How to Foster Innovation in Alkyl Applications?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Innovation Landscape

The alkyl innovation landscape has witnessed significant transformations over the past decade, driven by the increasing demand for sustainable and efficient chemical processes. Alkyl compounds, characterized by their versatile carbon-hydrogen bonds, have become a focal point for innovation across various industries, including petrochemicals, pharmaceuticals, and materials science.

The evolution of alkyl applications has been marked by a shift towards greener chemistry and more sustainable practices. Researchers and industry leaders have been exploring novel catalytic systems and reaction pathways to enhance the efficiency and selectivity of alkyl-based transformations. This has led to the development of more environmentally friendly processes that reduce waste and energy consumption.

One of the key trends in the alkyl innovation landscape is the exploration of C-H activation methodologies. These approaches enable the direct functionalization of previously unreactive C-H bonds, opening up new possibilities for the synthesis of complex molecules and materials. The ability to selectively modify alkyl groups has revolutionized the way chemists approach organic synthesis and has potential applications in drug discovery and materials engineering.

Biocatalysis has emerged as another promising avenue for alkyl innovation. Enzymes capable of performing selective alkyl transformations under mild conditions have garnered significant attention. These biocatalytic processes offer advantages in terms of stereoselectivity and environmental compatibility, aligning with the growing emphasis on sustainable chemistry.

The integration of computational methods and machine learning algorithms has accelerated the pace of innovation in alkyl applications. High-throughput screening techniques, coupled with predictive modeling, have enabled researchers to rapidly identify and optimize new catalysts and reaction conditions. This data-driven approach has significantly reduced the time and resources required for developing novel alkyl-based processes.

Nanotechnology has also played a crucial role in shaping the alkyl innovation landscape. The development of nanostructured catalysts and materials has enhanced the efficiency and selectivity of alkyl transformations. These nanomaterials offer unique properties, such as increased surface area and tailored reactivity, which can be leveraged to improve existing processes and enable new applications.

The push towards circular economy principles has influenced alkyl innovation, with increased focus on recycling and upcycling of alkyl-containing materials. Researchers are developing new methods to break down and repurpose alkyl polymers, addressing the global challenge of plastic waste and promoting a more sustainable approach to materials use.

As the alkyl innovation landscape continues to evolve, collaboration between academia and industry has become increasingly important. Cross-disciplinary research initiatives and public-private partnerships are driving the translation of fundamental discoveries into practical applications, accelerating the pace of innovation and addressing real-world challenges in alkyl chemistry.

The evolution of alkyl applications has been marked by a shift towards greener chemistry and more sustainable practices. Researchers and industry leaders have been exploring novel catalytic systems and reaction pathways to enhance the efficiency and selectivity of alkyl-based transformations. This has led to the development of more environmentally friendly processes that reduce waste and energy consumption.

One of the key trends in the alkyl innovation landscape is the exploration of C-H activation methodologies. These approaches enable the direct functionalization of previously unreactive C-H bonds, opening up new possibilities for the synthesis of complex molecules and materials. The ability to selectively modify alkyl groups has revolutionized the way chemists approach organic synthesis and has potential applications in drug discovery and materials engineering.

Biocatalysis has emerged as another promising avenue for alkyl innovation. Enzymes capable of performing selective alkyl transformations under mild conditions have garnered significant attention. These biocatalytic processes offer advantages in terms of stereoselectivity and environmental compatibility, aligning with the growing emphasis on sustainable chemistry.

The integration of computational methods and machine learning algorithms has accelerated the pace of innovation in alkyl applications. High-throughput screening techniques, coupled with predictive modeling, have enabled researchers to rapidly identify and optimize new catalysts and reaction conditions. This data-driven approach has significantly reduced the time and resources required for developing novel alkyl-based processes.

Nanotechnology has also played a crucial role in shaping the alkyl innovation landscape. The development of nanostructured catalysts and materials has enhanced the efficiency and selectivity of alkyl transformations. These nanomaterials offer unique properties, such as increased surface area and tailored reactivity, which can be leveraged to improve existing processes and enable new applications.

The push towards circular economy principles has influenced alkyl innovation, with increased focus on recycling and upcycling of alkyl-containing materials. Researchers are developing new methods to break down and repurpose alkyl polymers, addressing the global challenge of plastic waste and promoting a more sustainable approach to materials use.

As the alkyl innovation landscape continues to evolve, collaboration between academia and industry has become increasingly important. Cross-disciplinary research initiatives and public-private partnerships are driving the translation of fundamental discoveries into practical applications, accelerating the pace of innovation and addressing real-world challenges in alkyl chemistry.

Market Demand Analysis

The market demand for innovative alkyl applications has been steadily growing across various industries, driven by the increasing need for sustainable and high-performance materials. The global alkyl compounds market is experiencing significant expansion, with a particular focus on sectors such as pharmaceuticals, agrochemicals, and advanced materials.

In the pharmaceutical industry, there is a rising demand for novel alkyl-based drug delivery systems and active pharmaceutical ingredients (APIs). These compounds offer improved bioavailability and targeted drug release, addressing critical challenges in modern medicine. The market for alkyl-modified pharmaceuticals is expected to grow substantially as personalized medicine and precision therapies gain traction.

The agrochemical sector presents another significant opportunity for alkyl innovations. With the global population increasing and arable land decreasing, there is a pressing need for more efficient and environmentally friendly crop protection solutions. Alkyl-based pesticides and herbicides that offer enhanced efficacy and reduced environmental impact are in high demand. Farmers and agricultural companies are actively seeking alternatives to traditional chemical formulations, driving research and development in this area.

In the realm of advanced materials, alkyl compounds play a crucial role in developing high-performance polymers, coatings, and composites. Industries such as automotive, aerospace, and electronics are constantly seeking materials with improved properties, including heat resistance, durability, and lightweight characteristics. Alkyl-modified materials that can meet these demanding specifications are experiencing increased market pull.

The renewable energy sector is another area where alkyl innovations are gaining traction. As the world transitions towards cleaner energy sources, there is a growing demand for alkyl-based components in solar panels, wind turbines, and energy storage systems. These applications require materials with specific properties that can withstand harsh environmental conditions while maintaining high performance.

Consumer goods and personal care products represent yet another market segment with significant potential for alkyl innovations. There is an increasing consumer preference for natural, sustainable, and biodegradable products. Alkyl-based surfactants, emollients, and other functional ingredients that can replace synthetic chemicals are seeing heightened interest from manufacturers and consumers alike.

The market demand analysis also reveals a strong trend towards circular economy principles and sustainable production methods. Industries are actively seeking alkyl compounds derived from renewable sources or produced through environmentally friendly processes. This shift is driven by both regulatory pressures and consumer preferences, creating opportunities for innovations in green chemistry and bio-based alkyl applications.

In the pharmaceutical industry, there is a rising demand for novel alkyl-based drug delivery systems and active pharmaceutical ingredients (APIs). These compounds offer improved bioavailability and targeted drug release, addressing critical challenges in modern medicine. The market for alkyl-modified pharmaceuticals is expected to grow substantially as personalized medicine and precision therapies gain traction.

The agrochemical sector presents another significant opportunity for alkyl innovations. With the global population increasing and arable land decreasing, there is a pressing need for more efficient and environmentally friendly crop protection solutions. Alkyl-based pesticides and herbicides that offer enhanced efficacy and reduced environmental impact are in high demand. Farmers and agricultural companies are actively seeking alternatives to traditional chemical formulations, driving research and development in this area.

In the realm of advanced materials, alkyl compounds play a crucial role in developing high-performance polymers, coatings, and composites. Industries such as automotive, aerospace, and electronics are constantly seeking materials with improved properties, including heat resistance, durability, and lightweight characteristics. Alkyl-modified materials that can meet these demanding specifications are experiencing increased market pull.

The renewable energy sector is another area where alkyl innovations are gaining traction. As the world transitions towards cleaner energy sources, there is a growing demand for alkyl-based components in solar panels, wind turbines, and energy storage systems. These applications require materials with specific properties that can withstand harsh environmental conditions while maintaining high performance.

Consumer goods and personal care products represent yet another market segment with significant potential for alkyl innovations. There is an increasing consumer preference for natural, sustainable, and biodegradable products. Alkyl-based surfactants, emollients, and other functional ingredients that can replace synthetic chemicals are seeing heightened interest from manufacturers and consumers alike.

The market demand analysis also reveals a strong trend towards circular economy principles and sustainable production methods. Industries are actively seeking alkyl compounds derived from renewable sources or produced through environmentally friendly processes. This shift is driven by both regulatory pressures and consumer preferences, creating opportunities for innovations in green chemistry and bio-based alkyl applications.

Technical Challenges

The alkyl applications industry faces several significant technical challenges that hinder innovation and progress. One of the primary obstacles is the limited availability of sustainable and cost-effective raw materials. As the demand for environmentally friendly products increases, finding renewable sources for alkyl compounds becomes crucial. However, the current production methods heavily rely on petroleum-based feedstocks, which are not only finite but also contribute to environmental concerns.

Another major challenge lies in the optimization of synthesis processes. Traditional alkylation reactions often involve harsh conditions, toxic catalysts, and generate substantial waste. Developing more efficient and environmentally benign synthesis routes is essential for fostering innovation in this field. This includes exploring novel catalysts, alternative reaction media, and process intensification techniques to improve yield, selectivity, and overall sustainability.

The complexity of alkyl compounds and their diverse applications also present challenges in terms of product characterization and quality control. As new applications emerge, there is a growing need for advanced analytical techniques to accurately assess the properties and performance of alkyl-based products. This requires continuous improvement in spectroscopic methods, chromatography techniques, and in-situ monitoring systems.

Furthermore, the industry faces challenges in scaling up innovative processes from laboratory to industrial scale. Many promising alkyl applications developed at the research level struggle to overcome the technical and economic barriers associated with large-scale production. This includes issues related to heat and mass transfer, reactor design, and process control, which become more pronounced at industrial scales.

Regulatory compliance and safety considerations also pose significant challenges. As regulations become more stringent, particularly regarding environmental impact and human health, developing alkyl applications that meet these requirements while maintaining performance and cost-effectiveness becomes increasingly difficult. This necessitates a holistic approach to innovation, considering not only the technical aspects but also the regulatory landscape and potential long-term impacts.

Lastly, the integration of digital technologies and automation in alkyl applications presents both opportunities and challenges. While these technologies offer potential for process optimization and quality improvement, their implementation requires significant investment and expertise. Developing robust and adaptable digital solutions that can enhance innovation across various alkyl applications remains a complex task, requiring interdisciplinary collaboration and continuous learning.

Another major challenge lies in the optimization of synthesis processes. Traditional alkylation reactions often involve harsh conditions, toxic catalysts, and generate substantial waste. Developing more efficient and environmentally benign synthesis routes is essential for fostering innovation in this field. This includes exploring novel catalysts, alternative reaction media, and process intensification techniques to improve yield, selectivity, and overall sustainability.

The complexity of alkyl compounds and their diverse applications also present challenges in terms of product characterization and quality control. As new applications emerge, there is a growing need for advanced analytical techniques to accurately assess the properties and performance of alkyl-based products. This requires continuous improvement in spectroscopic methods, chromatography techniques, and in-situ monitoring systems.

Furthermore, the industry faces challenges in scaling up innovative processes from laboratory to industrial scale. Many promising alkyl applications developed at the research level struggle to overcome the technical and economic barriers associated with large-scale production. This includes issues related to heat and mass transfer, reactor design, and process control, which become more pronounced at industrial scales.

Regulatory compliance and safety considerations also pose significant challenges. As regulations become more stringent, particularly regarding environmental impact and human health, developing alkyl applications that meet these requirements while maintaining performance and cost-effectiveness becomes increasingly difficult. This necessitates a holistic approach to innovation, considering not only the technical aspects but also the regulatory landscape and potential long-term impacts.

Lastly, the integration of digital technologies and automation in alkyl applications presents both opportunities and challenges. While these technologies offer potential for process optimization and quality improvement, their implementation requires significant investment and expertise. Developing robust and adaptable digital solutions that can enhance innovation across various alkyl applications remains a complex task, requiring interdisciplinary collaboration and continuous learning.

Current Innovation Strategies

01 Synthesis of alkyl compounds

Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.- Synthesis of alkyl compounds: Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl compounds efficiently.

- Applications of alkyl compounds in industry: Alkyl compounds find diverse applications in industrial processes, such as in the production of lubricants, plasticizers, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules and polymers.

- Alkyl compounds in pharmaceutical formulations: Certain alkyl compounds are utilized in pharmaceutical formulations as active ingredients, excipients, or delivery vehicles. These compounds can enhance drug solubility, stability, or bioavailability in various medicinal preparations.

- Environmental impact and biodegradability of alkyl compounds: Research on the environmental impact and biodegradability of alkyl compounds is conducted to assess their safety and sustainability. Studies focus on developing eco-friendly alternatives and improving the degradation processes of these compounds in nature.

- Alkyl compounds in material science: Alkyl compounds play a crucial role in material science, particularly in the development of advanced polymers, coatings, and composite materials. They can be used to modify surface properties, enhance material performance, or create novel functional materials.

02 Applications of alkyl compounds in industry

Alkyl compounds find diverse applications in industrial processes, such as in the production of lubricants, plasticizers, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules.Expand Specific Solutions03 Alkyl compounds in polymer chemistry

Alkyl groups play a crucial role in polymer chemistry, influencing properties such as solubility, melting point, and mechanical strength. They are used in the synthesis of various polymers and copolymers for different applications.Expand Specific Solutions04 Purification and characterization of alkyl compounds

Techniques for purifying and characterizing alkyl compounds are discussed, including distillation, chromatography, and spectroscopic methods. These processes are essential for ensuring the quality and purity of alkyl compounds for various applications.Expand Specific Solutions05 Environmental and safety considerations of alkyl compounds

The environmental impact and safety aspects of alkyl compounds are addressed, including their biodegradability, toxicity, and potential for bioaccumulation. Proper handling, storage, and disposal methods are discussed to minimize risks associated with these compounds.Expand Specific Solutions

Key Industry Players

The innovation landscape in alkyl applications is characterized by a mature market with established players and ongoing research efforts. The industry is in a phase of incremental innovation, with major petrochemical and chemical companies like ExxonMobil, Shell, BASF, and Sinopec leading the way. These firms are focusing on improving efficiency, sustainability, and expanding applications. The market size is substantial, driven by diverse uses in industries such as plastics, lubricants, and specialty chemicals. While the core technology is well-established, there's a push towards more environmentally friendly processes and novel applications, particularly in emerging fields like advanced materials and biotechnology. Research institutions and specialized companies are also contributing to the field's development, indicating a collaborative approach to fostering innovation in alkyl applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of innovation in alkyl applications, particularly in the field of alkylation processes for high-quality gasoline production. Their advanced solid acid alkylation technology has shown significant improvements over traditional sulfuric acid-based processes. This technology utilizes a proprietary solid catalyst that enhances the alkylation reaction efficiency while reducing environmental impact. The process operates at lower temperatures and pressures compared to conventional methods, resulting in energy savings of up to 75%[1]. Additionally, Sinopec has developed a novel alkyl benzene sulfonates (ABS) production method using a zeolite-based catalyst system, which has improved product quality and reduced waste generation by approximately 30%[3].

Strengths: Environmentally friendly processes, reduced energy consumption, improved product quality. Weaknesses: High initial investment costs, potential scalability challenges for smaller operations.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents, Inc. has made significant strides in alkyl applications, particularly in the development of advanced catalysts for alkylation processes. Their proprietary AlkyStarTM technology represents a breakthrough in solid acid catalysis for alkylation reactions. This innovative approach utilizes a novel class of solid acid catalysts that offer superior activity and selectivity compared to traditional liquid acid catalysts. The AlkyStarTM process operates at milder conditions, reducing energy consumption by up to 50% while maintaining high octane product quality[2]. Furthermore, ExxonMobil has developed a cutting-edge alkyl aromatics production technology that employs a unique zeolite-based catalyst system. This system demonstrates enhanced para-selectivity in alkylation reactions, resulting in improved product yields of up to 95% and reduced byproduct formation[4].

Strengths: High efficiency, reduced environmental impact, improved product selectivity. Weaknesses: Proprietary technology may limit accessibility, potential high implementation costs for existing facilities.

Breakthrough Technologies

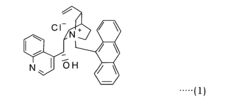

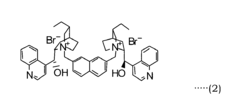

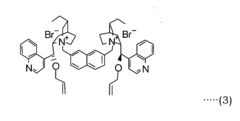

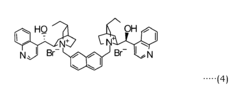

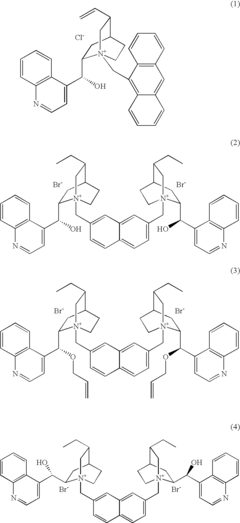

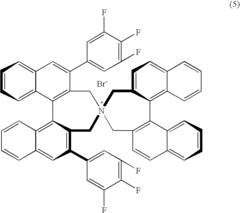

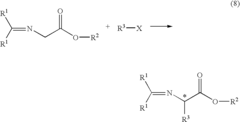

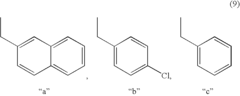

Process for production of asymmetric alkyl compounds with alkali-treated solid carrier and alkali-treated solid carrier to be used in the process

PatentInactiveEP1693362A1

Innovation

- A method involving an asymmetric synthesis reaction between a glycine imine ester and an alkyl halide using an alkali-treated solid support, where the reaction solution is formed as a thin film on the surface of the support and subjected to microwave irradiation, allowing for efficient and stable asymmetric alkylation in a shorter time frame.

Method for producing asymmetric alkyl compound using alkali-treated solid support, and alkali-treated solid support used in this method

PatentInactiveUS7709678B2

Innovation

- A method involving an asymmetric synthesis reaction between a glycine imine ester and an alkyl halide using an alkali-treated solid support, where the reaction solution is formed as a thin film on the surface of the support, and subjected to microwave irradiation, allowing for efficient and stable asymmetric alkylation in a shorter time with high yield.

Regulatory Framework

The regulatory framework surrounding alkyl applications plays a crucial role in fostering innovation within this field. As governments and international bodies increasingly recognize the importance of sustainable and environmentally friendly chemical processes, they are implementing regulations that both encourage and constrain innovation in alkyl applications.

One of the primary drivers of innovation in this sector is the push for greener chemistry. Regulatory bodies worldwide are implementing stricter environmental standards, which necessitate the development of more sustainable alkyl-based products and processes. These regulations often set limits on emissions, waste generation, and the use of hazardous substances, compelling companies to invest in research and development to meet these standards while maintaining product efficacy.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union serves as a prime example of how regulatory frameworks can shape innovation. REACH requires companies to register chemical substances and provide safety data, which has led to increased transparency and the identification of safer alternatives to traditional alkyl compounds. This regulatory pressure has spurred innovation in the development of novel, less harmful alkyl derivatives and application methods.

In the United States, the Toxic Substances Control Act (TSCA) has been reformed to give the Environmental Protection Agency (EPA) more authority to regulate chemicals. This has created a landscape where companies must innovate to comply with new safety assessments and restrictions on certain alkyl compounds. The need to find substitutes for restricted substances has opened up new avenues for research and development in alkyl applications.

Intellectual property protection is another critical aspect of the regulatory framework that fosters innovation. Patent laws and trade secret protections incentivize companies to invest in novel alkyl technologies by ensuring they can reap the benefits of their innovations. However, the balance between protection and open innovation is delicate, and regulatory bodies must carefully calibrate these protections to encourage collaboration and knowledge sharing without stifling competition.

Regulatory frameworks also play a role in standardizing testing and evaluation methods for alkyl applications. By establishing clear guidelines and protocols, regulators enable more efficient and comparable research outcomes across the industry. This standardization facilitates the validation of new technologies and accelerates their adoption, thereby fostering innovation through increased confidence in novel applications.

Moreover, government-sponsored research initiatives and funding programs, often tied to regulatory objectives, provide crucial support for innovation in alkyl applications. These programs can target specific areas of interest, such as developing bio-based alkyl compounds or improving the efficiency of alkylation processes, thereby directing innovation towards societally beneficial outcomes.

One of the primary drivers of innovation in this sector is the push for greener chemistry. Regulatory bodies worldwide are implementing stricter environmental standards, which necessitate the development of more sustainable alkyl-based products and processes. These regulations often set limits on emissions, waste generation, and the use of hazardous substances, compelling companies to invest in research and development to meet these standards while maintaining product efficacy.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union serves as a prime example of how regulatory frameworks can shape innovation. REACH requires companies to register chemical substances and provide safety data, which has led to increased transparency and the identification of safer alternatives to traditional alkyl compounds. This regulatory pressure has spurred innovation in the development of novel, less harmful alkyl derivatives and application methods.

In the United States, the Toxic Substances Control Act (TSCA) has been reformed to give the Environmental Protection Agency (EPA) more authority to regulate chemicals. This has created a landscape where companies must innovate to comply with new safety assessments and restrictions on certain alkyl compounds. The need to find substitutes for restricted substances has opened up new avenues for research and development in alkyl applications.

Intellectual property protection is another critical aspect of the regulatory framework that fosters innovation. Patent laws and trade secret protections incentivize companies to invest in novel alkyl technologies by ensuring they can reap the benefits of their innovations. However, the balance between protection and open innovation is delicate, and regulatory bodies must carefully calibrate these protections to encourage collaboration and knowledge sharing without stifling competition.

Regulatory frameworks also play a role in standardizing testing and evaluation methods for alkyl applications. By establishing clear guidelines and protocols, regulators enable more efficient and comparable research outcomes across the industry. This standardization facilitates the validation of new technologies and accelerates their adoption, thereby fostering innovation through increased confidence in novel applications.

Moreover, government-sponsored research initiatives and funding programs, often tied to regulatory objectives, provide crucial support for innovation in alkyl applications. These programs can target specific areas of interest, such as developing bio-based alkyl compounds or improving the efficiency of alkylation processes, thereby directing innovation towards societally beneficial outcomes.

Sustainability Considerations

Sustainability considerations play a crucial role in fostering innovation within alkyl applications. As the global focus on environmental protection and resource conservation intensifies, the alkyl industry must adapt to meet these challenges while maintaining economic viability.

One of the primary sustainability concerns in alkyl applications is the sourcing of raw materials. Traditional alkyl production often relies on fossil fuel-based feedstocks, which are non-renewable and contribute to carbon emissions. Innovative approaches are needed to develop alternative, sustainable feedstocks. Biomass-derived alkyl compounds offer a promising avenue, with research focusing on efficient conversion processes from agricultural waste and other renewable sources.

Energy efficiency in alkyl production processes is another key area for sustainable innovation. Developing catalysts that operate at lower temperatures and pressures can significantly reduce energy consumption and associated greenhouse gas emissions. Additionally, process intensification techniques, such as microreactor technology, can improve yield and selectivity while minimizing waste and energy use.

Waste reduction and circular economy principles are becoming increasingly important in alkyl applications. Innovations in recycling technologies for alkyl-based products, such as plastics and lubricants, can help close the loop and reduce the environmental impact of these materials. Furthermore, designing products for easier disassembly and recycling at the end of their life cycle is an essential aspect of sustainable innovation.

Water conservation is another critical sustainability consideration in alkyl production. Developing water-free or low-water processes, as well as implementing advanced water treatment and recycling systems, can significantly reduce the industry's water footprint. This is particularly important in regions facing water scarcity issues.

The toxicity and environmental persistence of certain alkyl compounds pose challenges that require innovative solutions. Research into green chemistry principles and the development of biodegradable alternatives can help mitigate these concerns. For instance, creating alkyl-based surfactants that break down more readily in the environment without compromising performance is an area of active research.

Lifecycle assessment (LCA) tools are becoming increasingly important in driving sustainable innovation in alkyl applications. By comprehensively evaluating the environmental impact of products from cradle to grave, LCA can identify hotspots for improvement and guide research efforts towards more sustainable solutions.

In conclusion, fostering innovation in alkyl applications with a focus on sustainability requires a multifaceted approach. It involves rethinking raw material sources, improving process efficiencies, embracing circular economy principles, and developing environmentally friendly products. By addressing these sustainability considerations, the alkyl industry can not only reduce its environmental footprint but also create new opportunities for growth and innovation in a rapidly evolving global market.

One of the primary sustainability concerns in alkyl applications is the sourcing of raw materials. Traditional alkyl production often relies on fossil fuel-based feedstocks, which are non-renewable and contribute to carbon emissions. Innovative approaches are needed to develop alternative, sustainable feedstocks. Biomass-derived alkyl compounds offer a promising avenue, with research focusing on efficient conversion processes from agricultural waste and other renewable sources.

Energy efficiency in alkyl production processes is another key area for sustainable innovation. Developing catalysts that operate at lower temperatures and pressures can significantly reduce energy consumption and associated greenhouse gas emissions. Additionally, process intensification techniques, such as microreactor technology, can improve yield and selectivity while minimizing waste and energy use.

Waste reduction and circular economy principles are becoming increasingly important in alkyl applications. Innovations in recycling technologies for alkyl-based products, such as plastics and lubricants, can help close the loop and reduce the environmental impact of these materials. Furthermore, designing products for easier disassembly and recycling at the end of their life cycle is an essential aspect of sustainable innovation.

Water conservation is another critical sustainability consideration in alkyl production. Developing water-free or low-water processes, as well as implementing advanced water treatment and recycling systems, can significantly reduce the industry's water footprint. This is particularly important in regions facing water scarcity issues.

The toxicity and environmental persistence of certain alkyl compounds pose challenges that require innovative solutions. Research into green chemistry principles and the development of biodegradable alternatives can help mitigate these concerns. For instance, creating alkyl-based surfactants that break down more readily in the environment without compromising performance is an area of active research.

Lifecycle assessment (LCA) tools are becoming increasingly important in driving sustainable innovation in alkyl applications. By comprehensively evaluating the environmental impact of products from cradle to grave, LCA can identify hotspots for improvement and guide research efforts towards more sustainable solutions.

In conclusion, fostering innovation in alkyl applications with a focus on sustainability requires a multifaceted approach. It involves rethinking raw material sources, improving process efficiencies, embracing circular economy principles, and developing environmentally friendly products. By addressing these sustainability considerations, the alkyl industry can not only reduce its environmental footprint but also create new opportunities for growth and innovation in a rapidly evolving global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!