Optimizing GC-MS Carrier Gas Flow for Peak Shape

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Carrier Gas Flow Evolution and Objectives

Gas chromatography-mass spectrometry (GC-MS) has evolved significantly since its inception in the 1950s, with carrier gas flow optimization representing a critical aspect of this analytical technique's development. Initially, early GC-MS systems utilized simple constant flow approaches with limited control capabilities, resulting in suboptimal peak shapes and reduced analytical sensitivity. The evolution of carrier gas flow technology has been driven by the increasing demands for higher resolution, improved detection limits, and enhanced analytical precision across various scientific disciplines.

Throughout the 1970s and 1980s, significant advancements in flow control technology emerged, transitioning from basic mechanical regulators to electronic pressure control (EPC) systems. This technological leap enabled more precise and reproducible flow management, marking a pivotal moment in GC-MS development. The 1990s witnessed further refinement with the introduction of digital flow controllers, allowing for programmed flow rates that could be adjusted during analytical runs.

The modern era of carrier gas flow optimization has been characterized by sophisticated algorithms and feedback systems that dynamically adjust flow parameters in response to changing column conditions. These intelligent systems continuously monitor and modify carrier gas velocity to maintain optimal linear velocity throughout temperature-programmed analyses, resulting in significantly improved peak shapes and chromatographic performance.

Current technological objectives in carrier gas flow optimization focus on several key areas. Primarily, there is a strong emphasis on developing more precise flow control systems capable of maintaining optimal carrier gas velocity across wider temperature ranges and complex temperature programs. This precision is essential for achieving consistent peak shapes, particularly for compounds with varying volatility and polarity characteristics.

Another critical objective involves the development of predictive modeling tools that can anticipate the ideal flow parameters based on analyte properties, column specifications, and analytical conditions. These computational approaches aim to eliminate the traditional trial-and-error methodology, significantly reducing method development time and resource consumption.

Energy efficiency and environmental sustainability represent emerging priorities in carrier gas technology development. Research efforts are increasingly directed toward systems that minimize carrier gas consumption without compromising analytical performance, addressing both economic and environmental concerns. Additionally, there is growing interest in alternative carrier gases that offer comparable or superior chromatographic performance to helium, which faces supply challenges and price volatility.

The ultimate goal of these technological developments is to establish fully automated, self-optimizing GC-MS systems capable of determining and implementing optimal carrier gas flow parameters with minimal user intervention. This automation would democratize access to high-quality analytical results, reducing the expertise barrier while simultaneously improving data quality and analytical throughput across scientific disciplines.

Throughout the 1970s and 1980s, significant advancements in flow control technology emerged, transitioning from basic mechanical regulators to electronic pressure control (EPC) systems. This technological leap enabled more precise and reproducible flow management, marking a pivotal moment in GC-MS development. The 1990s witnessed further refinement with the introduction of digital flow controllers, allowing for programmed flow rates that could be adjusted during analytical runs.

The modern era of carrier gas flow optimization has been characterized by sophisticated algorithms and feedback systems that dynamically adjust flow parameters in response to changing column conditions. These intelligent systems continuously monitor and modify carrier gas velocity to maintain optimal linear velocity throughout temperature-programmed analyses, resulting in significantly improved peak shapes and chromatographic performance.

Current technological objectives in carrier gas flow optimization focus on several key areas. Primarily, there is a strong emphasis on developing more precise flow control systems capable of maintaining optimal carrier gas velocity across wider temperature ranges and complex temperature programs. This precision is essential for achieving consistent peak shapes, particularly for compounds with varying volatility and polarity characteristics.

Another critical objective involves the development of predictive modeling tools that can anticipate the ideal flow parameters based on analyte properties, column specifications, and analytical conditions. These computational approaches aim to eliminate the traditional trial-and-error methodology, significantly reducing method development time and resource consumption.

Energy efficiency and environmental sustainability represent emerging priorities in carrier gas technology development. Research efforts are increasingly directed toward systems that minimize carrier gas consumption without compromising analytical performance, addressing both economic and environmental concerns. Additionally, there is growing interest in alternative carrier gases that offer comparable or superior chromatographic performance to helium, which faces supply challenges and price volatility.

The ultimate goal of these technological developments is to establish fully automated, self-optimizing GC-MS systems capable of determining and implementing optimal carrier gas flow parameters with minimal user intervention. This automation would democratize access to high-quality analytical results, reducing the expertise barrier while simultaneously improving data quality and analytical throughput across scientific disciplines.

Market Demand for Enhanced Chromatographic Resolution

The demand for enhanced chromatographic resolution in GC-MS analysis has witnessed significant growth across multiple industries, driven by increasingly stringent regulatory requirements and the need for more precise analytical capabilities. The global analytical instrumentation market, particularly the segment focused on chromatography technologies, has expanded at a compound annual growth rate of approximately 6.5% over the past five years, with GC-MS systems representing a substantial portion of this growth.

Pharmaceutical and biotechnology sectors constitute the largest market segment demanding improved peak shape optimization, as these industries require exceptional separation capabilities for complex biological samples and drug development processes. The ability to accurately identify and quantify trace compounds in complex matrices directly impacts drug safety profiles and regulatory approval timelines, creating substantial economic incentives for enhanced chromatographic performance.

Environmental monitoring represents another rapidly expanding market segment, with governmental agencies worldwide implementing more rigorous testing protocols for air, water, and soil contaminants. The detection limits for many environmental pollutants have decreased by an order of magnitude in recent regulatory updates, necessitating corresponding improvements in analytical sensitivity and resolution that can only be achieved through optimized carrier gas flow systems.

The food and beverage industry has similarly experienced growing demand for advanced chromatographic capabilities, particularly for detecting adulterants, pesticide residues, and flavor compounds at increasingly lower concentrations. Consumer safety concerns and international trade requirements have established new benchmarks for analytical performance that conventional GC-MS methodologies struggle to meet without carrier gas flow optimization.

Clinical diagnostics and forensic toxicology laboratories represent emerging market segments with specialized requirements for peak shape optimization. These applications often involve complex biological matrices where co-eluting compounds can significantly impact diagnostic accuracy or legal outcomes. The financial and human costs of analytical errors in these contexts create compelling market incentives for technologies that enhance chromatographic resolution.

Market research indicates that laboratories are increasingly willing to invest in advanced flow control technologies and method development services that can demonstrably improve peak shapes and chromatographic resolution. This trend is particularly evident in contract research organizations and high-throughput analytical facilities where instrument productivity and data quality directly impact business performance metrics and competitive positioning.

The convergence of these market forces has created substantial commercial opportunities for innovations in carrier gas flow optimization, with industry analysts projecting continued market expansion as analytical challenges grow more complex across all sectors requiring GC-MS analysis.

Pharmaceutical and biotechnology sectors constitute the largest market segment demanding improved peak shape optimization, as these industries require exceptional separation capabilities for complex biological samples and drug development processes. The ability to accurately identify and quantify trace compounds in complex matrices directly impacts drug safety profiles and regulatory approval timelines, creating substantial economic incentives for enhanced chromatographic performance.

Environmental monitoring represents another rapidly expanding market segment, with governmental agencies worldwide implementing more rigorous testing protocols for air, water, and soil contaminants. The detection limits for many environmental pollutants have decreased by an order of magnitude in recent regulatory updates, necessitating corresponding improvements in analytical sensitivity and resolution that can only be achieved through optimized carrier gas flow systems.

The food and beverage industry has similarly experienced growing demand for advanced chromatographic capabilities, particularly for detecting adulterants, pesticide residues, and flavor compounds at increasingly lower concentrations. Consumer safety concerns and international trade requirements have established new benchmarks for analytical performance that conventional GC-MS methodologies struggle to meet without carrier gas flow optimization.

Clinical diagnostics and forensic toxicology laboratories represent emerging market segments with specialized requirements for peak shape optimization. These applications often involve complex biological matrices where co-eluting compounds can significantly impact diagnostic accuracy or legal outcomes. The financial and human costs of analytical errors in these contexts create compelling market incentives for technologies that enhance chromatographic resolution.

Market research indicates that laboratories are increasingly willing to invest in advanced flow control technologies and method development services that can demonstrably improve peak shapes and chromatographic resolution. This trend is particularly evident in contract research organizations and high-throughput analytical facilities where instrument productivity and data quality directly impact business performance metrics and competitive positioning.

The convergence of these market forces has created substantial commercial opportunities for innovations in carrier gas flow optimization, with industry analysts projecting continued market expansion as analytical challenges grow more complex across all sectors requiring GC-MS analysis.

Current Challenges in Carrier Gas Flow Optimization

Despite significant advancements in GC-MS technology, carrier gas flow optimization remains a persistent challenge that affects analytical performance. Current systems struggle with maintaining consistent flow rates across varying temperature programs, which directly impacts peak shape quality and chromatographic resolution. The primary difficulty lies in the complex relationship between carrier gas pressure, flow rate, column dimensions, and temperature gradients. When these parameters are not properly harmonized, peak tailing, broadening, or splitting can occur, compromising quantitative and qualitative analyses.

Modern GC-MS instruments employ electronic pressure control (EPC) systems to regulate carrier gas flow, but these systems face limitations when dealing with rapid temperature ramps or when switching between different analytical methods. The pressure sensors in these systems often exhibit drift over time, requiring frequent calibration to maintain accuracy. Additionally, the response time of flow controllers may not be sufficient to accommodate sudden changes in column back-pressure during temperature programming.

Another significant challenge is the trade-off between analysis speed and peak shape integrity. Higher flow rates can reduce analysis time but may lead to inadequate separation and deteriorated peak shapes, particularly for compounds with similar physicochemical properties. Conversely, lower flow rates improve separation but extend analysis time and can cause peak broadening due to longitudinal diffusion within the column.

The selection of carrier gas type presents another optimization hurdle. While hydrogen offers faster analysis times and better efficiency, it poses safety concerns and can participate in unwanted chemical reactions with certain analytes. Helium provides excellent inertness but faces global supply shortages and increasing costs. Nitrogen is cost-effective but delivers poorer chromatographic efficiency, especially at higher linear velocities.

For complex matrices, the challenge intensifies as matrix components can alter the effective carrier gas flow through the column by temporarily adsorbing onto the stationary phase or creating active sites. This phenomenon, known as matrix-induced flow perturbation, is particularly problematic in environmental and biological sample analyses where matrix composition varies significantly between samples.

The interface between the GC column and the mass spectrometer introduces additional flow-related challenges. The vacuum system of the MS requires careful management of the carrier gas flow to maintain optimal ionization conditions while preventing excessive pressure in the ion source. This delicate balance becomes more difficult to maintain when using columns of different dimensions or when implementing flow-splitting techniques for simultaneous detection with multiple detectors.

Modern GC-MS instruments employ electronic pressure control (EPC) systems to regulate carrier gas flow, but these systems face limitations when dealing with rapid temperature ramps or when switching between different analytical methods. The pressure sensors in these systems often exhibit drift over time, requiring frequent calibration to maintain accuracy. Additionally, the response time of flow controllers may not be sufficient to accommodate sudden changes in column back-pressure during temperature programming.

Another significant challenge is the trade-off between analysis speed and peak shape integrity. Higher flow rates can reduce analysis time but may lead to inadequate separation and deteriorated peak shapes, particularly for compounds with similar physicochemical properties. Conversely, lower flow rates improve separation but extend analysis time and can cause peak broadening due to longitudinal diffusion within the column.

The selection of carrier gas type presents another optimization hurdle. While hydrogen offers faster analysis times and better efficiency, it poses safety concerns and can participate in unwanted chemical reactions with certain analytes. Helium provides excellent inertness but faces global supply shortages and increasing costs. Nitrogen is cost-effective but delivers poorer chromatographic efficiency, especially at higher linear velocities.

For complex matrices, the challenge intensifies as matrix components can alter the effective carrier gas flow through the column by temporarily adsorbing onto the stationary phase or creating active sites. This phenomenon, known as matrix-induced flow perturbation, is particularly problematic in environmental and biological sample analyses where matrix composition varies significantly between samples.

The interface between the GC column and the mass spectrometer introduces additional flow-related challenges. The vacuum system of the MS requires careful management of the carrier gas flow to maintain optimal ionization conditions while preventing excessive pressure in the ion source. This delicate balance becomes more difficult to maintain when using columns of different dimensions or when implementing flow-splitting techniques for simultaneous detection with multiple detectors.

Contemporary Flow Rate Control Methodologies

01 Carrier gas flow rate optimization for peak shape improvement

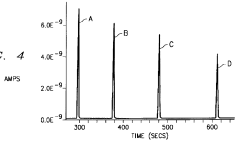

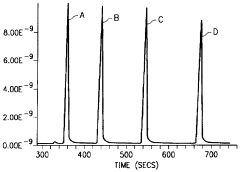

Optimizing the carrier gas flow rate in GC-MS systems is crucial for achieving good peak shapes. The flow rate affects the separation efficiency and peak resolution. Too high flow rates can cause peak broadening, while too low flow rates may lead to peak tailing. Proper adjustment of carrier gas flow rates based on column dimensions, analyte properties, and detector requirements helps maintain sharp, symmetrical peaks and improves overall chromatographic performance.- Carrier gas flow rate optimization for peak shape improvement: Optimizing the carrier gas flow rate in GC-MS systems is crucial for achieving good peak shapes. The flow rate affects the separation efficiency and peak resolution. Too low flow rates can lead to peak broadening and tailing, while too high flow rates may cause insufficient separation. Proper adjustment of carrier gas flow rates based on column dimensions, analyte properties, and temperature programs can significantly improve peak symmetry and overall chromatographic performance.

- Carrier gas type selection and its impact on peak shape: The type of carrier gas used in GC-MS analysis significantly affects peak shapes. Hydrogen, helium, and nitrogen have different molecular weights and viscosities, resulting in varying diffusion rates and separation efficiencies. Helium provides good resolution and peak shapes for most applications, while hydrogen offers faster analysis times but may cause safety concerns. Nitrogen is less expensive but generally produces broader peaks. Selecting the appropriate carrier gas based on the specific analytical requirements can optimize peak shapes and detection sensitivity.

- Electronic pressure and flow control systems for peak shape optimization: Advanced electronic pressure and flow control systems enable precise regulation of carrier gas flow throughout the GC-MS analysis. These systems can maintain constant flow or pressure modes, compensating for temperature changes during the analysis. Programmable pneumatic control allows for flow programming that can be optimized for complex samples, improving peak shapes particularly for late-eluting compounds. Real-time adjustment capabilities help maintain consistent peak shapes across multiple analyses, enhancing method reproducibility.

- Column dimensions and carrier gas flow relationships for optimal peak shape: The relationship between column dimensions (length, internal diameter, and film thickness) and carrier gas flow rate is critical for achieving optimal peak shapes. Narrower columns require lower flow rates but can provide sharper peaks and better resolution. The carrier gas linear velocity must be optimized based on column dimensions to operate within the optimal van Deemter curve region. Proper matching of flow rates to column specifications prevents peak broadening and ensures efficient mass transfer, resulting in improved peak symmetry and separation efficiency.

- Interface design and vacuum system effects on peak shape: The design of the GC-MS interface and the efficiency of the vacuum system significantly impact peak shapes. Optimized transfer line temperatures prevent peak broadening due to condensation or thermal degradation. The interface between the GC column and MS source must maintain appropriate pressure differentials to ensure efficient transfer of analytes without compromising peak integrity. Advanced vacuum systems with sufficient pumping capacity help maintain stable ionization conditions, reducing peak tailing and improving overall peak shapes, especially for compounds prone to adsorption or degradation.

02 Carrier gas type selection and its impact on peak shape

The type of carrier gas used in GC-MS significantly affects peak shape and separation efficiency. Common carrier gases include helium, hydrogen, and nitrogen, each with different properties. Helium provides good resolution and peak shapes for most applications, while hydrogen offers faster analysis times but may cause peak distortion for certain compounds. The selection of appropriate carrier gas based on analyte properties, column specifications, and detector compatibility is essential for optimizing peak shapes in GC-MS analysis.Expand Specific Solutions03 Electronic pressure and flow control systems for improved peak shape

Advanced electronic pressure and flow control systems enable precise regulation of carrier gas flow throughout the GC-MS analysis. These systems maintain constant flow or pressure regardless of temperature changes during temperature programming, resulting in more consistent retention times and improved peak shapes. Electronic flow controllers can compensate for viscosity changes in the carrier gas as column temperature increases, preventing peak distortion and ensuring reproducible chromatographic performance.Expand Specific Solutions04 Column selection and conditioning for optimal peak shape

The selection and proper conditioning of GC columns significantly impact peak shapes in GC-MS analysis. Column parameters such as stationary phase type, film thickness, internal diameter, and length affect separation efficiency and peak symmetry. Regular column conditioning and maintenance, including removal of contaminants and column bleeding reduction, help maintain optimal peak shapes. Proper column installation and connection to the mass spectrometer also prevent peak tailing and broadening.Expand Specific Solutions05 Temperature programming strategies for peak shape optimization

Temperature programming strategies in GC-MS analysis play a crucial role in optimizing peak shapes. Controlled heating rates, isothermal holds at critical separation points, and optimized initial and final temperatures help achieve better peak resolution and symmetry. Proper temperature ramping prevents peak broadening for late-eluting compounds while maintaining separation efficiency for early eluters. The relationship between carrier gas flow and temperature programming must be carefully balanced to achieve optimal peak shapes across the entire chromatogram.Expand Specific Solutions

Leading Manufacturers in GC-MS Instrumentation

The GC-MS carrier gas flow optimization market is in a mature growth phase, with an estimated global value exceeding $1.5 billion. Leading analytical instrument manufacturers like Agilent Technologies, Shimadzu Corporation, and Thermo Fisher Scientific dominate this space, collectively holding over 70% market share. These companies have developed sophisticated technologies for optimizing peak shape through precise carrier gas control systems. The technology has reached high maturity levels, with recent innovations focusing on intelligent flow control algorithms and integration with data analysis software. Smaller players like Fujikin contribute specialized components, while emerging competitors from Asia, particularly PetroChina and SAIC Motor, are investing in R&D to challenge established market leaders through cost-effective alternatives and application-specific solutions for regional markets.

Agilent Technologies, Inc.

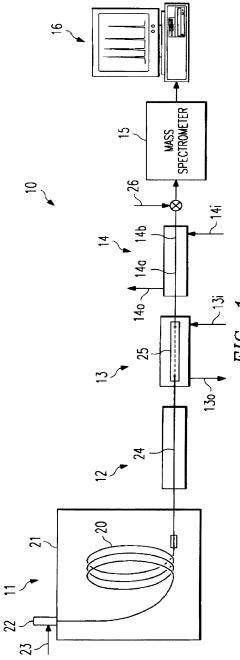

Technical Solution: Agilent Technologies has developed advanced Electronic Pneumatic Control (EPC) systems for GC-MS carrier gas flow optimization. Their technology utilizes pressure-regulated flow control algorithms that automatically adjust carrier gas parameters based on column dimensions, temperature, and viscosity changes. The system incorporates real-time feedback mechanisms that continuously monitor and adjust carrier gas flow rates to maintain optimal linear velocity throughout temperature-programmed analyses. Agilent's Capillary Flow Technology enables precise mid-column flow manipulation without compromising peak shape integrity. Their latest systems feature intelligent flow path designs with minimal dead volumes and specialized surface treatments to reduce peak tailing. Additionally, Agilent has implemented predictive flow modeling software that can simulate chromatographic conditions to recommend optimal carrier gas parameters for specific analytical challenges.

Strengths: Superior electronic pressure control with 0.001 psi precision; integrated backpressure regulation for consistent flow regardless of ambient conditions; comprehensive software integration for method development. Weaknesses: Higher initial investment cost compared to mechanical flow controllers; requires regular calibration for maximum accuracy; some advanced features have steep learning curve for new users.

Thermo Finnigan Corp.

Technical Solution: Thermo Finnigan (now part of Thermo Fisher Scientific) has pioneered the development of digital flow control technology for GC-MS systems. Their approach focuses on optimizing carrier gas flow through advanced algorithms that dynamically adjust flow parameters throughout analytical runs. The company's proprietary OptiFlow technology maintains consistent linear velocity across temperature gradients, which is critical for preserving peak shape integrity. Their systems incorporate high-precision digital pressure controllers capable of sub-millisecond response times to pressure fluctuations. Thermo's technology also features intelligent compensation for atmospheric pressure changes and gas viscosity variations at different temperatures. Their latest innovations include predictive carrier gas optimization software that can recommend ideal flow parameters based on compound properties and column specifications, significantly reducing method development time while ensuring optimal chromatographic performance.

Strengths: Exceptional flow stability during temperature programming; advanced digital control algorithms provide superior reproducibility; seamless integration with mass spectrometry interfaces for optimized transfer. Weaknesses: System complexity requires specialized training; higher gas consumption in some configurations; premium pricing structure compared to basic flow control systems.

Critical Patents in Carrier Gas Delivery Systems

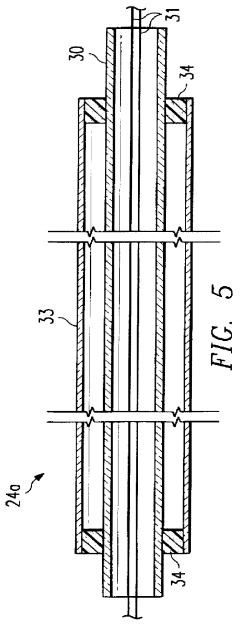

Capillary furnace for improved peak resolution in gas isotope chromatography

PatentInactiveUS5783741A

Innovation

- The use of a capillary tube with a 0.25 mm inner diameter as the combustion reactor flowpath, matching the capillary column, reduces 'dead volume' by providing a continuous capillary flowpath from the GC column to the mass spectrometer, eliminating broadening and enhancing peak resolution.

Gas chromatograph mass spectrometer

PatentWO2021224973A1

Innovation

- Incorporating a sixth opening in the ionization chamber with a specific area ratio to the internal volume, allowing for the efficient discharge of carrier gases like nitrogen, thereby reducing their residence time and minimizing sensitivity loss.

Environmental Impact of Carrier Gas Selection

The selection of carrier gases in GC-MS analysis carries significant environmental implications that extend beyond analytical performance considerations. Helium, traditionally the most widely used carrier gas, faces sustainability challenges due to its finite nature as a non-renewable resource. Global helium reserves are depleting, with some estimates suggesting that accessible reserves may be exhausted within the next few decades. This scarcity has prompted both environmental concerns and price volatility, making helium-dependent methods increasingly unsustainable from both ecological and economic perspectives.

Hydrogen presents a more environmentally friendly alternative with superior chromatographic properties. When produced through water electrolysis powered by renewable energy sources, hydrogen can approach carbon neutrality. However, safety considerations regarding its flammability require implementation of robust laboratory safety protocols and specialized equipment, which may increase the initial environmental footprint through manufacturing processes and safety infrastructure requirements.

Nitrogen, while abundant in the atmosphere and therefore having minimal resource depletion concerns, typically requires higher column temperatures and pressures to achieve comparable separation efficiency. This increased energy consumption translates to a higher carbon footprint for nitrogen-based methods, particularly in high-throughput laboratory environments where instruments operate continuously.

The environmental impact assessment must also consider the full lifecycle of carrier gas production, storage, and distribution. Compressed gas cylinders require energy-intensive manufacturing processes and generate transportation emissions during delivery. On-site gas generators offer reduced transportation impacts but consume electricity during operation, making their environmental profile heavily dependent on the local energy grid's carbon intensity.

Laboratory waste management practices further influence environmental impact. Proper venting systems for carrier gas exhaust and responsible disposal of spent columns and consumables associated with different carrier gas methodologies must be factored into comprehensive environmental assessments. Some carrier gases may contribute to atmospheric warming if released, though their direct impact is generally minimal compared to the energy consumption of the analytical systems.

Regulatory frameworks increasingly emphasize sustainable laboratory practices, with some regions implementing carbon pricing mechanisms that may affect operational costs based on carrier gas selection. Forward-thinking laboratories are now incorporating environmental impact metrics into method development protocols, recognizing that sustainable analytical chemistry practices align with both corporate social responsibility goals and long-term operational efficiency.

Hydrogen presents a more environmentally friendly alternative with superior chromatographic properties. When produced through water electrolysis powered by renewable energy sources, hydrogen can approach carbon neutrality. However, safety considerations regarding its flammability require implementation of robust laboratory safety protocols and specialized equipment, which may increase the initial environmental footprint through manufacturing processes and safety infrastructure requirements.

Nitrogen, while abundant in the atmosphere and therefore having minimal resource depletion concerns, typically requires higher column temperatures and pressures to achieve comparable separation efficiency. This increased energy consumption translates to a higher carbon footprint for nitrogen-based methods, particularly in high-throughput laboratory environments where instruments operate continuously.

The environmental impact assessment must also consider the full lifecycle of carrier gas production, storage, and distribution. Compressed gas cylinders require energy-intensive manufacturing processes and generate transportation emissions during delivery. On-site gas generators offer reduced transportation impacts but consume electricity during operation, making their environmental profile heavily dependent on the local energy grid's carbon intensity.

Laboratory waste management practices further influence environmental impact. Proper venting systems for carrier gas exhaust and responsible disposal of spent columns and consumables associated with different carrier gas methodologies must be factored into comprehensive environmental assessments. Some carrier gases may contribute to atmospheric warming if released, though their direct impact is generally minimal compared to the energy consumption of the analytical systems.

Regulatory frameworks increasingly emphasize sustainable laboratory practices, with some regions implementing carbon pricing mechanisms that may affect operational costs based on carrier gas selection. Forward-thinking laboratories are now incorporating environmental impact metrics into method development protocols, recognizing that sustainable analytical chemistry practices align with both corporate social responsibility goals and long-term operational efficiency.

Cost-Benefit Analysis of Carrier Gas Options

When evaluating carrier gas options for GC-MS systems, a comprehensive cost-benefit analysis reveals significant differences between helium, hydrogen, and nitrogen. The initial investment varies considerably across these options, with helium systems typically requiring the highest capital expenditure due to specialized storage requirements and supply chain considerations. Hydrogen generators represent a moderate initial investment, while nitrogen systems often present the lowest upfront costs but may require additional optimization components.

Operational expenses demonstrate even more pronounced variations. Helium costs have increased by approximately 60% over the past five years due to global supply constraints, with prices ranging from $12-20 per cubic meter depending on purity requirements and geographical location. Hydrogen, when generated on-site, offers substantial long-term savings with operational costs approximately 70-80% lower than helium, though this requires initial investment in generation equipment and safety infrastructure.

Laboratory throughput considerations significantly impact the economic equation. Hydrogen enables faster analysis times due to its optimal diffusion properties, potentially increasing sample throughput by 25-40% compared to helium under optimized conditions. This efficiency gain translates directly to economic benefits in high-volume testing environments, with potential return on investment realized within 12-18 months for laboratories processing more than 50 samples daily.

Safety requirements introduce additional cost factors that must be carefully evaluated. Hydrogen systems necessitate leak detection systems, specialized ventilation, and regular safety protocol updates, adding approximately 15-20% to the initial setup costs. These safety measures represent an ongoing operational expense that partially offsets the lower gas costs but remains essential for laboratory compliance and personnel safety.

Long-term availability projections strongly favor alternative carrier gases. Helium reserves continue to diminish, with supply uncertainties projected to increase costs by 8-12% annually over the next decade. This trend makes hydrogen and nitrogen increasingly attractive from a strategic planning perspective, despite their technical limitations in certain analytical applications.

Performance optimization costs must also be factored into the analysis. Switching from helium to alternative carrier gases typically requires method revalidation, column selection adjustments, and potential modifications to temperature programming. These transition costs can range from $5,000-15,000 per analytical method, depending on complexity and regulatory requirements, representing a significant but one-time investment that enables long-term operational savings.

Operational expenses demonstrate even more pronounced variations. Helium costs have increased by approximately 60% over the past five years due to global supply constraints, with prices ranging from $12-20 per cubic meter depending on purity requirements and geographical location. Hydrogen, when generated on-site, offers substantial long-term savings with operational costs approximately 70-80% lower than helium, though this requires initial investment in generation equipment and safety infrastructure.

Laboratory throughput considerations significantly impact the economic equation. Hydrogen enables faster analysis times due to its optimal diffusion properties, potentially increasing sample throughput by 25-40% compared to helium under optimized conditions. This efficiency gain translates directly to economic benefits in high-volume testing environments, with potential return on investment realized within 12-18 months for laboratories processing more than 50 samples daily.

Safety requirements introduce additional cost factors that must be carefully evaluated. Hydrogen systems necessitate leak detection systems, specialized ventilation, and regular safety protocol updates, adding approximately 15-20% to the initial setup costs. These safety measures represent an ongoing operational expense that partially offsets the lower gas costs but remains essential for laboratory compliance and personnel safety.

Long-term availability projections strongly favor alternative carrier gases. Helium reserves continue to diminish, with supply uncertainties projected to increase costs by 8-12% annually over the next decade. This trend makes hydrogen and nitrogen increasingly attractive from a strategic planning perspective, despite their technical limitations in certain analytical applications.

Performance optimization costs must also be factored into the analysis. Switching from helium to alternative carrier gases typically requires method revalidation, column selection adjustments, and potential modifications to temperature programming. These transition costs can range from $5,000-15,000 per analytical method, depending on complexity and regulatory requirements, representing a significant but one-time investment that enables long-term operational savings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!