How to Approach Alkyl Chemistry Challenges in Green Initiatives?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Chemistry Evolution

Alkyl chemistry has undergone significant evolution since its inception in the early 20th century. The field has progressed from basic understanding of alkyl groups to complex manipulations in organic synthesis. Initially, alkyl chemistry focused on simple reactions like halogenation and oxidation of alkanes. As analytical techniques improved, researchers gained deeper insights into reaction mechanisms and stereochemistry.

The 1950s and 1960s saw a surge in alkyl chemistry research, driven by the petrochemical industry's growth. This period marked the development of catalytic processes for alkylation, crucial for producing high-octane gasoline. Simultaneously, academic research advanced our understanding of carbocation chemistry and rearrangement reactions, laying the groundwork for modern organic synthesis.

The late 20th century brought a paradigm shift towards greener chemistry. Environmental concerns and sustainability goals prompted chemists to seek alternatives to traditional alkyl chemistry methods. This led to the exploration of biocatalysis, where enzymes are used to perform alkyl transformations under mild conditions. Additionally, the concept of atom economy gained traction, encouraging more efficient use of reagents in alkyl reactions.

Recent decades have witnessed a surge in transition metal-catalyzed alkyl chemistry. These methods allow for precise control over carbon-carbon bond formation, enabling the synthesis of complex molecules with high selectivity. Palladium-catalyzed cross-coupling reactions, recognized by the 2010 Nobel Prize in Chemistry, revolutionized alkyl chemistry by providing new tools for constructing carbon frameworks.

The advent of flow chemistry and microreactor technology has further transformed alkyl chemistry practices. These techniques offer improved control over reaction conditions, enhanced safety, and the potential for continuous processing. This has been particularly beneficial for scaling up alkyl chemistry processes in industrial settings.

Current research in alkyl chemistry is increasingly focused on sustainable practices. Scientists are developing methods for C-H activation, allowing direct functionalization of alkyl groups without pre-activation. This approach reduces waste and improves atom economy. Moreover, there's growing interest in using renewable feedstocks as starting materials for alkyl chemistry, aligning with green chemistry principles.

The integration of computational chemistry has accelerated progress in alkyl chemistry. Advanced modeling techniques now allow researchers to predict reaction outcomes and design more efficient catalysts. This computational approach, combined with high-throughput experimentation, is speeding up the discovery of novel alkyl chemistry transformations and optimizing existing processes.

The 1950s and 1960s saw a surge in alkyl chemistry research, driven by the petrochemical industry's growth. This period marked the development of catalytic processes for alkylation, crucial for producing high-octane gasoline. Simultaneously, academic research advanced our understanding of carbocation chemistry and rearrangement reactions, laying the groundwork for modern organic synthesis.

The late 20th century brought a paradigm shift towards greener chemistry. Environmental concerns and sustainability goals prompted chemists to seek alternatives to traditional alkyl chemistry methods. This led to the exploration of biocatalysis, where enzymes are used to perform alkyl transformations under mild conditions. Additionally, the concept of atom economy gained traction, encouraging more efficient use of reagents in alkyl reactions.

Recent decades have witnessed a surge in transition metal-catalyzed alkyl chemistry. These methods allow for precise control over carbon-carbon bond formation, enabling the synthesis of complex molecules with high selectivity. Palladium-catalyzed cross-coupling reactions, recognized by the 2010 Nobel Prize in Chemistry, revolutionized alkyl chemistry by providing new tools for constructing carbon frameworks.

The advent of flow chemistry and microreactor technology has further transformed alkyl chemistry practices. These techniques offer improved control over reaction conditions, enhanced safety, and the potential for continuous processing. This has been particularly beneficial for scaling up alkyl chemistry processes in industrial settings.

Current research in alkyl chemistry is increasingly focused on sustainable practices. Scientists are developing methods for C-H activation, allowing direct functionalization of alkyl groups without pre-activation. This approach reduces waste and improves atom economy. Moreover, there's growing interest in using renewable feedstocks as starting materials for alkyl chemistry, aligning with green chemistry principles.

The integration of computational chemistry has accelerated progress in alkyl chemistry. Advanced modeling techniques now allow researchers to predict reaction outcomes and design more efficient catalysts. This computational approach, combined with high-throughput experimentation, is speeding up the discovery of novel alkyl chemistry transformations and optimizing existing processes.

Green Market Demand

The global market for green chemistry solutions has been experiencing significant growth in recent years, driven by increasing environmental awareness and stringent regulations. The alkyl chemistry sector, in particular, faces mounting pressure to adopt more sustainable practices. This demand stems from various stakeholders, including consumers, regulatory bodies, and industry leaders committed to reducing their environmental footprint.

Consumer preferences have shifted dramatically towards eco-friendly products, with a growing segment willing to pay premium prices for sustainable alternatives. This trend is particularly evident in industries such as personal care, cleaning products, and packaging, where alkyl-based chemicals are widely used. Market research indicates that products marketed as "green" or "eco-friendly" have seen double-digit growth rates in many sectors, outpacing conventional alternatives.

Regulatory frameworks worldwide are becoming increasingly stringent regarding the use of harmful chemicals and emissions. The European Union's REACH regulation, for instance, has set a precedent for chemical management, influencing global standards. This regulatory landscape has created a strong incentive for companies to invest in green alkyl chemistry solutions to ensure compliance and maintain market access.

The industrial sector, a major consumer of alkyl-based chemicals, is also driving demand for greener alternatives. Many corporations have set ambitious sustainability targets, aiming to reduce their carbon footprint and minimize the use of hazardous substances in their supply chains. This corporate commitment has translated into a growing market for bio-based and renewable alkyl chemicals, as well as processes that reduce waste and energy consumption.

The automotive and aerospace industries, in particular, are seeking innovative solutions in alkyl chemistry to develop lightweight materials and more efficient fuels, aligning with global efforts to reduce transportation-related emissions. Similarly, the construction sector is exploring green alkyl chemistry for developing sustainable building materials and coatings.

Emerging economies present a significant opportunity for green alkyl chemistry. As these markets develop, there is a unique chance to leapfrog traditional chemical processes and adopt more sustainable practices from the outset. This potential is particularly evident in rapidly industrializing nations in Asia and Africa, where environmental concerns are increasingly shaping industrial policy.

Investment in research and development for green alkyl chemistry has seen a notable uptick, with both public and private funding supporting innovation in this field. Venture capital and government grants are increasingly directed towards startups and research institutions working on sustainable chemical solutions, indicating a strong belief in the market potential of these technologies.

Consumer preferences have shifted dramatically towards eco-friendly products, with a growing segment willing to pay premium prices for sustainable alternatives. This trend is particularly evident in industries such as personal care, cleaning products, and packaging, where alkyl-based chemicals are widely used. Market research indicates that products marketed as "green" or "eco-friendly" have seen double-digit growth rates in many sectors, outpacing conventional alternatives.

Regulatory frameworks worldwide are becoming increasingly stringent regarding the use of harmful chemicals and emissions. The European Union's REACH regulation, for instance, has set a precedent for chemical management, influencing global standards. This regulatory landscape has created a strong incentive for companies to invest in green alkyl chemistry solutions to ensure compliance and maintain market access.

The industrial sector, a major consumer of alkyl-based chemicals, is also driving demand for greener alternatives. Many corporations have set ambitious sustainability targets, aiming to reduce their carbon footprint and minimize the use of hazardous substances in their supply chains. This corporate commitment has translated into a growing market for bio-based and renewable alkyl chemicals, as well as processes that reduce waste and energy consumption.

The automotive and aerospace industries, in particular, are seeking innovative solutions in alkyl chemistry to develop lightweight materials and more efficient fuels, aligning with global efforts to reduce transportation-related emissions. Similarly, the construction sector is exploring green alkyl chemistry for developing sustainable building materials and coatings.

Emerging economies present a significant opportunity for green alkyl chemistry. As these markets develop, there is a unique chance to leapfrog traditional chemical processes and adopt more sustainable practices from the outset. This potential is particularly evident in rapidly industrializing nations in Asia and Africa, where environmental concerns are increasingly shaping industrial policy.

Investment in research and development for green alkyl chemistry has seen a notable uptick, with both public and private funding supporting innovation in this field. Venture capital and government grants are increasingly directed towards startups and research institutions working on sustainable chemical solutions, indicating a strong belief in the market potential of these technologies.

Current Challenges

The current challenges in approaching alkyl chemistry within green initiatives are multifaceted and complex. One of the primary obstacles is the inherent reactivity of alkyl groups, which often necessitates the use of harsh conditions or toxic reagents that are incompatible with environmentally friendly practices. This contradiction between traditional alkyl chemistry methods and green chemistry principles poses a significant hurdle for researchers and industry professionals alike.

Another major challenge lies in the development of sustainable catalysts for alkyl transformations. While transition metal catalysts have shown promise in many areas of green chemistry, their application to alkyl chemistry often suffers from issues such as catalyst deactivation, poor selectivity, and the need for high catalyst loadings. These factors not only reduce the efficiency of processes but also increase their environmental impact, running counter to the goals of green initiatives.

The optimization of reaction conditions to align with green chemistry metrics presents yet another challenge. Many alkyl chemistry reactions require elevated temperatures, extended reaction times, or the use of volatile organic solvents. Adapting these processes to operate under milder conditions, in aqueous media, or with reduced energy input is crucial but technically demanding. This challenge is compounded by the need to maintain or improve reaction yields and selectivities while making these green modifications.

Waste reduction and atom economy in alkyl chemistry processes also remain significant hurdles. Traditional alkylation reactions often generate stoichiometric amounts of byproducts, leading to poor atom economy and increased waste streams. Developing new methodologies that maximize the incorporation of reactants into the final product while minimizing side reactions and waste formation is essential for aligning alkyl chemistry with green initiatives.

The scale-up of green alkyl chemistry processes from laboratory to industrial scale presents its own set of challenges. What works efficiently on a small scale may encounter unforeseen difficulties when scaled up, such as heat transfer issues, mixing problems, or unexpected side reactions. Bridging this gap requires careful engineering and often necessitates the development of new technologies or process intensification strategies.

Lastly, the economic viability of green alkyl chemistry processes remains a significant challenge. Many industries are hesitant to adopt new, greener technologies if they come at a higher cost or with reduced efficiency compared to established methods. Overcoming this barrier requires not only technological advancements but also shifts in regulatory frameworks and market incentives to make green alkyl chemistry economically competitive.

Another major challenge lies in the development of sustainable catalysts for alkyl transformations. While transition metal catalysts have shown promise in many areas of green chemistry, their application to alkyl chemistry often suffers from issues such as catalyst deactivation, poor selectivity, and the need for high catalyst loadings. These factors not only reduce the efficiency of processes but also increase their environmental impact, running counter to the goals of green initiatives.

The optimization of reaction conditions to align with green chemistry metrics presents yet another challenge. Many alkyl chemistry reactions require elevated temperatures, extended reaction times, or the use of volatile organic solvents. Adapting these processes to operate under milder conditions, in aqueous media, or with reduced energy input is crucial but technically demanding. This challenge is compounded by the need to maintain or improve reaction yields and selectivities while making these green modifications.

Waste reduction and atom economy in alkyl chemistry processes also remain significant hurdles. Traditional alkylation reactions often generate stoichiometric amounts of byproducts, leading to poor atom economy and increased waste streams. Developing new methodologies that maximize the incorporation of reactants into the final product while minimizing side reactions and waste formation is essential for aligning alkyl chemistry with green initiatives.

The scale-up of green alkyl chemistry processes from laboratory to industrial scale presents its own set of challenges. What works efficiently on a small scale may encounter unforeseen difficulties when scaled up, such as heat transfer issues, mixing problems, or unexpected side reactions. Bridging this gap requires careful engineering and often necessitates the development of new technologies or process intensification strategies.

Lastly, the economic viability of green alkyl chemistry processes remains a significant challenge. Many industries are hesitant to adopt new, greener technologies if they come at a higher cost or with reduced efficiency compared to established methods. Overcoming this barrier requires not only technological advancements but also shifts in regulatory frameworks and market incentives to make green alkyl chemistry economically competitive.

Green Alkyl Solutions

01 Alkyl-based chemical synthesis and modifications

This category focuses on the synthesis and modification of alkyl compounds. It includes various chemical reactions and processes involving alkyl groups, such as alkylation, dealkylation, and functionalization of alkyl chains. These processes are crucial in organic chemistry and have applications in the production of pharmaceuticals, polymers, and other industrial chemicals.- Alkyl-based chemical reactions and synthesis: This category focuses on various chemical reactions and synthesis methods involving alkyl groups. It includes processes for creating alkyl compounds, modifying existing molecules with alkyl groups, and studying the reactivity of alkyl-containing substances. These techniques are essential in organic chemistry and have applications in pharmaceuticals, materials science, and industrial processes.

- Alkyl-modified materials and coatings: This area explores the use of alkyl groups to modify materials and create specialized coatings. By incorporating alkyl chains into polymers, surfaces, or nanoparticles, researchers can alter properties such as hydrophobicity, chemical resistance, and thermal stability. These modifications have applications in areas like protective coatings, self-cleaning surfaces, and advanced materials for various industries.

- Alkyl-based surfactants and emulsifiers: This category covers the development and application of alkyl-based surfactants and emulsifiers. These compounds, which contain both hydrophilic and hydrophobic (alkyl) parts, are crucial in formulating stable emulsions, detergents, and personal care products. Research in this area focuses on optimizing alkyl chain lengths and structures for specific applications and improving the environmental profile of these substances.

- Alkyl-functionalized nanomaterials: This field involves the functionalization of nanomaterials with alkyl groups to enhance their properties or create new functionalities. By attaching alkyl chains to nanoparticles, nanotubes, or two-dimensional materials, researchers can improve their dispersibility, tune their electronic properties, or create novel hybrid materials. These functionalized nanomaterials have potential applications in electronics, energy storage, and biomedical devices.

- Analytical methods for alkyl compounds: This category encompasses analytical techniques and methods specifically developed or optimized for the detection, quantification, and characterization of alkyl compounds. It includes spectroscopic methods, chromatography techniques, and advanced imaging approaches tailored to analyze alkyl groups in various matrices. These analytical tools are crucial for quality control, environmental monitoring, and research in fields where alkyl chemistry plays a significant role.

02 Alkyl-containing materials in semiconductor manufacturing

Alkyl chemistry plays a significant role in semiconductor manufacturing. This includes the use of alkyl-containing precursors for chemical vapor deposition, the development of alkyl-based photoresists, and the application of alkyl groups in surface treatments for semiconductor devices. These processes contribute to the fabrication of advanced electronic components.Expand Specific Solutions03 Alkyl-based surfactants and cleaning compositions

Alkyl compounds are widely used in the formulation of surfactants and cleaning compositions. This category covers the development of alkyl-based detergents, emulsifiers, and other surface-active agents. These materials find applications in household cleaning products, personal care items, and industrial cleaning processes.Expand Specific Solutions04 Alkyl groups in polymer chemistry

This point focuses on the use of alkyl groups in polymer chemistry. It includes the synthesis of alkyl-containing monomers, the incorporation of alkyl side chains in polymer structures, and the modification of polymer properties through alkylation. These processes are important in the development of various plastic materials, adhesives, and coatings.Expand Specific Solutions05 Analytical methods for alkyl compounds

This category covers analytical techniques and methods specifically designed for the detection, quantification, and characterization of alkyl compounds. It includes chromatographic methods, spectroscopic techniques, and other analytical approaches used in research, quality control, and environmental monitoring of alkyl-containing substances.Expand Specific Solutions

Key Industry Players

The alkyl chemistry challenges in green initiatives present a competitive landscape characterized by a mature industry in transition. Major players like Shell Oil Co., China Petroleum & Chemical Corp., and AbbVie, Inc. are investing heavily in research and development to address environmental concerns. The market size is substantial, driven by increasing demand for sustainable chemical processes. Technological maturity varies, with established companies like Sinopec Research Institute of Petroleum Processing and Shanghai Institute of Organic Chemistry leading in traditional methods, while newer entrants such as Global Bioenergies SA focus on innovative bio-based solutions. Academic institutions like Northeastern University and Indian Institute of Technology Delhi contribute significantly to advancing green chemistry technologies, fostering collaboration between industry and academia.

Shell Oil Co.

Technical Solution: Shell Oil Co. has developed a novel approach to green alkyl chemistry through their Shell Higher Olefins Process (SHOP). This process utilizes ethylene to produce linear alpha olefins (LAOs) and internal olefins, which are key intermediates for various green initiatives[1]. The process involves oligomerization of ethylene, isomerization of the resulting alpha-olefins, and metathesis to produce a range of olefin products. Shell has also implemented catalytic distillation technology to enhance the efficiency and selectivity of alkylation reactions, reducing waste and energy consumption[2]. Furthermore, they have invested in bio-based feedstocks for alkyl chemistry, exploring the use of renewable resources to produce sustainable alkyl compounds[3].

Strengths: Established technology with proven industrial applications, integration of green chemistry principles. Weaknesses: Still relies partially on fossil-based feedstocks, potential for further optimization in terms of energy efficiency.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in addressing alkyl chemistry challenges in green initiatives. They have developed a proprietary alkylation technology using ionic liquid catalysts, which operates at lower temperatures and pressures compared to traditional sulfuric acid catalysts[4]. This approach reduces energy consumption and improves safety. Sinopec has also implemented a closed-loop recycling system for alkylation processes, minimizing waste and improving resource efficiency[5]. Additionally, they are exploring the use of biomass-derived alkyl compounds as a sustainable alternative to petroleum-based products, with pilot projects demonstrating up to 30% reduction in carbon footprint[6].

Strengths: Innovative catalyst technology, integrated recycling systems, and progress in bio-based alkyl compounds. Weaknesses: Scale-up challenges for bio-based processes, potential high initial investment costs for technology transition.

Innovative Approaches

Method of preparing alkyl and/or alkenyl oligoglycosides

PatentWO1993010132A1

Innovation

- The process involves acetalizing glucose with fatty alcohols in the presence of sulfomonocarboxylic acids with 2 to 8 carbon atoms, or their carboxylic acid anhydrides, as acidic catalysts at elevated temperatures, allowing for high yields, reduced byproduct formation, and easy catalyst incorporation, while being ecologically and toxicologically compatible.

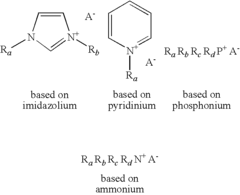

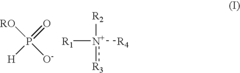

Alkyl H-phosphonates of N,N′-dialkylimidazoliums and of quaternary ammoniums and uses thereof

PatentInactiveUS8309736B2

Innovation

- A novel single-step synthesis method for salts associating an ammonium cation with an alkyl H-phosphonate anion, conducted in the absence of organic solvents, which results in room temperature ionic liquids (RTILHPAs) that are thermally stable, non-volatile, and non-flammable, with low viscosity and enhanced solvent properties.

Regulatory Framework

The regulatory framework surrounding alkyl chemistry in green initiatives is a complex and evolving landscape. Governments and international organizations are increasingly implementing stringent regulations to promote sustainable practices and reduce environmental impact in chemical processes.

At the global level, the United Nations' Sustainable Development Goals (SDGs) provide a broad framework for environmental sustainability, influencing national policies on green chemistry. The Paris Agreement on climate change also indirectly affects alkyl chemistry regulations by pushing for reduced carbon emissions across industries.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the use of alkyl compounds. It requires companies to register chemical substances and provide safety data, promoting the use of greener alternatives where possible. The EU's Circular Economy Action Plan further emphasizes the need for sustainable chemical processes, including those involving alkyl chemistry.

The United States Environmental Protection Agency (EPA) enforces several regulations relevant to alkyl chemistry under the Toxic Substances Control Act (TSCA). The Green Chemistry Initiative, launched by the EPA, encourages the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances.

In Asia, countries like China and Japan have been strengthening their environmental regulations. China's Environmental Protection Law and Japan's Chemical Substances Control Law both have provisions that impact alkyl chemistry practices, pushing for greener alternatives and stricter controls on potentially harmful substances.

Industry-specific regulations also play a significant role. For instance, the pharmaceutical industry faces stringent guidelines from regulatory bodies like the FDA and EMA, which increasingly emphasize the importance of green chemistry principles in drug development and manufacturing processes involving alkyl compounds.

Many countries have implemented tax incentives and funding programs to encourage research and development in green chemistry, including innovations in alkyl chemistry. These financial instruments serve as indirect regulatory tools to steer the industry towards more sustainable practices.

The regulatory landscape is continuously evolving, with a clear trend towards stricter environmental standards and a greater emphasis on sustainability. This dynamic environment presents both challenges and opportunities for companies working with alkyl chemistry, necessitating ongoing adaptation and innovation in chemical processes and product development.

At the global level, the United Nations' Sustainable Development Goals (SDGs) provide a broad framework for environmental sustainability, influencing national policies on green chemistry. The Paris Agreement on climate change also indirectly affects alkyl chemistry regulations by pushing for reduced carbon emissions across industries.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the use of alkyl compounds. It requires companies to register chemical substances and provide safety data, promoting the use of greener alternatives where possible. The EU's Circular Economy Action Plan further emphasizes the need for sustainable chemical processes, including those involving alkyl chemistry.

The United States Environmental Protection Agency (EPA) enforces several regulations relevant to alkyl chemistry under the Toxic Substances Control Act (TSCA). The Green Chemistry Initiative, launched by the EPA, encourages the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances.

In Asia, countries like China and Japan have been strengthening their environmental regulations. China's Environmental Protection Law and Japan's Chemical Substances Control Law both have provisions that impact alkyl chemistry practices, pushing for greener alternatives and stricter controls on potentially harmful substances.

Industry-specific regulations also play a significant role. For instance, the pharmaceutical industry faces stringent guidelines from regulatory bodies like the FDA and EMA, which increasingly emphasize the importance of green chemistry principles in drug development and manufacturing processes involving alkyl compounds.

Many countries have implemented tax incentives and funding programs to encourage research and development in green chemistry, including innovations in alkyl chemistry. These financial instruments serve as indirect regulatory tools to steer the industry towards more sustainable practices.

The regulatory landscape is continuously evolving, with a clear trend towards stricter environmental standards and a greater emphasis on sustainability. This dynamic environment presents both challenges and opportunities for companies working with alkyl chemistry, necessitating ongoing adaptation and innovation in chemical processes and product development.

Environmental Impact

Alkyl chemistry plays a crucial role in various industrial processes, but its environmental impact has become a growing concern in recent years. The traditional methods of alkyl chemistry often involve the use of toxic reagents, harsh reaction conditions, and generate significant amounts of waste. These practices contribute to environmental pollution, resource depletion, and potential health hazards.

One of the primary environmental concerns associated with alkyl chemistry is the release of volatile organic compounds (VOCs) into the atmosphere. These compounds can contribute to the formation of ground-level ozone and smog, leading to air quality issues and potential respiratory problems for humans and wildlife. Additionally, the improper disposal of alkyl-containing waste can contaminate soil and water resources, posing long-term risks to ecosystems and human health.

The production and use of alkyl compounds often require significant energy inputs, contributing to greenhouse gas emissions and climate change. Many alkyl-based products, such as plastics and synthetic materials, have long degradation times, leading to accumulation in landfills and marine environments. This persistence in the environment can have far-reaching consequences for biodiversity and ecosystem health.

To address these environmental challenges, green chemistry initiatives are focusing on developing more sustainable approaches to alkyl chemistry. These efforts include the use of renewable feedstocks, the design of more efficient catalysts, and the implementation of solvent-free or aqueous reaction conditions. By reducing the reliance on petroleum-based starting materials and minimizing waste generation, these green initiatives aim to decrease the overall environmental footprint of alkyl chemistry processes.

Another important aspect of improving the environmental impact of alkyl chemistry is the development of biodegradable and recyclable alkyl-based products. This approach not only reduces the accumulation of persistent materials in the environment but also promotes a circular economy model, where resources are used more efficiently and waste is minimized.

The adoption of green alkyl chemistry practices can lead to significant reductions in energy consumption, water usage, and hazardous waste generation. Furthermore, it can contribute to improved air and water quality, reduced greenhouse gas emissions, and the conservation of natural resources. As industries and researchers continue to innovate in this field, the potential for more environmentally friendly alkyl chemistry processes grows, offering promising solutions to mitigate the negative environmental impacts associated with traditional methods.

One of the primary environmental concerns associated with alkyl chemistry is the release of volatile organic compounds (VOCs) into the atmosphere. These compounds can contribute to the formation of ground-level ozone and smog, leading to air quality issues and potential respiratory problems for humans and wildlife. Additionally, the improper disposal of alkyl-containing waste can contaminate soil and water resources, posing long-term risks to ecosystems and human health.

The production and use of alkyl compounds often require significant energy inputs, contributing to greenhouse gas emissions and climate change. Many alkyl-based products, such as plastics and synthetic materials, have long degradation times, leading to accumulation in landfills and marine environments. This persistence in the environment can have far-reaching consequences for biodiversity and ecosystem health.

To address these environmental challenges, green chemistry initiatives are focusing on developing more sustainable approaches to alkyl chemistry. These efforts include the use of renewable feedstocks, the design of more efficient catalysts, and the implementation of solvent-free or aqueous reaction conditions. By reducing the reliance on petroleum-based starting materials and minimizing waste generation, these green initiatives aim to decrease the overall environmental footprint of alkyl chemistry processes.

Another important aspect of improving the environmental impact of alkyl chemistry is the development of biodegradable and recyclable alkyl-based products. This approach not only reduces the accumulation of persistent materials in the environment but also promotes a circular economy model, where resources are used more efficiently and waste is minimized.

The adoption of green alkyl chemistry practices can lead to significant reductions in energy consumption, water usage, and hazardous waste generation. Furthermore, it can contribute to improved air and water quality, reduced greenhouse gas emissions, and the conservation of natural resources. As industries and researchers continue to innovate in this field, the potential for more environmentally friendly alkyl chemistry processes grows, offering promising solutions to mitigate the negative environmental impacts associated with traditional methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!