2-Methylpentane-Based Solutions for Anti-Corrosion Coatings

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2-Methylpentane Coatings Background and Objectives

The field of anti-corrosion coatings has seen significant advancements over the past decades, with researchers and industry professionals continuously seeking innovative solutions to protect materials from degradation. In recent years, 2-methylpentane-based coatings have emerged as a promising avenue for enhancing corrosion resistance in various applications. This research aims to explore the potential of 2-methylpentane as a key component in developing next-generation anti-corrosion coatings.

2-Methylpentane, an isomer of hexane, has garnered attention due to its unique chemical properties and potential synergistic effects when incorporated into coating formulations. The compound's branched structure and relatively low volatility make it an attractive candidate for improving the durability and performance of protective coatings. As environmental regulations become increasingly stringent, the development of eco-friendly and efficient anti-corrosion solutions has become a priority for the coatings industry.

The evolution of anti-corrosion technology has been driven by the need to address challenges in diverse sectors, including aerospace, automotive, marine, and infrastructure. Traditional coating systems, while effective to some extent, often fall short in providing long-term protection against aggressive environments. This has led to a growing interest in exploring novel materials and formulations that can offer superior corrosion resistance while meeting sustainability criteria.

The primary objective of this research is to investigate the feasibility and effectiveness of 2-methylpentane-based solutions for anti-corrosion coatings. This involves a comprehensive examination of the compound's chemical and physical properties, its interactions with other coating components, and its impact on overall coating performance. Additionally, the study aims to identify optimal formulation strategies that maximize the protective capabilities of 2-methylpentane-based coatings.

Another crucial aspect of this research is to evaluate the potential of 2-methylpentane coatings in addressing specific industry challenges. This includes assessing their resistance to various corrosive agents, their ability to withstand extreme temperatures and mechanical stress, and their long-term stability under different environmental conditions. The research also seeks to explore the possibility of developing multi-functional coatings that combine corrosion protection with other desirable properties, such as self-healing or anti-fouling capabilities.

Furthermore, this study aims to investigate the scalability and cost-effectiveness of 2-methylpentane-based coating solutions. As commercial viability is a critical factor in the adoption of new technologies, the research will consider aspects such as raw material availability, manufacturing processes, and potential market demand. By addressing these factors, the study intends to provide a comprehensive assessment of the technology's potential for widespread implementation in industrial applications.

2-Methylpentane, an isomer of hexane, has garnered attention due to its unique chemical properties and potential synergistic effects when incorporated into coating formulations. The compound's branched structure and relatively low volatility make it an attractive candidate for improving the durability and performance of protective coatings. As environmental regulations become increasingly stringent, the development of eco-friendly and efficient anti-corrosion solutions has become a priority for the coatings industry.

The evolution of anti-corrosion technology has been driven by the need to address challenges in diverse sectors, including aerospace, automotive, marine, and infrastructure. Traditional coating systems, while effective to some extent, often fall short in providing long-term protection against aggressive environments. This has led to a growing interest in exploring novel materials and formulations that can offer superior corrosion resistance while meeting sustainability criteria.

The primary objective of this research is to investigate the feasibility and effectiveness of 2-methylpentane-based solutions for anti-corrosion coatings. This involves a comprehensive examination of the compound's chemical and physical properties, its interactions with other coating components, and its impact on overall coating performance. Additionally, the study aims to identify optimal formulation strategies that maximize the protective capabilities of 2-methylpentane-based coatings.

Another crucial aspect of this research is to evaluate the potential of 2-methylpentane coatings in addressing specific industry challenges. This includes assessing their resistance to various corrosive agents, their ability to withstand extreme temperatures and mechanical stress, and their long-term stability under different environmental conditions. The research also seeks to explore the possibility of developing multi-functional coatings that combine corrosion protection with other desirable properties, such as self-healing or anti-fouling capabilities.

Furthermore, this study aims to investigate the scalability and cost-effectiveness of 2-methylpentane-based coating solutions. As commercial viability is a critical factor in the adoption of new technologies, the research will consider aspects such as raw material availability, manufacturing processes, and potential market demand. By addressing these factors, the study intends to provide a comprehensive assessment of the technology's potential for widespread implementation in industrial applications.

Anti-Corrosion Market Analysis

The global anti-corrosion coatings market has been experiencing steady growth, driven by increasing demand from various industries such as oil and gas, marine, automotive, and construction. The market is expected to continue its upward trajectory due to the rising need for protecting infrastructure and equipment from corrosion-related damage.

In recent years, there has been a growing emphasis on developing environmentally friendly and sustainable anti-corrosion solutions. This trend has led to increased research and development efforts in bio-based and water-based coatings, which are seen as potential alternatives to traditional solvent-based coatings. The shift towards eco-friendly options is partly driven by stringent environmental regulations and growing consumer awareness about the impact of volatile organic compounds (VOCs) on health and the environment.

The Asia-Pacific region has emerged as a key market for anti-corrosion coatings, with China and India leading the growth. Rapid industrialization, infrastructure development, and increasing investments in the manufacturing sector are the primary factors contributing to this regional dominance. North America and Europe also maintain significant market shares, primarily due to the presence of established industries and ongoing maintenance activities in mature markets.

The oil and gas sector remains one of the largest end-users of anti-corrosion coatings, given the harsh operating conditions and the critical need to protect equipment and pipelines from corrosion. However, the marine industry is showing the fastest growth rate in terms of anti-corrosion coating adoption, driven by the expansion of global trade and the need to comply with stringent maritime regulations.

2-Methylpentane-based solutions for anti-corrosion coatings represent an emerging segment within the market. These solutions are gaining attention due to their potential to offer improved performance characteristics compared to traditional coating formulations. The interest in 2-methylpentane stems from its unique chemical properties, which may contribute to enhanced corrosion resistance and durability of coatings.

Market players are increasingly focusing on research and development to create innovative anti-corrosion coating solutions that offer superior protection while meeting environmental standards. Collaborations between coating manufacturers and raw material suppliers are becoming more common, aiming to develop advanced formulations that can address specific industry needs and challenges.

As the demand for long-lasting and efficient anti-corrosion solutions continues to grow, the market is likely to witness further technological advancements and product innovations. The integration of nanotechnology in coating formulations and the development of smart coatings with self-healing properties are among the trends that are expected to shape the future of the anti-corrosion coatings market.

In recent years, there has been a growing emphasis on developing environmentally friendly and sustainable anti-corrosion solutions. This trend has led to increased research and development efforts in bio-based and water-based coatings, which are seen as potential alternatives to traditional solvent-based coatings. The shift towards eco-friendly options is partly driven by stringent environmental regulations and growing consumer awareness about the impact of volatile organic compounds (VOCs) on health and the environment.

The Asia-Pacific region has emerged as a key market for anti-corrosion coatings, with China and India leading the growth. Rapid industrialization, infrastructure development, and increasing investments in the manufacturing sector are the primary factors contributing to this regional dominance. North America and Europe also maintain significant market shares, primarily due to the presence of established industries and ongoing maintenance activities in mature markets.

The oil and gas sector remains one of the largest end-users of anti-corrosion coatings, given the harsh operating conditions and the critical need to protect equipment and pipelines from corrosion. However, the marine industry is showing the fastest growth rate in terms of anti-corrosion coating adoption, driven by the expansion of global trade and the need to comply with stringent maritime regulations.

2-Methylpentane-based solutions for anti-corrosion coatings represent an emerging segment within the market. These solutions are gaining attention due to their potential to offer improved performance characteristics compared to traditional coating formulations. The interest in 2-methylpentane stems from its unique chemical properties, which may contribute to enhanced corrosion resistance and durability of coatings.

Market players are increasingly focusing on research and development to create innovative anti-corrosion coating solutions that offer superior protection while meeting environmental standards. Collaborations between coating manufacturers and raw material suppliers are becoming more common, aiming to develop advanced formulations that can address specific industry needs and challenges.

As the demand for long-lasting and efficient anti-corrosion solutions continues to grow, the market is likely to witness further technological advancements and product innovations. The integration of nanotechnology in coating formulations and the development of smart coatings with self-healing properties are among the trends that are expected to shape the future of the anti-corrosion coatings market.

Current Challenges in Anti-Corrosion Technology

The field of anti-corrosion technology faces several significant challenges that hinder the development of more effective and sustainable solutions. One of the primary issues is the persistent trade-off between corrosion protection efficacy and environmental impact. Traditional anti-corrosion methods often rely on toxic substances, such as chromates and heavy metals, which pose serious environmental and health risks. The industry is under increasing pressure to develop eco-friendly alternatives that maintain or exceed the performance of conventional coatings.

Another major challenge is the complexity of corrosion processes in diverse environments. Different materials and structures are exposed to varying conditions, including temperature fluctuations, pH levels, and mechanical stresses. This complexity makes it difficult to develop universal anti-corrosion solutions, necessitating specialized approaches for specific applications. The need for tailored solutions increases research and development costs and complicates large-scale implementation.

The longevity and durability of anti-corrosion coatings remain critical concerns. Many current solutions provide adequate short-term protection but fail to maintain their effectiveness over extended periods, especially in harsh environments. This limitation leads to frequent maintenance and reapplication, increasing overall costs and resource consumption. Developing coatings with enhanced long-term stability and self-healing properties is a key focus area for researchers.

Nanotechnology offers promising avenues for anti-corrosion solutions, but scaling up these technologies for industrial applications presents significant challenges. Issues such as uniform dispersion of nanoparticles, adhesion to substrates, and cost-effective production methods need to be addressed before widespread adoption can occur. Additionally, the potential long-term environmental and health impacts of nanomaterials in anti-corrosion applications require thorough investigation.

The integration of smart and responsive anti-corrosion systems is another frontier facing technical hurdles. These systems aim to detect and respond to corrosion in real-time, but challenges in sensor technology, data processing, and actuation mechanisms limit their practical implementation. Developing reliable, cost-effective smart coatings that can function autonomously in diverse environments remains a significant challenge for the industry.

In the context of 2-methylpentane-based solutions for anti-corrosion coatings, specific challenges include optimizing the compound's interaction with other coating components, ensuring compatibility with a wide range of substrates, and maintaining coating integrity under various environmental conditions. The volatility of 2-methylpentane also presents challenges in formulation and application processes, requiring innovative approaches to stabilize the compound within the coating matrix.

Another major challenge is the complexity of corrosion processes in diverse environments. Different materials and structures are exposed to varying conditions, including temperature fluctuations, pH levels, and mechanical stresses. This complexity makes it difficult to develop universal anti-corrosion solutions, necessitating specialized approaches for specific applications. The need for tailored solutions increases research and development costs and complicates large-scale implementation.

The longevity and durability of anti-corrosion coatings remain critical concerns. Many current solutions provide adequate short-term protection but fail to maintain their effectiveness over extended periods, especially in harsh environments. This limitation leads to frequent maintenance and reapplication, increasing overall costs and resource consumption. Developing coatings with enhanced long-term stability and self-healing properties is a key focus area for researchers.

Nanotechnology offers promising avenues for anti-corrosion solutions, but scaling up these technologies for industrial applications presents significant challenges. Issues such as uniform dispersion of nanoparticles, adhesion to substrates, and cost-effective production methods need to be addressed before widespread adoption can occur. Additionally, the potential long-term environmental and health impacts of nanomaterials in anti-corrosion applications require thorough investigation.

The integration of smart and responsive anti-corrosion systems is another frontier facing technical hurdles. These systems aim to detect and respond to corrosion in real-time, but challenges in sensor technology, data processing, and actuation mechanisms limit their practical implementation. Developing reliable, cost-effective smart coatings that can function autonomously in diverse environments remains a significant challenge for the industry.

In the context of 2-methylpentane-based solutions for anti-corrosion coatings, specific challenges include optimizing the compound's interaction with other coating components, ensuring compatibility with a wide range of substrates, and maintaining coating integrity under various environmental conditions. The volatility of 2-methylpentane also presents challenges in formulation and application processes, requiring innovative approaches to stabilize the compound within the coating matrix.

Existing 2-Methylpentane-Based Coating Solutions

01 2-Methylpentane as a base for anti-corrosion solutions

2-Methylpentane is used as a base solvent in anti-corrosion formulations. Its chemical properties make it suitable for dissolving and carrying corrosion inhibitors, while also providing a protective barrier on metal surfaces. This hydrocarbon solvent offers good stability and compatibility with various additives used in anti-corrosion products.- 2-Methylpentane as a base for anti-corrosion solutions: 2-Methylpentane is used as a primary component in formulating anti-corrosion solutions. Its unique chemical properties make it an effective base for creating protective coatings that prevent metal degradation. These solutions can be applied to various surfaces to enhance their resistance to corrosive environments.

- Additives to enhance anti-corrosion properties: Various additives are incorporated into 2-methylpentane-based solutions to improve their anti-corrosion effectiveness. These may include inhibitors, stabilizers, and other compounds that work synergistically with 2-methylpentane to provide superior protection against corrosion in different industrial applications.

- Application methods for 2-methylpentane anti-corrosion solutions: Specific techniques and equipment are developed for applying 2-methylpentane-based anti-corrosion solutions. These methods ensure optimal coverage and adhesion to the substrate, maximizing the protective properties of the solution. The application process may involve spraying, dipping, or brushing, depending on the specific requirements of the surface being treated.

- Environmental and safety considerations: The development of 2-methylpentane-based anti-corrosion solutions takes into account environmental and safety factors. Formulations are designed to minimize volatile organic compound (VOC) emissions and reduce potential health hazards associated with traditional corrosion inhibitors. This approach aligns with increasing regulatory requirements and industry sustainability goals.

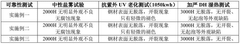

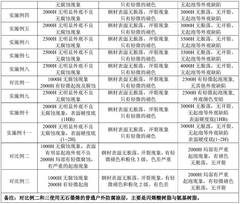

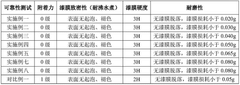

- Performance testing and quality control: Rigorous testing protocols are established to evaluate the effectiveness of 2-methylpentane-based anti-corrosion solutions. These tests assess factors such as corrosion resistance, durability, and long-term performance under various environmental conditions. Quality control measures ensure consistency in production and application of these solutions across different industrial sectors.

02 Corrosion inhibitor additives for 2-Methylpentane solutions

Various corrosion inhibitors are added to 2-Methylpentane-based solutions to enhance their anti-corrosion properties. These additives can include organic compounds, inorganic salts, and metal complexes that form protective films on metal surfaces or neutralize corrosive agents. The combination of these inhibitors with 2-Methylpentane creates effective anti-corrosion formulations for different industrial applications.Expand Specific Solutions03 Application methods for 2-Methylpentane anti-corrosion solutions

The application of 2-Methylpentane-based anti-corrosion solutions can be achieved through various methods such as spraying, dipping, or brushing. These techniques ensure uniform coverage of the metal surface, allowing the solution to penetrate and protect hard-to-reach areas. The volatile nature of 2-Methylpentane facilitates quick drying and formation of a protective layer.Expand Specific Solutions04 Environmental and safety considerations of 2-Methylpentane solutions

When formulating anti-corrosion solutions with 2-Methylpentane, environmental and safety aspects are considered. Efforts are made to reduce volatile organic compound (VOC) emissions and improve worker safety. This includes developing low-VOC formulations, incorporating safer additives, and implementing proper handling and application procedures for these solutions.Expand Specific Solutions05 Performance testing of 2-Methylpentane anti-corrosion solutions

To ensure the effectiveness of 2-Methylpentane-based anti-corrosion solutions, various performance tests are conducted. These may include salt spray tests, humidity chamber tests, and electrochemical impedance spectroscopy. Such tests evaluate the durability, protective properties, and long-term performance of the anti-corrosion coatings under different environmental conditions.Expand Specific Solutions

Key Players in Anti-Corrosion Coating Industry

The research on 2-Methylpentane-based solutions for anti-corrosion coatings is in a developing stage, with the market showing potential for growth. The global anti-corrosion coatings market is expanding, driven by increasing industrial applications and infrastructure development. Companies like BASF Coatings GmbH, Sherwin-Williams Coatings Deutschland GmbH, and Henkel AG & Co. KGaA are at the forefront of this technology, investing in R&D to improve coating performance and environmental sustainability. While 2-Methylpentane-based solutions are not yet widely commercialized, ongoing research by academic institutions such as Zhejiang University and Texas A&M University, in collaboration with industry players, indicates a growing interest in this specific approach to anti-corrosion coatings.

Covestro Deutschland AG

Technical Solution: Covestro has developed a 2-methylpentane-based anti-corrosion coating solution that utilizes their proprietary polyurethane technology. The coating incorporates 2-methylpentane as a key solvent, which enhances the coating's ability to form a protective barrier against corrosive elements. The formulation includes specially designed isocyanates and polyols that react to create a durable, flexible film[1]. This coating system also incorporates nano-sized corrosion inhibitors, which are uniformly dispersed throughout the matrix, providing long-term protection even in harsh environments[3]. The 2-methylpentane solvent allows for improved wetting and adhesion to metal substrates, resulting in superior corrosion resistance compared to traditional coating systems[5].

Strengths: Excellent adhesion to metal substrates, long-lasting protection, and environmentally friendly formulation. Weaknesses: Potentially higher cost compared to conventional coatings and may require specialized application equipment.

BASF Coatings GmbH

Technical Solution: BASF Coatings has engineered a novel 2-methylpentane-based anti-corrosion coating solution that leverages their expertise in polymer chemistry and nanotechnology. The coating system utilizes a unique blend of epoxy and acrylic resins dissolved in 2-methylpentane, which serves as both a solvent and a performance enhancer[2]. The formulation incorporates advanced nano-scale corrosion inhibitors, such as cerium compounds, which provide active protection by forming a self-healing barrier when exposed to corrosive agents[4]. BASF's coating also features a proprietary surface modification technology that improves the coating's adhesion to various metal substrates, including steel, aluminum, and galvanized surfaces[6]. The use of 2-methylpentane as a primary solvent contributes to the coating's rapid drying time and low VOC emissions, making it an environmentally friendly option for industrial applications[8].

Strengths: Versatile application on multiple metal substrates, self-healing properties, and low environmental impact. Weaknesses: May have limited resistance to extreme chemical exposure and potentially higher initial cost.

Core Innovations in 2-Methylpentane Coatings

Anti-corrosion coating composition having high-adhesion and fast curing properties, and production method thereof

PatentActiveKR1020170024759A

Innovation

- A composition comprising an epoxy intermediate modified with a polyamide elastomer, polythiol, and nano-copolymer, combined with an amine curing agent, epoxy reactive diluent, and polyacrylate, to enhance adhesion and accelerate curing to less than 8 hours at temperatures ranging from -10 to 50°C.

Anti-corrosion profile, frame, solar cell module, support, and photovoltaic system

PatentWO2024198551A1

Innovation

- It adopts a double-layer structure of alloy coating and graphene anti-corrosion coating. The coating includes a base coating and a top coating, both containing at least 5% of 2 to 5 layers of graphene. It is cured by spraying and high-temperature baking to form an optimized thickness. Anti-corrosion coating to improve anti-corrosion performance and adhesion.

Environmental Impact Assessment

The environmental impact assessment of 2-methylpentane-based solutions for anti-corrosion coatings is a critical aspect of their development and implementation. These coatings, while effective in protecting surfaces from corrosion, may have significant environmental implications that must be carefully evaluated.

One of the primary concerns is the potential release of volatile organic compounds (VOCs) during the application and curing process of these coatings. 2-Methylpentane, being a hydrocarbon solvent, can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. This can have adverse effects on air quality and human health, particularly in urban areas where VOC emissions are already a significant issue.

The production and disposal of 2-methylpentane-based coatings also warrant consideration. The manufacturing process may involve energy-intensive steps and the use of other potentially hazardous chemicals, contributing to carbon emissions and resource depletion. Proper disposal of unused coatings and coating-related waste is essential to prevent soil and water contamination.

Water pollution is another potential concern, especially if these coatings are used in marine or freshwater environments. The leaching of coating components into aquatic ecosystems could have detrimental effects on marine life and water quality. Long-term studies are needed to assess the persistence and bioaccumulation potential of these compounds in aquatic environments.

On the positive side, the enhanced corrosion protection offered by these coatings can lead to extended lifespans of metal structures and equipment. This longevity can reduce the need for frequent replacements, potentially lowering overall resource consumption and waste generation in the long term.

The environmental impact of these coatings also extends to their role in energy efficiency. By protecting metal surfaces from corrosion, they can maintain the operational efficiency of various industrial equipment and infrastructure, potentially leading to reduced energy consumption over time.

Efforts to mitigate the environmental impact of 2-methylpentane-based anti-corrosion coatings are ongoing. Research into low-VOC and water-based formulations is progressing, aiming to reduce air pollution while maintaining coating performance. Additionally, the development of more environmentally friendly application techniques and improved waste management practices are areas of active investigation.

In conclusion, while 2-methylpentane-based anti-corrosion coatings offer significant benefits in terms of surface protection, their environmental impact must be carefully managed. Balancing the need for effective corrosion protection with environmental sustainability remains a key challenge in this field, driving ongoing research and innovation in coating technologies.

One of the primary concerns is the potential release of volatile organic compounds (VOCs) during the application and curing process of these coatings. 2-Methylpentane, being a hydrocarbon solvent, can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. This can have adverse effects on air quality and human health, particularly in urban areas where VOC emissions are already a significant issue.

The production and disposal of 2-methylpentane-based coatings also warrant consideration. The manufacturing process may involve energy-intensive steps and the use of other potentially hazardous chemicals, contributing to carbon emissions and resource depletion. Proper disposal of unused coatings and coating-related waste is essential to prevent soil and water contamination.

Water pollution is another potential concern, especially if these coatings are used in marine or freshwater environments. The leaching of coating components into aquatic ecosystems could have detrimental effects on marine life and water quality. Long-term studies are needed to assess the persistence and bioaccumulation potential of these compounds in aquatic environments.

On the positive side, the enhanced corrosion protection offered by these coatings can lead to extended lifespans of metal structures and equipment. This longevity can reduce the need for frequent replacements, potentially lowering overall resource consumption and waste generation in the long term.

The environmental impact of these coatings also extends to their role in energy efficiency. By protecting metal surfaces from corrosion, they can maintain the operational efficiency of various industrial equipment and infrastructure, potentially leading to reduced energy consumption over time.

Efforts to mitigate the environmental impact of 2-methylpentane-based anti-corrosion coatings are ongoing. Research into low-VOC and water-based formulations is progressing, aiming to reduce air pollution while maintaining coating performance. Additionally, the development of more environmentally friendly application techniques and improved waste management practices are areas of active investigation.

In conclusion, while 2-methylpentane-based anti-corrosion coatings offer significant benefits in terms of surface protection, their environmental impact must be carefully managed. Balancing the need for effective corrosion protection with environmental sustainability remains a key challenge in this field, driving ongoing research and innovation in coating technologies.

Regulatory Compliance for Chemical Coatings

Regulatory compliance is a critical aspect of developing and marketing chemical coatings, including those based on 2-methylpentane for anti-corrosion applications. The regulatory landscape for such coatings is complex and varies across different regions and countries.

In the United States, the Environmental Protection Agency (EPA) regulates chemical coatings under the Toxic Substances Control Act (TSCA). Manufacturers must comply with reporting, record-keeping, and testing requirements for new and existing chemicals. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace safety related to the use of chemical coatings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that impacts the development and use of chemical coatings. Under REACH, companies must register chemicals they manufacture or import in quantities over one tonne per year. This includes providing detailed information on the properties, hazards, and safe use of the substances.

For 2-methylpentane-based anti-corrosion coatings, specific attention must be paid to volatile organic compound (VOC) regulations. Many jurisdictions have strict limits on VOC content in coatings to reduce air pollution. The California Air Resources Board (CARB) and the South Coast Air Quality Management District (SCAQMD) in the United States are known for their particularly stringent VOC regulations.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manufacturers of 2-methylpentane-based coatings must ensure their products are properly classified, labeled, and accompanied by safety data sheets (SDS) in accordance with GHS guidelines.

In addition to environmental and safety regulations, coatings used in specific industries may face additional regulatory scrutiny. For instance, coatings used in food packaging or medical devices must comply with FDA regulations in the United States or similar agencies in other countries.

Compliance with these regulations requires ongoing monitoring of regulatory changes, thorough documentation, and often significant investment in testing and certification. Companies developing 2-methylpentane-based anti-corrosion coatings must factor these regulatory requirements into their research and development processes, as well as their overall business strategy.

In the United States, the Environmental Protection Agency (EPA) regulates chemical coatings under the Toxic Substances Control Act (TSCA). Manufacturers must comply with reporting, record-keeping, and testing requirements for new and existing chemicals. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace safety related to the use of chemical coatings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another significant framework that impacts the development and use of chemical coatings. Under REACH, companies must register chemicals they manufacture or import in quantities over one tonne per year. This includes providing detailed information on the properties, hazards, and safe use of the substances.

For 2-methylpentane-based anti-corrosion coatings, specific attention must be paid to volatile organic compound (VOC) regulations. Many jurisdictions have strict limits on VOC content in coatings to reduce air pollution. The California Air Resources Board (CARB) and the South Coast Air Quality Management District (SCAQMD) in the United States are known for their particularly stringent VOC regulations.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manufacturers of 2-methylpentane-based coatings must ensure their products are properly classified, labeled, and accompanied by safety data sheets (SDS) in accordance with GHS guidelines.

In addition to environmental and safety regulations, coatings used in specific industries may face additional regulatory scrutiny. For instance, coatings used in food packaging or medical devices must comply with FDA regulations in the United States or similar agencies in other countries.

Compliance with these regulations requires ongoing monitoring of regulatory changes, thorough documentation, and often significant investment in testing and certification. Companies developing 2-methylpentane-based anti-corrosion coatings must factor these regulatory requirements into their research and development processes, as well as their overall business strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!