Alkyl Compounds and Their Influence on Catalysis

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Compounds in Catalysis: Background and Objectives

Alkyl compounds have played a pivotal role in the field of catalysis for decades, serving as both reactants and catalysts in various chemical processes. The study of these organic molecules and their influence on catalytic reactions has been a cornerstone of modern organic synthesis and industrial chemistry. As we delve into this research area, it is crucial to understand the historical context and the evolving objectives that drive current investigations.

The journey of alkyl compounds in catalysis began in the early 20th century with the advent of organometallic chemistry. Pioneering work by Victor Grignard and subsequent researchers laid the foundation for understanding the reactivity of carbon-metal bonds, which would later prove instrumental in catalytic processes. As the field progressed, the focus shifted from simple alkyl groups to more complex structures, expanding the repertoire of catalytic transformations.

In recent years, the objectives of research on alkyl compounds in catalysis have become increasingly sophisticated. One primary goal is to enhance the efficiency and selectivity of catalytic reactions. This involves designing alkyl-based catalysts that can perform transformations with higher yields, fewer side products, and under milder conditions. Additionally, there is a growing emphasis on developing sustainable catalytic processes that align with green chemistry principles.

Another significant objective is to unravel the mechanistic intricacies of alkyl-mediated catalysis. Researchers aim to elucidate the precise role of alkyl groups in various stages of catalytic cycles, from substrate activation to product formation. This fundamental understanding is crucial for rational catalyst design and optimization of reaction conditions.

The field is also witnessing a surge in interest towards developing novel alkyl-based catalysts for previously challenging or impossible transformations. This includes the activation of traditionally inert bonds, such as C-H functionalization, and the development of enantioselective catalysts for asymmetric synthesis.

Furthermore, the integration of alkyl compounds with other cutting-edge areas of chemistry, such as photocatalysis and electrochemistry, is opening new avenues for research. These interdisciplinary approaches aim to harness the unique properties of alkyl compounds to enable more efficient and sustainable chemical processes.

As we look to the future, the overarching goal of research in this field is to push the boundaries of what is possible in organic synthesis and industrial catalysis. By leveraging the versatility of alkyl compounds, scientists aspire to develop transformative technologies that can address global challenges in energy production, materials science, and pharmaceutical manufacturing.

The journey of alkyl compounds in catalysis began in the early 20th century with the advent of organometallic chemistry. Pioneering work by Victor Grignard and subsequent researchers laid the foundation for understanding the reactivity of carbon-metal bonds, which would later prove instrumental in catalytic processes. As the field progressed, the focus shifted from simple alkyl groups to more complex structures, expanding the repertoire of catalytic transformations.

In recent years, the objectives of research on alkyl compounds in catalysis have become increasingly sophisticated. One primary goal is to enhance the efficiency and selectivity of catalytic reactions. This involves designing alkyl-based catalysts that can perform transformations with higher yields, fewer side products, and under milder conditions. Additionally, there is a growing emphasis on developing sustainable catalytic processes that align with green chemistry principles.

Another significant objective is to unravel the mechanistic intricacies of alkyl-mediated catalysis. Researchers aim to elucidate the precise role of alkyl groups in various stages of catalytic cycles, from substrate activation to product formation. This fundamental understanding is crucial for rational catalyst design and optimization of reaction conditions.

The field is also witnessing a surge in interest towards developing novel alkyl-based catalysts for previously challenging or impossible transformations. This includes the activation of traditionally inert bonds, such as C-H functionalization, and the development of enantioselective catalysts for asymmetric synthesis.

Furthermore, the integration of alkyl compounds with other cutting-edge areas of chemistry, such as photocatalysis and electrochemistry, is opening new avenues for research. These interdisciplinary approaches aim to harness the unique properties of alkyl compounds to enable more efficient and sustainable chemical processes.

As we look to the future, the overarching goal of research in this field is to push the boundaries of what is possible in organic synthesis and industrial catalysis. By leveraging the versatility of alkyl compounds, scientists aspire to develop transformative technologies that can address global challenges in energy production, materials science, and pharmaceutical manufacturing.

Market Analysis for Alkyl-based Catalysts

The market for alkyl-based catalysts has experienced significant growth in recent years, driven by increasing demand across various industries. These catalysts play a crucial role in numerous chemical processes, particularly in the petrochemical, pharmaceutical, and fine chemical sectors. The global market for alkyl-based catalysts is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the primary factors contributing to this market expansion is the rising demand for cleaner and more efficient chemical processes. Alkyl-based catalysts offer improved selectivity and yield in many reactions, leading to reduced waste generation and energy consumption. This aligns well with the growing emphasis on sustainable and environmentally friendly manufacturing practices across industries.

The petrochemical industry remains the largest consumer of alkyl-based catalysts, accounting for a substantial portion of the market share. The ongoing shift towards lighter feedstocks and the increasing production of olefins and aromatics have further boosted the demand for these catalysts. Additionally, the pharmaceutical sector has emerged as a rapidly growing market for alkyl-based catalysts, driven by the need for more efficient and selective synthesis routes for complex drug molecules.

Geographically, Asia-Pacific dominates the alkyl-based catalyst market, with China and India being the major contributors to growth. The region's expanding chemical and pharmaceutical industries, coupled with increasing investments in research and development, are fueling the demand for advanced catalytic solutions. North America and Europe follow closely, with a strong focus on developing innovative catalyst technologies to meet stringent environmental regulations and improve process efficiency.

The market landscape is characterized by intense competition among key players, including multinational chemical companies and specialized catalyst manufacturers. These companies are investing heavily in research and development to enhance catalyst performance, expand their product portfolios, and gain a competitive edge. Collaborations between industry and academia are also becoming more prevalent, fostering innovation and accelerating the development of next-generation alkyl-based catalysts.

Despite the positive outlook, the market faces certain challenges. Fluctuations in raw material prices, particularly for precious metals used in catalyst formulations, can impact profit margins. Additionally, the development of alternative catalytic systems and the push towards bio-based chemicals pose potential threats to the long-term growth of alkyl-based catalysts in some applications.

In conclusion, the market for alkyl-based catalysts presents significant opportunities for growth and innovation. As industries continue to prioritize efficiency, sustainability, and product quality, the demand for advanced catalytic solutions is expected to rise. Companies that can successfully navigate the challenges and capitalize on emerging trends are likely to thrive in this dynamic market landscape.

One of the primary factors contributing to this market expansion is the rising demand for cleaner and more efficient chemical processes. Alkyl-based catalysts offer improved selectivity and yield in many reactions, leading to reduced waste generation and energy consumption. This aligns well with the growing emphasis on sustainable and environmentally friendly manufacturing practices across industries.

The petrochemical industry remains the largest consumer of alkyl-based catalysts, accounting for a substantial portion of the market share. The ongoing shift towards lighter feedstocks and the increasing production of olefins and aromatics have further boosted the demand for these catalysts. Additionally, the pharmaceutical sector has emerged as a rapidly growing market for alkyl-based catalysts, driven by the need for more efficient and selective synthesis routes for complex drug molecules.

Geographically, Asia-Pacific dominates the alkyl-based catalyst market, with China and India being the major contributors to growth. The region's expanding chemical and pharmaceutical industries, coupled with increasing investments in research and development, are fueling the demand for advanced catalytic solutions. North America and Europe follow closely, with a strong focus on developing innovative catalyst technologies to meet stringent environmental regulations and improve process efficiency.

The market landscape is characterized by intense competition among key players, including multinational chemical companies and specialized catalyst manufacturers. These companies are investing heavily in research and development to enhance catalyst performance, expand their product portfolios, and gain a competitive edge. Collaborations between industry and academia are also becoming more prevalent, fostering innovation and accelerating the development of next-generation alkyl-based catalysts.

Despite the positive outlook, the market faces certain challenges. Fluctuations in raw material prices, particularly for precious metals used in catalyst formulations, can impact profit margins. Additionally, the development of alternative catalytic systems and the push towards bio-based chemicals pose potential threats to the long-term growth of alkyl-based catalysts in some applications.

In conclusion, the market for alkyl-based catalysts presents significant opportunities for growth and innovation. As industries continue to prioritize efficiency, sustainability, and product quality, the demand for advanced catalytic solutions is expected to rise. Companies that can successfully navigate the challenges and capitalize on emerging trends are likely to thrive in this dynamic market landscape.

Current Challenges in Alkyl Compound Catalysis

The field of alkyl compound catalysis faces several significant challenges that hinder its full potential in various industrial applications. One of the primary obstacles is the stability and selectivity of catalysts when interacting with alkyl compounds. Many catalysts suffer from deactivation or degradation when exposed to these organic molecules, leading to reduced efficiency and increased costs in industrial processes.

Another major challenge lies in controlling the reactivity of alkyl compounds during catalytic reactions. The high reactivity of certain alkyl groups can lead to undesired side reactions, affecting product yield and purity. This issue is particularly pronounced in fine chemical synthesis and pharmaceutical manufacturing, where precise control over reaction pathways is crucial.

The development of sustainable and environmentally friendly catalytic processes involving alkyl compounds remains a significant hurdle. Many current methods rely on precious metal catalysts or harsh reaction conditions, which are not aligned with green chemistry principles. There is a pressing need for more efficient, cost-effective, and eco-friendly catalytic systems that can effectively handle alkyl compounds.

Catalyst design for alkyl compound reactions also presents challenges in terms of achieving high turnover numbers and frequencies. Many existing catalysts exhibit limited lifespans or require frequent regeneration, impacting the overall efficiency and economics of industrial processes. Improving catalyst longevity and performance under diverse reaction conditions is a key area of focus for researchers in this field.

The complexity of reaction mechanisms involving alkyl compounds and catalysts poses another significant challenge. Understanding the intricate interplay between catalyst structure, alkyl compound properties, and reaction conditions is crucial for optimizing catalytic processes. However, elucidating these mechanisms often requires advanced analytical techniques and computational modeling, which can be time-consuming and resource-intensive.

Scale-up and industrial implementation of laboratory-developed catalytic systems for alkyl compounds present additional hurdles. Processes that work well at small scales may encounter unforeseen issues when scaled up to industrial levels, such as heat and mass transfer limitations or unexpected side reactions. Bridging the gap between academic research and industrial application remains a persistent challenge in this field.

Lastly, the development of catalysts capable of activating inert C-H bonds in alkyl compounds for selective functionalization is an ongoing challenge. While progress has been made in this area, achieving high selectivity and efficiency in C-H activation reactions, particularly for complex molecules, continues to be a significant focus of research efforts in alkyl compound catalysis.

Another major challenge lies in controlling the reactivity of alkyl compounds during catalytic reactions. The high reactivity of certain alkyl groups can lead to undesired side reactions, affecting product yield and purity. This issue is particularly pronounced in fine chemical synthesis and pharmaceutical manufacturing, where precise control over reaction pathways is crucial.

The development of sustainable and environmentally friendly catalytic processes involving alkyl compounds remains a significant hurdle. Many current methods rely on precious metal catalysts or harsh reaction conditions, which are not aligned with green chemistry principles. There is a pressing need for more efficient, cost-effective, and eco-friendly catalytic systems that can effectively handle alkyl compounds.

Catalyst design for alkyl compound reactions also presents challenges in terms of achieving high turnover numbers and frequencies. Many existing catalysts exhibit limited lifespans or require frequent regeneration, impacting the overall efficiency and economics of industrial processes. Improving catalyst longevity and performance under diverse reaction conditions is a key area of focus for researchers in this field.

The complexity of reaction mechanisms involving alkyl compounds and catalysts poses another significant challenge. Understanding the intricate interplay between catalyst structure, alkyl compound properties, and reaction conditions is crucial for optimizing catalytic processes. However, elucidating these mechanisms often requires advanced analytical techniques and computational modeling, which can be time-consuming and resource-intensive.

Scale-up and industrial implementation of laboratory-developed catalytic systems for alkyl compounds present additional hurdles. Processes that work well at small scales may encounter unforeseen issues when scaled up to industrial levels, such as heat and mass transfer limitations or unexpected side reactions. Bridging the gap between academic research and industrial application remains a persistent challenge in this field.

Lastly, the development of catalysts capable of activating inert C-H bonds in alkyl compounds for selective functionalization is an ongoing challenge. While progress has been made in this area, achieving high selectivity and efficiency in C-H activation reactions, particularly for complex molecules, continues to be a significant focus of research efforts in alkyl compound catalysis.

Existing Alkyl Compound Catalytic Solutions

01 Catalytic influence of alkyl compounds in organic synthesis

Alkyl compounds play a significant role as catalysts in various organic synthesis reactions. They can influence reaction rates, selectivity, and yield. These compounds often act as Lewis acids or bases, facilitating the formation or breaking of chemical bonds. Their catalytic properties can be fine-tuned by modifying the alkyl chain length or branching.- Catalytic influence of alkyl compounds in organic synthesis: Alkyl compounds play a significant role as catalysts in various organic synthesis reactions. They can influence reaction rates, selectivity, and yield. These compounds often act as Lewis acids or bases, facilitating the formation or breaking of chemical bonds. Their catalytic properties can be fine-tuned by modifying the alkyl chain length or branching.

- Alkyl compounds in hydrocarbon processing: Alkyl compounds are widely used in hydrocarbon processing industries, particularly in petroleum refining and petrochemical production. They can act as catalysts or co-catalysts in processes such as alkylation, isomerization, and cracking. The catalytic influence of alkyl compounds in these processes can lead to improved product quality and increased process efficiency.

- Environmental applications of alkyl compound catalysts: Alkyl compounds have shown promising catalytic properties in environmental applications. They can be used in the treatment of pollutants, such as in the catalytic degradation of organic contaminants in wastewater or the reduction of harmful emissions from industrial processes. The catalytic influence of these compounds can lead to more efficient and environmentally friendly treatment methods.

- Alkyl compounds in polymerization catalysis: Alkyl compounds play a crucial role in polymerization reactions as catalysts or catalyst components. They can influence the molecular weight, structure, and properties of the resulting polymers. The catalytic influence of alkyl compounds in polymerization processes is particularly important in the production of various plastics and synthetic materials.

- Novel alkyl compound catalysts for sustainable chemistry: Research is ongoing to develop novel alkyl compound catalysts for sustainable chemical processes. These catalysts aim to improve reaction efficiency, reduce waste, and enable the use of renewable feedstocks. The catalytic influence of these novel alkyl compounds could lead to more environmentally friendly and economically viable chemical production methods.

02 Alkyl compounds in hydrocarbon processing

Alkyl compounds are widely used in hydrocarbon processing industries, particularly in petroleum refining and petrochemical production. They can act as catalysts or co-catalysts in processes such as alkylation, isomerization, and cracking. The catalytic influence of alkyl compounds in these processes can lead to improved product quality and increased process efficiency.Expand Specific Solutions03 Environmental applications of alkyl compound catalysts

Alkyl compounds with catalytic properties find applications in environmental remediation and green chemistry. They can be used in the treatment of industrial effluents, air pollution control, and the development of eco-friendly chemical processes. These compounds often promote reactions that break down pollutants or enable more sustainable synthesis routes.Expand Specific Solutions04 Alkyl compounds in polymerization catalysis

Alkyl compounds play a crucial role in polymerization reactions as catalysts or catalyst components. They can influence the molecular weight, structure, and properties of the resulting polymers. These compounds are particularly important in the production of various plastics and synthetic rubbers, where they can control the polymerization kinetics and product characteristics.Expand Specific Solutions05 Novel alkyl compound catalysts and their applications

Research continues to develop novel alkyl compound catalysts with enhanced performance and broader applications. These innovations include the design of supported alkyl catalysts, alkyl-metal complexes, and hybrid organic-inorganic catalytic systems. Such advancements aim to improve catalytic activity, selectivity, and stability across various chemical processes and industries.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The research on alkyl compounds and their influence on catalysis is in a mature stage of development, with significant market potential and ongoing technological advancements. The global market for catalysts is substantial, driven by increasing demand in various industries. Major players like China Petroleum & Chemical Corp., ExxonMobil Chemical Patents, Inc., and BASF Corp. are at the forefront of innovation in this field. These companies, along with research institutions such as the California Institute of Technology and Massachusetts Institute of Technology, are continuously improving catalyst efficiency and selectivity. The technology's maturity is evident in the diverse applications across petrochemicals, fine chemicals, and environmental sectors, with ongoing research focusing on enhancing catalytic performance and developing more sustainable processes.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced alkyl compound catalysts for petroleum refining and petrochemical processes. Their research focuses on improving catalytic efficiency and selectivity in alkylation reactions. Sinopec has implemented a novel alkylation technology using solid acid catalysts, which significantly reduces corrosion and environmental impact compared to traditional liquid acid catalysts[1]. The company has also made breakthroughs in the synthesis of high-performance alkyl benzene sulfonates, used in detergents and surfactants, by optimizing the alkylation process and catalyst composition[2]. Additionally, Sinopec has developed proprietary zeolite-based catalysts for alkylation of aromatics, enhancing product yield and reducing energy consumption in the production of important intermediates like ethylbenzene and cumene[3].

Strengths: Extensive R&D capabilities, large-scale industrial application, and integration of upstream and downstream processes. Weaknesses: Potential over-reliance on fossil fuel-based feedstocks and challenges in transitioning to more sustainable technologies.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents, Inc. has made significant advancements in alkyl compound research and catalysis. Their innovative approach includes the development of a new class of metallocene catalysts for olefin polymerization, which allows for precise control over polymer structure and properties[4]. In the field of alkylation, ExxonMobil has patented a solid acid catalyst system that operates at lower temperatures and pressures than conventional processes, resulting in improved energy efficiency and reduced environmental impact[5]. The company has also pioneered the use of ionic liquids as catalysts for alkylation reactions, offering a more environmentally friendly alternative to traditional acid catalysts[6]. Furthermore, ExxonMobil has developed novel alkyl-substituted zeolite catalysts for the production of high-octane gasoline blending components, enhancing fuel efficiency and reducing emissions[7].

Strengths: Strong intellectual property portfolio, cutting-edge catalyst technologies, and global research capabilities. Weaknesses: High dependence on petroleum-based products and potential regulatory challenges in transitioning to greener technologies.

Breakthrough Alkyl Compound Catalytic Technologies

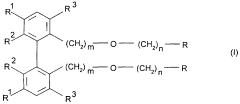

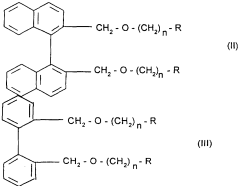

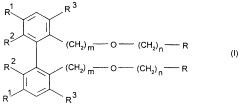

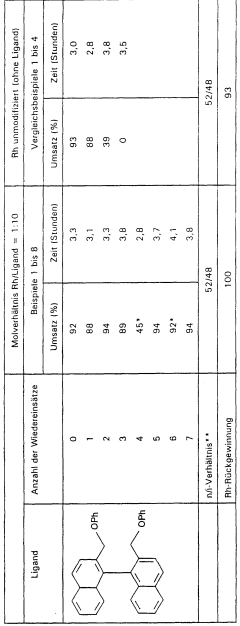

Catalyst and a process for preparation of aldehydes in the presence of said catalyst

PatentWO1997049490A1

Innovation

- A rhodium-based catalyst incorporating a bisether compound with a 2,2'-bisaryl radical, which is stable to oxygen and sulfur, and not hydrolyzable, maintaining high thermal stability and hydroformylation activity even after reuse.

Catalytic reactions involving alkenes

PatentWO2007027752A1

Innovation

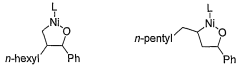

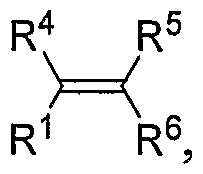

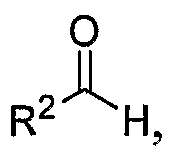

- A nickel-catalyzed method involving a catalyst system with a Group 9, 10, or 11 metal, using a nickel-containing compound, a phosphorus-containing ligand, a silicon-containing compound, and a base, such as dicyclohexylphenylphosphine or tri(ortho-anisyl)phosphine, to facilitate the coupling of alkenes and aldehydes, forming allylic alcohols or their precursors like silyl ethers in a one-pot reaction.

Environmental Impact of Alkyl Compound Catalysts

The environmental impact of alkyl compound catalysts is a critical consideration in the field of catalysis research. These catalysts, while essential for numerous industrial processes, can have significant effects on the environment throughout their lifecycle.

Alkyl compound catalysts often contain heavy metals or other potentially harmful substances, which can pose risks to ecosystems if released into the environment. During the production phase, the synthesis of these catalysts may involve the use of toxic precursors or generate hazardous waste streams. Proper handling and disposal of these materials are crucial to prevent soil and water contamination.

In their active use, alkyl compound catalysts can contribute to air pollution through the emission of volatile organic compounds (VOCs). These emissions may occur during catalytic reactions or through evaporation from storage and handling processes. VOCs can participate in the formation of ground-level ozone and smog, leading to adverse effects on air quality and human health.

Water pollution is another concern associated with alkyl compound catalysts. Effluents from catalytic processes may contain trace amounts of these compounds, which can accumulate in aquatic environments. This accumulation can disrupt ecosystems, affecting aquatic life and potentially entering the food chain.

The disposal of spent catalysts presents additional environmental challenges. Improper disposal can lead to the leaching of harmful components into soil and groundwater. Recycling and regeneration of catalysts are increasingly important practices to mitigate these risks and reduce the overall environmental footprint of catalytic processes.

On the positive side, alkyl compound catalysts often enable more efficient chemical reactions, potentially reducing energy consumption and waste generation in industrial processes. This efficiency can lead to a net positive environmental impact when compared to alternative, non-catalytic processes.

Research into green chemistry principles is driving the development of more environmentally friendly alkyl compound catalysts. This includes the design of catalysts with reduced toxicity, improved recyclability, and enhanced biodegradability. Innovations in this area aim to minimize the environmental impact while maintaining or improving catalytic performance.

Life cycle assessments (LCAs) are increasingly being employed to evaluate the overall environmental impact of alkyl compound catalysts. These assessments consider all stages from production to disposal, providing a comprehensive view of the environmental implications and guiding efforts to improve sustainability in catalysis.

Alkyl compound catalysts often contain heavy metals or other potentially harmful substances, which can pose risks to ecosystems if released into the environment. During the production phase, the synthesis of these catalysts may involve the use of toxic precursors or generate hazardous waste streams. Proper handling and disposal of these materials are crucial to prevent soil and water contamination.

In their active use, alkyl compound catalysts can contribute to air pollution through the emission of volatile organic compounds (VOCs). These emissions may occur during catalytic reactions or through evaporation from storage and handling processes. VOCs can participate in the formation of ground-level ozone and smog, leading to adverse effects on air quality and human health.

Water pollution is another concern associated with alkyl compound catalysts. Effluents from catalytic processes may contain trace amounts of these compounds, which can accumulate in aquatic environments. This accumulation can disrupt ecosystems, affecting aquatic life and potentially entering the food chain.

The disposal of spent catalysts presents additional environmental challenges. Improper disposal can lead to the leaching of harmful components into soil and groundwater. Recycling and regeneration of catalysts are increasingly important practices to mitigate these risks and reduce the overall environmental footprint of catalytic processes.

On the positive side, alkyl compound catalysts often enable more efficient chemical reactions, potentially reducing energy consumption and waste generation in industrial processes. This efficiency can lead to a net positive environmental impact when compared to alternative, non-catalytic processes.

Research into green chemistry principles is driving the development of more environmentally friendly alkyl compound catalysts. This includes the design of catalysts with reduced toxicity, improved recyclability, and enhanced biodegradability. Innovations in this area aim to minimize the environmental impact while maintaining or improving catalytic performance.

Life cycle assessments (LCAs) are increasingly being employed to evaluate the overall environmental impact of alkyl compound catalysts. These assessments consider all stages from production to disposal, providing a comprehensive view of the environmental implications and guiding efforts to improve sustainability in catalysis.

Regulatory Framework for Alkyl Compound Use in Catalysis

The regulatory framework for alkyl compound use in catalysis is a complex and evolving landscape that significantly impacts research, development, and industrial applications. At the global level, organizations such as the International Union of Pure and Applied Chemistry (IUPAC) and the World Health Organization (WHO) provide guidelines and recommendations for the safe handling and use of alkyl compounds in catalytic processes.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of alkyl compounds through the Toxic Substances Control Act (TSCA). This act requires manufacturers and importers to submit premanufacture notices for new chemical substances, including those used in catalysis. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace safety and exposure limits for various alkyl compounds used in industrial catalytic processes.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which aims to protect human health and the environment from the risks posed by chemicals. Under REACH, companies must register their use of alkyl compounds in catalysis and provide safety data to the European Chemicals Agency (ECHA). Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that the hazards of chemicals are clearly communicated to workers and consumers.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both require the registration and evaluation of chemical substances, including alkyl compounds used in catalysis.

Specific regulations often focus on the environmental impact of alkyl compounds, their potential for bioaccumulation, and their toxicity. For instance, many countries have strict controls on the use of certain alkyl compounds, such as alkyl mercury compounds, due to their high toxicity and environmental persistence. These regulations may limit the concentration of alkyl compounds in waste streams or require specific treatment methods before disposal.

The regulatory landscape also addresses the transportation and storage of alkyl compounds used in catalysis. International agreements like the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provide a standardized approach to communicating chemical hazards, which is crucial for the safe transport and handling of these compounds across borders.

As research in alkyl compound catalysis advances, regulatory frameworks continue to evolve. There is an increasing focus on promoting green chemistry principles, encouraging the development of less hazardous alternatives, and implementing lifecycle assessments for catalytic processes involving alkyl compounds. This dynamic regulatory environment necessitates ongoing compliance efforts and adaptability from researchers and industries working with alkyl compounds in catalysis.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of alkyl compounds through the Toxic Substances Control Act (TSCA). This act requires manufacturers and importers to submit premanufacture notices for new chemical substances, including those used in catalysis. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace safety and exposure limits for various alkyl compounds used in industrial catalytic processes.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which aims to protect human health and the environment from the risks posed by chemicals. Under REACH, companies must register their use of alkyl compounds in catalysis and provide safety data to the European Chemicals Agency (ECHA). Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that the hazards of chemicals are clearly communicated to workers and consumers.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both require the registration and evaluation of chemical substances, including alkyl compounds used in catalysis.

Specific regulations often focus on the environmental impact of alkyl compounds, their potential for bioaccumulation, and their toxicity. For instance, many countries have strict controls on the use of certain alkyl compounds, such as alkyl mercury compounds, due to their high toxicity and environmental persistence. These regulations may limit the concentration of alkyl compounds in waste streams or require specific treatment methods before disposal.

The regulatory landscape also addresses the transportation and storage of alkyl compounds used in catalysis. International agreements like the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provide a standardized approach to communicating chemical hazards, which is crucial for the safe transport and handling of these compounds across borders.

As research in alkyl compound catalysis advances, regulatory frameworks continue to evolve. There is an increasing focus on promoting green chemistry principles, encouraging the development of less hazardous alternatives, and implementing lifecycle assessments for catalytic processes involving alkyl compounds. This dynamic regulatory environment necessitates ongoing compliance efforts and adaptability from researchers and industries working with alkyl compounds in catalysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!