices but face challenges in scalability, cost-effectiveness, and integration with existing industrial infrastructure. The industry stands at a critical juncture where technological evolution must accelerate to meet both commercial demands and environmental imperatives.

The primary objective of optimizing oleoresin processing methods for eco-friendly production encompasses several interconnected goals. First, reducing or eliminating toxic solvent usage while maintaining extraction efficiency represents the most immediate challenge. Second, minimizing energy consumption throughout the processing chain would significantly lower the carbon footprint of operations. Third, developing closed-loop systems that recycle water and processing materials would address waste management concerns inherent in current methodologies.

Additionally, the optimization efforts aim to preserve or enhance the bioactive compounds in oleoresins that give them their commercial value. This requires precise control over processing parameters such as temperature, pressure, and extraction time to prevent degradation of sensitive compounds. The ultimate technological goal is to establish processing protocols that balance economic viability with environmental responsibility, potentially creating new industry standards that could influence regulatory frameworks globally.

The trajectory of oleoresin processing technology indicates a shift toward bio-based solvents, intensified extraction processes, and hybrid technologies that combine multiple approaches to maximize efficiency while minimizing environmental impact. These developments align with broader industry trends toward sustainable manufacturing and circular economy principles, positioning eco-friendly oleoresin processing as both a technical necessity and a market differentiator in the evolving natural products landscape.

Market Analysis for Sustainable Oleoresin Products

The global market for sustainable oleoresin products has witnessed significant growth in recent years, driven by increasing consumer awareness about environmental issues and a growing preference for eco-friendly products. The oleoresin market, valued at approximately $1.2 billion in 2022, is projected to reach $1.8 billion by 2028, with sustainable variants capturing an increasingly larger share of this expansion.

Consumer demand patterns clearly indicate a shift toward environmentally responsible products across various industries that utilize oleoresins, including food and beverages, pharmaceuticals, cosmetics, and aromatherapy. Market research shows that over 65% of consumers globally are willing to pay premium prices for products that demonstrate environmental stewardship in their production processes.

The food industry represents the largest application segment for sustainable oleoresins, accounting for roughly 40% of market consumption. This is primarily due to the growing demand for natural food colorants and flavoring agents as alternatives to synthetic additives. The pharmaceutical sector follows closely, with increasing incorporation of eco-friendly oleoresins in various medicinal formulations.

Geographically, Europe leads the sustainable oleoresin market with approximately 35% market share, followed by North America and Asia-Pacific regions. Developing economies in Asia, particularly India and China, are emerging as significant growth markets due to their expanding middle-class population and increasing environmental consciousness.

Market barriers for sustainable oleoresin products include higher production costs compared to conventional methods, supply chain complexities, and inconsistent regulatory frameworks across different regions. Despite these challenges, the price premium for sustainable variants has been decreasing as production technologies improve and economies of scale are achieved.

Industry forecasts suggest that the market for sustainable oleoresin products will grow at a compound annual growth rate of 8.2% through 2028, outpacing the conventional oleoresin market's growth rate of 5.1%. This accelerated growth is attributed to stricter environmental regulations, corporate sustainability initiatives, and evolving consumer preferences.

Key market drivers include the rising adoption of sustainable practices across industries, increasing research and development investments in green extraction technologies, and growing corporate commitments to reducing environmental footprints. Additionally, the expansion of organic and natural product categories in retail channels has created new opportunities for sustainable oleoresin products to reach environmentally conscious consumers.

Consumer demand patterns clearly indicate a shift toward environmentally responsible products across various industries that utilize oleoresins, including food and beverages, pharmaceuticals, cosmetics, and aromatherapy. Market research shows that over 65% of consumers globally are willing to pay premium prices for products that demonstrate environmental stewardship in their production processes.

The food industry represents the largest application segment for sustainable oleoresins, accounting for roughly 40% of market consumption. This is primarily due to the growing demand for natural food colorants and flavoring agents as alternatives to synthetic additives. The pharmaceutical sector follows closely, with increasing incorporation of eco-friendly oleoresins in various medicinal formulations.

Geographically, Europe leads the sustainable oleoresin market with approximately 35% market share, followed by North America and Asia-Pacific regions. Developing economies in Asia, particularly India and China, are emerging as significant growth markets due to their expanding middle-class population and increasing environmental consciousness.

Market barriers for sustainable oleoresin products include higher production costs compared to conventional methods, supply chain complexities, and inconsistent regulatory frameworks across different regions. Despite these challenges, the price premium for sustainable variants has been decreasing as production technologies improve and economies of scale are achieved.

Industry forecasts suggest that the market for sustainable oleoresin products will grow at a compound annual growth rate of 8.2% through 2028, outpacing the conventional oleoresin market's growth rate of 5.1%. This accelerated growth is attributed to stricter environmental regulations, corporate sustainability initiatives, and evolving consumer preferences.

Key market drivers include the rising adoption of sustainable practices across industries, increasing research and development investments in green extraction technologies, and growing corporate commitments to reducing environmental footprints. Additionally, the expansion of organic and natural product categories in retail channels has created new opportunities for sustainable oleoresin products to reach environmentally conscious consumers.

Global Oleoresin Technology Assessment and Barriers

The global oleoresin industry faces significant technological and environmental challenges despite its growing market value, estimated at USD 1.7 billion in 2022 with projections to reach USD 2.3 billion by 2027. Current extraction and processing methods predominantly rely on conventional solvent-based techniques that present substantial environmental concerns, including high energy consumption, chemical waste generation, and significant carbon footprints.

Traditional extraction methods using hexane, acetone, and other petrochemical solvents remain widespread due to their cost-effectiveness and established infrastructure. However, these methods typically recover only 60-75% of available compounds while generating hazardous waste streams that require specialized disposal procedures. The industry's heavy reliance on these methods has created technological inertia that impedes adoption of greener alternatives.

Regulatory barriers present another significant challenge, with inconsistent global standards creating a fragmented compliance landscape. While the European Union has implemented strict regulations on solvent residues and emissions through REACH legislation, developing nations often operate under less stringent frameworks, creating market disparities and complicating international trade of oleoresin products.

Infrastructure limitations further constrain technological advancement, particularly in major producing regions across Asia and Latin America. Many processing facilities lack the capital resources to invest in modern equipment, resulting in continued dependence on outdated technologies. The specialized nature of eco-friendly extraction equipment and its higher initial investment costs create significant barriers to entry for smaller producers.

Knowledge gaps regarding optimal processing parameters for environmentally sustainable methods represent another critical barrier. Research indicates that supercritical CO2 extraction, while promising, requires precise calibration for different plant materials to achieve comparable yields to conventional methods. Limited technical expertise in emerging markets compounds this challenge, with insufficient training programs and knowledge transfer mechanisms.

Supply chain vulnerabilities also impact technological adoption, as sustainable processing often requires specialized inputs and maintenance services that may be unavailable in remote production regions. The seasonal nature of raw material availability creates additional complexities, requiring technologies that can efficiently process variable feedstock quality while maintaining consistent output specifications.

Addressing these barriers requires coordinated efforts across the value chain, including targeted R&D investments, policy harmonization, and capacity building initiatives. Recent technological innovations in enzymatic pre-treatments, microwave-assisted extraction, and ultrasonic processing show promise for reducing environmental impacts while maintaining economic viability, but require further development and validation for commercial-scale implementation.

Traditional extraction methods using hexane, acetone, and other petrochemical solvents remain widespread due to their cost-effectiveness and established infrastructure. However, these methods typically recover only 60-75% of available compounds while generating hazardous waste streams that require specialized disposal procedures. The industry's heavy reliance on these methods has created technological inertia that impedes adoption of greener alternatives.

Regulatory barriers present another significant challenge, with inconsistent global standards creating a fragmented compliance landscape. While the European Union has implemented strict regulations on solvent residues and emissions through REACH legislation, developing nations often operate under less stringent frameworks, creating market disparities and complicating international trade of oleoresin products.

Infrastructure limitations further constrain technological advancement, particularly in major producing regions across Asia and Latin America. Many processing facilities lack the capital resources to invest in modern equipment, resulting in continued dependence on outdated technologies. The specialized nature of eco-friendly extraction equipment and its higher initial investment costs create significant barriers to entry for smaller producers.

Knowledge gaps regarding optimal processing parameters for environmentally sustainable methods represent another critical barrier. Research indicates that supercritical CO2 extraction, while promising, requires precise calibration for different plant materials to achieve comparable yields to conventional methods. Limited technical expertise in emerging markets compounds this challenge, with insufficient training programs and knowledge transfer mechanisms.

Supply chain vulnerabilities also impact technological adoption, as sustainable processing often requires specialized inputs and maintenance services that may be unavailable in remote production regions. The seasonal nature of raw material availability creates additional complexities, requiring technologies that can efficiently process variable feedstock quality while maintaining consistent output specifications.

Addressing these barriers requires coordinated efforts across the value chain, including targeted R&D investments, policy harmonization, and capacity building initiatives. Recent technological innovations in enzymatic pre-treatments, microwave-assisted extraction, and ultrasonic processing show promise for reducing environmental impacts while maintaining economic viability, but require further development and validation for commercial-scale implementation.

Current Green Processing Solutions and Techniques

01 Solvent-free extraction methods

Eco-friendly oleoresin processing methods that eliminate the use of chemical solvents. These techniques include supercritical fluid extraction, particularly using CO2, which leaves no toxic residues and produces high-quality oleoresins. The process operates at lower temperatures, preserving heat-sensitive compounds and resulting in products free from solvent contamination. This approach significantly reduces environmental impact while maintaining the integrity of bioactive compounds in the final product.- Solvent-free extraction methods: Eco-friendly oleoresin processing can be achieved through solvent-free extraction methods that eliminate the use of potentially harmful chemical solvents. These techniques include supercritical fluid extraction using CO2, which operates at lower temperatures to preserve the bioactive compounds while leaving no toxic residues. This approach reduces environmental impact and produces higher quality oleoresins with better preservation of natural compounds and flavors.

- Water-based extraction technologies: Water-based extraction represents an environmentally friendly alternative to conventional solvent extraction for oleoresin production. These methods utilize water as the primary extraction medium, sometimes enhanced with enzymes or natural surfactants to improve efficiency. The processes operate at moderate temperatures and pressures, reducing energy consumption while eliminating toxic solvent waste. Water-based technologies produce clean oleoresins suitable for food, pharmaceutical, and cosmetic applications.

- Renewable energy integration in processing: Integration of renewable energy sources in oleoresin processing significantly reduces the carbon footprint of production operations. Solar thermal systems can provide heat for extraction and distillation processes, while biomass-derived energy can power mechanical operations. These systems often incorporate energy recovery mechanisms to improve overall efficiency. The implementation of renewable energy in oleoresin production creates more sustainable supply chains while potentially reducing operational costs.

- Waste valorization and circular processing: Eco-friendly oleoresin production incorporates waste valorization principles by utilizing by-products and residues from the extraction process. Spent biomass can be converted into biofuels, organic fertilizers, or animal feed supplements. The process water is treated and recycled within the system, reducing freshwater consumption. This circular approach minimizes waste generation while creating additional value streams from what would otherwise be considered production waste.

- Green chemistry principles in oleoresin purification: Advanced purification techniques based on green chemistry principles enable the production of high-quality oleoresins without environmentally harmful processes. These methods include membrane filtration, adsorption with bio-based materials, and chromatographic techniques using environmentally benign mobile phases. The purification processes operate under mild conditions to preserve heat-sensitive compounds while reducing energy consumption and eliminating the need for harsh chemicals typically used in conventional purification methods.

02 Water-based extraction technologies

Environmentally friendly extraction methods using water as the primary medium for oleoresin production. These technologies include hydrodistillation, steam distillation, and aqueous enzymatic processes that break down plant cell walls to release oleoresins. The methods reduce or eliminate organic solvent usage, decrease energy consumption, and minimize waste generation. Water-based extraction is particularly suitable for heat-sensitive compounds and results in cleaner production processes with reduced environmental footprint.Expand Specific Solutions03 Renewable energy integration in oleoresin processing

Implementation of renewable energy sources in oleoresin extraction and processing to reduce carbon footprint. These methods incorporate solar, biomass, or geothermal energy to power extraction equipment and heating processes. Some systems utilize waste biomass from the extraction process itself as fuel, creating a circular energy model. The integration of renewable energy significantly reduces greenhouse gas emissions associated with traditional processing methods while maintaining product quality and production efficiency.Expand Specific Solutions04 Waste valorization and circular processing

Innovative approaches to utilize by-products and waste materials from oleoresin processing. These methods transform extraction residues into valuable products such as biofuels, organic fertilizers, or animal feed. The techniques include bioconversion processes, composting systems, and integrated biorefinery concepts that maximize resource utilization. This circular approach minimizes waste generation, reduces environmental pollution, and improves the overall sustainability and economic viability of oleoresin production.Expand Specific Solutions05 Enzymatic and microbial extraction methods

Biological processing techniques using enzymes or beneficial microorganisms to facilitate oleoresin extraction. These methods employ specific enzymes or microbial cultures to break down plant cell walls, enabling more efficient release of oleoresins under mild conditions. The biological approach reduces energy requirements, eliminates harsh chemicals, and operates at ambient temperatures and pressures. These processes result in high-quality oleoresins while significantly reducing environmental impact compared to conventional chemical extraction methods.Expand Specific Solutions

Leading Companies in Eco-Friendly Oleoresin Production

The oleoresin processing market is currently in a growth phase, with increasing demand for eco-friendly production methods driven by sustainability concerns. The global market size is estimated to exceed $1.2 billion, expanding at approximately 5-7% CAGR as industries seek greener alternatives. Technologically, the field is moderately mature but evolving rapidly toward sustainable innovations. Key players shaping this landscape include China Petroleum & Chemical Corp. (Sinopec) and Braskem SA, who lead with advanced bio-based processing technologies; KRICT and IFP Energies Nouvelles contributing significant research breakthroughs; and specialized entities like Sinopec Research Institute of Petroleum Processing developing proprietary eco-friendly extraction methods. BASF, Sumitomo Chemical, and Linde GmbH are also advancing catalytic processes that reduce environmental impact while maintaining production efficiency.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a supercritical CO2 extraction technology for oleoresin processing that eliminates the need for traditional chemical solvents. Their system operates at optimized pressure (300-350 bar) and temperature (40-60°C) conditions to efficiently extract oleoresins from plant materials while preserving bioactive compounds. The process incorporates a multi-stage fractionation system that allows for selective separation of different oleoresin components based on their solubility in CO2 under varying conditions. Sinopec has also implemented heat recovery systems that recycle thermal energy from the extraction process, reducing overall energy consumption by approximately 30%. Their closed-loop CO2 recycling system achieves over 99% recovery of the CO2 used in the extraction process, minimizing emissions and operational costs.

Strengths: Eliminates toxic solvent residues in final products, reduces energy consumption through efficient heat recovery, and produces higher quality extracts with better preservation of thermolabile compounds. Weaknesses: Higher initial capital investment compared to conventional methods and requires specialized technical expertise for operation and maintenance.

Sinopec Research Institute of Petroleum Processing

Technical Solution: Sinopec Research Institute of Petroleum Processing has developed an integrated microwave-assisted extraction (MAE) technology for oleoresin processing that significantly reduces processing time and energy consumption. Their system combines controlled microwave energy with green solvents (primarily water and bio-derived alcohols) to achieve rapid and efficient extraction. The technology features precision temperature control systems that prevent degradation of heat-sensitive compounds while accelerating extraction kinetics. Their process reduces extraction time by 70-80% compared to conventional methods while maintaining extract quality. The institute has also developed a complementary membrane filtration system that enables solvent recovery rates exceeding 95%, further enhancing the eco-friendly profile of the process. The technology includes a modular design that can be scaled from laboratory to industrial production levels with minimal modifications.

Strengths: Dramatically reduced processing time, lower energy consumption (approximately 40-50% less than conventional methods), and improved extraction efficiency for certain compounds. Weaknesses: Potential for uneven heating in large-scale operations and higher initial equipment costs compared to traditional extraction methods.

Key Patents in Sustainable Oleoresin Extraction

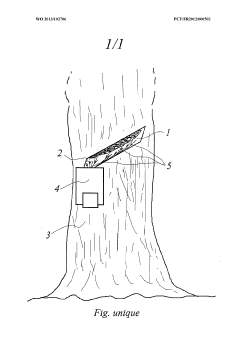

Method for promoting the exudation of oleoresin and composition for implementing said method

PatentWO2013102706A1

Innovation

- A process involving the application of a water-soluble organic acid, preferably citric acid, on a superficial wound of the tree, combined with an adsorber support like clay, to enhance oleoresin exudation, which includes additives for smooth application and retention, preventing flow and promoting healing.

Method for promoting the exudation of oleoresin and composition for implementing said method

PatentPendingEP2800465A1

Innovation

- A process involving the application of a water-soluble organic acid, preferably citric acid, adsorbed onto an adsorber support like clay, to a superficial wound on the tree to enhance oleoresin exudation, with additives like plasticizers and surfactants to improve application and retention.

Environmental Impact Assessment of Processing Technologies

The environmental impact of oleoresin processing technologies represents a critical dimension in the sustainable development of this industry. Traditional extraction methods, particularly those utilizing organic solvents like hexane and acetone, have been associated with significant environmental concerns including air pollution, greenhouse gas emissions, and potential soil contamination. These conventional approaches typically consume substantial energy resources, with estimates suggesting that solvent-based extraction can require up to 3-5 times more energy than newer, alternative methods.

Water usage presents another environmental challenge, as conventional processing can consume between 10-15 liters of water per kilogram of oleoresin produced. This water often becomes contaminated with processing chemicals and organic residues, requiring extensive treatment before discharge. Studies indicate that approximately 70% of processing facilities in developing regions lack adequate wastewater treatment systems, leading to potential ecosystem damage in surrounding water bodies.

Recent technological innovations have demonstrated promising environmental improvements. Supercritical CO2 extraction, for instance, reduces solvent waste by nearly 95% compared to conventional methods while decreasing energy consumption by approximately 30%. The closed-loop nature of this system minimizes emissions and eliminates wastewater generation. Similarly, enzyme-assisted extraction technologies have shown a 40-60% reduction in water requirements and significantly lower chemical inputs.

Life cycle assessments comparing traditional and emerging technologies reveal substantial differences in carbon footprint. Conventional solvent extraction methods generate approximately 2.3-3.1 kg CO2 equivalent per kilogram of oleoresin, while supercritical fluid extraction reduces this to 1.2-1.8 kg CO2 equivalent. Microwave-assisted extraction demonstrates even greater efficiency, with emissions as low as 0.8-1.3 kg CO2 equivalent per kilogram of product.

Waste management represents another critical environmental consideration. Traditional processing generates substantial solid waste, with biomass residues accounting for 40-60% of the initial raw material weight. Advanced technologies have implemented integrated approaches that repurpose these residues for bioenergy production or as agricultural amendments, achieving waste reduction rates of 50-75% in optimized systems.

Biodiversity impacts must also be considered, particularly when processing involves wild-harvested oleoresins. Sustainable harvesting protocols integrated with eco-friendly processing can reduce pressure on natural ecosystems. Certification systems that verify environmentally responsible production have shown 30-45% lower ecological footprints compared to non-certified operations, highlighting the importance of holistic environmental management approaches throughout the oleoresin value chain.

Water usage presents another environmental challenge, as conventional processing can consume between 10-15 liters of water per kilogram of oleoresin produced. This water often becomes contaminated with processing chemicals and organic residues, requiring extensive treatment before discharge. Studies indicate that approximately 70% of processing facilities in developing regions lack adequate wastewater treatment systems, leading to potential ecosystem damage in surrounding water bodies.

Recent technological innovations have demonstrated promising environmental improvements. Supercritical CO2 extraction, for instance, reduces solvent waste by nearly 95% compared to conventional methods while decreasing energy consumption by approximately 30%. The closed-loop nature of this system minimizes emissions and eliminates wastewater generation. Similarly, enzyme-assisted extraction technologies have shown a 40-60% reduction in water requirements and significantly lower chemical inputs.

Life cycle assessments comparing traditional and emerging technologies reveal substantial differences in carbon footprint. Conventional solvent extraction methods generate approximately 2.3-3.1 kg CO2 equivalent per kilogram of oleoresin, while supercritical fluid extraction reduces this to 1.2-1.8 kg CO2 equivalent. Microwave-assisted extraction demonstrates even greater efficiency, with emissions as low as 0.8-1.3 kg CO2 equivalent per kilogram of product.

Waste management represents another critical environmental consideration. Traditional processing generates substantial solid waste, with biomass residues accounting for 40-60% of the initial raw material weight. Advanced technologies have implemented integrated approaches that repurpose these residues for bioenergy production or as agricultural amendments, achieving waste reduction rates of 50-75% in optimized systems.

Biodiversity impacts must also be considered, particularly when processing involves wild-harvested oleoresins. Sustainable harvesting protocols integrated with eco-friendly processing can reduce pressure on natural ecosystems. Certification systems that verify environmentally responsible production have shown 30-45% lower ecological footprints compared to non-certified operations, highlighting the importance of holistic environmental management approaches throughout the oleoresin value chain.

Regulatory Framework for Natural Product Processing

The regulatory landscape governing oleoresin processing has become increasingly complex as environmental concerns gain prominence globally. Processors must navigate a multi-layered framework of international conventions, regional directives, and national legislation that collectively shape the compliance requirements for eco-friendly production methods. The United Nations Environment Programme (UNEP) and the Food and Agriculture Organization (FAO) have established baseline standards for sustainable extraction of plant-based materials, which serve as reference points for national regulatory bodies.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation imposes strict documentation requirements for oleoresin processors, mandating comprehensive safety assessments and environmental impact studies. Similarly, the EU Organic Regulation (2018/848) sets specific parameters for organic certification of plant extracts, including oleoresins, with particular emphasis on solvent selection and waste management protocols.

The United States regulatory framework centers around the FDA's Generally Recognized as Safe (GRAS) status for processing methods, while the Environmental Protection Agency (EPA) enforces the Clean Air Act and Clean Water Act provisions that directly impact oleoresin production facilities. The FDA's Good Manufacturing Practices (GMPs) further stipulate quality control measures that influence processing method selection, particularly regarding solvent residues in final products.

Emerging economies with significant oleoresin production, such as India, Brazil, and Indonesia, have developed specialized regulatory frameworks that balance economic development with environmental protection. India's Biodiversity Act and the subsequent Biological Diversity Rules govern access to biological resources used in oleoresin production, while Brazil's environmental licensing system requires impact assessments for extraction operations exceeding certain production thresholds.

International certification standards play a crucial role in market access for eco-friendly oleoresin products. The Forest Stewardship Council (FSC) certification ensures sustainable sourcing of plant materials, while ISO 14001 certification validates environmentally responsible processing methods. The Rainforest Alliance and similar organizations offer specialized certifications that are increasingly demanded by environmentally conscious markets.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches, where processors must demonstrate environmental responsibility across the entire production chain. This includes solvent recovery rates, energy efficiency metrics, waste valorization strategies, and carbon footprint calculations. Several jurisdictions have introduced extended producer responsibility provisions that hold oleoresin manufacturers accountable for environmental impacts throughout the product lifecycle.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation imposes strict documentation requirements for oleoresin processors, mandating comprehensive safety assessments and environmental impact studies. Similarly, the EU Organic Regulation (2018/848) sets specific parameters for organic certification of plant extracts, including oleoresins, with particular emphasis on solvent selection and waste management protocols.

The United States regulatory framework centers around the FDA's Generally Recognized as Safe (GRAS) status for processing methods, while the Environmental Protection Agency (EPA) enforces the Clean Air Act and Clean Water Act provisions that directly impact oleoresin production facilities. The FDA's Good Manufacturing Practices (GMPs) further stipulate quality control measures that influence processing method selection, particularly regarding solvent residues in final products.

Emerging economies with significant oleoresin production, such as India, Brazil, and Indonesia, have developed specialized regulatory frameworks that balance economic development with environmental protection. India's Biodiversity Act and the subsequent Biological Diversity Rules govern access to biological resources used in oleoresin production, while Brazil's environmental licensing system requires impact assessments for extraction operations exceeding certain production thresholds.

International certification standards play a crucial role in market access for eco-friendly oleoresin products. The Forest Stewardship Council (FSC) certification ensures sustainable sourcing of plant materials, while ISO 14001 certification validates environmentally responsible processing methods. The Rainforest Alliance and similar organizations offer specialized certifications that are increasingly demanded by environmentally conscious markets.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches, where processors must demonstrate environmental responsibility across the entire production chain. This includes solvent recovery rates, energy efficiency metrics, waste valorization strategies, and carbon footprint calculations. Several jurisdictions have introduced extended producer responsibility provisions that hold oleoresin manufacturers accountable for environmental impacts throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!