Real-world applications of transparent AMOLED displays.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Display Evolution

AMOLED (Active-Matrix Organic Light-Emitting Diode) display technology has undergone significant evolution since its inception in the late 1990s. The journey began with the development of small, monochrome displays primarily used in mobile devices. These early AMOLED displays offered improved contrast and power efficiency compared to traditional LCD screens, but were limited in size and color reproduction.

As manufacturing processes improved in the early 2000s, full-color AMOLED displays became commercially viable. This breakthrough led to their adoption in smartphones and other portable electronics, where their vibrant colors and deep blacks quickly gained popularity. The technology's ability to produce true blacks by turning off individual pixels also contributed to improved power efficiency in mobile devices.

The mid-2000s saw the emergence of larger AMOLED panels, paving the way for their use in televisions and monitors. However, challenges such as color accuracy, burn-in, and production costs initially limited widespread adoption in these larger formats. Manufacturers focused on addressing these issues through innovations in materials science and production techniques.

A significant milestone in AMOLED evolution came with the development of flexible AMOLED displays in the early 2010s. This innovation allowed for the creation of curved and bendable screens, opening up new design possibilities for smartphones and wearable devices. The flexibility of AMOLED technology also laid the groundwork for future developments in foldable displays.

The late 2010s marked the beginning of transparent AMOLED display research and development. This technology aimed to create displays that could seamlessly blend into their surroundings when not in use, offering new possibilities for augmented reality applications and innovative product designs. While initially limited to prototype demonstrations, transparent AMOLED displays have shown promise for integration into various consumer and industrial applications.

Recent years have seen continued improvements in AMOLED technology, including higher resolutions, increased refresh rates, and enhanced color accuracy. The development of more efficient blue OLED materials has also addressed previous concerns about display longevity and power consumption. These advancements have further solidified AMOLED's position as a premium display technology across a wide range of devices.

Looking ahead, the evolution of AMOLED displays is expected to focus on further refinements in transparency, flexibility, and energy efficiency. The integration of advanced features such as in-display cameras and sensors is also likely to shape the future development of AMOLED technology, potentially revolutionizing the way we interact with displays in our daily lives.

As manufacturing processes improved in the early 2000s, full-color AMOLED displays became commercially viable. This breakthrough led to their adoption in smartphones and other portable electronics, where their vibrant colors and deep blacks quickly gained popularity. The technology's ability to produce true blacks by turning off individual pixels also contributed to improved power efficiency in mobile devices.

The mid-2000s saw the emergence of larger AMOLED panels, paving the way for their use in televisions and monitors. However, challenges such as color accuracy, burn-in, and production costs initially limited widespread adoption in these larger formats. Manufacturers focused on addressing these issues through innovations in materials science and production techniques.

A significant milestone in AMOLED evolution came with the development of flexible AMOLED displays in the early 2010s. This innovation allowed for the creation of curved and bendable screens, opening up new design possibilities for smartphones and wearable devices. The flexibility of AMOLED technology also laid the groundwork for future developments in foldable displays.

The late 2010s marked the beginning of transparent AMOLED display research and development. This technology aimed to create displays that could seamlessly blend into their surroundings when not in use, offering new possibilities for augmented reality applications and innovative product designs. While initially limited to prototype demonstrations, transparent AMOLED displays have shown promise for integration into various consumer and industrial applications.

Recent years have seen continued improvements in AMOLED technology, including higher resolutions, increased refresh rates, and enhanced color accuracy. The development of more efficient blue OLED materials has also addressed previous concerns about display longevity and power consumption. These advancements have further solidified AMOLED's position as a premium display technology across a wide range of devices.

Looking ahead, the evolution of AMOLED displays is expected to focus on further refinements in transparency, flexibility, and energy efficiency. The integration of advanced features such as in-display cameras and sensors is also likely to shape the future development of AMOLED technology, potentially revolutionizing the way we interact with displays in our daily lives.

Transparent AMOLED Market

The transparent AMOLED market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for innovative display technologies across various industries. This market segment is characterized by its unique ability to offer see-through displays without compromising on visual quality, making it particularly attractive for applications that require both transparency and high-performance display capabilities.

Market analysis indicates that the transparent AMOLED sector is poised for substantial expansion in the coming years. The automotive industry has emerged as a key driver of this growth, with manufacturers increasingly incorporating transparent displays into windshields and windows for augmented reality (AR) applications, heads-up displays (HUDs), and infotainment systems. This trend is expected to accelerate as vehicle connectivity and autonomous driving technologies advance.

Another significant market for transparent AMOLED displays is the consumer electronics sector. Smartphones, smartwatches, and other wearable devices are exploring the integration of transparent displays to enhance user experience and functionality. These displays offer the potential for seamless AR overlays and novel form factors that could revolutionize how we interact with our devices.

The retail and advertising industries are also showing keen interest in transparent AMOLED technology. These displays enable the creation of interactive storefronts, digital signage, and immersive marketing experiences that can captivate consumers and provide new avenues for brand engagement. The ability to overlay digital content onto physical objects or environments opens up exciting possibilities for experiential marketing and product showcases.

In the architectural and interior design fields, transparent AMOLED displays are being incorporated into smart windows, partitions, and decorative elements. This application allows for dynamic space customization and the integration of information displays into previously unused surfaces, blending technology seamlessly with the built environment.

The healthcare sector is another area where transparent AMOLED displays are gaining traction. These displays can be used in medical imaging equipment, surgical planning tools, and patient monitoring systems, providing healthcare professionals with enhanced visualization capabilities while maintaining a clear view of the patient or surgical site.

As the technology matures and production costs decrease, we can expect to see wider adoption across various industries. The market is likely to witness the entry of new players and increased competition, which could drive further innovation and cost reductions. However, challenges such as power consumption, durability, and scalability of production will need to be addressed to fully realize the potential of transparent AMOLED displays in diverse real-world applications.

Market analysis indicates that the transparent AMOLED sector is poised for substantial expansion in the coming years. The automotive industry has emerged as a key driver of this growth, with manufacturers increasingly incorporating transparent displays into windshields and windows for augmented reality (AR) applications, heads-up displays (HUDs), and infotainment systems. This trend is expected to accelerate as vehicle connectivity and autonomous driving technologies advance.

Another significant market for transparent AMOLED displays is the consumer electronics sector. Smartphones, smartwatches, and other wearable devices are exploring the integration of transparent displays to enhance user experience and functionality. These displays offer the potential for seamless AR overlays and novel form factors that could revolutionize how we interact with our devices.

The retail and advertising industries are also showing keen interest in transparent AMOLED technology. These displays enable the creation of interactive storefronts, digital signage, and immersive marketing experiences that can captivate consumers and provide new avenues for brand engagement. The ability to overlay digital content onto physical objects or environments opens up exciting possibilities for experiential marketing and product showcases.

In the architectural and interior design fields, transparent AMOLED displays are being incorporated into smart windows, partitions, and decorative elements. This application allows for dynamic space customization and the integration of information displays into previously unused surfaces, blending technology seamlessly with the built environment.

The healthcare sector is another area where transparent AMOLED displays are gaining traction. These displays can be used in medical imaging equipment, surgical planning tools, and patient monitoring systems, providing healthcare professionals with enhanced visualization capabilities while maintaining a clear view of the patient or surgical site.

As the technology matures and production costs decrease, we can expect to see wider adoption across various industries. The market is likely to witness the entry of new players and increased competition, which could drive further innovation and cost reductions. However, challenges such as power consumption, durability, and scalability of production will need to be addressed to fully realize the potential of transparent AMOLED displays in diverse real-world applications.

Technical Challenges

Despite the promising potential of transparent AMOLED displays, several technical challenges persist in their development and widespread adoption. One of the primary hurdles is achieving sufficient transparency without compromising display quality. Current transparent AMOLED displays often struggle to maintain high brightness and contrast ratios, especially in bright ambient light conditions. This limitation affects their visibility and usability in various real-world applications, particularly in outdoor environments.

Another significant challenge lies in the power consumption of transparent AMOLED displays. The need for increased brightness to compensate for transparency often results in higher energy requirements, which can be problematic for battery-powered devices. Balancing power efficiency with display performance remains a critical area of focus for researchers and manufacturers.

The manufacturing process for transparent AMOLED displays also presents considerable difficulties. Producing consistent and uniform transparency across large display areas is technically demanding and can lead to increased production costs. Additionally, the integration of transparent displays into existing device designs often requires significant modifications to accommodate the unique properties of these displays, including considerations for heat dissipation and structural integrity.

Durability and longevity of transparent AMOLED displays pose another set of challenges. The exposure of internal components to light and potentially harsh environmental conditions can accelerate degradation and reduce the lifespan of these displays. Developing robust protective layers and sealants that maintain transparency while providing adequate protection is an ongoing area of research and development.

Color accuracy and gamut representation in transparent displays are also areas of concern. The transparency of the display can affect color perception and reproduction, potentially leading to inconsistencies in image quality across different viewing conditions. Addressing these color-related issues is crucial for applications that require high fidelity visual output, such as in automotive heads-up displays or augmented reality devices.

Furthermore, the integration of touch functionality with transparent AMOLED displays presents additional complexities. Traditional touch sensors can reduce transparency and affect display quality, necessitating the development of new, highly transparent touch-sensing technologies that can seamlessly integrate with the display without compromising its visual characteristics.

Lastly, the challenge of minimizing reflections and glare on transparent displays is significant. Unlike traditional displays, transparent AMOLEDs must contend with light passing through from both sides, potentially creating distracting reflections or reducing visibility. Developing effective anti-reflective coatings and optimizing the display structure to manage light transmission and reflection is crucial for enhancing the user experience in real-world applications.

Another significant challenge lies in the power consumption of transparent AMOLED displays. The need for increased brightness to compensate for transparency often results in higher energy requirements, which can be problematic for battery-powered devices. Balancing power efficiency with display performance remains a critical area of focus for researchers and manufacturers.

The manufacturing process for transparent AMOLED displays also presents considerable difficulties. Producing consistent and uniform transparency across large display areas is technically demanding and can lead to increased production costs. Additionally, the integration of transparent displays into existing device designs often requires significant modifications to accommodate the unique properties of these displays, including considerations for heat dissipation and structural integrity.

Durability and longevity of transparent AMOLED displays pose another set of challenges. The exposure of internal components to light and potentially harsh environmental conditions can accelerate degradation and reduce the lifespan of these displays. Developing robust protective layers and sealants that maintain transparency while providing adequate protection is an ongoing area of research and development.

Color accuracy and gamut representation in transparent displays are also areas of concern. The transparency of the display can affect color perception and reproduction, potentially leading to inconsistencies in image quality across different viewing conditions. Addressing these color-related issues is crucial for applications that require high fidelity visual output, such as in automotive heads-up displays or augmented reality devices.

Furthermore, the integration of touch functionality with transparent AMOLED displays presents additional complexities. Traditional touch sensors can reduce transparency and affect display quality, necessitating the development of new, highly transparent touch-sensing technologies that can seamlessly integrate with the display without compromising its visual characteristics.

Lastly, the challenge of minimizing reflections and glare on transparent displays is significant. Unlike traditional displays, transparent AMOLEDs must contend with light passing through from both sides, potentially creating distracting reflections or reducing visibility. Developing effective anti-reflective coatings and optimizing the display structure to manage light transmission and reflection is crucial for enhancing the user experience in real-world applications.

Current Solutions

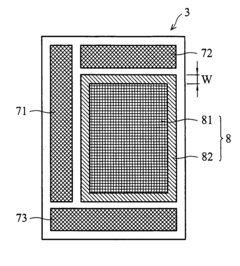

01 Transparent AMOLED display structure

Transparent AMOLED displays are designed with a unique structure that allows light to pass through the display, creating a see-through effect. This is achieved by using transparent materials for the substrate, electrodes, and organic layers. The structure typically includes a transparent cathode, transparent organic layers, and a transparent anode on a transparent substrate.- Transparent AMOLED display structure: Transparent AMOLED displays are designed with a unique structure that allows light to pass through the display. This typically involves using transparent electrodes, such as indium tin oxide (ITO), and optimizing the arrangement of organic layers and thin-film transistors to maximize transparency while maintaining display performance.

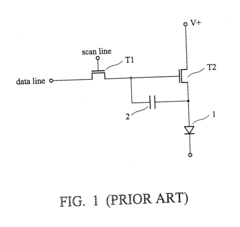

- Pixel circuit design for transparent AMOLEDs: Specialized pixel circuits are developed for transparent AMOLED displays to ensure proper light emission and transparency. These circuits often incorporate novel transistor arrangements and compensation schemes to maintain image quality while allowing light transmission through the display area.

- Transparent AMOLED fabrication techniques: Advanced fabrication techniques are employed to create transparent AMOLED displays. These may include specialized deposition methods for transparent conductive materials, patterning techniques for creating transparent circuit elements, and encapsulation processes that maintain transparency while protecting the organic layers.

- Driving methods for transparent AMOLED displays: Unique driving methods are developed to address the challenges of operating transparent AMOLED displays. These methods often focus on compensating for variations in transparency across the display area, managing power consumption, and optimizing image quality in both transmissive and emissive modes.

- Applications of transparent AMOLED technology: Transparent AMOLED displays find applications in various fields, including augmented reality (AR) devices, heads-up displays, smart windows, and automotive displays. The technology enables the integration of digital information with the real-world environment, opening up new possibilities for user interfaces and information display.

02 Pixel design for transparency

The pixel design in transparent AMOLED displays is crucial for achieving transparency while maintaining display quality. This involves optimizing the layout of the organic light-emitting diodes (OLEDs) and thin-film transistors (TFTs) to maximize the transparent area within each pixel. Advanced pixel architectures may include micro-LEDs or specialized arrangements to enhance transparency.Expand Specific Solutions03 Transparent electrode materials

The choice of transparent electrode materials is critical for transparent AMOLED displays. Common materials include indium tin oxide (ITO), graphene, and metal nanowires. These materials must balance high conductivity with high transparency to ensure proper display function while maintaining see-through capabilities.Expand Specific Solutions04 Driving methods for transparent displays

Specialized driving methods are employed in transparent AMOLED displays to optimize performance and power efficiency. These may include advanced pixel compensation techniques, variable refresh rates, and adaptive brightness control to ensure proper visibility in different lighting conditions while maintaining transparency.Expand Specific Solutions05 Integration with other technologies

Transparent AMOLED displays can be integrated with various technologies to enhance functionality. This includes touch sensors for interactive displays, ambient light sensors for automatic brightness adjustment, and integration with augmented reality (AR) systems. These combinations create versatile display solutions for applications such as smart windows, heads-up displays, and wearable devices.Expand Specific Solutions

Key Industry Players

The transparent AMOLED display market is in a growth phase, driven by increasing demand for innovative display solutions in consumer electronics, automotive, and wearable devices. The global market size is projected to expand significantly in the coming years, with major players like BOE Technology, LG Display, and Samsung Display leading the competition. These companies are investing heavily in R&D to improve display performance, flexibility, and energy efficiency. The technology's maturity is advancing rapidly, with companies like TCL China Star Optoelectronics and Everdisplay Optronics making significant strides in production capabilities. Academic institutions such as MIT and KAIST are also contributing to technological advancements, pushing the boundaries of transparent AMOLED applications in real-world scenarios.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced transparent AMOLED displays with high transmittance rates of up to 70%[1]. Their technology incorporates innovative pixel structures and transparent conducting materials to achieve improved clarity. BOE's displays feature a resolution of 1920x1080 pixels and support touch functionality[2]. The company has demonstrated applications in automotive windshields, showcasing real-time navigation, traffic information, and augmented reality features[3]. BOE has also explored using these displays in smart home appliances, integrating them into refrigerator doors to display contents and expiration dates without opening[4].

Strengths: High transmittance rate, advanced pixel structure, versatile applications. Weaknesses: Potential high production costs, limited mass production capability.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has made significant strides in transparent AMOLED technology, focusing on applications in the automotive and smart home sectors. Their displays feature a transparency rate of up to 50% and incorporate advanced touch sensors for interactive functionality[9]. TCL CSOT has demonstrated concept vehicles with transparent AMOLED windshields and side windows, displaying navigation, vehicle status, and environmental information[10]. In the smart home domain, the company has showcased transparent AMOLED panels integrated into windows and glass partitions, enabling them to transform from transparent surfaces to information displays or privacy screens on demand[11]. TCL CSOT's technology also includes flexible transparent AMOLED displays, opening up possibilities for curved and foldable transparent screens in various applications[12].

Strengths: High transparency rate, flexible display capabilities, strong focus on automotive applications. Weaknesses: Limited commercial deployment, potential durability concerns in harsh environments.

Innovative Technologies

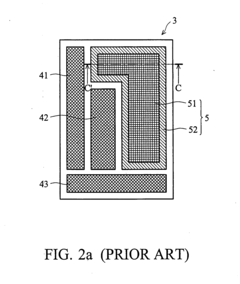

Active-matrix organic light emitting diode display

PatentInactiveUS20070268223A1

Innovation

- The indium tin oxide region is redesigned to be a rectangular shape with a surrounding silicon nitride isolation region, allowing for a more efficient layout by arranging the thin film transistors and capacitor regions in a hoof or L shape, maximizing the opening area and minimizing the isolation region.

Light-emitting diode, array substrate, and method of making the same

PatentWO2018223647A1

Innovation

- Introducing a substantially transparent protective layer between the second electrode and the transparent conductive layer to enhance device stability.

- Using a substantially transparent conductive layer on top of the protective layer to reduce IR drop while maintaining transparency.

- Electrically connecting the transparent conductive layer to the second electrode through vias to ensure proper current distribution.

Manufacturing Processes

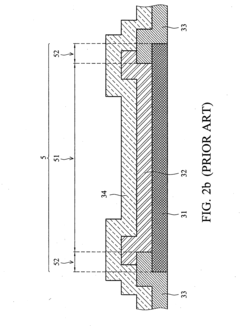

The manufacturing processes for transparent AMOLED displays involve several complex steps and advanced technologies. The production begins with the preparation of a transparent substrate, typically made of ultra-thin glass or flexible plastic materials. This substrate serves as the foundation for the display and must be carefully cleaned and treated to ensure optimal performance.

Next, the thin-film transistor (TFT) backplane is fabricated on the substrate. This process involves depositing and patterning multiple layers of semiconductors, insulators, and conductive materials. For transparent displays, special attention is given to using transparent conductive materials like indium tin oxide (ITO) for electrodes.

The OLED layers are then deposited onto the TFT backplane. This is typically done using vacuum thermal evaporation or inkjet printing techniques. The OLED stack consists of multiple organic layers, including hole injection, hole transport, emissive, and electron transport layers. For transparent displays, these layers must be carefully engineered to achieve both high transparency and efficient light emission.

Encapsulation is a critical step in the manufacturing process, especially for transparent displays. Advanced thin-film encapsulation techniques are employed to protect the sensitive OLED materials from moisture and oxygen while maintaining transparency. This often involves alternating layers of inorganic and organic materials deposited using atomic layer deposition (ALD) or plasma-enhanced chemical vapor deposition (PECVD).

The final steps include the integration of touch sensors and polarizers, which must also be transparent. These components are carefully bonded to the display stack using optically clear adhesives. Quality control and testing are performed throughout the manufacturing process to ensure uniformity, transparency, and functionality of the displays.

Challenges in manufacturing transparent AMOLED displays include achieving high transparency without compromising display performance, ensuring uniform light emission across the transparent areas, and maintaining long-term reliability in various environmental conditions. Ongoing research focuses on developing new materials and processes to improve transparency, efficiency, and durability of these innovative displays.

Next, the thin-film transistor (TFT) backplane is fabricated on the substrate. This process involves depositing and patterning multiple layers of semiconductors, insulators, and conductive materials. For transparent displays, special attention is given to using transparent conductive materials like indium tin oxide (ITO) for electrodes.

The OLED layers are then deposited onto the TFT backplane. This is typically done using vacuum thermal evaporation or inkjet printing techniques. The OLED stack consists of multiple organic layers, including hole injection, hole transport, emissive, and electron transport layers. For transparent displays, these layers must be carefully engineered to achieve both high transparency and efficient light emission.

Encapsulation is a critical step in the manufacturing process, especially for transparent displays. Advanced thin-film encapsulation techniques are employed to protect the sensitive OLED materials from moisture and oxygen while maintaining transparency. This often involves alternating layers of inorganic and organic materials deposited using atomic layer deposition (ALD) or plasma-enhanced chemical vapor deposition (PECVD).

The final steps include the integration of touch sensors and polarizers, which must also be transparent. These components are carefully bonded to the display stack using optically clear adhesives. Quality control and testing are performed throughout the manufacturing process to ensure uniformity, transparency, and functionality of the displays.

Challenges in manufacturing transparent AMOLED displays include achieving high transparency without compromising display performance, ensuring uniform light emission across the transparent areas, and maintaining long-term reliability in various environmental conditions. Ongoing research focuses on developing new materials and processes to improve transparency, efficiency, and durability of these innovative displays.

Energy Efficiency

Transparent AMOLED displays offer significant advantages in terms of energy efficiency compared to traditional display technologies. These displays utilize organic light-emitting diodes (OLEDs) that emit light directly, eliminating the need for a backlight found in conventional LCD screens. This fundamental difference in technology results in substantial power savings, especially when displaying darker content.

The energy efficiency of transparent AMOLED displays is particularly notable in applications where the display is not constantly active or where only portions of the screen need to be illuminated. In such scenarios, the ability to selectively activate individual pixels contributes to reduced power consumption. This feature is especially beneficial in wearable devices, automotive displays, and smart home appliances where battery life and energy conservation are critical factors.

Furthermore, transparent AMOLED displays can take advantage of ambient light to enhance visibility, potentially reducing the need for high brightness settings in well-lit environments. This adaptability can lead to additional energy savings in real-world applications, particularly in outdoor or brightly lit indoor settings.

Recent advancements in AMOLED technology have focused on improving the efficiency of organic materials and optimizing pixel structures. These developments have resulted in displays that consume less power while maintaining high image quality and transparency. For instance, the introduction of more efficient blue OLED emitters has addressed one of the primary energy consumption challenges in AMOLED technology.

In automotive applications, transparent AMOLED displays integrated into windshields or side windows can provide heads-up information without significantly impacting the vehicle's energy consumption. This is particularly important for electric vehicles where every watt of power saved translates to extended range.

Smart home devices incorporating transparent AMOLED displays can leverage their energy efficiency to provide always-on information displays without substantially increasing household energy usage. This enables the development of more intuitive and accessible smart home interfaces that seamlessly blend into the living environment.

The energy efficiency of transparent AMOLED displays also extends to their production process. As the technology matures, manufacturing techniques are becoming more streamlined, reducing the energy required to produce these displays. This improvement in production efficiency contributes to a lower overall environmental impact throughout the product lifecycle.

The energy efficiency of transparent AMOLED displays is particularly notable in applications where the display is not constantly active or where only portions of the screen need to be illuminated. In such scenarios, the ability to selectively activate individual pixels contributes to reduced power consumption. This feature is especially beneficial in wearable devices, automotive displays, and smart home appliances where battery life and energy conservation are critical factors.

Furthermore, transparent AMOLED displays can take advantage of ambient light to enhance visibility, potentially reducing the need for high brightness settings in well-lit environments. This adaptability can lead to additional energy savings in real-world applications, particularly in outdoor or brightly lit indoor settings.

Recent advancements in AMOLED technology have focused on improving the efficiency of organic materials and optimizing pixel structures. These developments have resulted in displays that consume less power while maintaining high image quality and transparency. For instance, the introduction of more efficient blue OLED emitters has addressed one of the primary energy consumption challenges in AMOLED technology.

In automotive applications, transparent AMOLED displays integrated into windshields or side windows can provide heads-up information without significantly impacting the vehicle's energy consumption. This is particularly important for electric vehicles where every watt of power saved translates to extended range.

Smart home devices incorporating transparent AMOLED displays can leverage their energy efficiency to provide always-on information displays without substantially increasing household energy usage. This enables the development of more intuitive and accessible smart home interfaces that seamlessly blend into the living environment.

The energy efficiency of transparent AMOLED displays also extends to their production process. As the technology matures, manufacturing techniques are becoming more streamlined, reducing the energy required to produce these displays. This improvement in production efficiency contributes to a lower overall environmental impact throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!