How Alkyl Chemistry is Transforming Waste Management?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Chemistry in Waste Management: Background and Objectives

Alkyl chemistry has emerged as a transformative force in the field of waste management, offering innovative solutions to longstanding environmental challenges. The evolution of this technology can be traced back to the early 20th century when scientists first began exploring the potential of organic compounds in industrial processes. Over the decades, alkyl chemistry has progressed from basic applications to sophisticated techniques that are now revolutionizing waste treatment and recycling methods.

The primary objective of applying alkyl chemistry to waste management is to develop more efficient, environmentally friendly, and cost-effective processes for handling various types of waste. This includes improving the degradation of organic pollutants, enhancing the recovery of valuable materials from waste streams, and reducing the overall environmental impact of waste disposal practices. By leveraging the unique properties of alkyl compounds, researchers and industry professionals aim to create sustainable solutions that address the growing global waste crisis.

One of the key trends in this field is the development of alkyl-based surfactants and solvents that can effectively separate and extract valuable components from complex waste mixtures. These advanced materials are designed to be highly selective, allowing for the targeted removal of specific contaminants or the recovery of precious resources. Additionally, alkyl chemistry is being employed to create novel biodegradable plastics and packaging materials, which could significantly reduce the accumulation of non-biodegradable waste in landfills and oceans.

The application of alkyl chemistry in waste management also extends to the treatment of industrial effluents and contaminated soils. Researchers are exploring the use of alkyl-functionalized materials as adsorbents for heavy metals and organic pollutants, offering a more efficient alternative to traditional remediation techniques. Furthermore, the development of alkyl-based catalysts is opening new avenues for the conversion of waste materials into valuable chemical feedstocks or energy sources, aligning with the principles of circular economy.

As the field continues to advance, the integration of alkyl chemistry with other emerging technologies, such as nanotechnology and biotechnology, is expected to yield even more innovative waste management solutions. These interdisciplinary approaches hold the promise of addressing complex environmental challenges while simultaneously creating new economic opportunities in the waste management sector. The ongoing research and development in this area are driven by the urgent need to find sustainable alternatives to conventional waste disposal methods and to mitigate the environmental impact of human activities.

The primary objective of applying alkyl chemistry to waste management is to develop more efficient, environmentally friendly, and cost-effective processes for handling various types of waste. This includes improving the degradation of organic pollutants, enhancing the recovery of valuable materials from waste streams, and reducing the overall environmental impact of waste disposal practices. By leveraging the unique properties of alkyl compounds, researchers and industry professionals aim to create sustainable solutions that address the growing global waste crisis.

One of the key trends in this field is the development of alkyl-based surfactants and solvents that can effectively separate and extract valuable components from complex waste mixtures. These advanced materials are designed to be highly selective, allowing for the targeted removal of specific contaminants or the recovery of precious resources. Additionally, alkyl chemistry is being employed to create novel biodegradable plastics and packaging materials, which could significantly reduce the accumulation of non-biodegradable waste in landfills and oceans.

The application of alkyl chemistry in waste management also extends to the treatment of industrial effluents and contaminated soils. Researchers are exploring the use of alkyl-functionalized materials as adsorbents for heavy metals and organic pollutants, offering a more efficient alternative to traditional remediation techniques. Furthermore, the development of alkyl-based catalysts is opening new avenues for the conversion of waste materials into valuable chemical feedstocks or energy sources, aligning with the principles of circular economy.

As the field continues to advance, the integration of alkyl chemistry with other emerging technologies, such as nanotechnology and biotechnology, is expected to yield even more innovative waste management solutions. These interdisciplinary approaches hold the promise of addressing complex environmental challenges while simultaneously creating new economic opportunities in the waste management sector. The ongoing research and development in this area are driven by the urgent need to find sustainable alternatives to conventional waste disposal methods and to mitigate the environmental impact of human activities.

Market Analysis for Alkyl-Based Waste Treatment Solutions

The market for alkyl-based waste treatment solutions is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on waste management. This sector is poised for substantial expansion over the next decade, with a projected compound annual growth rate (CAGR) of 7.5% from 2023 to 2033. The global market value for alkyl-based waste treatment solutions is expected to reach $12.3 billion by 2033, up from $6.1 billion in 2023.

Key factors contributing to this market growth include the rising volume of industrial waste, particularly in developing economies, and the growing awareness of the environmental impact of traditional waste management methods. Alkyl-based solutions offer several advantages over conventional techniques, including higher efficiency in treating organic pollutants, reduced environmental footprint, and potential for resource recovery.

The industrial sector remains the largest consumer of alkyl-based waste treatment solutions, accounting for approximately 65% of the market share. This is primarily due to the increasing adoption of these technologies in industries such as chemical manufacturing, petrochemicals, and pharmaceuticals. The municipal sector is also showing promising growth, with many cities and towns exploring alkyl-based solutions for wastewater treatment and solid waste management.

Geographically, North America and Europe currently dominate the market, collectively holding about 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 9.2% during the forecast period. This growth is attributed to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

The market is characterized by intense competition among key players, including multinational corporations and specialized waste management companies. These companies are investing heavily in research and development to improve the efficiency and cost-effectiveness of alkyl-based waste treatment technologies. Mergers, acquisitions, and strategic partnerships are common strategies employed by market leaders to expand their product portfolios and geographical presence.

Despite the positive outlook, the market faces several challenges. The high initial investment required for implementing alkyl-based waste treatment systems remains a significant barrier, particularly for small and medium-sized enterprises. Additionally, the lack of awareness and technical expertise in some regions hinders market growth. However, these challenges also present opportunities for market players to develop more cost-effective solutions and provide comprehensive training and support services.

Key factors contributing to this market growth include the rising volume of industrial waste, particularly in developing economies, and the growing awareness of the environmental impact of traditional waste management methods. Alkyl-based solutions offer several advantages over conventional techniques, including higher efficiency in treating organic pollutants, reduced environmental footprint, and potential for resource recovery.

The industrial sector remains the largest consumer of alkyl-based waste treatment solutions, accounting for approximately 65% of the market share. This is primarily due to the increasing adoption of these technologies in industries such as chemical manufacturing, petrochemicals, and pharmaceuticals. The municipal sector is also showing promising growth, with many cities and towns exploring alkyl-based solutions for wastewater treatment and solid waste management.

Geographically, North America and Europe currently dominate the market, collectively holding about 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 9.2% during the forecast period. This growth is attributed to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

The market is characterized by intense competition among key players, including multinational corporations and specialized waste management companies. These companies are investing heavily in research and development to improve the efficiency and cost-effectiveness of alkyl-based waste treatment technologies. Mergers, acquisitions, and strategic partnerships are common strategies employed by market leaders to expand their product portfolios and geographical presence.

Despite the positive outlook, the market faces several challenges. The high initial investment required for implementing alkyl-based waste treatment systems remains a significant barrier, particularly for small and medium-sized enterprises. Additionally, the lack of awareness and technical expertise in some regions hinders market growth. However, these challenges also present opportunities for market players to develop more cost-effective solutions and provide comprehensive training and support services.

Current Challenges in Alkyl Chemistry for Waste Management

Alkyl chemistry in waste management faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complexity of waste streams, which often contain a diverse mix of organic and inorganic materials. This heterogeneity makes it difficult to develop universal alkyl-based solutions that can effectively treat all types of waste simultaneously.

Another major challenge lies in the scalability of alkyl chemistry processes for large-scale waste management operations. While laboratory-scale experiments have shown promising results, translating these into industrial-scale applications presents numerous engineering and economic hurdles. The high costs associated with specialized equipment and the need for precise control over reaction conditions often make alkyl-based waste treatment methods less economically viable compared to traditional waste management techniques.

Environmental concerns also pose significant challenges to the implementation of alkyl chemistry in waste management. Some alkyl-based processes may generate harmful byproducts or require the use of toxic reagents, raising questions about their overall environmental impact. Regulatory bodies are increasingly scrutinizing these methods, demanding rigorous safety assessments and environmental impact studies before approving their use in waste treatment facilities.

The energy intensity of certain alkyl chemistry processes is another area of concern. Many reactions require high temperatures or pressures, leading to substantial energy consumption. This not only increases operational costs but also raises questions about the carbon footprint of these waste management solutions, potentially offsetting their environmental benefits.

Furthermore, the selectivity of alkyl-based reactions in complex waste matrices remains a significant technical challenge. Achieving high conversion rates and product yields in the presence of multiple interfering substances requires advanced catalyst design and process optimization. Researchers are still working to develop more robust and selective catalytic systems that can maintain their efficiency in real-world waste treatment scenarios.

The recovery and recycling of valuable materials from waste streams using alkyl chemistry also present challenges. While these methods show promise for extracting useful compounds, the processes often struggle with achieving high purity levels necessary for commercial applications. Developing more efficient separation and purification techniques is crucial for making these recovery processes economically viable.

Lastly, there is a knowledge gap in understanding the long-term effects of alkyl-based waste treatment methods on the environment and human health. More comprehensive studies are needed to assess the potential accumulation of reaction products in ecosystems and their impact on biodiversity. This lack of long-term data creates uncertainty and hesitation among policymakers and industry stakeholders in fully embracing these innovative waste management solutions.

Another major challenge lies in the scalability of alkyl chemistry processes for large-scale waste management operations. While laboratory-scale experiments have shown promising results, translating these into industrial-scale applications presents numerous engineering and economic hurdles. The high costs associated with specialized equipment and the need for precise control over reaction conditions often make alkyl-based waste treatment methods less economically viable compared to traditional waste management techniques.

Environmental concerns also pose significant challenges to the implementation of alkyl chemistry in waste management. Some alkyl-based processes may generate harmful byproducts or require the use of toxic reagents, raising questions about their overall environmental impact. Regulatory bodies are increasingly scrutinizing these methods, demanding rigorous safety assessments and environmental impact studies before approving their use in waste treatment facilities.

The energy intensity of certain alkyl chemistry processes is another area of concern. Many reactions require high temperatures or pressures, leading to substantial energy consumption. This not only increases operational costs but also raises questions about the carbon footprint of these waste management solutions, potentially offsetting their environmental benefits.

Furthermore, the selectivity of alkyl-based reactions in complex waste matrices remains a significant technical challenge. Achieving high conversion rates and product yields in the presence of multiple interfering substances requires advanced catalyst design and process optimization. Researchers are still working to develop more robust and selective catalytic systems that can maintain their efficiency in real-world waste treatment scenarios.

The recovery and recycling of valuable materials from waste streams using alkyl chemistry also present challenges. While these methods show promise for extracting useful compounds, the processes often struggle with achieving high purity levels necessary for commercial applications. Developing more efficient separation and purification techniques is crucial for making these recovery processes economically viable.

Lastly, there is a knowledge gap in understanding the long-term effects of alkyl-based waste treatment methods on the environment and human health. More comprehensive studies are needed to assess the potential accumulation of reaction products in ecosystems and their impact on biodiversity. This lack of long-term data creates uncertainty and hesitation among policymakers and industry stakeholders in fully embracing these innovative waste management solutions.

Existing Alkyl-Based Waste Treatment Methods

01 Alkyl-based chemical reactions and synthesis

This category focuses on various chemical reactions and synthesis methods involving alkyl groups. It includes processes for creating alkyl compounds, modifying existing molecules with alkyl groups, and studying the reactivity of alkyl-containing substances. These reactions are fundamental in organic chemistry and have applications in pharmaceuticals, materials science, and industrial processes.- Alkyl-based chemical synthesis and modifications: This category focuses on the synthesis and modification of alkyl compounds, including various chemical reactions and processes involving alkyl groups. It covers techniques for creating, altering, or functionalizing alkyl chains in different molecular structures.

- Alkyl compounds in polymer and material science: This area explores the use of alkyl compounds in polymer chemistry and material science applications. It includes the development of alkyl-based polymers, coatings, and advanced materials with specific properties derived from alkyl groups.

- Alkyl chemistry in biochemistry and pharmaceutical applications: This point covers the role of alkyl chemistry in biochemical processes and pharmaceutical development. It includes the use of alkyl groups in drug design, bioactive compounds, and their interactions with biological systems.

- Analytical methods and characterization of alkyl compounds: This category focuses on analytical techniques and methods for characterizing alkyl compounds. It includes spectroscopic, chromatographic, and other analytical approaches for identifying, quantifying, and studying the properties of alkyl-containing molecules.

- Industrial applications of alkyl chemistry: This point covers the various industrial applications of alkyl chemistry, including its use in fuel production, lubricants, surfactants, and other commercial products. It encompasses processes and formulations that leverage the properties of alkyl compounds for practical applications.

02 Alkyl-modified materials and coatings

This area explores the use of alkyl groups to modify materials and create specialized coatings. By incorporating alkyl chains into polymers, surfaces, or nanoparticles, researchers can alter properties such as hydrophobicity, chemical resistance, and thermal stability. These modifications have applications in areas like protective coatings, self-cleaning surfaces, and advanced materials for various industries.Expand Specific Solutions03 Alkyl-based surfactants and emulsifiers

This category covers the development and application of alkyl-based surfactants and emulsifiers. These compounds, which contain both hydrophilic and hydrophobic (alkyl) parts, are crucial in formulating stable emulsions, detergents, and personal care products. Research in this area focuses on optimizing alkyl chain length and structure for specific applications and improving the environmental profile of these substances.Expand Specific Solutions04 Analytical methods for alkyl compounds

This point encompasses the development and application of analytical techniques for detecting, identifying, and quantifying alkyl compounds. It includes chromatographic methods, spectroscopic techniques, and chemical sensors designed to analyze alkyl groups in various matrices. These analytical approaches are essential for quality control, environmental monitoring, and research in fields where alkyl chemistry plays a role.Expand Specific Solutions05 Alkyl-based catalysts and reaction mechanisms

This area focuses on the use of alkyl groups in catalysis and the study of reaction mechanisms involving alkyl compounds. It includes the design of alkyl-containing catalysts for organic synthesis, polymerization reactions, and industrial processes. Research in this field aims to understand the role of alkyl groups in catalytic cycles and develop more efficient and selective catalytic systems.Expand Specific Solutions

Key Players in Alkyl Chemistry and Waste Management Industry

The alkyl chemistry market in waste management is in a growth phase, driven by increasing environmental concerns and stringent regulations. The market size is expanding as more industries adopt sustainable practices. Technologically, the field is advancing rapidly, with companies like Henkel AG & Co. KGaA and China Petroleum & Chemical Corp. leading innovation. Smaller players such as Qingdao Ruifengyuan Chemical Co., Ltd. are also contributing to technological advancements. The involvement of research institutions like the Institute of Process Engineering, Chinese Academy of Sciences, indicates a focus on developing cutting-edge solutions. While the technology is maturing, there is still room for significant improvements and applications in waste management processes.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed innovative alkyl-based solutions for waste management, focusing on biodegradable surfactants and enzymes. Their approach involves using alkyl polyglucosides (APGs) as eco-friendly cleaning agents in waste treatment processes. These APGs are derived from renewable raw materials and offer excellent biodegradability[1]. Henkel's technology also incorporates specialized enzymes that break down complex organic waste, enhancing the efficiency of wastewater treatment plants. The company has implemented a closed-loop recycling system for plastic waste, utilizing alkyl chemistry to improve the quality of recycled materials[2].

Strengths: Eco-friendly solutions, improved biodegradability, and enhanced waste treatment efficiency. Weaknesses: Potentially higher production costs and limited applicability to certain types of waste.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced alkylation technologies for waste oil recycling and conversion. Their process involves using solid acid catalysts to convert waste cooking oils and other hydrocarbon waste into high-value alkylate products. This technology significantly reduces sulfur content in the final products, meeting stringent environmental standards[3]. Sinopec has also implemented a large-scale alkylation unit that processes refinery waste streams, converting them into clean-burning gasoline blendstocks. The company's research focuses on improving catalyst efficiency and reducing energy consumption in the alkylation process[4].

Strengths: Large-scale implementation, efficient waste oil conversion, and production of high-value products. Weaknesses: High initial investment costs and potential catalyst deactivation issues.

Innovative Alkyl Chemistry Applications in Waste Management

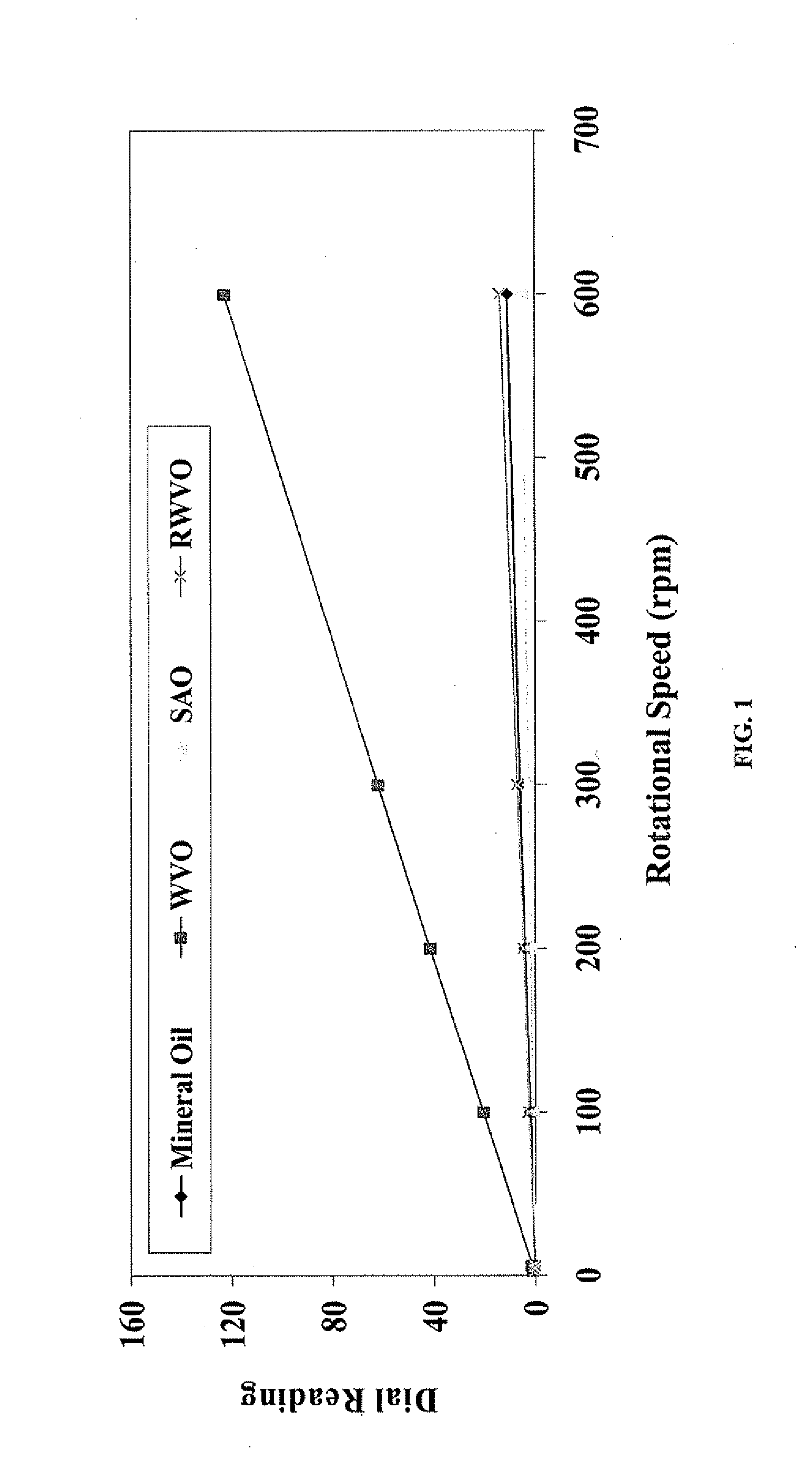

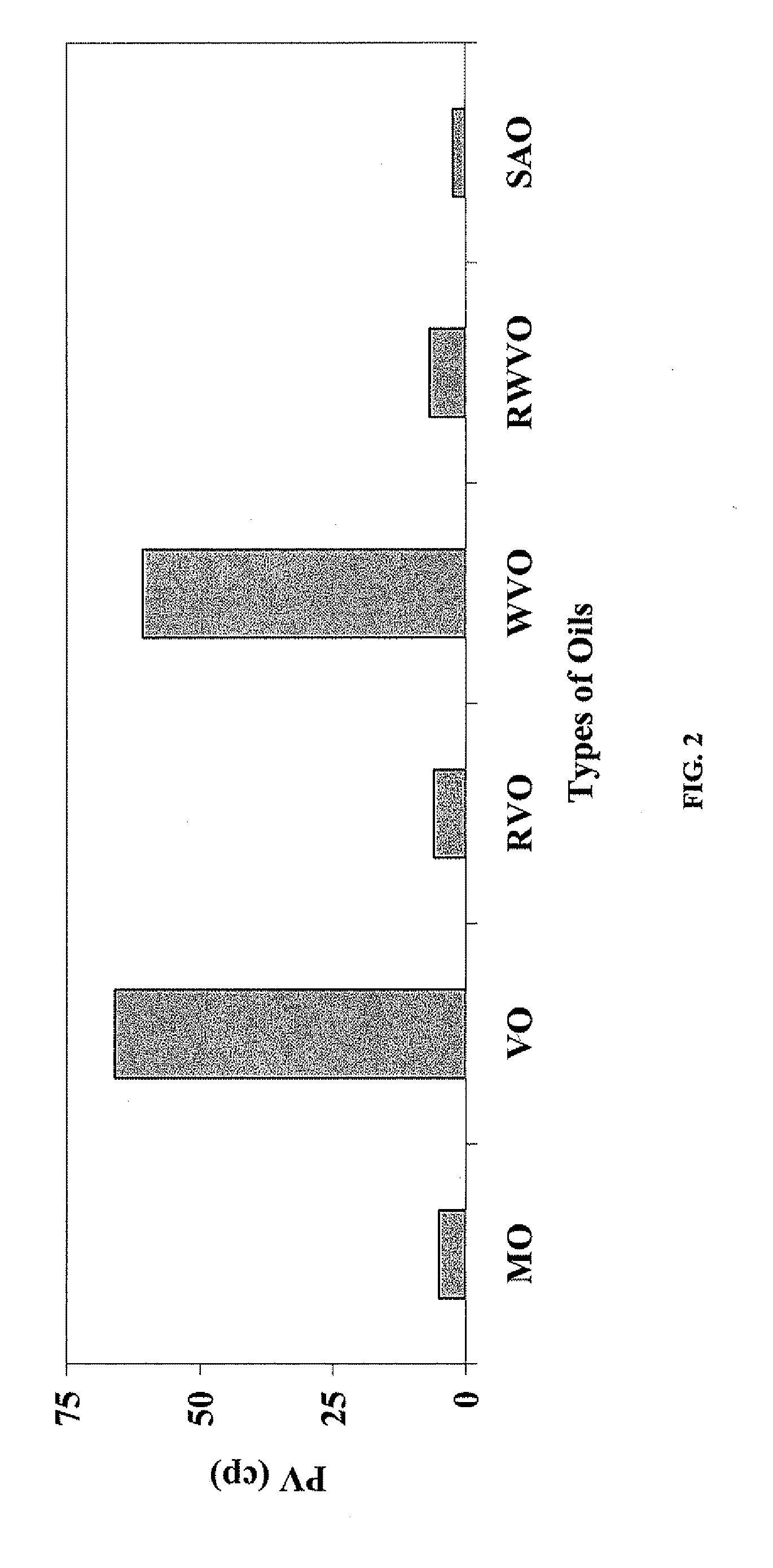

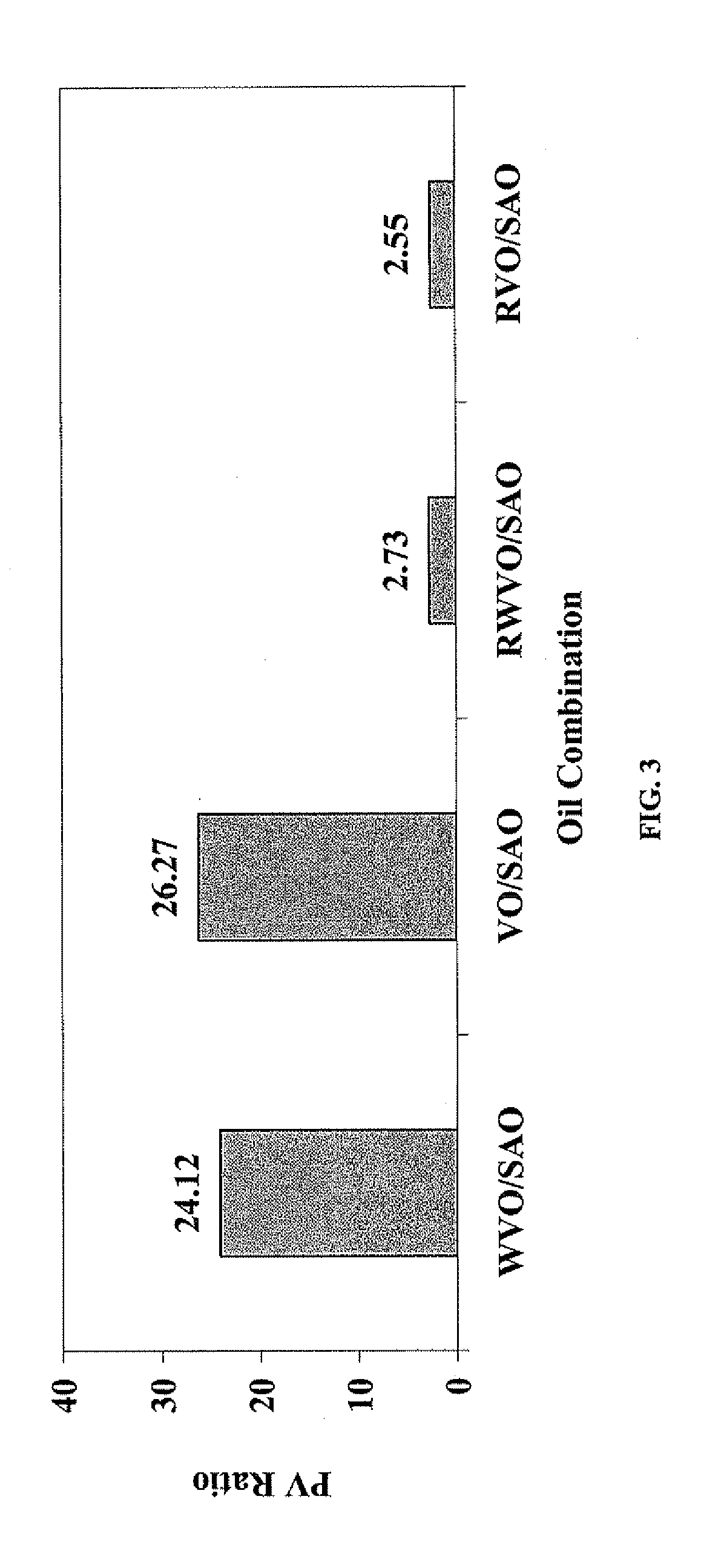

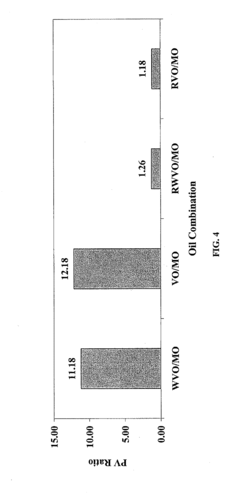

Environment Friendly Base Fluid to Replace the Toxic Mineral Oil-Based Base Fluids

PatentActiveUS20120071369A1

Innovation

- Development of a biodegradable vegetable oil-based base fluid produced through a process involving esterification of waste vegetable oils with short-chain alcohols, followed by purification and drying to achieve properties similar to mineral oil-based fluids, including high fire and flash points, low viscosity, and reduced occupational hazards.

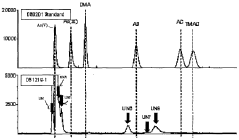

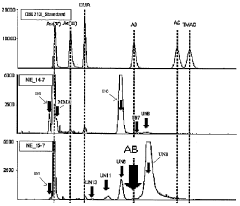

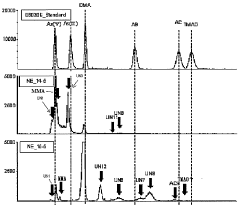

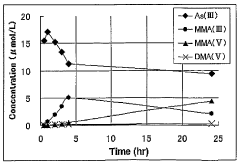

Alkylation composition, and method for detoxification of toxic compound using the composition

PatentWO2008012953A1

Innovation

- A cobalt complex-based alkylation composition that methylates harmful compounds containing arsenic, antimony, and selenium, using reducing agents like glutathione and methionine to convert them into less toxic forms such as arsenobetaine, reducing the need for storage and minimizing by-product generation.

Environmental Impact Assessment of Alkyl-Based Waste Solutions

The environmental impact assessment of alkyl-based waste solutions reveals both promising benefits and potential concerns. Alkyl chemistry offers innovative approaches to waste management, particularly in the treatment and disposal of organic waste materials. One significant advantage is the potential reduction in greenhouse gas emissions. Traditional waste management methods often result in the release of methane, a potent greenhouse gas. Alkyl-based solutions can help mitigate these emissions by converting organic waste into less harmful compounds or useful products.

Furthermore, alkyl chemistry enables more efficient waste processing, potentially reducing the overall volume of waste that ends up in landfills. This not only conserves valuable land resources but also minimizes the long-term environmental risks associated with landfill sites, such as soil and groundwater contamination. The ability to transform waste into value-added products also aligns with circular economy principles, promoting resource efficiency and sustainability.

However, the environmental impact assessment also highlights some potential drawbacks. The production and use of alkyl-based chemicals in waste management may lead to the release of volatile organic compounds (VOCs) into the atmosphere. These emissions can contribute to air pollution and potentially impact local air quality if not properly managed. Additionally, there are concerns about the potential accumulation of alkyl compounds in soil and water systems, which could have long-term ecological consequences.

The assessment also considers the energy requirements of alkyl-based waste solutions. While these processes can be more efficient than traditional methods, they may still require significant energy inputs, which could offset some of the environmental benefits if not sourced from renewable energy.

Another important aspect is the potential for alkyl-based waste management to reduce the need for harmful chemical treatments in waste processing. This could lead to a decrease in the release of toxic substances into the environment, improving overall ecosystem health. However, the assessment emphasizes the need for comprehensive life cycle analyses to fully understand the net environmental impact of these technologies.

The long-term effects of widespread adoption of alkyl-based waste solutions on biodiversity and ecosystem functioning are still being studied. While initial results are promising, ongoing monitoring and research are crucial to ensure that these technologies do not introduce unforeseen ecological disruptions.

In conclusion, the environmental impact assessment of alkyl-based waste solutions indicates a complex balance of benefits and potential risks. While offering significant improvements in waste management efficiency and greenhouse gas reduction, careful implementation and continued research are necessary to maximize the positive environmental outcomes while minimizing potential negative impacts.

Furthermore, alkyl chemistry enables more efficient waste processing, potentially reducing the overall volume of waste that ends up in landfills. This not only conserves valuable land resources but also minimizes the long-term environmental risks associated with landfill sites, such as soil and groundwater contamination. The ability to transform waste into value-added products also aligns with circular economy principles, promoting resource efficiency and sustainability.

However, the environmental impact assessment also highlights some potential drawbacks. The production and use of alkyl-based chemicals in waste management may lead to the release of volatile organic compounds (VOCs) into the atmosphere. These emissions can contribute to air pollution and potentially impact local air quality if not properly managed. Additionally, there are concerns about the potential accumulation of alkyl compounds in soil and water systems, which could have long-term ecological consequences.

The assessment also considers the energy requirements of alkyl-based waste solutions. While these processes can be more efficient than traditional methods, they may still require significant energy inputs, which could offset some of the environmental benefits if not sourced from renewable energy.

Another important aspect is the potential for alkyl-based waste management to reduce the need for harmful chemical treatments in waste processing. This could lead to a decrease in the release of toxic substances into the environment, improving overall ecosystem health. However, the assessment emphasizes the need for comprehensive life cycle analyses to fully understand the net environmental impact of these technologies.

The long-term effects of widespread adoption of alkyl-based waste solutions on biodiversity and ecosystem functioning are still being studied. While initial results are promising, ongoing monitoring and research are crucial to ensure that these technologies do not introduce unforeseen ecological disruptions.

In conclusion, the environmental impact assessment of alkyl-based waste solutions indicates a complex balance of benefits and potential risks. While offering significant improvements in waste management efficiency and greenhouse gas reduction, careful implementation and continued research are necessary to maximize the positive environmental outcomes while minimizing potential negative impacts.

Regulatory Framework for Alkyl Chemistry in Waste Management

The regulatory framework for alkyl chemistry in waste management is a complex and evolving landscape that plays a crucial role in shaping the industry's practices and innovations. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous waste, including those containing alkyl compounds. This convention sets standards for the responsible handling and disposal of such materials across borders.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of alkyl chemistry in waste management through various acts and programs. The Resource Conservation and Recovery Act (RCRA) is the primary law governing the disposal of solid and hazardous waste. Under RCRA, the EPA has established specific guidelines for the treatment, storage, and disposal of alkyl-containing waste materials. Additionally, the Toxic Substances Control Act (TSCA) regulates the production, importation, use, and disposal of specific chemical substances, including many alkyl compounds.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the use of alkyl compounds in various industries, including waste management. REACH requires companies to register chemical substances and provide safety data, ensuring a high level of protection for human health and the environment. The EU Waste Framework Directive also sets the basic concepts and definitions related to waste management, including those involving alkyl chemistry.

In Asia, countries like China and Japan have been strengthening their regulatory frameworks. China's Solid Waste Environmental Pollution Prevention and Control Law was recently amended to include stricter controls on the import and handling of waste materials. Japan's Waste Management and Public Cleansing Law provides comprehensive regulations for waste treatment, including specific provisions for chemical waste management.

Emerging economies are also developing more robust regulatory frameworks. India, for instance, has introduced the Hazardous and Other Wastes (Management and Transboundary Movement) Rules, which govern the handling and disposal of chemical waste, including those with alkyl compounds. Brazil's National Solid Waste Policy establishes guidelines for the integrated management of hazardous waste, incorporating principles of sustainable development and environmental protection.

As the field of alkyl chemistry continues to advance, regulatory bodies worldwide are adapting their frameworks to address new challenges and opportunities. This includes the development of regulations for novel waste treatment technologies that utilize alkyl chemistry, as well as updating existing guidelines to reflect the latest scientific understanding of environmental and health impacts. The ongoing evolution of these regulatory frameworks will be critical in ensuring that the transformative potential of alkyl chemistry in waste management is realized while maintaining the highest standards of safety and environmental stewardship.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of alkyl chemistry in waste management through various acts and programs. The Resource Conservation and Recovery Act (RCRA) is the primary law governing the disposal of solid and hazardous waste. Under RCRA, the EPA has established specific guidelines for the treatment, storage, and disposal of alkyl-containing waste materials. Additionally, the Toxic Substances Control Act (TSCA) regulates the production, importation, use, and disposal of specific chemical substances, including many alkyl compounds.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the use of alkyl compounds in various industries, including waste management. REACH requires companies to register chemical substances and provide safety data, ensuring a high level of protection for human health and the environment. The EU Waste Framework Directive also sets the basic concepts and definitions related to waste management, including those involving alkyl chemistry.

In Asia, countries like China and Japan have been strengthening their regulatory frameworks. China's Solid Waste Environmental Pollution Prevention and Control Law was recently amended to include stricter controls on the import and handling of waste materials. Japan's Waste Management and Public Cleansing Law provides comprehensive regulations for waste treatment, including specific provisions for chemical waste management.

Emerging economies are also developing more robust regulatory frameworks. India, for instance, has introduced the Hazardous and Other Wastes (Management and Transboundary Movement) Rules, which govern the handling and disposal of chemical waste, including those with alkyl compounds. Brazil's National Solid Waste Policy establishes guidelines for the integrated management of hazardous waste, incorporating principles of sustainable development and environmental protection.

As the field of alkyl chemistry continues to advance, regulatory bodies worldwide are adapting their frameworks to address new challenges and opportunities. This includes the development of regulations for novel waste treatment technologies that utilize alkyl chemistry, as well as updating existing guidelines to reflect the latest scientific understanding of environmental and health impacts. The ongoing evolution of these regulatory frameworks will be critical in ensuring that the transformative potential of alkyl chemistry in waste management is realized while maintaining the highest standards of safety and environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!