Alkyl Compounds in Next‑Gen Battery Technologies

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Compounds in Battery Tech: Background and Objectives

The exploration of alkyl compounds in next-generation battery technologies represents a significant frontier in energy storage research. This field has evolved from the early days of lead-acid batteries to the current dominance of lithium-ion technology. The progression has been driven by the increasing demand for higher energy density, longer cycle life, and improved safety in battery systems.

Alkyl compounds, organic molecules consisting of carbon and hydrogen atoms arranged in various chain structures, have emerged as promising candidates for enhancing battery performance. Their potential lies in their ability to form stable interfaces between electrodes and electrolytes, potentially mitigating issues such as dendrite formation and capacity fade that plague many current battery technologies.

The development of alkyl compound applications in batteries can be traced back to the late 20th century, with initial research focusing on their use as electrolyte additives. However, recent advancements have expanded their role to include active electrode materials and solid electrolytes, opening new avenues for battery innovation.

The primary objective of research in this area is to leverage the unique properties of alkyl compounds to overcome existing limitations in battery technology. These properties include their structural versatility, which allows for fine-tuning of molecular designs to optimize specific battery parameters. Additionally, the potential for alkyl compounds to facilitate faster ion transport and enhance electrode stability has garnered significant attention.

Key goals in this field include developing alkyl-based electrolytes with wider electrochemical stability windows, synthesizing alkyl-functionalized electrode materials for improved capacity retention, and creating alkyl-based solid electrolytes for next-generation solid-state batteries. Researchers aim to exploit the molecular engineering possibilities of alkyl compounds to create battery components that are not only more efficient but also more environmentally friendly and cost-effective.

The trajectory of this research aligns with broader trends in sustainable energy storage, as alkyl compounds offer the potential for batteries that are less reliant on rare earth metals and more amenable to recycling. This aspect is particularly crucial as the global demand for energy storage solutions continues to grow, driven by the expansion of renewable energy sources and the electrification of transportation.

As the field progresses, interdisciplinary collaboration between organic chemists, materials scientists, and electrochemists will be essential to fully realize the potential of alkyl compounds in battery technology. The ultimate aim is to develop batteries that not only surpass current performance metrics but also address the environmental and economic challenges associated with large-scale energy storage.

Alkyl compounds, organic molecules consisting of carbon and hydrogen atoms arranged in various chain structures, have emerged as promising candidates for enhancing battery performance. Their potential lies in their ability to form stable interfaces between electrodes and electrolytes, potentially mitigating issues such as dendrite formation and capacity fade that plague many current battery technologies.

The development of alkyl compound applications in batteries can be traced back to the late 20th century, with initial research focusing on their use as electrolyte additives. However, recent advancements have expanded their role to include active electrode materials and solid electrolytes, opening new avenues for battery innovation.

The primary objective of research in this area is to leverage the unique properties of alkyl compounds to overcome existing limitations in battery technology. These properties include their structural versatility, which allows for fine-tuning of molecular designs to optimize specific battery parameters. Additionally, the potential for alkyl compounds to facilitate faster ion transport and enhance electrode stability has garnered significant attention.

Key goals in this field include developing alkyl-based electrolytes with wider electrochemical stability windows, synthesizing alkyl-functionalized electrode materials for improved capacity retention, and creating alkyl-based solid electrolytes for next-generation solid-state batteries. Researchers aim to exploit the molecular engineering possibilities of alkyl compounds to create battery components that are not only more efficient but also more environmentally friendly and cost-effective.

The trajectory of this research aligns with broader trends in sustainable energy storage, as alkyl compounds offer the potential for batteries that are less reliant on rare earth metals and more amenable to recycling. This aspect is particularly crucial as the global demand for energy storage solutions continues to grow, driven by the expansion of renewable energy sources and the electrification of transportation.

As the field progresses, interdisciplinary collaboration between organic chemists, materials scientists, and electrochemists will be essential to fully realize the potential of alkyl compounds in battery technology. The ultimate aim is to develop batteries that not only surpass current performance metrics but also address the environmental and economic challenges associated with large-scale energy storage.

Market Analysis for Advanced Battery Technologies

The market for advanced battery technologies is experiencing rapid growth and transformation, driven by the increasing demand for electric vehicles, renewable energy storage, and portable electronics. The global advanced battery market is projected to reach significant value in the coming years, with a compound annual growth rate exceeding industry averages. This growth is primarily fueled by the automotive sector's shift towards electrification, government initiatives promoting clean energy, and the rising adoption of smart devices.

In the context of next-generation battery technologies, alkyl compounds are gaining attention for their potential to enhance battery performance. These compounds are being researched for their ability to improve electrolyte stability, increase energy density, and extend battery life cycles. The market demand for such innovations is particularly strong in the electric vehicle segment, where range anxiety and charging times remain key consumer concerns.

The Asia-Pacific region, led by China, Japan, and South Korea, dominates the advanced battery market, both in terms of production and consumption. These countries have established robust supply chains and are investing heavily in research and development. North America and Europe are also significant markets, with a focus on high-performance batteries for automotive and grid storage applications.

Consumer electronics continue to be a major driver for advanced battery technologies, with smartphones, laptops, and wearables requiring ever-increasing battery life and faster charging capabilities. The industrial sector is another growing market, as factories and warehouses adopt more automated and electric-powered equipment.

The market is characterized by intense competition among established battery manufacturers and new entrants. Key players are investing in research and development to gain a competitive edge, with a focus on improving energy density, reducing costs, and enhancing safety features. Collaborations between battery manufacturers, automotive companies, and technology firms are becoming more common, accelerating innovation in the field.

Challenges in the market include the high cost of advanced battery technologies, concerns about the environmental impact of battery production and disposal, and the need for more efficient recycling processes. However, these challenges also present opportunities for companies that can develop sustainable and cost-effective solutions.

As the market for advanced battery technologies continues to evolve, the role of alkyl compounds in next-generation batteries represents a promising area for growth and innovation. Companies that can successfully leverage these compounds to address key market demands are likely to gain a significant competitive advantage in this rapidly expanding industry.

In the context of next-generation battery technologies, alkyl compounds are gaining attention for their potential to enhance battery performance. These compounds are being researched for their ability to improve electrolyte stability, increase energy density, and extend battery life cycles. The market demand for such innovations is particularly strong in the electric vehicle segment, where range anxiety and charging times remain key consumer concerns.

The Asia-Pacific region, led by China, Japan, and South Korea, dominates the advanced battery market, both in terms of production and consumption. These countries have established robust supply chains and are investing heavily in research and development. North America and Europe are also significant markets, with a focus on high-performance batteries for automotive and grid storage applications.

Consumer electronics continue to be a major driver for advanced battery technologies, with smartphones, laptops, and wearables requiring ever-increasing battery life and faster charging capabilities. The industrial sector is another growing market, as factories and warehouses adopt more automated and electric-powered equipment.

The market is characterized by intense competition among established battery manufacturers and new entrants. Key players are investing in research and development to gain a competitive edge, with a focus on improving energy density, reducing costs, and enhancing safety features. Collaborations between battery manufacturers, automotive companies, and technology firms are becoming more common, accelerating innovation in the field.

Challenges in the market include the high cost of advanced battery technologies, concerns about the environmental impact of battery production and disposal, and the need for more efficient recycling processes. However, these challenges also present opportunities for companies that can develop sustainable and cost-effective solutions.

As the market for advanced battery technologies continues to evolve, the role of alkyl compounds in next-generation batteries represents a promising area for growth and innovation. Companies that can successfully leverage these compounds to address key market demands are likely to gain a significant competitive advantage in this rapidly expanding industry.

Current Challenges in Alkyl Compound Integration

The integration of alkyl compounds in next-generation battery technologies faces several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the stability of alkyl compounds within the battery environment. These compounds are often susceptible to degradation under the high-voltage and high-temperature conditions typical in advanced battery systems. This degradation can lead to reduced battery performance, shortened lifespan, and potential safety issues.

Another critical challenge is the compatibility of alkyl compounds with other battery components. The interaction between alkyl compounds and electrode materials, electrolytes, and separators can result in undesired side reactions, which may compromise the overall battery efficiency. Researchers are struggling to find the right balance of alkyl compound formulations that can enhance battery performance without negatively impacting other crucial elements of the battery system.

The scalability of alkyl compound integration presents yet another hurdle. While promising results have been achieved in laboratory settings, translating these successes to large-scale manufacturing processes remains problematic. Issues such as uniform distribution of alkyl compounds within battery cells and maintaining consistent quality across mass production are significant concerns that need to be addressed.

Furthermore, the long-term effects of alkyl compounds on battery performance and safety are not yet fully understood. Extensive testing and real-world trials are necessary to ensure that batteries incorporating these compounds can meet the rigorous standards required for commercial applications, particularly in sectors like electric vehicles and grid energy storage.

Cost considerations also pose a substantial challenge. Many high-performance alkyl compounds are expensive to synthesize or source, which could significantly increase the overall cost of battery production. Finding cost-effective alternatives or developing more economical synthesis methods is crucial for the widespread adoption of this technology.

Lastly, environmental and sustainability concerns surrounding alkyl compounds cannot be overlooked. As the battery industry moves towards more sustainable practices, the environmental impact of these compounds throughout the battery lifecycle – from production to disposal or recycling – must be carefully evaluated and mitigated.

Addressing these challenges requires a multidisciplinary approach, combining expertise from chemistry, materials science, engineering, and environmental studies. Overcoming these hurdles will be critical in realizing the full potential of alkyl compounds in next-generation battery technologies and paving the way for more efficient, durable, and sustainable energy storage solutions.

Another critical challenge is the compatibility of alkyl compounds with other battery components. The interaction between alkyl compounds and electrode materials, electrolytes, and separators can result in undesired side reactions, which may compromise the overall battery efficiency. Researchers are struggling to find the right balance of alkyl compound formulations that can enhance battery performance without negatively impacting other crucial elements of the battery system.

The scalability of alkyl compound integration presents yet another hurdle. While promising results have been achieved in laboratory settings, translating these successes to large-scale manufacturing processes remains problematic. Issues such as uniform distribution of alkyl compounds within battery cells and maintaining consistent quality across mass production are significant concerns that need to be addressed.

Furthermore, the long-term effects of alkyl compounds on battery performance and safety are not yet fully understood. Extensive testing and real-world trials are necessary to ensure that batteries incorporating these compounds can meet the rigorous standards required for commercial applications, particularly in sectors like electric vehicles and grid energy storage.

Cost considerations also pose a substantial challenge. Many high-performance alkyl compounds are expensive to synthesize or source, which could significantly increase the overall cost of battery production. Finding cost-effective alternatives or developing more economical synthesis methods is crucial for the widespread adoption of this technology.

Lastly, environmental and sustainability concerns surrounding alkyl compounds cannot be overlooked. As the battery industry moves towards more sustainable practices, the environmental impact of these compounds throughout the battery lifecycle – from production to disposal or recycling – must be carefully evaluated and mitigated.

Addressing these challenges requires a multidisciplinary approach, combining expertise from chemistry, materials science, engineering, and environmental studies. Overcoming these hurdles will be critical in realizing the full potential of alkyl compounds in next-generation battery technologies and paving the way for more efficient, durable, and sustainable energy storage solutions.

Existing Alkyl Compound Solutions in Batteries

01 Synthesis of alkyl compounds

Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.- Synthesis of alkyl compounds: Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.

- Applications of alkyl compounds in industry: Alkyl compounds find diverse applications in industrial processes, such as in the production of lubricants, plasticizers, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules.

- Alkyl compounds in polymer chemistry: Alkyl groups play a crucial role in polymer chemistry, influencing the properties of polymeric materials. They are used in the synthesis of various polymers and copolymers, affecting characteristics such as solubility, flexibility, and thermal stability.

- Purification and characterization of alkyl compounds: Techniques for purifying and characterizing alkyl compounds are described, including distillation, chromatography, and spectroscopic methods. These processes are essential for ensuring the quality and purity of alkyl compounds for various applications.

- Environmental and safety considerations of alkyl compounds: The environmental impact and safety aspects of alkyl compounds are addressed, including their biodegradability, toxicity, and potential for bioaccumulation. Methods for safe handling, storage, and disposal of these compounds are also discussed.

02 Applications of alkyl compounds in industry

Alkyl compounds find diverse applications in industrial processes, such as in the production of lubricants, plasticizers, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules.Expand Specific Solutions03 Alkyl compounds in polymer chemistry

Alkyl groups play a crucial role in polymer chemistry, influencing properties such as solubility, melting point, and mechanical strength. They are used in the synthesis of various polymers and copolymers for different applications.Expand Specific Solutions04 Environmental and safety considerations of alkyl compounds

The use and disposal of certain alkyl compounds raise environmental and safety concerns. Research focuses on developing safer alternatives and improving handling procedures to minimize risks associated with these chemicals.Expand Specific Solutions05 Analytical methods for alkyl compounds

Various analytical techniques are employed for the identification, quantification, and characterization of alkyl compounds. These methods include spectroscopic techniques, chromatography, and mass spectrometry, which are crucial for quality control and research purposes.Expand Specific Solutions

Key Players in Next-Gen Battery Research

The research on alkyl compounds in next-generation battery technologies is in a dynamic phase, with significant market potential and growing technological maturity. The industry is transitioning from early-stage research to more advanced development, driven by the increasing demand for high-performance energy storage solutions. The market size is expanding rapidly, fueled by applications in electric vehicles, consumer electronics, and renewable energy systems. Technologically, companies like Samsung SDI, LG Chem, and Panasonic are leading the charge, with significant advancements in alkyl-based electrolytes and electrode materials. Emerging players such as BASF and UBE Corp are also making notable contributions, particularly in developing novel alkyl compounds for enhanced battery performance and safety.

BASF Corp.

Technical Solution: BASF has developed advanced alkyl carbonate-based electrolytes for next-generation batteries. Their research focuses on optimizing the molecular structure of alkyl carbonates to enhance battery performance. They have introduced fluorinated alkyl carbonates that demonstrate improved thermal stability and electrochemical performance[1]. BASF's electrolyte formulations incorporate a blend of linear and cyclic alkyl carbonates, which synergistically improve the ionic conductivity and form stable solid electrolyte interphase (SEI) layers[2]. The company has also explored the use of asymmetric alkyl carbonates to fine-tune electrolyte properties for specific battery chemistries[3].

Strengths: Extensive R&D capabilities, global presence, and diverse chemical expertise. Weaknesses: High development costs and potential regulatory challenges for new chemical compounds.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has made significant strides in alkyl compound research for next-generation batteries. They have developed novel silicon-carbon composite anodes incorporating alkyl-functionalized graphene oxide, which enhances the stability of the electrode-electrolyte interface[4]. Their research also extends to high-voltage electrolytes containing alkyl phosphates, which have shown promise in improving the cycling stability of high-nickel cathodes[5]. Samsung SDI has patented electrolyte additives based on unsaturated alkyl compounds that form protective films on electrode surfaces, mitigating capacity fade and improving battery longevity[6].

Strengths: Strong integration with consumer electronics and automotive sectors, extensive patent portfolio. Weaknesses: Potential supply chain dependencies for specialized materials.

Innovative Alkyl Compound Applications

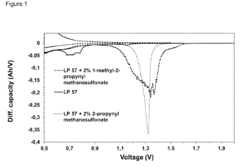

Non-aqueous electrolytic solution, electrochemical element using same, and alkynyl compound used therefor

PatentWO2011096450A1

Innovation

- Incorporating an alkynyl compound with a specific structure into the non-aqueous electrolyte, where the alkynyl group is bonded via a specific functional group, such as -C(=O)-, -S(=O)2-, or -P(=O)-, to enhance the electrolyte's stability and reduce decomposition, thereby improving low-temperature and high-temperature cycle characteristics and load characteristics.

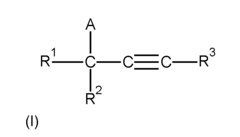

Use of substituted alkynyl sulfonates, carbonates and oxalates as additives in electrolytes of secondary lithium-ion batteries

PatentInactiveEP2768064A1

Innovation

- An electrolyte composition comprising an aprotic organic solvent, a conducting salt, and a compound of formula (I), where R1, R2, and R3 are defined by specific alkyl, alkenyl, cycloalkyl, aryl, and heteroaryl groups, along with optional additives, is used to enhance the stability and temperature range of lithium ion batteries by forming a beneficial film on the anode and cathode.

Environmental Impact of Alkyl Compounds in Batteries

The environmental impact of alkyl compounds in batteries is a critical consideration as next-generation battery technologies continue to evolve. These compounds, while essential for improving battery performance, can have significant implications for ecosystems and human health throughout the battery lifecycle.

During the production phase, the synthesis of alkyl compounds often involves the use of volatile organic solvents and potentially hazardous reagents. These processes can lead to air and water pollution if not properly managed. Additionally, the energy-intensive nature of alkyl compound production contributes to increased carbon emissions, further exacerbating environmental concerns.

In the operational phase of batteries, alkyl compounds play a crucial role in electrolyte formulations. While they enhance battery efficiency and longevity, there are potential risks associated with leakage or thermal runaway events. In such cases, the release of these compounds into the environment can contaminate soil and water sources, potentially harming local flora and fauna.

The end-of-life stage of batteries presents another set of environmental challenges. Improper disposal or recycling of batteries containing alkyl compounds can lead to soil and groundwater contamination. The persistence of certain alkyl compounds in the environment raises concerns about bioaccumulation in food chains and long-term ecological impacts.

However, ongoing research is focused on developing more environmentally friendly alkyl compounds and improving battery recycling technologies. Green chemistry approaches are being explored to synthesize alkyl compounds using less toxic solvents and more sustainable processes. Additionally, efforts are being made to design batteries with easily separable components, facilitating more efficient recycling and reducing the environmental footprint of alkyl compounds.

The regulatory landscape is also evolving to address the environmental concerns associated with alkyl compounds in batteries. Stricter guidelines for production, use, and disposal are being implemented in many regions, pushing manufacturers to adopt more sustainable practices and invest in cleaner technologies.

As the demand for high-performance batteries continues to grow, balancing technological advancements with environmental stewardship becomes increasingly important. The development of biodegradable alkyl compounds and closed-loop recycling systems are promising avenues for mitigating the environmental impact of these essential battery components.

During the production phase, the synthesis of alkyl compounds often involves the use of volatile organic solvents and potentially hazardous reagents. These processes can lead to air and water pollution if not properly managed. Additionally, the energy-intensive nature of alkyl compound production contributes to increased carbon emissions, further exacerbating environmental concerns.

In the operational phase of batteries, alkyl compounds play a crucial role in electrolyte formulations. While they enhance battery efficiency and longevity, there are potential risks associated with leakage or thermal runaway events. In such cases, the release of these compounds into the environment can contaminate soil and water sources, potentially harming local flora and fauna.

The end-of-life stage of batteries presents another set of environmental challenges. Improper disposal or recycling of batteries containing alkyl compounds can lead to soil and groundwater contamination. The persistence of certain alkyl compounds in the environment raises concerns about bioaccumulation in food chains and long-term ecological impacts.

However, ongoing research is focused on developing more environmentally friendly alkyl compounds and improving battery recycling technologies. Green chemistry approaches are being explored to synthesize alkyl compounds using less toxic solvents and more sustainable processes. Additionally, efforts are being made to design batteries with easily separable components, facilitating more efficient recycling and reducing the environmental footprint of alkyl compounds.

The regulatory landscape is also evolving to address the environmental concerns associated with alkyl compounds in batteries. Stricter guidelines for production, use, and disposal are being implemented in many regions, pushing manufacturers to adopt more sustainable practices and invest in cleaner technologies.

As the demand for high-performance batteries continues to grow, balancing technological advancements with environmental stewardship becomes increasingly important. The development of biodegradable alkyl compounds and closed-loop recycling systems are promising avenues for mitigating the environmental impact of these essential battery components.

Safety Considerations for Alkyl-Based Battery Systems

The safety considerations for alkyl-based battery systems are paramount in the development and implementation of next-generation battery technologies. These systems, while promising in terms of energy density and performance, present unique challenges that must be carefully addressed to ensure their safe operation and widespread adoption.

One of the primary safety concerns in alkyl-based battery systems is the reactivity of alkyl compounds. These organic materials can be highly flammable and volatile, potentially leading to thermal runaway events if not properly managed. To mitigate this risk, researchers are focusing on developing advanced thermal management systems and incorporating flame-retardant additives into the battery components.

Electrolyte stability is another critical aspect of safety in alkyl-based batteries. The interaction between alkyl compounds and other battery components can lead to unwanted side reactions, potentially compromising the integrity of the cell. Extensive research is being conducted to identify stable electrolyte formulations that can withstand the chemical environment within the battery while maintaining performance.

The potential for gas generation during battery operation is a significant safety consideration. Alkyl compounds may decompose or react under certain conditions, producing gases that can build up pressure within the cell. This necessitates the development of robust venting mechanisms and pressure-relief systems to prevent catastrophic failure.

Electrical safety is also a key focus area, as alkyl-based batteries may have different conductivity properties compared to traditional lithium-ion systems. Researchers are investigating novel electrode designs and separator materials to prevent internal short circuits and ensure consistent electrical performance across a wide range of operating conditions.

Environmental and health considerations play a crucial role in the safety assessment of alkyl-based battery systems. The potential toxicity of certain alkyl compounds and their degradation products must be thoroughly evaluated. This includes studying the long-term effects of exposure and developing appropriate handling and disposal protocols for both manufacturing and end-of-life scenarios.

Standardization and regulatory compliance are essential for the safe implementation of alkyl-based battery technologies. Industry stakeholders are working closely with regulatory bodies to establish comprehensive safety standards and testing protocols specific to these novel systems. This collaborative effort aims to create a framework that ensures consistent safety measures across different applications and manufacturers.

As research progresses, the integration of advanced monitoring and control systems is becoming increasingly important. These systems can provide real-time data on battery health and performance, allowing for early detection of potential safety issues and enabling proactive maintenance strategies.

One of the primary safety concerns in alkyl-based battery systems is the reactivity of alkyl compounds. These organic materials can be highly flammable and volatile, potentially leading to thermal runaway events if not properly managed. To mitigate this risk, researchers are focusing on developing advanced thermal management systems and incorporating flame-retardant additives into the battery components.

Electrolyte stability is another critical aspect of safety in alkyl-based batteries. The interaction between alkyl compounds and other battery components can lead to unwanted side reactions, potentially compromising the integrity of the cell. Extensive research is being conducted to identify stable electrolyte formulations that can withstand the chemical environment within the battery while maintaining performance.

The potential for gas generation during battery operation is a significant safety consideration. Alkyl compounds may decompose or react under certain conditions, producing gases that can build up pressure within the cell. This necessitates the development of robust venting mechanisms and pressure-relief systems to prevent catastrophic failure.

Electrical safety is also a key focus area, as alkyl-based batteries may have different conductivity properties compared to traditional lithium-ion systems. Researchers are investigating novel electrode designs and separator materials to prevent internal short circuits and ensure consistent electrical performance across a wide range of operating conditions.

Environmental and health considerations play a crucial role in the safety assessment of alkyl-based battery systems. The potential toxicity of certain alkyl compounds and their degradation products must be thoroughly evaluated. This includes studying the long-term effects of exposure and developing appropriate handling and disposal protocols for both manufacturing and end-of-life scenarios.

Standardization and regulatory compliance are essential for the safe implementation of alkyl-based battery technologies. Industry stakeholders are working closely with regulatory bodies to establish comprehensive safety standards and testing protocols specific to these novel systems. This collaborative effort aims to create a framework that ensures consistent safety measures across different applications and manufacturers.

As research progresses, the integration of advanced monitoring and control systems is becoming increasingly important. These systems can provide real-time data on battery health and performance, allowing for early detection of potential safety issues and enabling proactive maintenance strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!