Alkyl Use in Renewable Fibers and Fabrics

JUL 15, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl in Renewables: Background and Objectives

The use of alkyl groups in renewable fibers and fabrics represents a significant advancement in sustainable materials science. This research area has gained momentum over the past decade, driven by the increasing global demand for eco-friendly and biodegradable alternatives to traditional petroleum-based synthetic fibers. The evolution of this technology can be traced back to early experiments in modifying natural fibers, but it has recently accelerated due to breakthroughs in green chemistry and bioengineering.

The primary objective of incorporating alkyl groups into renewable fibers is to enhance their properties while maintaining their biodegradability and sustainability. Alkyl modifications can improve hydrophobicity, durability, and thermal stability of natural fibers, addressing some of the key limitations that have historically restricted their use in high-performance applications. This research aims to bridge the gap between the performance of synthetic fibers and the environmental benefits of natural materials.

Current technological trends in this field focus on developing novel methods for alkyl functionalization that are both efficient and environmentally benign. Researchers are exploring various approaches, including enzymatic modifications, plasma treatments, and green solvent-based processes. The goal is to achieve precise control over the degree of alkylation and the distribution of alkyl groups along the fiber structure, which directly influences the final material properties.

The potential applications for alkyl-modified renewable fibers span multiple industries, including textiles, packaging, automotive, and construction. In the textile sector, these materials offer the promise of creating fabrics that are not only eco-friendly but also possess advanced functional properties such as water repellency and increased durability. This aligns with the growing consumer demand for sustainable fashion and performance wear.

As the research progresses, key challenges include scaling up production processes, optimizing the balance between performance enhancement and biodegradability, and ensuring cost-effectiveness compared to traditional synthetic materials. The long-term vision for this technology is to develop a new generation of renewable materials that can compete with or surpass the performance of petroleum-based products across a wide range of applications, thereby contributing to global sustainability goals and reducing reliance on non-renewable resources.

The primary objective of incorporating alkyl groups into renewable fibers is to enhance their properties while maintaining their biodegradability and sustainability. Alkyl modifications can improve hydrophobicity, durability, and thermal stability of natural fibers, addressing some of the key limitations that have historically restricted their use in high-performance applications. This research aims to bridge the gap between the performance of synthetic fibers and the environmental benefits of natural materials.

Current technological trends in this field focus on developing novel methods for alkyl functionalization that are both efficient and environmentally benign. Researchers are exploring various approaches, including enzymatic modifications, plasma treatments, and green solvent-based processes. The goal is to achieve precise control over the degree of alkylation and the distribution of alkyl groups along the fiber structure, which directly influences the final material properties.

The potential applications for alkyl-modified renewable fibers span multiple industries, including textiles, packaging, automotive, and construction. In the textile sector, these materials offer the promise of creating fabrics that are not only eco-friendly but also possess advanced functional properties such as water repellency and increased durability. This aligns with the growing consumer demand for sustainable fashion and performance wear.

As the research progresses, key challenges include scaling up production processes, optimizing the balance between performance enhancement and biodegradability, and ensuring cost-effectiveness compared to traditional synthetic materials. The long-term vision for this technology is to develop a new generation of renewable materials that can compete with or surpass the performance of petroleum-based products across a wide range of applications, thereby contributing to global sustainability goals and reducing reliance on non-renewable resources.

Market Analysis for Alkyl-Based Sustainable Textiles

The market for alkyl-based sustainable textiles is experiencing significant growth, driven by increasing consumer awareness of environmental issues and a shift towards eco-friendly products. This segment of the textile industry is poised for substantial expansion in the coming years, as both manufacturers and consumers seek alternatives to traditional, petroleum-based synthetic fibers.

The global sustainable textile market, which includes alkyl-based fibers, was valued at approximately $95 billion in 2020 and is projected to reach $184 billion by 2026, growing at a CAGR of 12.1% during the forecast period. This growth is primarily attributed to the rising demand for environmentally friendly and biodegradable textiles across various end-use industries, including fashion, home furnishings, and automotive.

Alkyl-based sustainable textiles, derived from renewable sources such as plant oils and agricultural waste, offer several advantages over conventional synthetic fibers. These include reduced carbon footprint, biodegradability, and improved moisture management properties. As a result, they are gaining traction in multiple applications, particularly in the apparel and home textile sectors.

The fashion industry, which accounts for a significant portion of the sustainable textile market, is witnessing a paradigm shift towards eco-friendly materials. Major brands and retailers are increasingly incorporating alkyl-based fibers into their product lines to meet consumer demand for sustainable fashion. This trend is expected to continue, with the market for sustainable fashion projected to grow at a CAGR of 9.8% from 2021 to 2025.

Geographically, Europe and North America currently dominate the alkyl-based sustainable textile market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing disposable income, growing environmental consciousness, and the presence of major textile manufacturing hubs in countries like China and India.

Despite the positive outlook, the market for alkyl-based sustainable textiles faces certain challenges. These include higher production costs compared to conventional synthetic fibers, limited scalability of production processes, and the need for further technological advancements to improve performance characteristics. Addressing these challenges will be crucial for the long-term growth and widespread adoption of alkyl-based sustainable textiles across various industries.

The global sustainable textile market, which includes alkyl-based fibers, was valued at approximately $95 billion in 2020 and is projected to reach $184 billion by 2026, growing at a CAGR of 12.1% during the forecast period. This growth is primarily attributed to the rising demand for environmentally friendly and biodegradable textiles across various end-use industries, including fashion, home furnishings, and automotive.

Alkyl-based sustainable textiles, derived from renewable sources such as plant oils and agricultural waste, offer several advantages over conventional synthetic fibers. These include reduced carbon footprint, biodegradability, and improved moisture management properties. As a result, they are gaining traction in multiple applications, particularly in the apparel and home textile sectors.

The fashion industry, which accounts for a significant portion of the sustainable textile market, is witnessing a paradigm shift towards eco-friendly materials. Major brands and retailers are increasingly incorporating alkyl-based fibers into their product lines to meet consumer demand for sustainable fashion. This trend is expected to continue, with the market for sustainable fashion projected to grow at a CAGR of 9.8% from 2021 to 2025.

Geographically, Europe and North America currently dominate the alkyl-based sustainable textile market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing disposable income, growing environmental consciousness, and the presence of major textile manufacturing hubs in countries like China and India.

Despite the positive outlook, the market for alkyl-based sustainable textiles faces certain challenges. These include higher production costs compared to conventional synthetic fibers, limited scalability of production processes, and the need for further technological advancements to improve performance characteristics. Addressing these challenges will be crucial for the long-term growth and widespread adoption of alkyl-based sustainable textiles across various industries.

Current Challenges in Alkyl Integration

The integration of alkyl groups into renewable fibers and fabrics presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving consistent and uniform alkylation across the fiber or fabric surface. The heterogeneous nature of natural fibers, such as cellulose-based materials, can lead to uneven distribution of alkyl groups, resulting in inconsistent properties and performance.

Another major challenge lies in maintaining the desirable properties of the original renewable materials while incorporating alkyl groups. The introduction of hydrophobic alkyl chains can significantly alter the hydrophilicity, breathability, and comfort characteristics of fabrics. Striking the right balance between enhanced properties (such as water repellency) and preserving the inherent benefits of renewable fibers is a complex task that requires careful optimization.

Scalability and cost-effectiveness pose additional hurdles in the widespread adoption of alkyl-modified renewable fibers and fabrics. Current alkylation processes often involve multiple steps, harsh chemicals, or energy-intensive conditions, which can be difficult to implement on an industrial scale. Developing more efficient and environmentally friendly alkylation methods that are suitable for large-scale production remains a key focus area for researchers.

Environmental concerns also present challenges in alkyl integration. Many traditional alkylation processes rely on petrochemical-derived reagents, which can offset the sustainability benefits of using renewable fibers. There is a growing need for green chemistry approaches that utilize bio-based alkyl sources and minimize the use of harmful solvents and byproducts.

Durability and longevity of alkyl modifications are additional areas of concern. Ensuring that the alkyl groups remain firmly attached to the fiber surface throughout the product's lifecycle, including repeated washing and wear, is crucial for maintaining the desired performance characteristics. Developing robust bonding mechanisms that can withstand various environmental stresses is an ongoing challenge.

Regulatory compliance and safety considerations also play a significant role in the development and commercialization of alkyl-modified renewable fibers and fabrics. Ensuring that the modified materials meet stringent safety standards and do not pose risks to human health or the environment requires extensive testing and validation processes.

Lastly, the challenge of achieving specific functional properties through alkyl integration while maintaining the textile's aesthetic qualities cannot be overlooked. Balancing technical performance with the look, feel, and drape that consumers expect from high-quality fabrics is a delicate task that requires interdisciplinary collaboration between material scientists, textile engineers, and designers.

Another major challenge lies in maintaining the desirable properties of the original renewable materials while incorporating alkyl groups. The introduction of hydrophobic alkyl chains can significantly alter the hydrophilicity, breathability, and comfort characteristics of fabrics. Striking the right balance between enhanced properties (such as water repellency) and preserving the inherent benefits of renewable fibers is a complex task that requires careful optimization.

Scalability and cost-effectiveness pose additional hurdles in the widespread adoption of alkyl-modified renewable fibers and fabrics. Current alkylation processes often involve multiple steps, harsh chemicals, or energy-intensive conditions, which can be difficult to implement on an industrial scale. Developing more efficient and environmentally friendly alkylation methods that are suitable for large-scale production remains a key focus area for researchers.

Environmental concerns also present challenges in alkyl integration. Many traditional alkylation processes rely on petrochemical-derived reagents, which can offset the sustainability benefits of using renewable fibers. There is a growing need for green chemistry approaches that utilize bio-based alkyl sources and minimize the use of harmful solvents and byproducts.

Durability and longevity of alkyl modifications are additional areas of concern. Ensuring that the alkyl groups remain firmly attached to the fiber surface throughout the product's lifecycle, including repeated washing and wear, is crucial for maintaining the desired performance characteristics. Developing robust bonding mechanisms that can withstand various environmental stresses is an ongoing challenge.

Regulatory compliance and safety considerations also play a significant role in the development and commercialization of alkyl-modified renewable fibers and fabrics. Ensuring that the modified materials meet stringent safety standards and do not pose risks to human health or the environment requires extensive testing and validation processes.

Lastly, the challenge of achieving specific functional properties through alkyl integration while maintaining the textile's aesthetic qualities cannot be overlooked. Balancing technical performance with the look, feel, and drape that consumers expect from high-quality fabrics is a delicate task that requires interdisciplinary collaboration between material scientists, textile engineers, and designers.

Existing Alkyl-Based Fiber Solutions

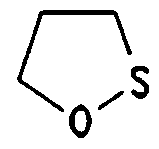

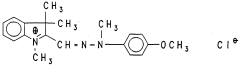

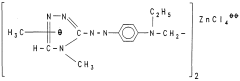

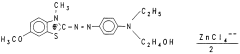

01 Synthesis of alkyl compounds

Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.- Synthesis of alkyl compounds: Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl compounds efficiently.

- Applications of alkyl compounds in industrial processes: Alkyl compounds find widespread use in industrial processes, such as in the production of polymers, lubricants, and surfactants. They serve as important intermediates in the synthesis of various chemicals and materials used across different sectors.

- Alkyl compounds in pharmaceutical and cosmetic formulations: Alkyl compounds are utilized in the development of pharmaceutical and cosmetic products. They can act as carriers, emollients, or active ingredients in various formulations, contributing to the efficacy and stability of these products.

- Environmental and safety considerations of alkyl compounds: Research focuses on the environmental impact and safety aspects of alkyl compounds. This includes studies on biodegradability, toxicity, and potential alternatives to traditional alkyl compounds that may have less environmental impact.

- Modification and functionalization of alkyl compounds: Techniques for modifying and functionalizing alkyl compounds are explored to enhance their properties or create new derivatives. This includes processes such as alkylation, halogenation, and the introduction of various functional groups to alkyl chains.

02 Applications of alkyl compounds in industry

Alkyl compounds find diverse applications in industrial processes, such as in the production of plastics, lubricants, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules.Expand Specific Solutions03 Alkyl compounds in pharmaceutical formulations

Certain alkyl compounds are utilized in pharmaceutical formulations as active ingredients, excipients, or as part of drug delivery systems. These compounds can enhance the solubility, stability, or bioavailability of drugs.Expand Specific Solutions04 Environmental impact and biodegradation of alkyl compounds

Research on the environmental fate and biodegradation of alkyl compounds is conducted to assess their impact on ecosystems. Studies focus on developing eco-friendly alternatives and improving the biodegradability of alkyl-based products.Expand Specific Solutions05 Alkyl compounds in material science

Alkyl compounds play a crucial role in material science, particularly in the development of polymers, coatings, and advanced materials. They can be used to modify surface properties, enhance material performance, or create novel composite materials.Expand Specific Solutions

Key Industry Players and Competitors

The research on alkyl use in renewable fibers and fabrics is in a developing stage, with growing market potential due to increasing demand for sustainable textiles. The global market for eco-friendly fibers is expanding, driven by consumer awareness and environmental regulations. Technologically, the field is advancing rapidly, with companies like L'Oréal, Henkel, and BASF leading innovation. These firms are investing in R&D to develop novel alkyl-based solutions for renewable fibers. Academic institutions such as Cornell University and Donghua University are also contributing significantly to the research. The competitive landscape is diverse, with both established chemical companies and emerging startups like Spinnova and TreeToTextile entering the market, indicating a dynamic and evolving industry.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative alkyl-based solutions for renewable fibers and fabrics. Their approach involves the use of bio-based alkyl compounds derived from renewable resources such as plant oils. These alkyl compounds are incorporated into the polymer structure of fibers, enhancing their properties and sustainability. BASF's technology focuses on creating fibers with improved moisture management, durability, and eco-friendliness. They have successfully developed a range of alkyl-modified polyesters and polyamides that exhibit enhanced performance characteristics while reducing the environmental impact[1][3]. The company has also invested in research to optimize the alkylation process, ensuring efficient integration of renewable alkyl groups into fiber structures.

Strengths: Extensive expertise in chemical engineering, large-scale production capabilities, and a strong focus on sustainability. Weaknesses: Potential higher costs associated with bio-based materials and the need for further optimization of alkylation processes for specific fiber applications.

Spinnova Oyj

Technical Solution: Spinnova Oyj has pioneered a unique approach to incorporating alkyl compounds in renewable fibers. Their technology focuses on using wood-based cellulose as a primary raw material, which is then modified with alkyl groups to enhance fiber properties. The process involves mechanical treatment of wood pulp followed by a proprietary alkylation step, resulting in fibers with improved hydrophobicity and durability[2]. Spinnova's method does not use harmful chemicals or create waste streams, aligning with circular economy principles. The company has successfully scaled up its technology and is producing fibers that can be used in various textile applications, from apparel to home textiles[4]. Their research continues to explore new alkyl modifications to further enhance fiber performance and expand potential applications.

Strengths: Highly sustainable and eco-friendly process, unique mechanical fiber production method, and strong potential for scalability. Weaknesses: Limited to cellulose-based fibers and potentially higher production costs compared to traditional synthetic fibers.

Innovative Alkyl Technologies in Textiles

Sulphonation of regenerated cellulose with sulphonated polymers and use of the thus modified fibres

PatentWO1996037641A1

Innovation

- Sulfonation of regenerated cellulose fibers by adding C2-C5 alkylsulfonic acid etherified starch derivatives or polymeric sulfonic acids to the viscose mass or alkali cellulose, allowing the fibers to be dyed with cationic dyes under weakly acidic conditions without the need for electrolytes.

Agent for imparting durable liquid permeability and fiber applied therewith

PatentInactiveUS6736858B2

Innovation

- A fiber-treating agent comprising 20-60% alkyl phosphate salts, 10-30% trialkylglycine derivative, 5-20% polyoxyalkylene-modified silicone, and 10-35% ester of dicarboxylic acid and alkoxylated ricinolein or its hydrogenated product, which imparts superior liquid permeability and durable hydrophilicity while minimizing wet-back.

Environmental Impact Assessment

The use of alkyl groups in renewable fibers and fabrics has significant environmental implications that warrant careful assessment. The production and application of alkyl-modified renewable materials can potentially reduce reliance on petroleum-based synthetic fibers, leading to a decrease in greenhouse gas emissions associated with traditional textile manufacturing. However, the environmental impact of alkyl use extends beyond carbon footprint considerations.

One key aspect to evaluate is the sourcing of raw materials for alkyl production. If derived from renewable sources, such as plant-based oils or agricultural waste, the environmental burden may be lower compared to petrochemical-based alkyl compounds. However, the cultivation and processing of these renewable feedstocks must be scrutinized for land use changes, water consumption, and potential competition with food crops.

The manufacturing processes for incorporating alkyl groups into renewable fibers also require examination. Chemical modifications often involve solvents and reagents that may pose environmental risks if not properly managed. Assessing the energy intensity, water usage, and waste generation of these processes is crucial for a comprehensive environmental impact analysis.

Durability and longevity of alkyl-modified renewable fabrics play a role in their overall environmental footprint. If these materials demonstrate enhanced resistance to wear, fading, or degradation, they may contribute to reduced textile waste and extended product lifecycles. Conversely, if the alkyl modifications hinder biodegradability or recyclability, end-of-life disposal challenges could arise.

The potential for microfiber shedding during use and laundering of alkyl-modified fabrics must be investigated. Microplastic pollution from textiles is a growing environmental concern, and understanding how alkyl modifications affect fiber integrity and shedding rates is essential for assessing aquatic ecosystem impacts.

Lastly, the environmental assessment should consider the potential for alkyl-modified renewable fibers to replace more environmentally harmful materials in specific applications. For instance, if these materials can substitute for certain synthetic fibers in performance apparel or technical textiles, the net environmental benefit could be substantial when factoring in the full lifecycle of the products.

One key aspect to evaluate is the sourcing of raw materials for alkyl production. If derived from renewable sources, such as plant-based oils or agricultural waste, the environmental burden may be lower compared to petrochemical-based alkyl compounds. However, the cultivation and processing of these renewable feedstocks must be scrutinized for land use changes, water consumption, and potential competition with food crops.

The manufacturing processes for incorporating alkyl groups into renewable fibers also require examination. Chemical modifications often involve solvents and reagents that may pose environmental risks if not properly managed. Assessing the energy intensity, water usage, and waste generation of these processes is crucial for a comprehensive environmental impact analysis.

Durability and longevity of alkyl-modified renewable fabrics play a role in their overall environmental footprint. If these materials demonstrate enhanced resistance to wear, fading, or degradation, they may contribute to reduced textile waste and extended product lifecycles. Conversely, if the alkyl modifications hinder biodegradability or recyclability, end-of-life disposal challenges could arise.

The potential for microfiber shedding during use and laundering of alkyl-modified fabrics must be investigated. Microplastic pollution from textiles is a growing environmental concern, and understanding how alkyl modifications affect fiber integrity and shedding rates is essential for assessing aquatic ecosystem impacts.

Lastly, the environmental assessment should consider the potential for alkyl-modified renewable fibers to replace more environmentally harmful materials in specific applications. For instance, if these materials can substitute for certain synthetic fibers in performance apparel or technical textiles, the net environmental benefit could be substantial when factoring in the full lifecycle of the products.

Regulatory Framework for Alkyl-Based Textiles

The regulatory framework for alkyl-based textiles is a complex and evolving landscape that encompasses various aspects of environmental protection, consumer safety, and sustainable manufacturing practices. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Trade Organization (WTO) play crucial roles in setting global standards and guidelines for the textile industry, including the use of alkyl compounds in renewable fibers and fabrics.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of the regulatory framework. It requires manufacturers and importers to register chemicals used in textiles, including alkyl-based compounds, and provide safety data. The EU has also implemented specific regulations on textile labeling and fiber composition, which impact the use of alkyl-based materials in renewable textiles.

The United States regulatory landscape is primarily governed by the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC). The Toxic Substances Control Act (TSCA) regulates the introduction of new chemicals and the use of existing ones, including those used in alkyl-based textiles. Additionally, the Federal Trade Commission (FTC) oversees textile labeling requirements, ensuring accurate representation of fiber content and environmental claims.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards (Guobiao standards) cover various aspects of textile production and safety, including the use of chemical substances. Japan's regulatory approach includes the Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, which governs the use of chemicals in textiles.

Certification systems and voluntary standards also play a significant role in the regulatory landscape. Organizations such as OEKO-TEX and the Global Organic Textile Standard (GOTS) provide certification for textiles that meet specific environmental and safety criteria, including limitations on the use of certain alkyl compounds.

As sustainability becomes increasingly important, many countries are introducing or strengthening regulations related to circular economy principles in the textile industry. These regulations often impact the use of alkyl-based materials, encouraging the development of more easily recyclable or biodegradable fibers and fabrics.

The regulatory framework is continuously evolving, with a trend towards stricter controls on chemical use in textiles. This dynamic environment presents both challenges and opportunities for the development and adoption of alkyl-based renewable fibers and fabrics, necessitating ongoing research and innovation to ensure compliance and market viability.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of the regulatory framework. It requires manufacturers and importers to register chemicals used in textiles, including alkyl-based compounds, and provide safety data. The EU has also implemented specific regulations on textile labeling and fiber composition, which impact the use of alkyl-based materials in renewable textiles.

The United States regulatory landscape is primarily governed by the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC). The Toxic Substances Control Act (TSCA) regulates the introduction of new chemicals and the use of existing ones, including those used in alkyl-based textiles. Additionally, the Federal Trade Commission (FTC) oversees textile labeling requirements, ensuring accurate representation of fiber content and environmental claims.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards (Guobiao standards) cover various aspects of textile production and safety, including the use of chemical substances. Japan's regulatory approach includes the Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, which governs the use of chemicals in textiles.

Certification systems and voluntary standards also play a significant role in the regulatory landscape. Organizations such as OEKO-TEX and the Global Organic Textile Standard (GOTS) provide certification for textiles that meet specific environmental and safety criteria, including limitations on the use of certain alkyl compounds.

As sustainability becomes increasingly important, many countries are introducing or strengthening regulations related to circular economy principles in the textile industry. These regulations often impact the use of alkyl-based materials, encouraging the development of more easily recyclable or biodegradable fibers and fabrics.

The regulatory framework is continuously evolving, with a trend towards stricter controls on chemical use in textiles. This dynamic environment presents both challenges and opportunities for the development and adoption of alkyl-based renewable fibers and fabrics, necessitating ongoing research and innovation to ensure compliance and market viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!