Applying Alkyl Principles to Modern Engineering Challenges

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Principles Overview and Engineering Goals

Alkyl principles have been a cornerstone in organic chemistry for decades, providing fundamental insights into the behavior and properties of carbon-based compounds. These principles, which govern the structure, reactivity, and physical characteristics of alkyl groups, have far-reaching implications beyond their traditional applications in chemical synthesis and analysis. As we face increasingly complex engineering challenges in the 21st century, the application of alkyl principles to modern engineering problems presents a promising avenue for innovation and problem-solving.

The evolution of alkyl chemistry has been marked by significant milestones, from the early understanding of carbon bonding to the sophisticated manipulation of molecular structures. This progression has led to a deep comprehension of how alkyl groups influence material properties, reactivity, and functionality. In the context of modern engineering, these principles offer a wealth of opportunities for developing advanced materials, optimizing industrial processes, and addressing environmental concerns.

The primary goal of applying alkyl principles to contemporary engineering challenges is to leverage this fundamental chemical knowledge to create novel solutions in diverse fields such as materials science, energy technology, and environmental engineering. By understanding the behavior of alkyl groups at a molecular level, engineers can design materials with tailored properties, develop more efficient catalysts, and create innovative approaches to energy storage and conversion.

One of the key objectives is to explore how alkyl principles can contribute to the development of sustainable technologies. This includes the creation of biodegradable polymers, the enhancement of renewable energy systems, and the improvement of carbon capture and utilization methods. By manipulating alkyl structures, engineers aim to design materials that are not only high-performing but also environmentally friendly and resource-efficient.

Another critical goal is to harness alkyl principles for the advancement of nanotechnology and smart materials. The ability to control molecular structures at the nanoscale opens up possibilities for creating self-healing materials, responsive surfaces, and adaptive systems that can revolutionize industries ranging from aerospace to healthcare. Engineers are exploring how alkyl-based nanostructures can be used to develop sensors, drug delivery systems, and advanced coatings with unprecedented properties.

Furthermore, the application of alkyl principles in modern engineering seeks to address the growing demand for energy-efficient processes and materials. This includes the development of novel lubricants, heat transfer fluids, and insulation materials that can significantly improve the performance and efficiency of various engineering systems. By optimizing the alkyl components in these applications, engineers aim to reduce energy consumption and minimize environmental impact across multiple industries.

The evolution of alkyl chemistry has been marked by significant milestones, from the early understanding of carbon bonding to the sophisticated manipulation of molecular structures. This progression has led to a deep comprehension of how alkyl groups influence material properties, reactivity, and functionality. In the context of modern engineering, these principles offer a wealth of opportunities for developing advanced materials, optimizing industrial processes, and addressing environmental concerns.

The primary goal of applying alkyl principles to contemporary engineering challenges is to leverage this fundamental chemical knowledge to create novel solutions in diverse fields such as materials science, energy technology, and environmental engineering. By understanding the behavior of alkyl groups at a molecular level, engineers can design materials with tailored properties, develop more efficient catalysts, and create innovative approaches to energy storage and conversion.

One of the key objectives is to explore how alkyl principles can contribute to the development of sustainable technologies. This includes the creation of biodegradable polymers, the enhancement of renewable energy systems, and the improvement of carbon capture and utilization methods. By manipulating alkyl structures, engineers aim to design materials that are not only high-performing but also environmentally friendly and resource-efficient.

Another critical goal is to harness alkyl principles for the advancement of nanotechnology and smart materials. The ability to control molecular structures at the nanoscale opens up possibilities for creating self-healing materials, responsive surfaces, and adaptive systems that can revolutionize industries ranging from aerospace to healthcare. Engineers are exploring how alkyl-based nanostructures can be used to develop sensors, drug delivery systems, and advanced coatings with unprecedented properties.

Furthermore, the application of alkyl principles in modern engineering seeks to address the growing demand for energy-efficient processes and materials. This includes the development of novel lubricants, heat transfer fluids, and insulation materials that can significantly improve the performance and efficiency of various engineering systems. By optimizing the alkyl components in these applications, engineers aim to reduce energy consumption and minimize environmental impact across multiple industries.

Market Demand for Alkyl-Based Solutions

The market demand for alkyl-based solutions has been steadily growing across various industries, driven by the increasing need for sustainable and efficient engineering practices. As environmental concerns and regulatory pressures mount, industries are seeking innovative approaches to address modern engineering challenges. Alkyl-based solutions have emerged as a promising avenue, offering unique properties that can enhance performance while reducing environmental impact.

In the automotive sector, there is a significant demand for alkyl-based lubricants and additives. These products offer improved fuel efficiency, reduced emissions, and extended engine life. The global automotive lubricants market, which heavily relies on alkyl-based formulations, is projected to experience substantial growth in the coming years. This growth is fueled by the rising production of vehicles worldwide and the increasing adoption of high-performance lubricants.

The construction industry has also shown a keen interest in alkyl-based solutions, particularly in the development of advanced concrete admixtures. These additives improve the workability, strength, and durability of concrete, addressing key challenges in modern construction projects. The global concrete admixtures market, which includes alkyl-based products, is expected to expand significantly, driven by urbanization and infrastructure development in emerging economies.

In the electronics sector, alkyl-based materials are gaining traction for their application in semiconductor manufacturing and electronic packaging. These materials offer improved thermal management and electrical insulation properties, crucial for the development of next-generation electronic devices. The demand for alkyl-based solutions in this sector is closely tied to the growth of the global semiconductor industry, which continues to expand rapidly.

The pharmaceutical and healthcare industries are exploring alkyl-based compounds for drug delivery systems and medical devices. These materials offer biocompatibility and controlled release properties, addressing challenges in targeted drug delivery and implant technologies. The market for advanced drug delivery systems, including those utilizing alkyl-based materials, is expected to grow substantially in the coming years.

Environmental remediation is another area where alkyl-based solutions are seeing increased demand. These materials are being used in soil and water treatment applications, offering effective and eco-friendly alternatives to traditional remediation methods. The global environmental remediation market, which includes alkyl-based technologies, is projected to expand as governments and industries focus on addressing pollution and contamination issues.

As industries continue to seek innovative solutions to modern engineering challenges, the demand for alkyl-based products is expected to grow across multiple sectors. This trend is supported by ongoing research and development efforts aimed at expanding the applications of alkyl principles in various engineering fields. The market's growth is further bolstered by the increasing emphasis on sustainability and environmental responsibility in industrial practices worldwide.

In the automotive sector, there is a significant demand for alkyl-based lubricants and additives. These products offer improved fuel efficiency, reduced emissions, and extended engine life. The global automotive lubricants market, which heavily relies on alkyl-based formulations, is projected to experience substantial growth in the coming years. This growth is fueled by the rising production of vehicles worldwide and the increasing adoption of high-performance lubricants.

The construction industry has also shown a keen interest in alkyl-based solutions, particularly in the development of advanced concrete admixtures. These additives improve the workability, strength, and durability of concrete, addressing key challenges in modern construction projects. The global concrete admixtures market, which includes alkyl-based products, is expected to expand significantly, driven by urbanization and infrastructure development in emerging economies.

In the electronics sector, alkyl-based materials are gaining traction for their application in semiconductor manufacturing and electronic packaging. These materials offer improved thermal management and electrical insulation properties, crucial for the development of next-generation electronic devices. The demand for alkyl-based solutions in this sector is closely tied to the growth of the global semiconductor industry, which continues to expand rapidly.

The pharmaceutical and healthcare industries are exploring alkyl-based compounds for drug delivery systems and medical devices. These materials offer biocompatibility and controlled release properties, addressing challenges in targeted drug delivery and implant technologies. The market for advanced drug delivery systems, including those utilizing alkyl-based materials, is expected to grow substantially in the coming years.

Environmental remediation is another area where alkyl-based solutions are seeing increased demand. These materials are being used in soil and water treatment applications, offering effective and eco-friendly alternatives to traditional remediation methods. The global environmental remediation market, which includes alkyl-based technologies, is projected to expand as governments and industries focus on addressing pollution and contamination issues.

As industries continue to seek innovative solutions to modern engineering challenges, the demand for alkyl-based products is expected to grow across multiple sectors. This trend is supported by ongoing research and development efforts aimed at expanding the applications of alkyl principles in various engineering fields. The market's growth is further bolstered by the increasing emphasis on sustainability and environmental responsibility in industrial practices worldwide.

Current State and Challenges in Alkyl Engineering

Alkyl engineering has made significant strides in recent years, with applications spanning various industries. However, the field still faces numerous challenges that hinder its full potential. Currently, the most advanced alkyl engineering techniques focus on optimizing carbon chain lengths and branching patterns to achieve desired properties in materials and chemicals.

One of the primary challenges in alkyl engineering is the precise control of reaction selectivity. While researchers have developed sophisticated catalysts and reaction conditions, achieving high selectivity for specific alkyl products remains difficult, especially in complex systems. This challenge is particularly evident in the production of specialty chemicals and advanced materials, where even small variations in alkyl structure can significantly impact performance.

Another significant hurdle is the scalability of alkyl engineering processes. Many innovative techniques that show promise in laboratory settings face obstacles when scaled up for industrial production. Issues such as heat transfer, mixing efficiency, and catalyst stability become more pronounced at larger scales, often leading to reduced yields and increased costs.

Environmental concerns also pose challenges to the field of alkyl engineering. Traditional alkylation processes often rely on strong acids or hazardous reagents, raising safety and environmental issues. The development of greener, more sustainable alkylation methods is an ongoing area of research, with a focus on using renewable feedstocks and minimizing waste production.

The energy intensity of many alkyl engineering processes presents another challenge. High-pressure and high-temperature conditions are often required for efficient alkylation reactions, contributing to significant energy consumption. Researchers are exploring novel catalysts and process intensification techniques to reduce energy requirements while maintaining or improving product quality.

In the realm of polymer science, controlling the distribution and placement of alkyl side chains remains a complex task. This challenge affects the development of advanced materials with tailored properties, such as self-healing polymers or materials with specific thermal and mechanical characteristics.

Computational modeling and prediction of alkyl-based systems have advanced considerably but still face limitations. The complexity of molecular interactions and the vast number of possible alkyl configurations make accurate simulations challenging, particularly for large-scale systems or long-term behavior predictions.

Lastly, the integration of alkyl engineering principles with emerging technologies, such as nanotechnology and biotechnology, presents both opportunities and challenges. While these intersections offer exciting possibilities for innovation, they also require interdisciplinary approaches and new methodologies that are still in development.

One of the primary challenges in alkyl engineering is the precise control of reaction selectivity. While researchers have developed sophisticated catalysts and reaction conditions, achieving high selectivity for specific alkyl products remains difficult, especially in complex systems. This challenge is particularly evident in the production of specialty chemicals and advanced materials, where even small variations in alkyl structure can significantly impact performance.

Another significant hurdle is the scalability of alkyl engineering processes. Many innovative techniques that show promise in laboratory settings face obstacles when scaled up for industrial production. Issues such as heat transfer, mixing efficiency, and catalyst stability become more pronounced at larger scales, often leading to reduced yields and increased costs.

Environmental concerns also pose challenges to the field of alkyl engineering. Traditional alkylation processes often rely on strong acids or hazardous reagents, raising safety and environmental issues. The development of greener, more sustainable alkylation methods is an ongoing area of research, with a focus on using renewable feedstocks and minimizing waste production.

The energy intensity of many alkyl engineering processes presents another challenge. High-pressure and high-temperature conditions are often required for efficient alkylation reactions, contributing to significant energy consumption. Researchers are exploring novel catalysts and process intensification techniques to reduce energy requirements while maintaining or improving product quality.

In the realm of polymer science, controlling the distribution and placement of alkyl side chains remains a complex task. This challenge affects the development of advanced materials with tailored properties, such as self-healing polymers or materials with specific thermal and mechanical characteristics.

Computational modeling and prediction of alkyl-based systems have advanced considerably but still face limitations. The complexity of molecular interactions and the vast number of possible alkyl configurations make accurate simulations challenging, particularly for large-scale systems or long-term behavior predictions.

Lastly, the integration of alkyl engineering principles with emerging technologies, such as nanotechnology and biotechnology, presents both opportunities and challenges. While these intersections offer exciting possibilities for innovation, they also require interdisciplinary approaches and new methodologies that are still in development.

Existing Alkyl Applications in Modern Engineering

01 Alkyl group modifications in chemical compounds

Alkyl groups play a crucial role in modifying the properties of chemical compounds. The addition or modification of alkyl chains can affect solubility, reactivity, and other physicochemical characteristics. This principle is widely applied in various fields, including pharmaceuticals, cosmetics, and materials science.- Alkyl group structure and properties: Alkyl groups are hydrocarbon chains derived from alkanes by removing one hydrogen atom. They play a crucial role in organic chemistry, affecting the physical and chemical properties of compounds. The structure and length of alkyl chains influence factors such as solubility, boiling point, and reactivity of molecules.

- Alkyl-based surfactants and emulsifiers: Alkyl chains are essential components in surfactants and emulsifiers used in various industries. These compounds have both hydrophobic (alkyl chain) and hydrophilic parts, allowing them to stabilize mixtures of oil and water. They are widely used in personal care products, pharmaceuticals, and food applications.

- Alkyl substitution in drug design: The addition or modification of alkyl groups in drug molecules can significantly impact their pharmacological properties. Alkyl substitution can alter a drug's lipophilicity, affecting its absorption, distribution, metabolism, and excretion (ADME) profile. This principle is widely applied in medicinal chemistry to optimize drug candidates.

- Alkyl-based polymers and materials: Alkyl groups are incorporated into various polymers and materials to impart specific properties such as hydrophobicity, flexibility, or thermal stability. These materials find applications in coatings, adhesives, and specialty plastics. The length and branching of alkyl chains can be tailored to achieve desired material characteristics.

- Computational modeling of alkyl interactions: Advanced computational methods are employed to model and predict the behavior of alkyl groups in various chemical systems. These models help in understanding intermolecular interactions, conformational analysis, and reactivity patterns. Such computational approaches aid in the design of new molecules and materials with specific alkyl-related properties.

02 Computational methods for alkyl compound analysis

Advanced computational techniques are employed to analyze and predict the behavior of alkyl compounds. These methods include molecular modeling, quantum mechanical calculations, and machine learning algorithms. Such approaches aid in understanding structure-property relationships and optimizing alkyl-based formulations.Expand Specific Solutions03 Alkyl-based drug delivery systems

Alkyl chains are utilized in the design of drug delivery systems to enhance the efficacy and bioavailability of active pharmaceutical ingredients. The incorporation of alkyl groups can improve membrane permeability, control release rates, and increase the stability of drug formulations.Expand Specific Solutions04 Environmental impact of alkyl compounds

The environmental fate and impact of alkyl compounds are subjects of ongoing research. Studies focus on biodegradability, bioaccumulation, and potential toxicity of various alkyl-containing substances. This knowledge informs the development of more sustainable and eco-friendly alkyl-based products.Expand Specific Solutions05 Industrial applications of alkyl principles

Alkyl principles find extensive applications in industrial processes, including lubricant formulation, polymer synthesis, and surfactant production. The selection and optimization of alkyl chain lengths and structures are critical for achieving desired product performance and process efficiency.Expand Specific Solutions

Key Players in Alkyl-Based Engineering

The field of applying alkyl principles to modern engineering challenges is in a growth phase, with increasing market size and evolving technological maturity. Major players like Shell, ExxonMobil, and Dow are driving innovation, leveraging their extensive R&D capabilities. Universities such as MIT and Sorbonne are contributing fundamental research, while specialized companies like Arkema and Johnson Matthey focus on niche applications. The market is characterized by a mix of established petrochemical giants and emerging specialized firms, indicating a dynamic competitive landscape. As environmental concerns grow, there's an increasing focus on sustainable alkyl-based solutions, pushing the technology towards greater efficiency and eco-friendliness.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed innovative alkylation technologies to address modern engineering challenges in the oil and gas industry. Their FLEXICOKING™ technology integrates gasification with fluid catalytic cracking, allowing for the efficient conversion of heavy oil residues into valuable light products, including alkylate gasoline components[12]. Shell's research in alkylation extends to the development of novel ionic liquid catalysts for isobutane/butene alkylation, offering a more environmentally friendly alternative to traditional acid catalysts[13]. The company has also implemented advanced process control and optimization techniques in their alkylation units, improving product quality and reducing energy consumption. Furthermore, Shell is exploring the use of renewable feedstocks in alkylation processes to produce sustainable aviation fuels and biofuels[14].

Strengths: Integrated refining solutions, environmentally friendly catalysts, and focus on sustainable fuels. Weaknesses: High capital investment requirements and potential challenges in scaling up new technologies.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced alkylation technologies to address modern engineering challenges in the petrochemical industry. Their Alkylene™ process utilizes solid acid catalyst technology for alkylation of light olefins with isobutane to produce high-octane gasoline blending components[1]. This innovative approach significantly reduces acid consumption and waste generation compared to traditional liquid acid alkylation processes. ExxonMobil has also implemented molecular modeling and computational chemistry techniques to optimize catalyst design and reaction conditions, leading to improved selectivity and yield in alkylation reactions[3].

Strengths: Reduced environmental impact, improved process efficiency, and enhanced product quality. Weaknesses: High initial capital investment and potential complexity in process control.

Core Innovations in Alkyl Principles

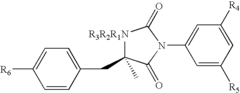

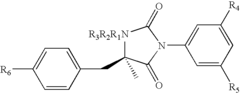

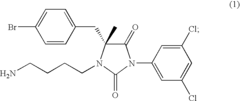

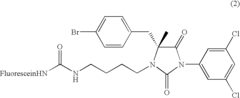

Small molecules for inhibition of function and drug delivery to leukocytes

PatentInactiveUS20040023929A1

Innovation

- Development of small molecules with specific affinity for LFA-1, comprising an alkyl or aryl group, a urea or phosphate linkage, and an active group such as fluorescein, toxin, or radiolabel, designed to inhibit leukocyte function and facilitate drug delivery.

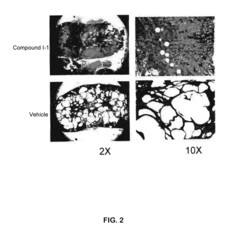

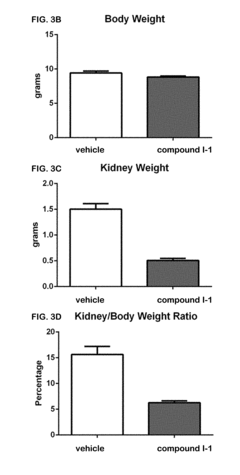

Methods for treating polycystic kidney disease and polycystic liver disease

PatentInactiveUS20180362574A1

Innovation

- Development of compounds that inhibit the mTOR signaling pathway, induce the unfolded protein response (UPR), and perturb mitochondrial function in cyst cells, formulated into pharmaceutical compositions for treating and preventing PKD and PLD, inhibiting cyst cell growth, and killing cyst cells.

Environmental Impact of Alkyl Technologies

The environmental impact of alkyl technologies is a critical consideration in modern engineering applications. These technologies, while offering significant benefits in various industries, also pose potential risks to ecosystems and human health. One of the primary concerns is the release of volatile organic compounds (VOCs) during the production and use of alkyl-based products. VOCs contribute to air pollution and can lead to the formation of ground-level ozone, a key component of smog that negatively affects respiratory health and plant growth.

Water contamination is another significant environmental issue associated with alkyl technologies. Alkyl compounds, particularly those with longer carbon chains, can persist in aquatic environments and accumulate in sediments. This persistence can lead to long-term ecological impacts, affecting aquatic organisms and potentially entering the food chain. Moreover, the bioaccumulation of certain alkyl compounds in marine life poses risks to both wildlife and human consumers of seafood.

Soil contamination is also a concern, especially in areas where alkyl-based products are manufactured or heavily used. Leaks, spills, and improper disposal can result in soil pollution, affecting soil microorganisms and potentially contaminating groundwater. The remediation of alkyl-contaminated soils can be a complex and costly process, often requiring specialized treatment methods.

The production of alkyl compounds often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change. As the demand for alkyl-based products grows, the carbon footprint of their production becomes an increasingly important environmental consideration. Efforts to improve energy efficiency and transition to renewable energy sources in manufacturing processes are crucial for mitigating these impacts.

Biodegradability is a key factor in assessing the environmental impact of alkyl technologies. While some alkyl compounds are readily biodegradable, others can persist in the environment for extended periods. The development of more environmentally friendly, biodegradable alternatives is an active area of research aimed at reducing the long-term environmental impact of these technologies.

Despite these challenges, advancements in green chemistry and sustainable engineering are driving improvements in alkyl technologies. Innovations in production methods, such as the use of bio-based feedstocks and catalytic processes, are reducing the environmental footprint of alkyl compounds. Additionally, the implementation of closed-loop systems and improved waste management practices in industrial settings is helping to minimize environmental releases and promote resource efficiency.

Water contamination is another significant environmental issue associated with alkyl technologies. Alkyl compounds, particularly those with longer carbon chains, can persist in aquatic environments and accumulate in sediments. This persistence can lead to long-term ecological impacts, affecting aquatic organisms and potentially entering the food chain. Moreover, the bioaccumulation of certain alkyl compounds in marine life poses risks to both wildlife and human consumers of seafood.

Soil contamination is also a concern, especially in areas where alkyl-based products are manufactured or heavily used. Leaks, spills, and improper disposal can result in soil pollution, affecting soil microorganisms and potentially contaminating groundwater. The remediation of alkyl-contaminated soils can be a complex and costly process, often requiring specialized treatment methods.

The production of alkyl compounds often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change. As the demand for alkyl-based products grows, the carbon footprint of their production becomes an increasingly important environmental consideration. Efforts to improve energy efficiency and transition to renewable energy sources in manufacturing processes are crucial for mitigating these impacts.

Biodegradability is a key factor in assessing the environmental impact of alkyl technologies. While some alkyl compounds are readily biodegradable, others can persist in the environment for extended periods. The development of more environmentally friendly, biodegradable alternatives is an active area of research aimed at reducing the long-term environmental impact of these technologies.

Despite these challenges, advancements in green chemistry and sustainable engineering are driving improvements in alkyl technologies. Innovations in production methods, such as the use of bio-based feedstocks and catalytic processes, are reducing the environmental footprint of alkyl compounds. Additionally, the implementation of closed-loop systems and improved waste management practices in industrial settings is helping to minimize environmental releases and promote resource efficiency.

Safety Considerations in Alkyl-Based Solutions

The application of alkyl principles in modern engineering solutions necessitates a comprehensive approach to safety considerations. The inherent reactivity and potential hazards associated with alkyl compounds require stringent safety protocols and risk management strategies. One primary concern is the flammability of many alkyl-based substances, which demands robust fire prevention and suppression systems in manufacturing and storage facilities. Additionally, the volatility of certain alkyl compounds poses inhalation risks, necessitating advanced ventilation systems and personal protective equipment for workers.

Chemical compatibility is another crucial safety aspect when dealing with alkyl-based solutions. Engineers must carefully consider the materials used in containment vessels, piping, and processing equipment to prevent corrosion, degradation, or unwanted reactions. This often involves selecting specialized alloys or coatings that can withstand the aggressive nature of certain alkyl compounds. Furthermore, the potential for static electricity accumulation in alkyl-based processes requires the implementation of grounding and bonding procedures to mitigate the risk of ignition.

Environmental safety is equally paramount in alkyl-based engineering applications. Proper containment and disposal methods must be developed to prevent soil and water contamination. This includes designing fail-safe systems to contain spills and implementing advanced wastewater treatment processes to remove alkyl residues before discharge. Moreover, air quality management systems are essential to capture and treat volatile organic compounds (VOCs) emitted during alkyl-based processes, ensuring compliance with environmental regulations and protecting surrounding communities.

The transportation of alkyl compounds and alkyl-based products presents unique safety challenges. Specialized containers, such as pressure vessels or temperature-controlled tanks, are often required to maintain stability during transit. Rigorous safety protocols for loading, unloading, and emergency response must be established to mitigate risks associated with accidents or spills during transportation. This includes training personnel in hazardous materials handling and equipping transport vehicles with appropriate safety features and communication systems.

Lastly, the integration of advanced monitoring and control systems is crucial for maintaining safety in alkyl-based engineering solutions. Real-time sensors and analytics can detect anomalies in process conditions, allowing for rapid response to potential safety hazards. Automated shutdown systems and redundant safety measures provide additional layers of protection against equipment failures or human errors. Continuous improvement of safety protocols through regular risk assessments, incident investigations, and incorporation of lessons learned is essential for maintaining the highest safety standards in alkyl-based engineering applications.

Chemical compatibility is another crucial safety aspect when dealing with alkyl-based solutions. Engineers must carefully consider the materials used in containment vessels, piping, and processing equipment to prevent corrosion, degradation, or unwanted reactions. This often involves selecting specialized alloys or coatings that can withstand the aggressive nature of certain alkyl compounds. Furthermore, the potential for static electricity accumulation in alkyl-based processes requires the implementation of grounding and bonding procedures to mitigate the risk of ignition.

Environmental safety is equally paramount in alkyl-based engineering applications. Proper containment and disposal methods must be developed to prevent soil and water contamination. This includes designing fail-safe systems to contain spills and implementing advanced wastewater treatment processes to remove alkyl residues before discharge. Moreover, air quality management systems are essential to capture and treat volatile organic compounds (VOCs) emitted during alkyl-based processes, ensuring compliance with environmental regulations and protecting surrounding communities.

The transportation of alkyl compounds and alkyl-based products presents unique safety challenges. Specialized containers, such as pressure vessels or temperature-controlled tanks, are often required to maintain stability during transit. Rigorous safety protocols for loading, unloading, and emergency response must be established to mitigate risks associated with accidents or spills during transportation. This includes training personnel in hazardous materials handling and equipping transport vehicles with appropriate safety features and communication systems.

Lastly, the integration of advanced monitoring and control systems is crucial for maintaining safety in alkyl-based engineering solutions. Real-time sensors and analytics can detect anomalies in process conditions, allowing for rapid response to potential safety hazards. Automated shutdown systems and redundant safety measures provide additional layers of protection against equipment failures or human errors. Continuous improvement of safety protocols through regular risk assessments, incident investigations, and incorporation of lessons learned is essential for maintaining the highest safety standards in alkyl-based engineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!