Alkyls in Cutting‑Edge Chemical Sensor Technologies

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Sensor Tech Background and Objectives

Alkyl-based chemical sensors have emerged as a critical technology in the field of advanced sensing systems. The evolution of these sensors can be traced back to the early 1990s when researchers first began exploring the potential of alkyl compounds in detecting various chemical substances. Over the past three decades, significant advancements have been made in improving the sensitivity, selectivity, and stability of alkyl sensors, leading to their widespread adoption in numerous applications.

The technological trajectory of alkyl sensors has been driven by the increasing demand for rapid, accurate, and cost-effective detection methods in industries such as environmental monitoring, food safety, and healthcare. As global concerns about air and water pollution have grown, so too has the need for sophisticated sensing technologies capable of detecting trace amounts of harmful chemicals. This has spurred continuous innovation in alkyl sensor design and functionality.

One of the key trends in alkyl sensor technology has been the miniaturization of devices, enabling the development of portable and wearable sensors. This trend aligns with the broader movement towards Internet of Things (IoT) and smart sensing systems, where real-time data collection and analysis are paramount. Additionally, there has been a push towards developing multi-analyte sensors capable of detecting multiple chemical species simultaneously, enhancing the versatility and efficiency of sensing platforms.

The integration of nanotechnology with alkyl sensors has opened up new avenues for enhancing sensor performance. Nanostructured materials, such as carbon nanotubes and metal nanoparticles, have been incorporated into alkyl-based sensing elements to improve sensitivity and reduce response times. This convergence of nanotechnology and chemical sensing represents a significant frontier in the field.

Looking ahead, the objectives for alkyl sensor technology are multifaceted. Researchers aim to further improve the sensitivity of these sensors, pushing the limits of detection to even lower concentrations. There is also a focus on enhancing the selectivity of alkyl sensors to minimize false positives and ensure accurate readings in complex chemical environments. Durability and long-term stability remain key goals, particularly for sensors deployed in harsh or remote environments.

Another important objective is the development of "smart" alkyl sensors that can adapt to changing environmental conditions and self-calibrate, reducing the need for frequent maintenance. The integration of artificial intelligence and machine learning algorithms with alkyl sensor systems is expected to play a crucial role in achieving this goal, enabling more sophisticated data analysis and predictive capabilities.

The technological trajectory of alkyl sensors has been driven by the increasing demand for rapid, accurate, and cost-effective detection methods in industries such as environmental monitoring, food safety, and healthcare. As global concerns about air and water pollution have grown, so too has the need for sophisticated sensing technologies capable of detecting trace amounts of harmful chemicals. This has spurred continuous innovation in alkyl sensor design and functionality.

One of the key trends in alkyl sensor technology has been the miniaturization of devices, enabling the development of portable and wearable sensors. This trend aligns with the broader movement towards Internet of Things (IoT) and smart sensing systems, where real-time data collection and analysis are paramount. Additionally, there has been a push towards developing multi-analyte sensors capable of detecting multiple chemical species simultaneously, enhancing the versatility and efficiency of sensing platforms.

The integration of nanotechnology with alkyl sensors has opened up new avenues for enhancing sensor performance. Nanostructured materials, such as carbon nanotubes and metal nanoparticles, have been incorporated into alkyl-based sensing elements to improve sensitivity and reduce response times. This convergence of nanotechnology and chemical sensing represents a significant frontier in the field.

Looking ahead, the objectives for alkyl sensor technology are multifaceted. Researchers aim to further improve the sensitivity of these sensors, pushing the limits of detection to even lower concentrations. There is also a focus on enhancing the selectivity of alkyl sensors to minimize false positives and ensure accurate readings in complex chemical environments. Durability and long-term stability remain key goals, particularly for sensors deployed in harsh or remote environments.

Another important objective is the development of "smart" alkyl sensors that can adapt to changing environmental conditions and self-calibrate, reducing the need for frequent maintenance. The integration of artificial intelligence and machine learning algorithms with alkyl sensor systems is expected to play a crucial role in achieving this goal, enabling more sophisticated data analysis and predictive capabilities.

Market Analysis for Alkyl Detection Solutions

The market for alkyl detection solutions has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations across various industries. The global chemical sensor market, which includes alkyl detection technologies, is projected to reach substantial market value by 2025, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising demand for real-time monitoring and detection of hazardous chemicals in industrial processes, environmental monitoring, and safety applications.

The oil and gas industry remains a major contributor to the demand for alkyl detection solutions, as these compounds are crucial indicators of hydrocarbon presence and potential leaks. Additionally, the petrochemical sector's expansion in emerging economies has further bolstered market growth. Environmental monitoring agencies and regulatory bodies have also become significant consumers of alkyl detection technologies, driven by the need to enforce stricter air and water quality standards.

In the automotive industry, the push for reduced emissions and improved fuel efficiency has led to increased adoption of alkyl sensors in engine management systems. This trend is expected to continue as automotive manufacturers strive to meet increasingly stringent environmental regulations. The pharmaceutical and food industries have also shown growing interest in alkyl detection solutions for quality control and safety assurance purposes.

Geographically, North America and Europe currently dominate the market for alkyl detection technologies, owing to their advanced industrial infrastructure and stringent regulatory frameworks. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives to improve air and water quality.

The market landscape is characterized by a mix of established players and innovative start-ups. Key market players are focusing on developing more sensitive, selective, and cost-effective alkyl detection solutions to gain a competitive edge. Miniaturization and integration of sensors with IoT platforms are emerging trends, enabling real-time monitoring and data analytics capabilities. These advancements are expected to open up new application areas and drive further market expansion.

Despite the positive outlook, challenges such as high initial costs, technical complexities in detecting specific alkyl compounds, and the need for regular calibration and maintenance of sensors may hinder market growth to some extent. However, ongoing research and development efforts are addressing these challenges, paving the way for more robust and user-friendly alkyl detection solutions in the future.

The oil and gas industry remains a major contributor to the demand for alkyl detection solutions, as these compounds are crucial indicators of hydrocarbon presence and potential leaks. Additionally, the petrochemical sector's expansion in emerging economies has further bolstered market growth. Environmental monitoring agencies and regulatory bodies have also become significant consumers of alkyl detection technologies, driven by the need to enforce stricter air and water quality standards.

In the automotive industry, the push for reduced emissions and improved fuel efficiency has led to increased adoption of alkyl sensors in engine management systems. This trend is expected to continue as automotive manufacturers strive to meet increasingly stringent environmental regulations. The pharmaceutical and food industries have also shown growing interest in alkyl detection solutions for quality control and safety assurance purposes.

Geographically, North America and Europe currently dominate the market for alkyl detection technologies, owing to their advanced industrial infrastructure and stringent regulatory frameworks. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives to improve air and water quality.

The market landscape is characterized by a mix of established players and innovative start-ups. Key market players are focusing on developing more sensitive, selective, and cost-effective alkyl detection solutions to gain a competitive edge. Miniaturization and integration of sensors with IoT platforms are emerging trends, enabling real-time monitoring and data analytics capabilities. These advancements are expected to open up new application areas and drive further market expansion.

Despite the positive outlook, challenges such as high initial costs, technical complexities in detecting specific alkyl compounds, and the need for regular calibration and maintenance of sensors may hinder market growth to some extent. However, ongoing research and development efforts are addressing these challenges, paving the way for more robust and user-friendly alkyl detection solutions in the future.

Current Challenges in Alkyl Sensing Technologies

Despite significant advancements in chemical sensor technologies, the detection and analysis of alkyls continue to present several challenges. One of the primary obstacles is the low reactivity and volatility of many alkyl compounds, making them difficult to detect using traditional sensing methods. This is particularly problematic for longer-chain alkyls, which often require more sophisticated techniques for accurate identification and quantification.

Selectivity remains a critical issue in alkyl sensing. Many current sensors struggle to differentiate between structurally similar alkyl groups, leading to potential false positives or misidentifications. This challenge is exacerbated in complex mixtures or real-world environmental samples where multiple alkyl species may be present simultaneously.

Sensitivity is another area of concern, especially for trace-level detection of alkyls in environmental monitoring or industrial applications. Achieving the required parts-per-billion or even parts-per-trillion detection limits for certain alkyl compounds demands highly sensitive and precise instrumentation, which can be costly and complex to operate.

The stability and longevity of alkyl sensors pose additional challenges. Many sensing materials degrade or lose sensitivity over time when exposed to alkyl compounds, necessitating frequent calibration or replacement. This issue is particularly pronounced in harsh industrial environments or when dealing with reactive alkyl species.

Miniaturization and portability of alkyl sensing technologies present ongoing difficulties. While there is a growing demand for field-deployable and real-time monitoring systems, shrinking sensor sizes often comes at the cost of reduced sensitivity or selectivity. Balancing these factors while maintaining robust performance remains a significant challenge for researchers and engineers.

The development of cost-effective sensing solutions for widespread alkyl detection is also a persistent challenge. Many current high-performance alkyl sensors rely on expensive materials or complex fabrication processes, limiting their adoption in large-scale applications or resource-constrained settings.

Lastly, the integration of alkyl sensors into multi-analyte detection systems presents both opportunities and challenges. While there is a growing need for comprehensive chemical analysis platforms, incorporating alkyl sensing capabilities alongside other detection modalities often requires careful consideration of potential interferences and cross-sensitivities.

Selectivity remains a critical issue in alkyl sensing. Many current sensors struggle to differentiate between structurally similar alkyl groups, leading to potential false positives or misidentifications. This challenge is exacerbated in complex mixtures or real-world environmental samples where multiple alkyl species may be present simultaneously.

Sensitivity is another area of concern, especially for trace-level detection of alkyls in environmental monitoring or industrial applications. Achieving the required parts-per-billion or even parts-per-trillion detection limits for certain alkyl compounds demands highly sensitive and precise instrumentation, which can be costly and complex to operate.

The stability and longevity of alkyl sensors pose additional challenges. Many sensing materials degrade or lose sensitivity over time when exposed to alkyl compounds, necessitating frequent calibration or replacement. This issue is particularly pronounced in harsh industrial environments or when dealing with reactive alkyl species.

Miniaturization and portability of alkyl sensing technologies present ongoing difficulties. While there is a growing demand for field-deployable and real-time monitoring systems, shrinking sensor sizes often comes at the cost of reduced sensitivity or selectivity. Balancing these factors while maintaining robust performance remains a significant challenge for researchers and engineers.

The development of cost-effective sensing solutions for widespread alkyl detection is also a persistent challenge. Many current high-performance alkyl sensors rely on expensive materials or complex fabrication processes, limiting their adoption in large-scale applications or resource-constrained settings.

Lastly, the integration of alkyl sensors into multi-analyte detection systems presents both opportunities and challenges. While there is a growing need for comprehensive chemical analysis platforms, incorporating alkyl sensing capabilities alongside other detection modalities often requires careful consideration of potential interferences and cross-sensitivities.

Existing Alkyl Detection Methodologies

01 Alkyl compounds in organic synthesis

Alkyl compounds play a crucial role in organic synthesis, serving as important intermediates and building blocks for various chemical reactions. They are used in the production of pharmaceuticals, polymers, and other industrial chemicals. The versatility of alkyl groups allows for the creation of diverse molecular structures and functionalities.- Synthesis of alkyl compounds: Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.

- Alkyl-based polymers and copolymers: The development and production of polymers and copolymers containing alkyl groups are discussed. These materials have applications in various industries, including plastics, adhesives, and coatings, due to their unique properties derived from the alkyl components.

- Alkyl compounds in catalysis: Alkyl compounds play important roles in catalytic processes, either as catalysts themselves or as components of catalyst systems. These applications are found in various chemical reactions, including polymerization and organic synthesis.

- Alkyl derivatives in pharmaceutical applications: The use of alkyl derivatives in pharmaceutical compounds is explored, including their role in drug delivery systems, as active pharmaceutical ingredients, or as intermediates in the synthesis of medicinal compounds.

- Industrial applications of alkyl compounds: Alkyl compounds find widespread use in various industrial applications, including as solvents, lubricants, surfactants, and additives in fuel and oil formulations. Their properties make them valuable in diverse sectors such as petrochemicals, textiles, and agriculture.

02 Alkyl halides and their applications

Alkyl halides are a significant class of alkyl compounds with wide-ranging applications. They are used as alkylating agents, solvents, and precursors in the synthesis of other organic compounds. The reactivity of alkyl halides makes them valuable in various industrial processes and chemical transformations.Expand Specific Solutions03 Alkyl groups in polymer chemistry

Alkyl groups are extensively used in polymer chemistry for modifying the properties of polymeric materials. They can be incorporated into polymer chains or used as side groups to alter characteristics such as solubility, thermal stability, and mechanical properties. This versatility makes alkyl-containing polymers valuable in various industries.Expand Specific Solutions04 Alkyl-substituted aromatic compounds

Alkyl-substituted aromatic compounds are an important class of chemicals with applications in pharmaceuticals, fragrances, and materials science. The alkyl substituents can modify the electronic and steric properties of aromatic rings, leading to compounds with unique characteristics and reactivity patterns.Expand Specific Solutions05 Alkyl metal compounds and catalysis

Alkyl metal compounds play a significant role in catalysis and organometallic chemistry. They are used as catalysts or catalyst precursors in various industrial processes, including polymerization reactions and organic syntheses. The nature of the alkyl group and the metal center can be tailored to achieve specific catalytic activities and selectivities.Expand Specific Solutions

Key Players in Chemical Sensor Industry

The research on alkyls in cutting-edge chemical sensor technologies is in a dynamic growth phase, with a rapidly expanding market and increasing technological maturity. The global chemical sensor market is projected to reach significant value in the coming years, driven by advancements in alkyl-based sensing technologies. Companies like Abbott Diabetes Care, Roche Diabetes Care, and Medtronic MiniMed are at the forefront, developing innovative glucose monitoring systems incorporating alkyl-based sensors. Academic institutions such as Arizona State University and Tufts University are contributing to fundamental research, while industry leaders like DuPont and Schlumberger are exploring applications in diverse sectors, indicating a broad and competitive landscape with potential for further expansion and technological breakthroughs.

F. Hoffmann-La Roche Ltd.

Technical Solution: Roche has developed advanced alkyl-based chemical sensors for continuous glucose monitoring. Their technology utilizes alkyl-modified enzymes to enhance sensor stability and longevity. The sensors employ a novel alkyl-chain tethering approach to immobilize glucose oxidase on electrode surfaces, resulting in improved sensor performance and reduced signal drift[1]. This method allows for real-time, accurate glucose measurements in interstitial fluid, with extended sensor lifetimes of up to 14 days[2]. Roche's sensors also incorporate alkyl-functionalized nanomaterials to enhance electron transfer and increase sensitivity, enabling detection of glucose at physiologically relevant concentrations with high precision[3].

Strengths: Extended sensor lifetime, improved stability, and high precision in glucose detection. Weaknesses: Potential for biofouling in long-term use and complexity in manufacturing process.

Medtronic MiniMed, Inc.

Technical Solution: Medtronic MiniMed has pioneered the use of alkyl-based chemical sensors in their closed-loop insulin delivery systems. Their technology incorporates alkyl-modified glucose oxidase enzymes coupled with advanced electrochemical detection methods. The sensors utilize a proprietary alkyl-chain spacer technology to optimize enzyme orientation on the electrode surface, enhancing glucose binding efficiency and sensor sensitivity[4]. This approach has enabled the development of miniaturized sensors suitable for long-term implantation, with demonstrated stability for up to six months in vivo[5]. Medtronic's sensors also feature alkyl-functionalized protective membranes that mitigate interference from other electroactive species in bodily fluids, improving sensor selectivity and accuracy[6].

Strengths: Long-term implantable sensors, high selectivity, and integration with insulin delivery systems. Weaknesses: Invasive nature of implantation and potential for foreign body response.

Innovative Alkyl Sensing Mechanisms

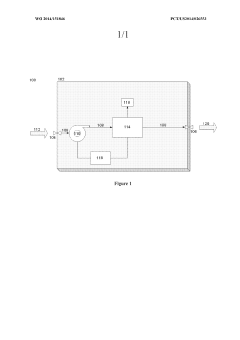

An organic molecule sensor for detecting, differentiating, and measuring organic compounds

PatentWO2014151846A1

Innovation

- A compact sensor assembly using a surface acoustic wave (SAW) sensor array or chemiresistor array, or a combination of both, with thiol layers to detect and quantify hydrocarbons in gases and liquids, capable of differentiating between various organic compounds and operating in harsh conditions, including high temperatures and pressures.

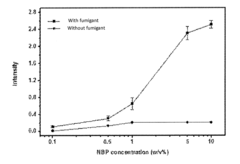

Colorimetric sensors for alkylating agents

PatentActiveUS20160077070A1

Innovation

- Development of sensors using a sensor moiety with a specific formula that detects alkylating agents through changes in light absorbance, which can be easily manufactured and used without additional chemicals or elevated temperatures, and can be integrated into wearable devices for rapid detection.

Environmental Impact of Alkyl Sensors

The environmental impact of alkyl sensors is a critical consideration in the development and deployment of cutting-edge chemical sensor technologies. These sensors, which utilize alkyl compounds for detection and measurement, have both positive and negative implications for the environment.

On the positive side, alkyl sensors contribute significantly to environmental monitoring and protection efforts. They enable the detection of various pollutants and contaminants in air, water, and soil with high sensitivity and specificity. This capability allows for early warning systems and more effective environmental management strategies. For instance, alkyl-based sensors can detect trace amounts of volatile organic compounds (VOCs) in industrial emissions, helping to reduce air pollution and improve air quality in urban areas.

However, the production and disposal of alkyl sensors raise environmental concerns. The manufacturing process of these sensors often involves the use of hazardous chemicals and energy-intensive procedures. The synthesis of alkyl compounds and other sensor components may result in the generation of toxic by-products and waste materials. Proper handling and disposal of these substances are crucial to prevent environmental contamination.

Furthermore, the end-of-life management of alkyl sensors presents challenges. Many of these devices contain electronic components and specialized materials that are not easily recyclable. Improper disposal can lead to the release of harmful substances into the environment, potentially causing soil and water pollution. This issue is particularly relevant as the demand for chemical sensors continues to grow across various industries.

The energy consumption of alkyl sensors during operation is another environmental factor to consider. While individual sensors may have low power requirements, the cumulative energy demand of large-scale sensor networks can be substantial. This energy use contributes to carbon emissions if the power source is not from renewable energy.

Efforts are being made to address these environmental concerns. Research is ongoing to develop more environmentally friendly manufacturing processes for alkyl sensors, including the use of green chemistry principles and sustainable materials. Additionally, there is a growing focus on designing sensors with improved energy efficiency and longer lifespans to reduce their overall environmental footprint.

The potential for bioaccumulation of alkyl compounds used in sensors is also under scrutiny. Some alkyl groups, particularly those with longer carbon chains, can persist in the environment and accumulate in living organisms. This persistence raises concerns about long-term ecological impacts and potential effects on food chains.

In conclusion, while alkyl sensors play a crucial role in environmental monitoring and protection, their own environmental impact must be carefully managed. Balancing the benefits of these advanced sensing technologies with their potential environmental costs is essential for sustainable development in the field of chemical sensors.

On the positive side, alkyl sensors contribute significantly to environmental monitoring and protection efforts. They enable the detection of various pollutants and contaminants in air, water, and soil with high sensitivity and specificity. This capability allows for early warning systems and more effective environmental management strategies. For instance, alkyl-based sensors can detect trace amounts of volatile organic compounds (VOCs) in industrial emissions, helping to reduce air pollution and improve air quality in urban areas.

However, the production and disposal of alkyl sensors raise environmental concerns. The manufacturing process of these sensors often involves the use of hazardous chemicals and energy-intensive procedures. The synthesis of alkyl compounds and other sensor components may result in the generation of toxic by-products and waste materials. Proper handling and disposal of these substances are crucial to prevent environmental contamination.

Furthermore, the end-of-life management of alkyl sensors presents challenges. Many of these devices contain electronic components and specialized materials that are not easily recyclable. Improper disposal can lead to the release of harmful substances into the environment, potentially causing soil and water pollution. This issue is particularly relevant as the demand for chemical sensors continues to grow across various industries.

The energy consumption of alkyl sensors during operation is another environmental factor to consider. While individual sensors may have low power requirements, the cumulative energy demand of large-scale sensor networks can be substantial. This energy use contributes to carbon emissions if the power source is not from renewable energy.

Efforts are being made to address these environmental concerns. Research is ongoing to develop more environmentally friendly manufacturing processes for alkyl sensors, including the use of green chemistry principles and sustainable materials. Additionally, there is a growing focus on designing sensors with improved energy efficiency and longer lifespans to reduce their overall environmental footprint.

The potential for bioaccumulation of alkyl compounds used in sensors is also under scrutiny. Some alkyl groups, particularly those with longer carbon chains, can persist in the environment and accumulate in living organisms. This persistence raises concerns about long-term ecological impacts and potential effects on food chains.

In conclusion, while alkyl sensors play a crucial role in environmental monitoring and protection, their own environmental impact must be carefully managed. Balancing the benefits of these advanced sensing technologies with their potential environmental costs is essential for sustainable development in the field of chemical sensors.

Alkyl Sensor Miniaturization Trends

The miniaturization of alkyl sensors has been a significant trend in chemical sensor technologies, driven by the demand for more compact, portable, and energy-efficient devices. This trend has been particularly evident in the past decade, with researchers and manufacturers pushing the boundaries of sensor size reduction while maintaining or even improving performance.

One of the key drivers of this miniaturization trend has been the advancement in nanotechnology and microfabrication techniques. These technologies have enabled the development of sensors with dimensions in the nanometer to micrometer range, significantly reducing the overall size of alkyl sensing devices. For instance, the integration of nanostructured materials, such as carbon nanotubes and graphene, has allowed for the creation of highly sensitive and selective alkyl sensors with minimal footprints.

The miniaturization of alkyl sensors has also been facilitated by improvements in microelectronics and signal processing capabilities. The development of low-power, high-performance microcontrollers and application-specific integrated circuits (ASICs) has made it possible to process and analyze sensor data more efficiently within smaller form factors. This has led to the creation of complete alkyl sensing systems that are not only compact but also capable of real-time data analysis and wireless communication.

Another important aspect of the miniaturization trend is the integration of multiple sensing modalities into a single device. Researchers have been working on developing multi-functional sensors that can detect various alkyl compounds simultaneously, further reducing the overall size and complexity of sensing systems. This approach has been particularly beneficial in environmental monitoring and industrial applications, where space and power constraints are often significant considerations.

The trend towards miniaturization has also had a profound impact on the power consumption of alkyl sensors. As devices become smaller, their energy requirements typically decrease, leading to longer battery life and the potential for energy harvesting solutions. This has opened up new possibilities for deploying alkyl sensors in remote or hard-to-reach locations, where frequent battery replacement or wired power sources are impractical.

Looking ahead, the miniaturization trend in alkyl sensor technologies is expected to continue, with a focus on further reducing size while enhancing sensitivity, selectivity, and durability. Emerging technologies such as molecular imprinting, microfluidics, and advanced nanomaterials are likely to play crucial roles in driving this trend forward. As these sensors become increasingly compact and efficient, their applications are expected to expand into new areas, including wearable devices, smart packaging, and Internet of Things (IoT) networks for environmental and industrial monitoring.

One of the key drivers of this miniaturization trend has been the advancement in nanotechnology and microfabrication techniques. These technologies have enabled the development of sensors with dimensions in the nanometer to micrometer range, significantly reducing the overall size of alkyl sensing devices. For instance, the integration of nanostructured materials, such as carbon nanotubes and graphene, has allowed for the creation of highly sensitive and selective alkyl sensors with minimal footprints.

The miniaturization of alkyl sensors has also been facilitated by improvements in microelectronics and signal processing capabilities. The development of low-power, high-performance microcontrollers and application-specific integrated circuits (ASICs) has made it possible to process and analyze sensor data more efficiently within smaller form factors. This has led to the creation of complete alkyl sensing systems that are not only compact but also capable of real-time data analysis and wireless communication.

Another important aspect of the miniaturization trend is the integration of multiple sensing modalities into a single device. Researchers have been working on developing multi-functional sensors that can detect various alkyl compounds simultaneously, further reducing the overall size and complexity of sensing systems. This approach has been particularly beneficial in environmental monitoring and industrial applications, where space and power constraints are often significant considerations.

The trend towards miniaturization has also had a profound impact on the power consumption of alkyl sensors. As devices become smaller, their energy requirements typically decrease, leading to longer battery life and the potential for energy harvesting solutions. This has opened up new possibilities for deploying alkyl sensors in remote or hard-to-reach locations, where frequent battery replacement or wired power sources are impractical.

Looking ahead, the miniaturization trend in alkyl sensor technologies is expected to continue, with a focus on further reducing size while enhancing sensitivity, selectivity, and durability. Emerging technologies such as molecular imprinting, microfluidics, and advanced nanomaterials are likely to play crucial roles in driving this trend forward. As these sensors become increasingly compact and efficient, their applications are expected to expand into new areas, including wearable devices, smart packaging, and Internet of Things (IoT) networks for environmental and industrial monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!