Alkyl Chemistry: Paving the Way for Biofuels

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Chemistry Evolution

Alkyl chemistry has undergone significant evolution over the past century, playing a crucial role in the development of biofuels. The journey began in the early 20th century with the discovery of alkyl compounds and their potential applications in organic synthesis. Initially, alkyl chemistry focused primarily on petroleum-based feedstocks, with researchers exploring various methods to manipulate carbon-carbon bonds.

The 1950s and 1960s saw a surge in alkyl chemistry research, driven by the growing demand for petrochemicals. Scientists developed new catalytic processes for alkylation reactions, enabling more efficient production of high-octane gasoline components. This period also marked the beginning of investigations into alternative feedstocks, including biomass-derived materials.

The oil crisis of the 1970s sparked renewed interest in biofuels, prompting researchers to explore alkyl chemistry's potential in converting renewable resources into fuel alternatives. This led to the development of first-generation biofuels, such as bioethanol and biodiesel, which relied heavily on alkyl chemistry principles for their production processes.

The 1980s and 1990s witnessed significant advancements in analytical techniques and computational modeling, allowing for a deeper understanding of alkyl reaction mechanisms. This knowledge facilitated the design of more selective and efficient catalysts, paving the way for improved biofuel production methods.

The turn of the millennium brought about a paradigm shift in alkyl chemistry research, with a greater emphasis on sustainability and green chemistry principles. Scientists began exploring novel approaches to synthesize alkyl compounds from renewable feedstocks, such as lignocellulosic biomass and algae. This period also saw the emergence of second-generation biofuels, which aimed to address the limitations of their first-generation counterparts.

In recent years, alkyl chemistry has continued to evolve rapidly, driven by the urgent need for sustainable energy solutions. Researchers have made significant strides in developing advanced catalysts and reaction systems for the efficient conversion of biomass into high-value alkyl compounds. These innovations have led to the creation of third-generation biofuels, which offer improved energy density and reduced environmental impact.

The latest frontier in alkyl chemistry for biofuels involves the integration of biotechnology and chemical catalysis. Scientists are exploring enzymatic processes and metabolic engineering techniques to produce alkyl compounds directly from microorganisms. This approach holds promise for the development of fourth-generation biofuels, which could potentially revolutionize the renewable energy landscape.

The 1950s and 1960s saw a surge in alkyl chemistry research, driven by the growing demand for petrochemicals. Scientists developed new catalytic processes for alkylation reactions, enabling more efficient production of high-octane gasoline components. This period also marked the beginning of investigations into alternative feedstocks, including biomass-derived materials.

The oil crisis of the 1970s sparked renewed interest in biofuels, prompting researchers to explore alkyl chemistry's potential in converting renewable resources into fuel alternatives. This led to the development of first-generation biofuels, such as bioethanol and biodiesel, which relied heavily on alkyl chemistry principles for their production processes.

The 1980s and 1990s witnessed significant advancements in analytical techniques and computational modeling, allowing for a deeper understanding of alkyl reaction mechanisms. This knowledge facilitated the design of more selective and efficient catalysts, paving the way for improved biofuel production methods.

The turn of the millennium brought about a paradigm shift in alkyl chemistry research, with a greater emphasis on sustainability and green chemistry principles. Scientists began exploring novel approaches to synthesize alkyl compounds from renewable feedstocks, such as lignocellulosic biomass and algae. This period also saw the emergence of second-generation biofuels, which aimed to address the limitations of their first-generation counterparts.

In recent years, alkyl chemistry has continued to evolve rapidly, driven by the urgent need for sustainable energy solutions. Researchers have made significant strides in developing advanced catalysts and reaction systems for the efficient conversion of biomass into high-value alkyl compounds. These innovations have led to the creation of third-generation biofuels, which offer improved energy density and reduced environmental impact.

The latest frontier in alkyl chemistry for biofuels involves the integration of biotechnology and chemical catalysis. Scientists are exploring enzymatic processes and metabolic engineering techniques to produce alkyl compounds directly from microorganisms. This approach holds promise for the development of fourth-generation biofuels, which could potentially revolutionize the renewable energy landscape.

Biofuel Market Analysis

The biofuel market has experienced significant growth and transformation in recent years, driven by increasing environmental concerns and the need for sustainable energy alternatives. As alkyl chemistry plays a crucial role in the development of advanced biofuels, understanding the market dynamics is essential for assessing the potential impact and opportunities in this sector.

The global biofuel market size was valued at approximately $141 billion in 2022 and is projected to reach $201 billion by 2030, growing at a compound annual growth rate (CAGR) of 4.5% during the forecast period. This growth is primarily attributed to supportive government policies, rising energy demand, and the increasing adoption of renewable energy sources.

Ethanol and biodiesel remain the dominant biofuels in the market, accounting for the majority of production and consumption. However, advanced biofuels derived from non-food feedstocks, such as lignocellulosic biomass and algae, are gaining traction due to their potential to address food security concerns and offer improved environmental performance.

The market is characterized by regional variations in production and consumption patterns. The United States and Brazil are the leading producers and consumers of ethanol, while the European Union dominates the biodiesel market. Emerging economies, particularly in Asia-Pacific and Latin America, are expected to drive future growth as they seek to reduce dependence on fossil fuels and promote rural development.

Key market drivers include government mandates and incentives, such as blending requirements and tax credits, which have been instrumental in fostering market growth. Additionally, the increasing focus on reducing greenhouse gas emissions and achieving climate targets has bolstered the demand for biofuels across various sectors, including transportation, aviation, and marine applications.

However, the biofuel market faces several challenges, including feedstock availability, production costs, and infrastructure limitations. The volatility of feedstock prices and competition with food crops remain significant concerns, particularly for first-generation biofuels. These factors have spurred research and development efforts in advanced biofuels and novel production technologies, where alkyl chemistry plays a crucial role.

The market landscape is highly competitive, with a mix of established oil and gas companies, dedicated biofuel producers, and emerging startups. Key players are investing heavily in research and development to improve production efficiency, expand feedstock options, and develop next-generation biofuels. Collaborations and partnerships between industry stakeholders, research institutions, and government agencies are becoming increasingly common to accelerate innovation and commercialization efforts.

Looking ahead, the biofuel market is poised for continued growth and evolution. The integration of alkyl chemistry in biofuel production processes is expected to unlock new opportunities for product diversification and performance enhancement. As technology advances and production costs decrease, biofuels are likely to play an increasingly important role in the global energy mix, contributing to energy security and sustainability goals.

The global biofuel market size was valued at approximately $141 billion in 2022 and is projected to reach $201 billion by 2030, growing at a compound annual growth rate (CAGR) of 4.5% during the forecast period. This growth is primarily attributed to supportive government policies, rising energy demand, and the increasing adoption of renewable energy sources.

Ethanol and biodiesel remain the dominant biofuels in the market, accounting for the majority of production and consumption. However, advanced biofuels derived from non-food feedstocks, such as lignocellulosic biomass and algae, are gaining traction due to their potential to address food security concerns and offer improved environmental performance.

The market is characterized by regional variations in production and consumption patterns. The United States and Brazil are the leading producers and consumers of ethanol, while the European Union dominates the biodiesel market. Emerging economies, particularly in Asia-Pacific and Latin America, are expected to drive future growth as they seek to reduce dependence on fossil fuels and promote rural development.

Key market drivers include government mandates and incentives, such as blending requirements and tax credits, which have been instrumental in fostering market growth. Additionally, the increasing focus on reducing greenhouse gas emissions and achieving climate targets has bolstered the demand for biofuels across various sectors, including transportation, aviation, and marine applications.

However, the biofuel market faces several challenges, including feedstock availability, production costs, and infrastructure limitations. The volatility of feedstock prices and competition with food crops remain significant concerns, particularly for first-generation biofuels. These factors have spurred research and development efforts in advanced biofuels and novel production technologies, where alkyl chemistry plays a crucial role.

The market landscape is highly competitive, with a mix of established oil and gas companies, dedicated biofuel producers, and emerging startups. Key players are investing heavily in research and development to improve production efficiency, expand feedstock options, and develop next-generation biofuels. Collaborations and partnerships between industry stakeholders, research institutions, and government agencies are becoming increasingly common to accelerate innovation and commercialization efforts.

Looking ahead, the biofuel market is poised for continued growth and evolution. The integration of alkyl chemistry in biofuel production processes is expected to unlock new opportunities for product diversification and performance enhancement. As technology advances and production costs decrease, biofuels are likely to play an increasingly important role in the global energy mix, contributing to energy security and sustainability goals.

Alkylation Challenges

Alkylation processes face several significant challenges in the context of biofuel production. One of the primary issues is the high energy consumption associated with traditional alkylation methods. These processes often require elevated temperatures and pressures, leading to substantial energy inputs and increased production costs. This energy-intensive nature conflicts with the sustainability goals of biofuel production, potentially offsetting some of the environmental benefits.

Another major challenge is the selectivity of alkylation reactions. Achieving high selectivity towards desired products while minimizing unwanted side reactions remains a persistent issue. This is particularly crucial in biofuel production, where specific molecular structures are required for optimal fuel properties. Poor selectivity can result in lower yields of the target compounds and increased purification costs.

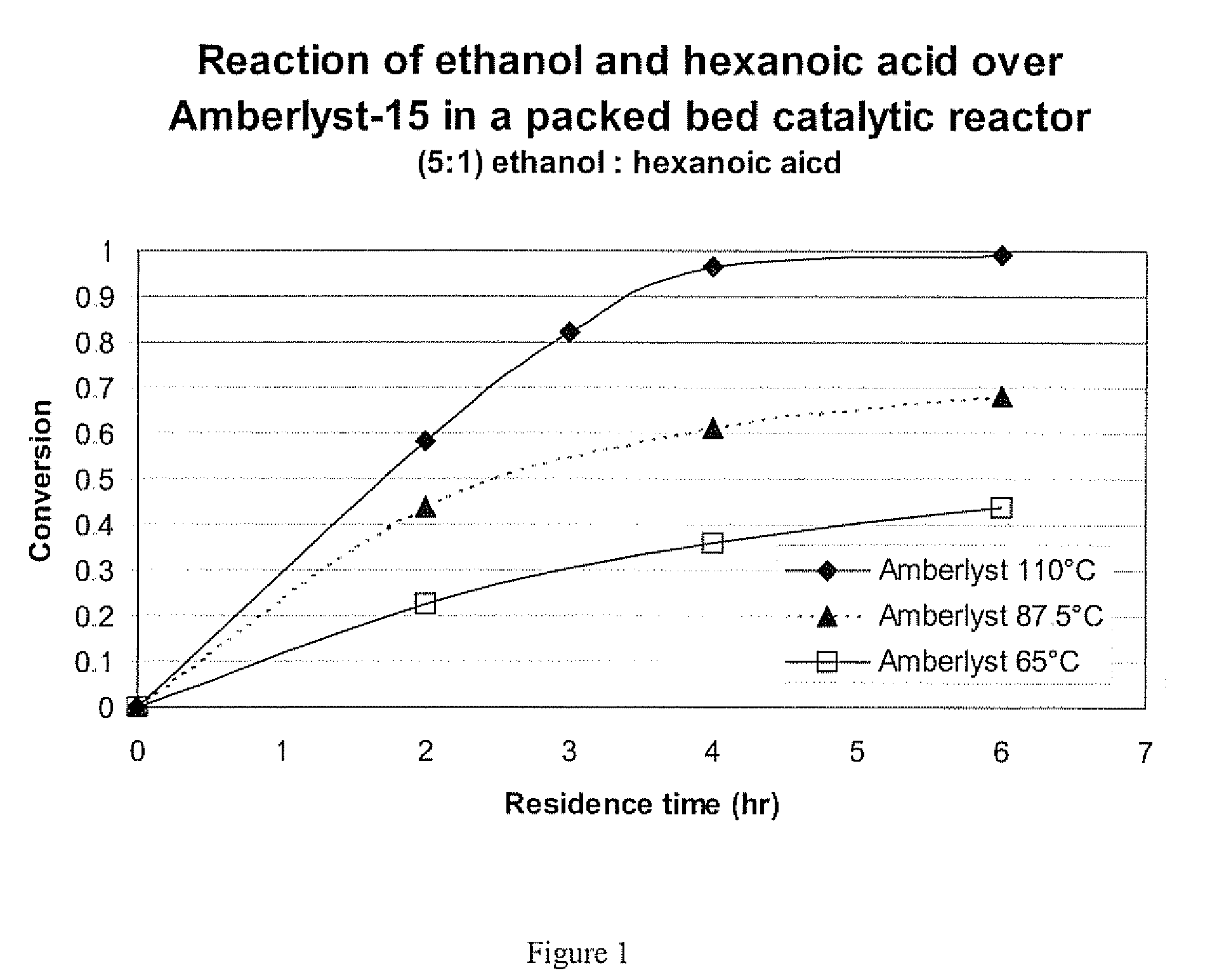

The choice of catalysts presents another significant hurdle. Many conventional alkylation processes rely on homogeneous acid catalysts, such as sulfuric acid or hydrofluoric acid. These catalysts pose environmental and safety risks, necessitating complex handling and disposal procedures. The development of more environmentally friendly, heterogeneous catalysts that maintain high activity and selectivity is an ongoing challenge in the field.

Feedstock variability is a considerable concern in biofuel-related alkylation processes. Unlike petroleum-based feedstocks, biomass-derived materials often have inconsistent compositions, which can affect reaction outcomes and product quality. Adapting alkylation processes to handle this variability while maintaining consistent product specifications is a significant technical challenge.

Scale-up and process integration pose additional difficulties. Many promising alkylation techniques developed at the laboratory scale face obstacles when transitioning to industrial-scale production. Issues such as heat and mass transfer limitations, catalyst deactivation, and equipment corrosion become more pronounced at larger scales. Integrating alkylation processes seamlessly into existing biofuel production chains while maintaining economic viability is a complex engineering challenge.

Lastly, the regulatory landscape surrounding biofuel production and chemical processes adds another layer of complexity. Stringent environmental regulations and safety standards must be met, which can impact process design and operation. Developing alkylation technologies that comply with these regulations while remaining economically competitive is an ongoing challenge for researchers and industry professionals in the biofuel sector.

Another major challenge is the selectivity of alkylation reactions. Achieving high selectivity towards desired products while minimizing unwanted side reactions remains a persistent issue. This is particularly crucial in biofuel production, where specific molecular structures are required for optimal fuel properties. Poor selectivity can result in lower yields of the target compounds and increased purification costs.

The choice of catalysts presents another significant hurdle. Many conventional alkylation processes rely on homogeneous acid catalysts, such as sulfuric acid or hydrofluoric acid. These catalysts pose environmental and safety risks, necessitating complex handling and disposal procedures. The development of more environmentally friendly, heterogeneous catalysts that maintain high activity and selectivity is an ongoing challenge in the field.

Feedstock variability is a considerable concern in biofuel-related alkylation processes. Unlike petroleum-based feedstocks, biomass-derived materials often have inconsistent compositions, which can affect reaction outcomes and product quality. Adapting alkylation processes to handle this variability while maintaining consistent product specifications is a significant technical challenge.

Scale-up and process integration pose additional difficulties. Many promising alkylation techniques developed at the laboratory scale face obstacles when transitioning to industrial-scale production. Issues such as heat and mass transfer limitations, catalyst deactivation, and equipment corrosion become more pronounced at larger scales. Integrating alkylation processes seamlessly into existing biofuel production chains while maintaining economic viability is a complex engineering challenge.

Lastly, the regulatory landscape surrounding biofuel production and chemical processes adds another layer of complexity. Stringent environmental regulations and safety standards must be met, which can impact process design and operation. Developing alkylation technologies that comply with these regulations while remaining economically competitive is an ongoing challenge for researchers and industry professionals in the biofuel sector.

Current Alkylation Methods

01 Alkyl-based chemical reactions and synthesis

This category focuses on various chemical reactions and synthesis methods involving alkyl groups. It includes processes for creating alkyl compounds, modifying existing molecules with alkyl groups, and studying the reactivity of alkyl-containing substances. These reactions are fundamental in organic chemistry and have applications in pharmaceuticals, materials science, and industrial processes.- Alkyl-based chemical synthesis and modifications: This category focuses on the synthesis and modification of alkyl compounds, including various chemical reactions and processes involving alkyl groups. It encompasses the creation of new alkyl-based materials and the alteration of existing compounds through alkylation, dealkylation, and other related chemical transformations.

- Alkyl compounds in polymer and material science: This area explores the use of alkyl compounds in the development and modification of polymers and advanced materials. It includes the incorporation of alkyl groups into polymer structures, the study of alkyl-based surfactants, and the creation of novel materials with specific properties derived from alkyl chemistry.

- Alkyl chemistry in biochemistry and pharmaceutical applications: This category covers the role of alkyl compounds in biochemical processes and pharmaceutical development. It includes the study of alkyl-based drug delivery systems, the interaction of alkyl groups with biological molecules, and the use of alkyl chemistry in the synthesis of pharmaceutical compounds.

- Analytical techniques and characterization methods for alkyl compounds: This area focuses on the development and application of analytical techniques for the characterization and study of alkyl compounds. It includes spectroscopic methods, chromatography, and other analytical approaches specifically tailored for alkyl chemistry research and quality control in industrial applications.

- Industrial applications and processes involving alkyl chemistry: This category encompasses the various industrial applications and processes that utilize alkyl chemistry. It includes the use of alkyl compounds in petrochemical industries, the development of alkyl-based lubricants and additives, and the application of alkyl chemistry in manufacturing processes across different sectors.

02 Alkyl-modified materials and coatings

This area explores the use of alkyl groups to modify materials and create specialized coatings. By incorporating alkyl chains into polymers, surfaces, or nanoparticles, researchers can alter properties such as hydrophobicity, durability, and chemical resistance. These modifications have applications in areas like water-repellent textiles, anti-fouling coatings, and advanced composite materials.Expand Specific Solutions03 Alkyl-based surfactants and emulsifiers

This category covers the development and application of alkyl-based surfactants and emulsifiers. These compounds, which typically contain both hydrophilic and hydrophobic (alkyl) portions, are crucial in various industries. They are used in personal care products, detergents, food processing, and industrial applications to stabilize emulsions, reduce surface tension, and facilitate mixing of otherwise immiscible substances.Expand Specific Solutions04 Alkyl-functionalized nanomaterials

This area focuses on the functionalization of nanomaterials with alkyl groups. By attaching alkyl chains to nanoparticles, nanotubes, or other nanoscale structures, researchers can modify their properties and behaviors. This functionalization can improve dispersion in various media, alter electronic properties, or enable specific interactions with other molecules. Applications range from drug delivery systems to advanced electronic materials.Expand Specific Solutions05 Analytical methods for alkyl compounds

This category encompasses analytical techniques and methods specifically developed or adapted for the detection, quantification, and characterization of alkyl compounds. It includes spectroscopic methods, chromatography techniques, and specialized sensors designed to identify and measure alkyl groups in various samples. These analytical approaches are crucial in fields such as environmental monitoring, quality control in chemical manufacturing, and forensic analysis.Expand Specific Solutions

Biofuel Industry Players

The alkyl chemistry sector for biofuels is in a growth phase, with increasing market size driven by the global push for sustainable energy solutions. The technology is maturing, but still evolving, as evidenced by ongoing research and development efforts. Major players like Shell Oil Co., PetroChina Co., Ltd., and Genomatica, Inc. are investing heavily in this field, leveraging their expertise in petrochemicals and biotechnology. Universities and research institutions, such as the University of California and the National University of Singapore, are contributing to technological advancements. The competitive landscape is diverse, with both established energy companies and innovative startups vying for market share, indicating a dynamic and promising future for alkyl chemistry in biofuel production.

Shell Oil Co.

Technical Solution: Shell Oil Co. has developed advanced alkyl chemistry processes for biofuel production. Their approach focuses on converting biomass-derived feedstocks into high-quality biofuels through catalytic alkylation. The company utilizes a proprietary catalyst system that enhances the efficiency of alkylation reactions, resulting in improved yield and selectivity[1]. Shell's process incorporates a two-stage reactor configuration, allowing for optimal control of reaction conditions and minimizing unwanted side products[3]. Additionally, they have implemented innovative separation techniques to purify the alkylated products, ensuring high-quality biofuel output suitable for various applications, including transportation and industrial use[5].

Strengths: Proprietary catalyst system, efficient two-stage reactor configuration, and advanced separation techniques. Weaknesses: Potential high costs associated with catalyst development and process optimization.

Genomatica, Inc.

Technical Solution: Genomatica has pioneered a bio-based approach to alkyl chemistry for biofuel production. Their technology platform utilizes engineered microorganisms to produce alkyl-based chemicals and biofuels from renewable feedstocks. The company's process involves fermenting sugars derived from biomass using specially designed strains of bacteria that can efficiently synthesize alkyl compounds[2]. Genomatica has developed a scalable fermentation process that achieves high yields and selectivity, reducing the need for extensive downstream processing[4]. Their technology also incorporates continuous product recovery systems, enhancing overall process efficiency and reducing energy consumption[6].

Strengths: Bio-based production method, potential for lower environmental impact, and scalable fermentation process. Weaknesses: Dependence on specific feedstocks and potential challenges in achieving consistent product quality.

Key Alkylation Patents

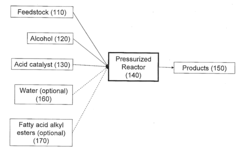

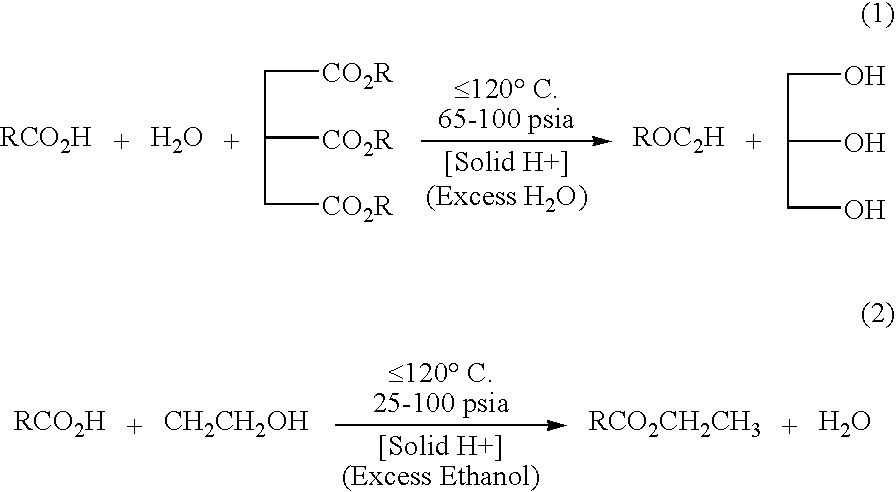

Production of biodiesel, cellulosic sugars, and peptides from the simultaneous esterification and alcoholysis/hydrolysis of materials with oil-containing substituents including phospholipids and cellulosic and peptidic content

PatentInactiveUS20110195471A1

Innovation

- A single-step method involving the reaction of feedstocks containing free fatty acids, glycerides, and cellulosic material with an alcohol and acid catalyst at controlled pH and temperature, allowing for direct esterification, transesterification, hydrolysis, and alcoholysis to produce fatty acid alkyl esters and cellulosic sugars, while minimizing water usage and optimizing co-product conversion.

Method of making alkyl esters

PatentInactiveUS20070260077A1

Innovation

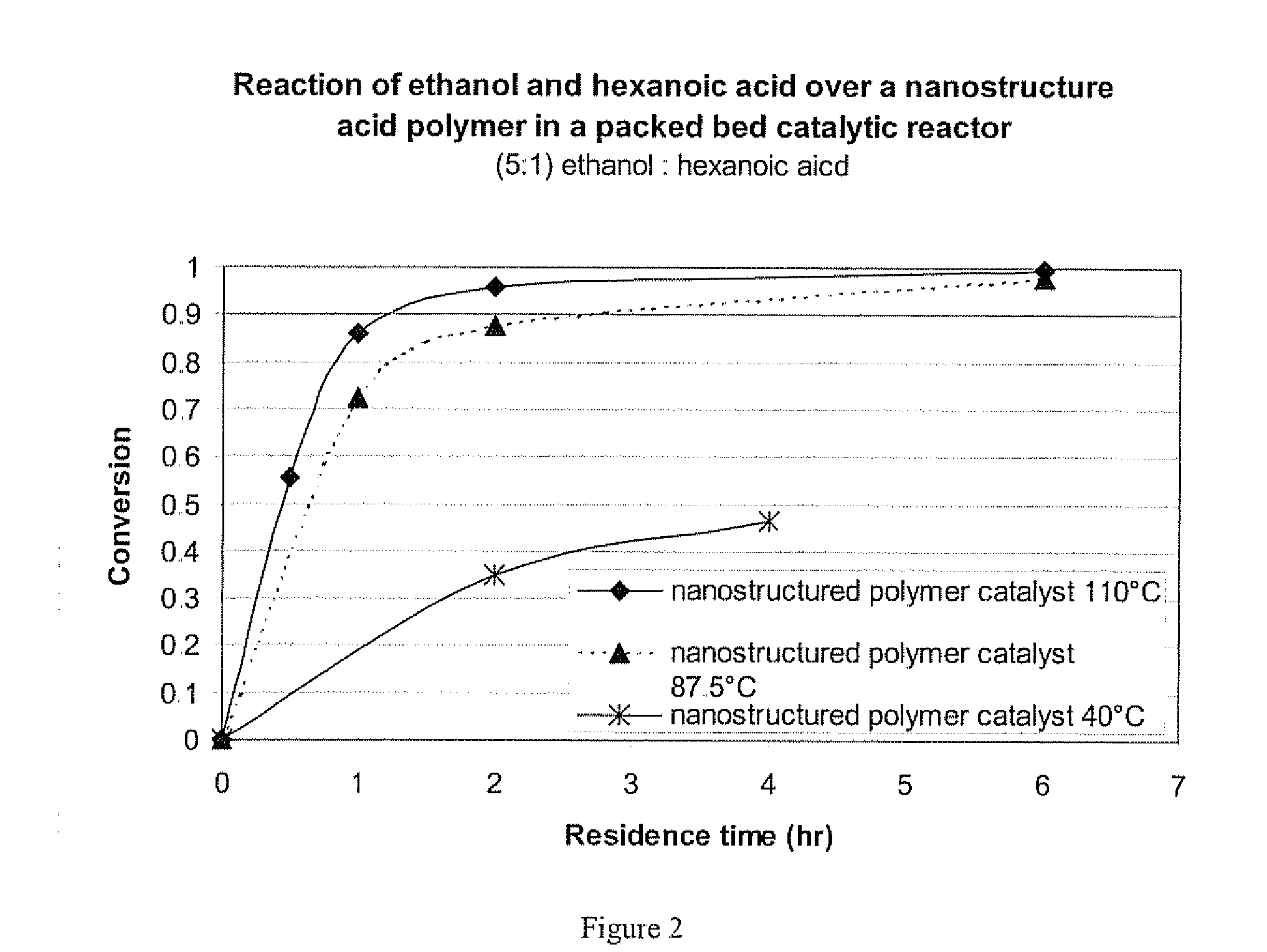

- A method using a solid acid catalyst in packed bed reactors or reactive distillation to convert low-cost, unrefined glyceride sources into fatty acid compositions, which are then esterified to produce alkyl esters, allowing for the use of raw, unprocessed feedstocks and reducing catalyst consumption.

Environmental Impact

The environmental impact of alkyl chemistry in biofuel production is a critical consideration as the world seeks sustainable alternatives to fossil fuels. Biofuels derived from alkyl compounds offer potential benefits in reducing greenhouse gas emissions and dependence on non-renewable resources. However, their production and use also present environmental challenges that must be carefully evaluated.

One of the primary environmental advantages of alkyl-based biofuels is their potential to reduce carbon dioxide emissions compared to conventional fossil fuels. When burned, biofuels release carbon that was recently captured by plants, creating a shorter carbon cycle. This can lead to a lower net increase in atmospheric CO2 levels, potentially mitigating climate change impacts.

However, the production of alkyl biofuels can have significant land-use implications. Large-scale cultivation of crops for biofuel production may lead to deforestation, loss of biodiversity, and competition with food crops for arable land. This indirect land-use change can potentially offset some of the carbon benefits of biofuels if not managed sustainably.

Water usage and quality are also important environmental factors to consider. The cultivation of biofuel crops often requires substantial irrigation, potentially straining water resources in some regions. Additionally, the use of fertilizers and pesticides in crop production can lead to water pollution through runoff, impacting aquatic ecosystems and drinking water sources.

The production process of alkyl biofuels itself can have environmental implications. Depending on the specific chemical processes used, there may be emissions of volatile organic compounds (VOCs) or other pollutants. Proper management and control of these emissions are crucial to minimize air quality impacts and potential health risks to nearby communities.

Energy efficiency in the production of alkyl biofuels is another important environmental consideration. The energy input required to cultivate, harvest, and process biofuel crops must be carefully balanced against the energy output of the resulting fuel. Improving production efficiencies and utilizing renewable energy sources in the manufacturing process can help enhance the overall environmental benefits of biofuels.

Waste management in alkyl biofuel production presents both challenges and opportunities. The process generates various by-products and residues that must be properly handled to prevent environmental contamination. However, many of these by-products can be repurposed or recycled, potentially creating additional value streams and reducing overall waste.

As the technology for alkyl-based biofuels continues to evolve, ongoing research and development efforts are focused on addressing these environmental challenges. Innovations in crop selection, cultivation practices, and production processes aim to maximize the environmental benefits while minimizing negative impacts. The goal is to create a more sustainable and environmentally friendly alternative to fossil fuels, contributing to global efforts in combating climate change and promoting energy security.

One of the primary environmental advantages of alkyl-based biofuels is their potential to reduce carbon dioxide emissions compared to conventional fossil fuels. When burned, biofuels release carbon that was recently captured by plants, creating a shorter carbon cycle. This can lead to a lower net increase in atmospheric CO2 levels, potentially mitigating climate change impacts.

However, the production of alkyl biofuels can have significant land-use implications. Large-scale cultivation of crops for biofuel production may lead to deforestation, loss of biodiversity, and competition with food crops for arable land. This indirect land-use change can potentially offset some of the carbon benefits of biofuels if not managed sustainably.

Water usage and quality are also important environmental factors to consider. The cultivation of biofuel crops often requires substantial irrigation, potentially straining water resources in some regions. Additionally, the use of fertilizers and pesticides in crop production can lead to water pollution through runoff, impacting aquatic ecosystems and drinking water sources.

The production process of alkyl biofuels itself can have environmental implications. Depending on the specific chemical processes used, there may be emissions of volatile organic compounds (VOCs) or other pollutants. Proper management and control of these emissions are crucial to minimize air quality impacts and potential health risks to nearby communities.

Energy efficiency in the production of alkyl biofuels is another important environmental consideration. The energy input required to cultivate, harvest, and process biofuel crops must be carefully balanced against the energy output of the resulting fuel. Improving production efficiencies and utilizing renewable energy sources in the manufacturing process can help enhance the overall environmental benefits of biofuels.

Waste management in alkyl biofuel production presents both challenges and opportunities. The process generates various by-products and residues that must be properly handled to prevent environmental contamination. However, many of these by-products can be repurposed or recycled, potentially creating additional value streams and reducing overall waste.

As the technology for alkyl-based biofuels continues to evolve, ongoing research and development efforts are focused on addressing these environmental challenges. Innovations in crop selection, cultivation practices, and production processes aim to maximize the environmental benefits while minimizing negative impacts. The goal is to create a more sustainable and environmentally friendly alternative to fossil fuels, contributing to global efforts in combating climate change and promoting energy security.

Regulatory Framework

The regulatory framework surrounding alkyl chemistry and biofuels plays a crucial role in shaping the industry's development and adoption. As governments worldwide seek to reduce carbon emissions and promote sustainable energy sources, biofuels have gained significant attention. This has led to the implementation of various policies and regulations that directly impact the production, distribution, and use of biofuels derived from alkyl chemistry processes.

In the United States, the Renewable Fuel Standard (RFS) program, established under the Energy Policy Act of 2005 and expanded by the Energy Independence and Security Act of 2007, mandates the blending of renewable fuels into transportation fuels. This program has been instrumental in driving the growth of the biofuel industry, particularly for ethanol and biodiesel production. The Environmental Protection Agency (EPA) is responsible for setting annual volume requirements for different categories of renewable fuels, including advanced biofuels derived from alkyl chemistry processes.

The European Union has also implemented robust regulatory measures to promote biofuels. The Renewable Energy Directive (RED) sets targets for renewable energy consumption in the transport sector, with a specific focus on advanced biofuels. The RED II, adopted in 2018, further strengthens these targets and introduces sustainability criteria for biofuels, including those produced through alkyl chemistry pathways.

Many countries have introduced tax incentives and subsidies to encourage the production and use of biofuels. These financial mechanisms aim to make biofuels more competitive with conventional fossil fuels and stimulate investment in research and development of advanced biofuel technologies. However, the regulatory landscape is not without challenges. Concerns about food security and indirect land-use change have led to debates about the sustainability of first-generation biofuels, prompting a shift towards advanced biofuels derived from non-food feedstocks.

Sustainability certification schemes have emerged as a critical component of the regulatory framework. These schemes, such as the Roundtable on Sustainable Biomaterials (RSB) and the International Sustainability and Carbon Certification (ISCC), provide standards and verification processes to ensure that biofuels meet specific environmental and social criteria. Compliance with these certification schemes is often required to qualify for government incentives or to meet regulatory obligations.

As the field of alkyl chemistry continues to advance, regulators face the challenge of keeping pace with technological developments. The emergence of novel biofuel production pathways and feedstocks necessitates ongoing review and adaptation of existing regulations. This dynamic regulatory environment requires close collaboration between policymakers, industry stakeholders, and scientific experts to ensure that regulations effectively promote innovation while addressing environmental and social concerns.

In the United States, the Renewable Fuel Standard (RFS) program, established under the Energy Policy Act of 2005 and expanded by the Energy Independence and Security Act of 2007, mandates the blending of renewable fuels into transportation fuels. This program has been instrumental in driving the growth of the biofuel industry, particularly for ethanol and biodiesel production. The Environmental Protection Agency (EPA) is responsible for setting annual volume requirements for different categories of renewable fuels, including advanced biofuels derived from alkyl chemistry processes.

The European Union has also implemented robust regulatory measures to promote biofuels. The Renewable Energy Directive (RED) sets targets for renewable energy consumption in the transport sector, with a specific focus on advanced biofuels. The RED II, adopted in 2018, further strengthens these targets and introduces sustainability criteria for biofuels, including those produced through alkyl chemistry pathways.

Many countries have introduced tax incentives and subsidies to encourage the production and use of biofuels. These financial mechanisms aim to make biofuels more competitive with conventional fossil fuels and stimulate investment in research and development of advanced biofuel technologies. However, the regulatory landscape is not without challenges. Concerns about food security and indirect land-use change have led to debates about the sustainability of first-generation biofuels, prompting a shift towards advanced biofuels derived from non-food feedstocks.

Sustainability certification schemes have emerged as a critical component of the regulatory framework. These schemes, such as the Roundtable on Sustainable Biomaterials (RSB) and the International Sustainability and Carbon Certification (ISCC), provide standards and verification processes to ensure that biofuels meet specific environmental and social criteria. Compliance with these certification schemes is often required to qualify for government incentives or to meet regulatory obligations.

As the field of alkyl chemistry continues to advance, regulators face the challenge of keeping pace with technological developments. The emergence of novel biofuel production pathways and feedstocks necessitates ongoing review and adaptation of existing regulations. This dynamic regulatory environment requires close collaboration between policymakers, industry stakeholders, and scientific experts to ensure that regulations effectively promote innovation while addressing environmental and social concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!