Optimizing Nylon 66 Spinning Techniques for Fiber Consistency

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 66 Fiber Development History and Objectives

Nylon 66 fiber development traces back to Wallace Carothers' groundbreaking work at DuPont in the 1930s, culminating in the first commercial production in 1939. This revolutionary synthetic polymer, formed through the condensation of hexamethylenediamine and adipic acid, marked a significant milestone in materials science and textile manufacturing. The initial applications focused primarily on women's hosiery, but quickly expanded to industrial uses during World War II when natural fibers became scarce.

The 1950s and 1960s witnessed substantial advancements in spinning technologies, with the introduction of melt spinning processes that allowed for greater control over fiber properties. During this period, manufacturers began optimizing draw ratios and solidification parameters to enhance tensile strength and durability. The 1970s brought increased focus on energy efficiency in production methods, coinciding with the global energy crisis.

By the 1980s and 1990s, computerized process control systems revolutionized nylon 66 manufacturing, enabling more precise monitoring and adjustment of spinning conditions. This technological leap significantly improved consistency in fiber diameter, crystallinity, and mechanical properties. Concurrently, environmental considerations began influencing production methods, with manufacturers seeking to reduce chemical waste and energy consumption.

The early 2000s saw the integration of nanotechnology into nylon 66 production, allowing for novel fiber properties through the incorporation of nanoparticles and precise control of molecular orientation. This period also marked increased attention to sustainability, with research focusing on bio-based precursors and environmentally friendly catalysts.

Current technological objectives in nylon 66 spinning center on achieving unprecedented consistency in fiber properties while maintaining high production rates. Key goals include minimizing variations in diameter, tensile strength, and elongation characteristics across production batches. Manufacturers seek to develop adaptive spinning systems that can automatically adjust parameters in response to subtle changes in polymer properties or environmental conditions.

Advanced objectives include the development of in-line quality monitoring systems capable of detecting inconsistencies in real-time, allowing for immediate corrective actions. There is also significant interest in reducing energy consumption during the spinning process while maintaining or improving fiber quality. The industry is moving toward closed-loop systems that minimize waste and maximize resource efficiency.

Looking forward, the integration of artificial intelligence and machine learning algorithms into spinning process control represents a promising frontier. These technologies could potentially predict optimal spinning parameters based on raw material characteristics and desired fiber properties, further enhancing consistency and reducing the need for post-production quality testing.

The 1950s and 1960s witnessed substantial advancements in spinning technologies, with the introduction of melt spinning processes that allowed for greater control over fiber properties. During this period, manufacturers began optimizing draw ratios and solidification parameters to enhance tensile strength and durability. The 1970s brought increased focus on energy efficiency in production methods, coinciding with the global energy crisis.

By the 1980s and 1990s, computerized process control systems revolutionized nylon 66 manufacturing, enabling more precise monitoring and adjustment of spinning conditions. This technological leap significantly improved consistency in fiber diameter, crystallinity, and mechanical properties. Concurrently, environmental considerations began influencing production methods, with manufacturers seeking to reduce chemical waste and energy consumption.

The early 2000s saw the integration of nanotechnology into nylon 66 production, allowing for novel fiber properties through the incorporation of nanoparticles and precise control of molecular orientation. This period also marked increased attention to sustainability, with research focusing on bio-based precursors and environmentally friendly catalysts.

Current technological objectives in nylon 66 spinning center on achieving unprecedented consistency in fiber properties while maintaining high production rates. Key goals include minimizing variations in diameter, tensile strength, and elongation characteristics across production batches. Manufacturers seek to develop adaptive spinning systems that can automatically adjust parameters in response to subtle changes in polymer properties or environmental conditions.

Advanced objectives include the development of in-line quality monitoring systems capable of detecting inconsistencies in real-time, allowing for immediate corrective actions. There is also significant interest in reducing energy consumption during the spinning process while maintaining or improving fiber quality. The industry is moving toward closed-loop systems that minimize waste and maximize resource efficiency.

Looking forward, the integration of artificial intelligence and machine learning algorithms into spinning process control represents a promising frontier. These technologies could potentially predict optimal spinning parameters based on raw material characteristics and desired fiber properties, further enhancing consistency and reducing the need for post-production quality testing.

Market Analysis for Consistent Nylon 66 Fibers

The global market for nylon 66 fibers has shown consistent growth over the past decade, with a current market valuation exceeding $20 billion. This growth is primarily driven by increasing demand from automotive, textile, and industrial applications where fiber consistency is paramount. The compound annual growth rate (CAGR) for consistent nylon 66 fibers specifically stands at approximately 5.7%, outpacing the broader synthetic fiber market's growth of 4.2%.

Consumer expectations for high-performance textiles have risen dramatically, creating significant market pull for optimized spinning techniques that deliver consistent fiber properties. End-users in technical textiles and automotive sectors are willing to pay premium prices of 15-20% higher for guaranteed consistency in mechanical properties, dimensional stability, and dyeability.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global consumption, with China leading manufacturing capacity. North America and Europe follow with 25% and 20% market share respectively, though these regions focus more on high-value specialized applications where consistency commands higher margins.

The automotive sector represents the largest application segment (32% of market volume), where nylon 66 fibers are critical components in airbags, seat belts, and tire reinforcements. Here, inconsistencies in fiber properties directly impact safety performance, creating a strong market incentive for optimization technologies.

Technical textile applications constitute the fastest-growing segment with 7.8% annual growth, driven by stringent performance requirements in medical textiles, filtration, and protective clothing. In these applications, fiber consistency directly correlates with product reliability and regulatory compliance.

Market research indicates that manufacturing inefficiencies due to inconsistent fiber quality cost producers an estimated $1.2 billion annually through waste, rework, and customer returns. This represents a significant opportunity for optimization technologies that can reduce variability in the spinning process.

Consumer brands are increasingly implementing traceability and quality assurance programs that require consistent fiber properties throughout the supply chain. This trend is expected to accelerate, with 68% of major textile brands having announced commitments to improved consistency metrics by 2025.

The market landscape shows a clear correlation between spinning technique sophistication and market premium, with manufacturers employing advanced process control systems commanding price premiums of up to 25% for guaranteed consistency specifications.

Consumer expectations for high-performance textiles have risen dramatically, creating significant market pull for optimized spinning techniques that deliver consistent fiber properties. End-users in technical textiles and automotive sectors are willing to pay premium prices of 15-20% higher for guaranteed consistency in mechanical properties, dimensional stability, and dyeability.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 45% of global consumption, with China leading manufacturing capacity. North America and Europe follow with 25% and 20% market share respectively, though these regions focus more on high-value specialized applications where consistency commands higher margins.

The automotive sector represents the largest application segment (32% of market volume), where nylon 66 fibers are critical components in airbags, seat belts, and tire reinforcements. Here, inconsistencies in fiber properties directly impact safety performance, creating a strong market incentive for optimization technologies.

Technical textile applications constitute the fastest-growing segment with 7.8% annual growth, driven by stringent performance requirements in medical textiles, filtration, and protective clothing. In these applications, fiber consistency directly correlates with product reliability and regulatory compliance.

Market research indicates that manufacturing inefficiencies due to inconsistent fiber quality cost producers an estimated $1.2 billion annually through waste, rework, and customer returns. This represents a significant opportunity for optimization technologies that can reduce variability in the spinning process.

Consumer brands are increasingly implementing traceability and quality assurance programs that require consistent fiber properties throughout the supply chain. This trend is expected to accelerate, with 68% of major textile brands having announced commitments to improved consistency metrics by 2025.

The market landscape shows a clear correlation between spinning technique sophistication and market premium, with manufacturers employing advanced process control systems commanding price premiums of up to 25% for guaranteed consistency specifications.

Technical Challenges in Nylon 66 Spinning Processes

The current Nylon 66 spinning process faces several significant technical challenges that impact fiber consistency and overall product quality. The primary issue lies in temperature control during the melt spinning phase, where even minor fluctuations of 2-3°C can dramatically alter the polymer's viscosity and flow characteristics. This sensitivity creates inconsistencies in fiber diameter and tensile properties, particularly problematic for high-performance applications requiring precise specifications.

Polymer degradation presents another substantial challenge, as Nylon 66 is susceptible to thermal oxidation during processing. Extended residence times at elevated temperatures (above 280°C) accelerate chain scission reactions, reducing molecular weight and compromising mechanical properties. This degradation manifests as yellowing, brittleness, and diminished fiber strength, significantly impacting product quality and process economics.

Die design and spinneret configuration pose persistent engineering challenges. Current geometries often create uneven polymer distribution and inconsistent shear forces across the melt flow, resulting in variations in fiber cross-sectional uniformity. The industry standard tolerance for diameter variation remains at ±3%, which is insufficient for advanced technical applications demanding tolerances below ±1%.

Quenching dynamics represent a critical process bottleneck. The transition from molten polymer to solid fiber occurs rapidly, and controlling cooling rates determines crystallinity development. Conventional air quenching systems struggle to maintain uniform cooling conditions across all filaments, especially in high-density spinnerets with 500+ holes, creating radial variations in fiber properties within the same production batch.

Draw ratio optimization remains problematic, particularly for high-speed spinning operations exceeding 5000 m/min. The narrow processing window between insufficient molecular orientation and excessive stress-induced crystallization limits production flexibility. Current technologies cannot dynamically adjust draw ratios in response to detected variations in upstream process conditions.

Finish application systems face challenges in achieving uniform coating distribution. Conventional kiss-roll applicators deliver inconsistent finish levels, varying by up to 15% across the fiber bundle. This variation affects downstream processability, especially in texturing and fabric formation stages where consistent fiber-to-fiber friction is essential.

Monitoring and control systems represent a significant technological gap. Real-time measurement of critical fiber parameters remains limited, with most quality assessments occurring offline. The industry lacks integrated sensor technologies capable of detecting subtle variations in fiber properties during high-speed production, preventing immediate process adjustments to maintain consistency.

Polymer degradation presents another substantial challenge, as Nylon 66 is susceptible to thermal oxidation during processing. Extended residence times at elevated temperatures (above 280°C) accelerate chain scission reactions, reducing molecular weight and compromising mechanical properties. This degradation manifests as yellowing, brittleness, and diminished fiber strength, significantly impacting product quality and process economics.

Die design and spinneret configuration pose persistent engineering challenges. Current geometries often create uneven polymer distribution and inconsistent shear forces across the melt flow, resulting in variations in fiber cross-sectional uniformity. The industry standard tolerance for diameter variation remains at ±3%, which is insufficient for advanced technical applications demanding tolerances below ±1%.

Quenching dynamics represent a critical process bottleneck. The transition from molten polymer to solid fiber occurs rapidly, and controlling cooling rates determines crystallinity development. Conventional air quenching systems struggle to maintain uniform cooling conditions across all filaments, especially in high-density spinnerets with 500+ holes, creating radial variations in fiber properties within the same production batch.

Draw ratio optimization remains problematic, particularly for high-speed spinning operations exceeding 5000 m/min. The narrow processing window between insufficient molecular orientation and excessive stress-induced crystallization limits production flexibility. Current technologies cannot dynamically adjust draw ratios in response to detected variations in upstream process conditions.

Finish application systems face challenges in achieving uniform coating distribution. Conventional kiss-roll applicators deliver inconsistent finish levels, varying by up to 15% across the fiber bundle. This variation affects downstream processability, especially in texturing and fabric formation stages where consistent fiber-to-fiber friction is essential.

Monitoring and control systems represent a significant technological gap. Real-time measurement of critical fiber parameters remains limited, with most quality assessments occurring offline. The industry lacks integrated sensor technologies capable of detecting subtle variations in fiber properties during high-speed production, preventing immediate process adjustments to maintain consistency.

Current Spinning Techniques for Nylon 66 Consistency

01 Melt spinning techniques for Nylon 66 fiber consistency

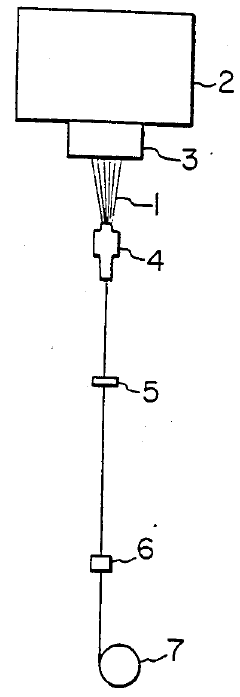

Melt spinning is a critical process for producing Nylon 66 fibers with consistent properties. The technique involves melting the polymer, extruding it through spinnerets, and then cooling and drawing the filaments. Temperature control during melting and extrusion is essential for maintaining uniform viscosity and preventing polymer degradation. Advanced melt spinning techniques incorporate precise pressure control systems and specialized spinnerets to ensure consistent fiber diameter and mechanical properties.- Melt spinning techniques for Nylon 66 fiber production: Melt spinning is a fundamental technique for producing Nylon 66 fibers with consistent properties. This process involves melting the polymer, extruding it through spinnerets, and then cooling and solidifying the filaments. Key parameters that affect fiber consistency include melt temperature control, extrusion pressure, spinneret design, and cooling rate. Advanced melt spinning techniques incorporate precise temperature profiles and controlled quenching to ensure uniform fiber structure and mechanical properties.

- Additives and modifiers for improving Nylon 66 fiber consistency: Various additives and modifiers can be incorporated into Nylon 66 formulations to enhance fiber consistency. These include nucleating agents that promote uniform crystallization, thermal stabilizers that prevent degradation during processing, and viscosity modifiers that ensure consistent melt flow properties. Certain surface-active agents can also improve fiber uniformity by reducing variations in fiber diameter and preventing filament fusion. The proper selection and concentration of these additives significantly impact the consistency of the final fiber properties.

- Process control systems for maintaining Nylon 66 fiber consistency: Advanced process control systems are essential for maintaining consistency in Nylon 66 fiber production. These systems monitor and adjust critical parameters such as temperature, pressure, draw ratio, and winding tension in real-time. Automated feedback loops can detect deviations from target specifications and make immediate corrections to prevent quality variations. Integrated sensors throughout the spinning line provide continuous data on fiber properties, allowing for precise control of the production process and ensuring consistent fiber quality across different production batches.

- Draw-texturing techniques for consistent Nylon 66 fiber properties: Draw-texturing is a critical post-spinning process that significantly affects the consistency of Nylon 66 fibers. This technique involves stretching the fibers under controlled conditions to orient the polymer molecules and impart desired physical properties. Factors such as draw ratio, drawing temperature, and tension control directly influence fiber uniformity. Advanced draw-texturing methods incorporate multi-stage drawing processes with precisely controlled heating and cooling zones to achieve consistent fiber dimensions, crystallinity, and tensile properties across the entire production lot.

- Quality testing and monitoring methods for Nylon 66 fiber consistency: Comprehensive quality testing and monitoring methods are crucial for ensuring Nylon 66 fiber consistency. These include online monitoring systems that continuously measure fiber diameter, tensile strength, elongation, and other critical parameters during production. Advanced analytical techniques such as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and rheological testing help characterize the polymer properties that affect fiber consistency. Statistical process control methods are employed to identify trends and variations, allowing manufacturers to maintain tight tolerances and produce fibers with highly consistent properties batch after batch.

02 Quenching and solidification control methods

The quenching phase after extrusion significantly impacts Nylon 66 fiber consistency. Controlled cooling rates and air flow patterns during solidification determine the crystalline structure and uniformity of the fibers. Advanced quenching systems employ precisely regulated air temperature gradients and adjustable air flow velocities to achieve consistent fiber properties. Some techniques utilize specialized quenching chambers with humidity control to further enhance fiber consistency and prevent surface defects during solidification.Expand Specific Solutions03 Drawing and orientation processes for fiber uniformity

Drawing processes are essential for achieving molecular orientation and improving the mechanical properties of Nylon 66 fibers. Multi-stage drawing with controlled tension and temperature profiles ensures consistent fiber strength and elongation characteristics. Advanced techniques incorporate precision rollers with surface treatments that prevent fiber slippage and maintain uniform drawing ratios. Some methods employ zone-specific heating to optimize molecular alignment while preventing excessive crystallization that could lead to brittleness or inconsistent fiber properties.Expand Specific Solutions04 Additives and modifiers for improved consistency

Various additives and modifiers can be incorporated into Nylon 66 spinning formulations to enhance fiber consistency. Nucleating agents promote uniform crystallization, while thermal stabilizers prevent degradation during processing. Lubricants and surface modifiers improve processing consistency by reducing friction during spinning and drawing operations. Some formulations include specialized polymeric compatibilizers that ensure homogeneous distribution of additives throughout the fiber structure, resulting in more consistent physical and chemical properties across production batches.Expand Specific Solutions05 Monitoring and control systems for process stability

Advanced monitoring and control systems are crucial for maintaining Nylon 66 fiber consistency during production. Real-time viscosity measurement and feedback control systems adjust processing parameters to compensate for variations in raw materials or environmental conditions. Inline quality monitoring using optical sensors, laser measurement systems, and tension sensors provides immediate feedback on fiber dimensions and properties. Some systems incorporate artificial intelligence and machine learning algorithms to predict and prevent consistency issues before they occur, optimizing process parameters continuously throughout production runs.Expand Specific Solutions

Leading Manufacturers in Nylon 66 Fiber Production

The Nylon 66 spinning techniques optimization market is in a mature growth phase, with an estimated global market size of $3-4 billion. The competitive landscape features established industry leaders like Toray Industries, HYOSUNG Corp, and NILIT Ltd, who have developed proprietary spinning technologies for fiber consistency. Asian manufacturers, particularly Chinese companies such as Liaoning Yinzhu Chemtex and Jiangsu Boiln Plastics, are rapidly gaining market share through technological advancements. Equipment suppliers like Rieter and Maschinenfabrik Rieter AG provide critical spinning machinery solutions. Academic institutions including Donghua University and Hangzhou Normal University collaborate with industry players on R&D initiatives, focusing on process optimization and sustainability. The technology has reached commercial maturity but continues to evolve toward greater automation, energy efficiency, and quality control systems.

HS HYOSUNG ADVANCED MATERIALS

Technical Solution: HS HYOSUNG ADVANCED MATERIALS has developed the "NylonPrecision" system for optimizing Nylon 66 fiber consistency. Their approach begins with enhanced polymer conditioning techniques that ensure uniform melt properties before extrusion. The technology incorporates a specialized thermal management system that maintains precise temperature control throughout the spinning path. Their innovation includes a multi-zone drawing system with individual tension control for each filament group, allowing for compensation of position-related variations. HS HYOSUNG's process features advanced quenching technology with laminar flow control that creates uniform cooling conditions across the fiber bundle. The system includes real-time monitoring of birefringence and orientation development during processing, with feedback controls that adjust process parameters to maintain target properties. Their technology also incorporates specialized finish application systems with precise metering and distribution control. The company has implemented machine learning algorithms that continuously optimize process parameters based on historical quality data and current production conditions.

Strengths: Superior dimensional stability with diameter variations less than 1.8% across production runs. Excellent consistency in mechanical properties, particularly in tensile strength and elongation. Weaknesses: Relatively high energy consumption due to the precision thermal management systems. Complex control systems require specialized maintenance and technical support.

HYOSUNG Corp.

Technical Solution: HYOSUNG has developed the "CreoraTech" system specifically for Nylon 66 spinning optimization. This comprehensive approach begins with polymer formulation adjustments that enhance spinnability and thermal stability. Their spinning technology incorporates a multi-point tension control system that maintains precise filament tension throughout the process. HYOSUNG's innovation includes specialized quenching technology with zoned air flow control that creates uniform cooling conditions across the fiber bundle. The system features advanced draw ratio management that automatically adjusts based on continuous monitoring of fiber properties. Their technology also incorporates a proprietary surface treatment application system that ensures consistent finish distribution. HYOSUNG has implemented digital twin modeling of the entire spinning process, allowing for predictive quality control and process optimization. The company's approach also includes specialized take-up winding technology that minimizes tension variations during package formation, contributing to overall fiber consistency.

Strengths: Highly adaptable system that can be optimized for different fiber deniers and end-use applications. Excellent package-to-package consistency with variation less than 3%. Weaknesses: Requires significant initial calibration time when changing between different product specifications. Higher maintenance requirements due to the complexity of the tension control systems.

Key Patents in Nylon 66 Spinning Optimization

Process for the production of uniformly dyeable nylon 66 fiber

PatentInactiveUS4732720A

Innovation

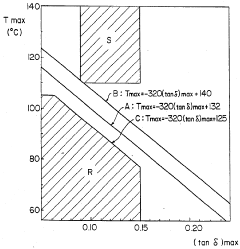

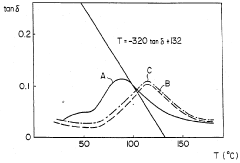

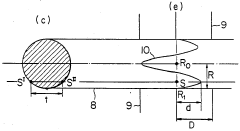

- A novel nylon 66 fiber with a specific microstructure characterized by a dynamic mechanical loss tangent (tan δ) and peak temperature relationship (Tmax ≤ -320(tan δ)max + 132) and a refractive index difference between the outer and inner layers, combined with a high-speed spinning process involving an extruded filament passing through a heating zone and suction by an aspirator, enhances dyeability and spinning stability.

Manufacturing method of Nylon 66 fiber having high strength

PatentActiveKR1020180085408A

Innovation

- A method involving low-temperature spinning in a spin tube, multi-stage drawing, and controlled heat treatment to maintain birefringence within specific ranges, ensuring the spin tube temperature is 65°C or lower, and employing a multi-stage stretching process with defined temperature and draw ratios to produce high-strength nylon 66 fibers.

Environmental Impact of Nylon 66 Production Methods

The production of Nylon 66 fibers through spinning techniques carries significant environmental implications that must be carefully considered in optimization efforts. Traditional manufacturing processes for Nylon 66 involve energy-intensive operations and chemical treatments that generate substantial environmental footprints across multiple ecological domains.

Water consumption represents a critical environmental concern in Nylon 66 production. The spinning process typically requires 500-700 liters of water per kilogram of fiber produced, primarily for cooling, washing, and chemical processing. Advanced spinning techniques incorporating closed-loop water systems have demonstrated potential to reduce consumption by 30-45%, significantly mitigating water resource depletion.

Energy utilization during spinning operations constitutes another major environmental factor. Conventional Nylon 66 spinning consumes approximately 25-30 kWh per kilogram of fiber, contributing substantially to carbon emissions. Recent innovations in low-temperature spinning technologies have achieved energy reductions of 15-20%, while maintaining fiber consistency parameters.

Chemical emissions present ongoing challenges, as spinning processes typically release volatile organic compounds (VOCs), particulate matter, and nitrogen oxides. Measurements indicate that unoptimized spinning operations can generate 3-5 kg of CO2 equivalent per kilogram of fiber. Implementation of advanced filtration systems and catalytic converters has proven effective in reducing these emissions by up to 60%.

Waste generation throughout the spinning process includes polymer residues, spent solvents, and packaging materials. Approximately 8-12% of raw materials become waste in conventional operations. Optimized spinning techniques incorporating precision control systems have demonstrated capacity to reduce waste generation to 3-5%, representing significant improvements in material efficiency.

Life cycle assessments of Nylon 66 production reveal that spinning techniques significantly influence the overall environmental impact. Optimized spinning methods can reduce the carbon footprint by 25-35% compared to conventional approaches. The implementation of bio-based additives and renewable energy sources in spinning operations has shown promising results in further reducing environmental impacts while maintaining fiber consistency.

Regulatory frameworks increasingly address environmental aspects of synthetic fiber production. The European Union's Best Available Techniques Reference Documents (BREFs) for polymers and textiles specifically target emissions and resource efficiency in spinning operations. Compliance with these evolving standards necessitates continuous improvement in spinning techniques that balance environmental performance with fiber quality requirements.

Water consumption represents a critical environmental concern in Nylon 66 production. The spinning process typically requires 500-700 liters of water per kilogram of fiber produced, primarily for cooling, washing, and chemical processing. Advanced spinning techniques incorporating closed-loop water systems have demonstrated potential to reduce consumption by 30-45%, significantly mitigating water resource depletion.

Energy utilization during spinning operations constitutes another major environmental factor. Conventional Nylon 66 spinning consumes approximately 25-30 kWh per kilogram of fiber, contributing substantially to carbon emissions. Recent innovations in low-temperature spinning technologies have achieved energy reductions of 15-20%, while maintaining fiber consistency parameters.

Chemical emissions present ongoing challenges, as spinning processes typically release volatile organic compounds (VOCs), particulate matter, and nitrogen oxides. Measurements indicate that unoptimized spinning operations can generate 3-5 kg of CO2 equivalent per kilogram of fiber. Implementation of advanced filtration systems and catalytic converters has proven effective in reducing these emissions by up to 60%.

Waste generation throughout the spinning process includes polymer residues, spent solvents, and packaging materials. Approximately 8-12% of raw materials become waste in conventional operations. Optimized spinning techniques incorporating precision control systems have demonstrated capacity to reduce waste generation to 3-5%, representing significant improvements in material efficiency.

Life cycle assessments of Nylon 66 production reveal that spinning techniques significantly influence the overall environmental impact. Optimized spinning methods can reduce the carbon footprint by 25-35% compared to conventional approaches. The implementation of bio-based additives and renewable energy sources in spinning operations has shown promising results in further reducing environmental impacts while maintaining fiber consistency.

Regulatory frameworks increasingly address environmental aspects of synthetic fiber production. The European Union's Best Available Techniques Reference Documents (BREFs) for polymers and textiles specifically target emissions and resource efficiency in spinning operations. Compliance with these evolving standards necessitates continuous improvement in spinning techniques that balance environmental performance with fiber quality requirements.

Quality Control Standards for Synthetic Fiber Manufacturing

Quality control standards in synthetic fiber manufacturing, particularly for Nylon 66 spinning processes, have evolved significantly to address the critical need for fiber consistency. These standards encompass multiple dimensions of quality assurance, from raw material specifications to final product testing protocols.

The foundation of quality control in Nylon 66 fiber production begins with strict raw material specifications. Polymer viscosity, molecular weight distribution, and monomer purity levels must meet predetermined thresholds to ensure consistent spinning performance. Industry standards typically require relative viscosity values between 2.7-3.0 for textile applications and 3.0-3.5 for industrial applications, with monomer purity exceeding 99.5%.

Process parameter monitoring represents another crucial aspect of quality control. Modern manufacturing facilities implement real-time monitoring systems that track critical variables including melt temperature (typically maintained at 265-285°C), spinning speed (ranging from 3000-6000 m/min depending on application), quench air flow rates, and draw ratios. Statistical Process Control (SPC) methodologies are employed to detect deviations before they impact fiber consistency.

Physical property testing forms the cornerstone of finished product quality assessment. Standard tests include tenacity measurements (minimum requirements of 4.5-5.5 g/denier for industrial applications), elongation at break (typically 15-45% depending on end-use), modulus evaluation, and dimensional stability under various conditions. These tests are conducted according to internationally recognized standards such as ASTM D2256 and ISO 2062.

Surface and structural uniformity assessment has gained prominence with advancing technology. Techniques including Scanning Electron Microscopy (SEM) analysis, birefringence measurements, and cross-section uniformity evaluations are now standard practice. These methods detect subtle variations in fiber morphology that can affect downstream processing and end-product performance.

Defect classification systems have been standardized across the industry, with common categories including diameter variations (acceptable tolerance typically ±2%), surface irregularities, broken filaments, and color inconsistencies. Automated inspection systems utilizing machine vision technology can detect defects at production speeds exceeding 6000 m/min with resolution capabilities identifying anomalies as small as 10 microns.

Documentation and traceability requirements have become increasingly stringent, with ISO 9001 certification considered the minimum standard for quality management systems in synthetic fiber production. Complete batch records must maintain detailed process parameters, quality test results, and material genealogy to facilitate root cause analysis in the event of quality deviations.

The foundation of quality control in Nylon 66 fiber production begins with strict raw material specifications. Polymer viscosity, molecular weight distribution, and monomer purity levels must meet predetermined thresholds to ensure consistent spinning performance. Industry standards typically require relative viscosity values between 2.7-3.0 for textile applications and 3.0-3.5 for industrial applications, with monomer purity exceeding 99.5%.

Process parameter monitoring represents another crucial aspect of quality control. Modern manufacturing facilities implement real-time monitoring systems that track critical variables including melt temperature (typically maintained at 265-285°C), spinning speed (ranging from 3000-6000 m/min depending on application), quench air flow rates, and draw ratios. Statistical Process Control (SPC) methodologies are employed to detect deviations before they impact fiber consistency.

Physical property testing forms the cornerstone of finished product quality assessment. Standard tests include tenacity measurements (minimum requirements of 4.5-5.5 g/denier for industrial applications), elongation at break (typically 15-45% depending on end-use), modulus evaluation, and dimensional stability under various conditions. These tests are conducted according to internationally recognized standards such as ASTM D2256 and ISO 2062.

Surface and structural uniformity assessment has gained prominence with advancing technology. Techniques including Scanning Electron Microscopy (SEM) analysis, birefringence measurements, and cross-section uniformity evaluations are now standard practice. These methods detect subtle variations in fiber morphology that can affect downstream processing and end-product performance.

Defect classification systems have been standardized across the industry, with common categories including diameter variations (acceptable tolerance typically ±2%), surface irregularities, broken filaments, and color inconsistencies. Automated inspection systems utilizing machine vision technology can detect defects at production speeds exceeding 6000 m/min with resolution capabilities identifying anomalies as small as 10 microns.

Documentation and traceability requirements have become increasingly stringent, with ISO 9001 certification considered the minimum standard for quality management systems in synthetic fiber production. Complete batch records must maintain detailed process parameters, quality test results, and material genealogy to facilitate root cause analysis in the event of quality deviations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!