How to Harness Alkyls for Sustainable Energy Production?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Energy Background

Alkyls, organic compounds consisting of carbon and hydrogen atoms, have emerged as a promising avenue for sustainable energy production. The exploration of alkyl-based energy solutions stems from the growing global demand for clean, renewable energy sources that can mitigate the environmental impact of traditional fossil fuels.

The concept of harnessing alkyls for energy production has its roots in the broader field of organic chemistry and hydrocarbon research. Initially, alkyls were primarily studied for their role in petrochemical processes and as intermediates in various chemical reactions. However, as the world grapples with the challenges of climate change and energy security, researchers have begun to investigate the potential of alkyls as a sustainable energy source.

The development of alkyl-based energy technologies has been driven by several key factors. First, the abundance of organic compounds containing alkyl groups in nature provides a potentially vast and renewable resource base. Second, the chemical properties of alkyls, particularly their ability to store and release energy through bond formation and breaking, make them attractive candidates for energy applications.

One of the most promising areas of alkyl energy research is in the field of biofuels. Certain types of algae and bacteria can produce alkyl compounds as part of their metabolic processes, which can be harvested and converted into usable fuels. This approach offers a renewable and potentially carbon-neutral alternative to fossil fuels, as the carbon dioxide released during combustion is offset by the carbon absorbed during the growth of the organisms.

Another significant development in alkyl energy is the exploration of alkyl-based batteries and energy storage systems. Researchers are investigating the use of organic alkyl compounds as electrolytes and electrode materials in next-generation batteries, aiming to create more efficient and environmentally friendly energy storage solutions.

The potential of alkyls in hydrogen production has also garnered attention. Some alkyl compounds can be used as hydrogen carriers, offering a safer and more convenient method of storing and transporting hydrogen for fuel cell applications. This could play a crucial role in the development of a hydrogen-based economy, which is seen as a key component of future sustainable energy systems.

As research in this field progresses, scientists are also exploring the integration of alkyl-based energy solutions with existing renewable technologies. For instance, the combination of solar energy harvesting with alkyl-based energy storage could provide a more reliable and consistent power supply, addressing one of the main challenges of intermittent renewable sources.

The concept of harnessing alkyls for energy production has its roots in the broader field of organic chemistry and hydrocarbon research. Initially, alkyls were primarily studied for their role in petrochemical processes and as intermediates in various chemical reactions. However, as the world grapples with the challenges of climate change and energy security, researchers have begun to investigate the potential of alkyls as a sustainable energy source.

The development of alkyl-based energy technologies has been driven by several key factors. First, the abundance of organic compounds containing alkyl groups in nature provides a potentially vast and renewable resource base. Second, the chemical properties of alkyls, particularly their ability to store and release energy through bond formation and breaking, make them attractive candidates for energy applications.

One of the most promising areas of alkyl energy research is in the field of biofuels. Certain types of algae and bacteria can produce alkyl compounds as part of their metabolic processes, which can be harvested and converted into usable fuels. This approach offers a renewable and potentially carbon-neutral alternative to fossil fuels, as the carbon dioxide released during combustion is offset by the carbon absorbed during the growth of the organisms.

Another significant development in alkyl energy is the exploration of alkyl-based batteries and energy storage systems. Researchers are investigating the use of organic alkyl compounds as electrolytes and electrode materials in next-generation batteries, aiming to create more efficient and environmentally friendly energy storage solutions.

The potential of alkyls in hydrogen production has also garnered attention. Some alkyl compounds can be used as hydrogen carriers, offering a safer and more convenient method of storing and transporting hydrogen for fuel cell applications. This could play a crucial role in the development of a hydrogen-based economy, which is seen as a key component of future sustainable energy systems.

As research in this field progresses, scientists are also exploring the integration of alkyl-based energy solutions with existing renewable technologies. For instance, the combination of solar energy harvesting with alkyl-based energy storage could provide a more reliable and consistent power supply, addressing one of the main challenges of intermittent renewable sources.

Market Demand Analysis

The market demand for sustainable energy production using alkyls is experiencing significant growth, driven by the global push towards cleaner and more efficient energy sources. As traditional fossil fuels face increasing scrutiny due to their environmental impact, alternative energy solutions are gaining traction. Alkyls, particularly in the form of alkyl-based fuels and energy storage systems, are emerging as promising candidates for sustainable energy production.

The automotive industry represents a key market for alkyl-based energy solutions. With the rise of electric vehicles and hybrid technologies, there is a growing need for high-energy-density fuels and advanced battery systems. Alkyls offer potential advantages in both areas, as they can be used to create more efficient combustion engines and serve as components in next-generation battery technologies.

In the renewable energy sector, alkyls are finding applications in energy storage systems. As wind and solar power generation continue to expand, the demand for efficient and scalable energy storage solutions is increasing. Alkyl-based technologies, such as flow batteries and advanced capacitors, are being explored to address the intermittency issues associated with renewable energy sources.

The chemical industry is another significant market for alkyl-based energy production. Alkyls serve as important feedstocks for various chemical processes, and their potential as energy carriers is being investigated. This dual-use capability makes alkyls attractive for industrial applications, where energy efficiency and chemical production can be integrated.

The aerospace sector is also showing interest in alkyl-based energy solutions. The need for high-performance, lightweight energy sources in aircraft and spacecraft is driving research into advanced alkyl fuels and power systems. These technologies could potentially revolutionize air and space travel by providing more efficient and sustainable propulsion methods.

In the residential and commercial building sector, there is a growing demand for distributed energy solutions. Alkyl-based fuel cells and micro-generation systems are being developed to provide clean, on-site power generation for homes and businesses. This market segment is expected to expand as energy efficiency regulations become more stringent and consumers seek greater energy independence.

The marine industry is another potential market for alkyl-based energy production. As international regulations on maritime emissions tighten, ship operators are looking for cleaner fuel alternatives. Alkyl-derived fuels and propulsion systems could offer a pathway to reducing the environmental impact of shipping while maintaining the necessary power output for large vessels.

Overall, the market demand for harnessing alkyls in sustainable energy production is diverse and expanding. From transportation to stationary power generation, the versatility of alkyls positions them as a key player in the transition to a more sustainable energy landscape. As research and development in this field progress, we can expect to see increased adoption across various industries, driven by the need for cleaner, more efficient energy solutions.

The automotive industry represents a key market for alkyl-based energy solutions. With the rise of electric vehicles and hybrid technologies, there is a growing need for high-energy-density fuels and advanced battery systems. Alkyls offer potential advantages in both areas, as they can be used to create more efficient combustion engines and serve as components in next-generation battery technologies.

In the renewable energy sector, alkyls are finding applications in energy storage systems. As wind and solar power generation continue to expand, the demand for efficient and scalable energy storage solutions is increasing. Alkyl-based technologies, such as flow batteries and advanced capacitors, are being explored to address the intermittency issues associated with renewable energy sources.

The chemical industry is another significant market for alkyl-based energy production. Alkyls serve as important feedstocks for various chemical processes, and their potential as energy carriers is being investigated. This dual-use capability makes alkyls attractive for industrial applications, where energy efficiency and chemical production can be integrated.

The aerospace sector is also showing interest in alkyl-based energy solutions. The need for high-performance, lightweight energy sources in aircraft and spacecraft is driving research into advanced alkyl fuels and power systems. These technologies could potentially revolutionize air and space travel by providing more efficient and sustainable propulsion methods.

In the residential and commercial building sector, there is a growing demand for distributed energy solutions. Alkyl-based fuel cells and micro-generation systems are being developed to provide clean, on-site power generation for homes and businesses. This market segment is expected to expand as energy efficiency regulations become more stringent and consumers seek greater energy independence.

The marine industry is another potential market for alkyl-based energy production. As international regulations on maritime emissions tighten, ship operators are looking for cleaner fuel alternatives. Alkyl-derived fuels and propulsion systems could offer a pathway to reducing the environmental impact of shipping while maintaining the necessary power output for large vessels.

Overall, the market demand for harnessing alkyls in sustainable energy production is diverse and expanding. From transportation to stationary power generation, the versatility of alkyls positions them as a key player in the transition to a more sustainable energy landscape. As research and development in this field progress, we can expect to see increased adoption across various industries, driven by the need for cleaner, more efficient energy solutions.

Technical Challenges

The utilization of alkyls for sustainable energy production faces several significant technical challenges that need to be addressed. One of the primary obstacles is the inherent instability of many alkyl compounds, particularly those with longer carbon chains. This instability can lead to rapid degradation and reduced efficiency in energy conversion processes, limiting their practical application in sustainable energy systems.

Another major challenge lies in the efficient and cost-effective production of alkyl compounds at scale. Current manufacturing processes often rely on petrochemical feedstocks, which contradicts the goal of sustainability. Developing green synthesis methods that utilize renewable resources as starting materials remains a significant hurdle in the widespread adoption of alkyl-based energy technologies.

The catalytic conversion of alkyls into usable energy forms presents another technical barrier. While alkyls possess high energy density, harnessing this potential requires advanced catalytic systems that can efficiently break down the compounds and release their stored energy. Designing catalysts that are both highly active and selective, while also being durable and cost-effective, is a complex task that demands further research and development.

Environmental concerns also pose challenges in the use of alkyls for energy production. Some alkyl compounds and their byproducts can be toxic or environmentally harmful if released. Developing closed-loop systems that minimize emissions and ensure safe handling and disposal of these materials is crucial for the technology's sustainability credentials.

Energy storage and transportation issues associated with alkyl compounds further complicate their integration into existing energy infrastructure. Many alkyls are volatile and require specialized containment and handling procedures, which can increase costs and complexity in energy distribution systems.

The intermittency of renewable energy sources like solar and wind power creates a need for efficient energy storage solutions. While alkyls show promise in this area, optimizing their storage capacity, charge-discharge efficiency, and long-term stability under various environmental conditions remains a significant technical challenge.

Lastly, the integration of alkyl-based energy systems with existing power grids and energy networks presents both technical and regulatory challenges. Ensuring compatibility with current infrastructure, developing appropriate safety standards, and creating regulatory frameworks that support the adoption of this technology are all critical aspects that require attention from researchers, engineers, and policymakers alike.

Another major challenge lies in the efficient and cost-effective production of alkyl compounds at scale. Current manufacturing processes often rely on petrochemical feedstocks, which contradicts the goal of sustainability. Developing green synthesis methods that utilize renewable resources as starting materials remains a significant hurdle in the widespread adoption of alkyl-based energy technologies.

The catalytic conversion of alkyls into usable energy forms presents another technical barrier. While alkyls possess high energy density, harnessing this potential requires advanced catalytic systems that can efficiently break down the compounds and release their stored energy. Designing catalysts that are both highly active and selective, while also being durable and cost-effective, is a complex task that demands further research and development.

Environmental concerns also pose challenges in the use of alkyls for energy production. Some alkyl compounds and their byproducts can be toxic or environmentally harmful if released. Developing closed-loop systems that minimize emissions and ensure safe handling and disposal of these materials is crucial for the technology's sustainability credentials.

Energy storage and transportation issues associated with alkyl compounds further complicate their integration into existing energy infrastructure. Many alkyls are volatile and require specialized containment and handling procedures, which can increase costs and complexity in energy distribution systems.

The intermittency of renewable energy sources like solar and wind power creates a need for efficient energy storage solutions. While alkyls show promise in this area, optimizing their storage capacity, charge-discharge efficiency, and long-term stability under various environmental conditions remains a significant technical challenge.

Lastly, the integration of alkyl-based energy systems with existing power grids and energy networks presents both technical and regulatory challenges. Ensuring compatibility with current infrastructure, developing appropriate safety standards, and creating regulatory frameworks that support the adoption of this technology are all critical aspects that require attention from researchers, engineers, and policymakers alike.

Current Alkyl Solutions

01 Synthesis of alkyl compounds

Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.- Alkyl compounds in organic synthesis: Alkyl compounds play a crucial role in organic synthesis, serving as important intermediates and reagents. They are used in various reactions, including alkylation, substitution, and elimination processes. These compounds are essential in the production of pharmaceuticals, polymers, and other industrial chemicals.

- Alkyl halides and their applications: Alkyl halides are a significant class of alkyl compounds with diverse applications. They are widely used in the synthesis of other organic compounds, including alcohols, ethers, and amines. These compounds are also employed as solvents, refrigerants, and in the production of polymers and pharmaceuticals.

- Alkyl groups in petroleum and fuel industry: Alkyl groups are essential components in the petroleum and fuel industry. They are present in various hydrocarbons found in crude oil and natural gas. Alkyl compounds are used in the production of gasoline additives, lubricants, and other petroleum-based products to improve their performance and efficiency.

- Alkyl-substituted aromatic compounds: Alkyl-substituted aromatic compounds are an important class of chemicals with various industrial applications. These compounds are used in the production of dyes, pharmaceuticals, and agrochemicals. The alkyl substituents can modify the properties of the aromatic ring, leading to unique chemical and physical characteristics.

- Alkyl metal compounds and catalysts: Alkyl metal compounds play a significant role in organometallic chemistry and catalysis. They are used as catalysts or catalyst precursors in various industrial processes, including polymerization reactions and organic syntheses. These compounds often exhibit high reactivity and selectivity, making them valuable in chemical manufacturing.

02 Alkyl substitution in organic molecules

Techniques for introducing alkyl groups into organic molecules are presented. These methods include alkylation reactions, substitution of functional groups with alkyl moieties, and modification of existing alkyl chains to create more complex structures.Expand Specific Solutions03 Applications of alkyl compounds in industry

Alkyl compounds find diverse applications in various industries. They are used as solvents, lubricants, fuel additives, and intermediates in the production of plastics, detergents, and other chemicals. The specific properties of different alkyl groups contribute to their utility in these applications.Expand Specific Solutions04 Alkyl-based polymers and materials

The development and properties of polymers and materials containing alkyl groups are discussed. These materials often exhibit unique characteristics such as hydrophobicity, thermal stability, or specific mechanical properties, making them suitable for various applications in manufacturing and consumer products.Expand Specific Solutions05 Environmental and safety considerations of alkyl compounds

The environmental impact and safety aspects of alkyl compounds are addressed. This includes their biodegradability, potential toxicity, and methods for safe handling and disposal. Regulations and guidelines for the use of certain alkyl compounds in consumer products and industrial processes are also discussed.Expand Specific Solutions

Key Industry Players

The competition landscape for harnessing alkyls for sustainable energy production is in an early development stage, with significant potential for growth as the global focus on clean energy intensifies. The market size is expanding, driven by increasing demand for sustainable energy solutions. Technologically, the field is still evolving, with varying levels of maturity among key players. Companies like BASF Corp., Shell Oil Co., and China Petroleum & Chemical Corp. are leveraging their extensive petrochemical expertise to advance alkyl-based energy technologies. Research institutions such as The Scripps Research Institute, University of Tokyo, and Tianjin University are contributing fundamental scientific breakthroughs. Emerging players like TDA Research, Inc. and Hyconix, Inc. are developing innovative processes, indicating a dynamic and competitive landscape with diverse approaches to alkyl utilization in sustainable energy production.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to harness alkyls for sustainable energy production through their proprietary alkylation technology. This process involves the catalytic conversion of light olefins and isobutane into high-octane gasoline blending components[1]. The company has optimized the use of solid acid catalysts, which offer significant advantages over traditional liquid acid catalysts in terms of safety and environmental impact[2]. BASF's alkylation units are designed to operate at lower temperatures and pressures, reducing energy consumption and improving overall efficiency. Additionally, they have implemented advanced process control systems to maximize yield and minimize waste production[3].

Strengths: Improved safety and environmental profile, higher energy efficiency, and better product quality. Weaknesses: Initial capital investment may be higher, and the technology may require specialized training for operators.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed a groundbreaking approach to utilizing alkyls for sustainable energy production through their Gas-to-Liquids (GTL) technology. This process converts natural gas into high-quality liquid fuels and other products, including alkylates[1]. Shell's proprietary technology involves a three-step process: synthesis gas production, Fischer-Tropsch synthesis, and product upgrading[2]. In the final stage, alkylation plays a crucial role in producing high-octane gasoline components. Shell has also invested in research to improve catalyst efficiency and selectivity, reducing energy consumption and increasing yield[3]. Furthermore, they have integrated carbon capture and storage technologies into their GTL facilities to minimize greenhouse gas emissions[4].

Strengths: Versatile technology that can utilize various feedstocks, produces ultra-clean fuels, and offers a pathway to monetize stranded gas reserves. Weaknesses: High capital costs and sensitivity to natural gas prices.

Core Alkyl Innovations

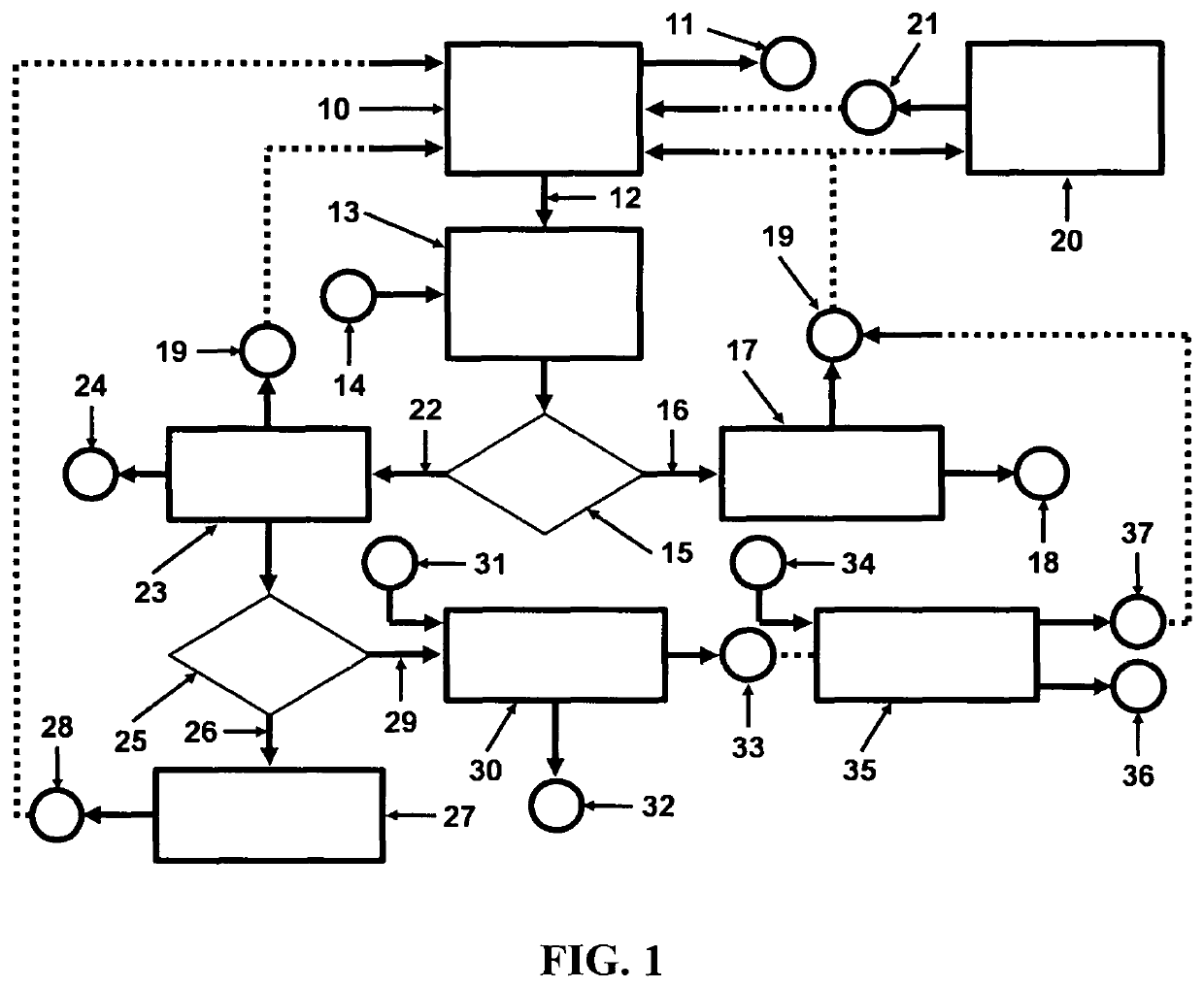

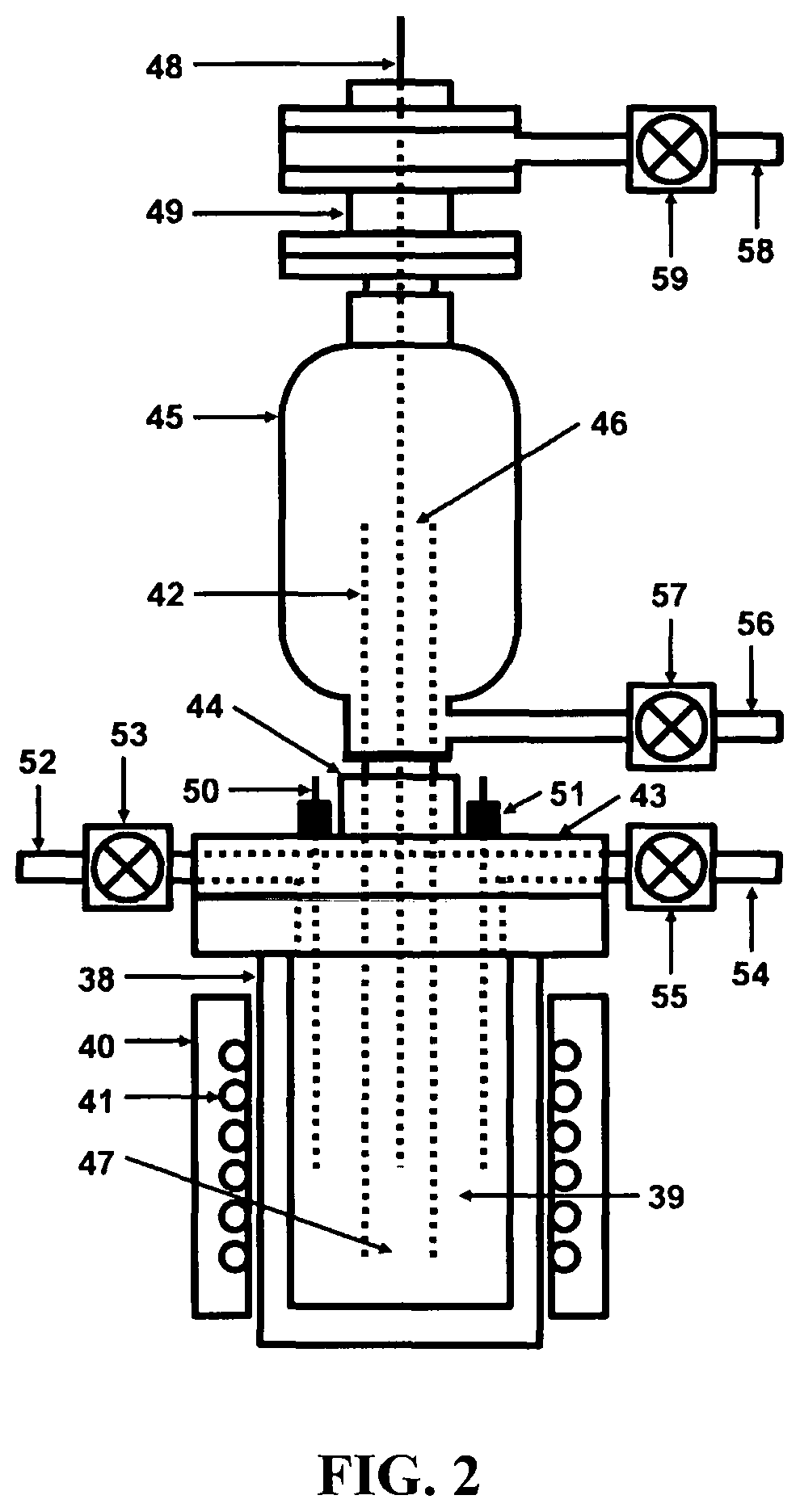

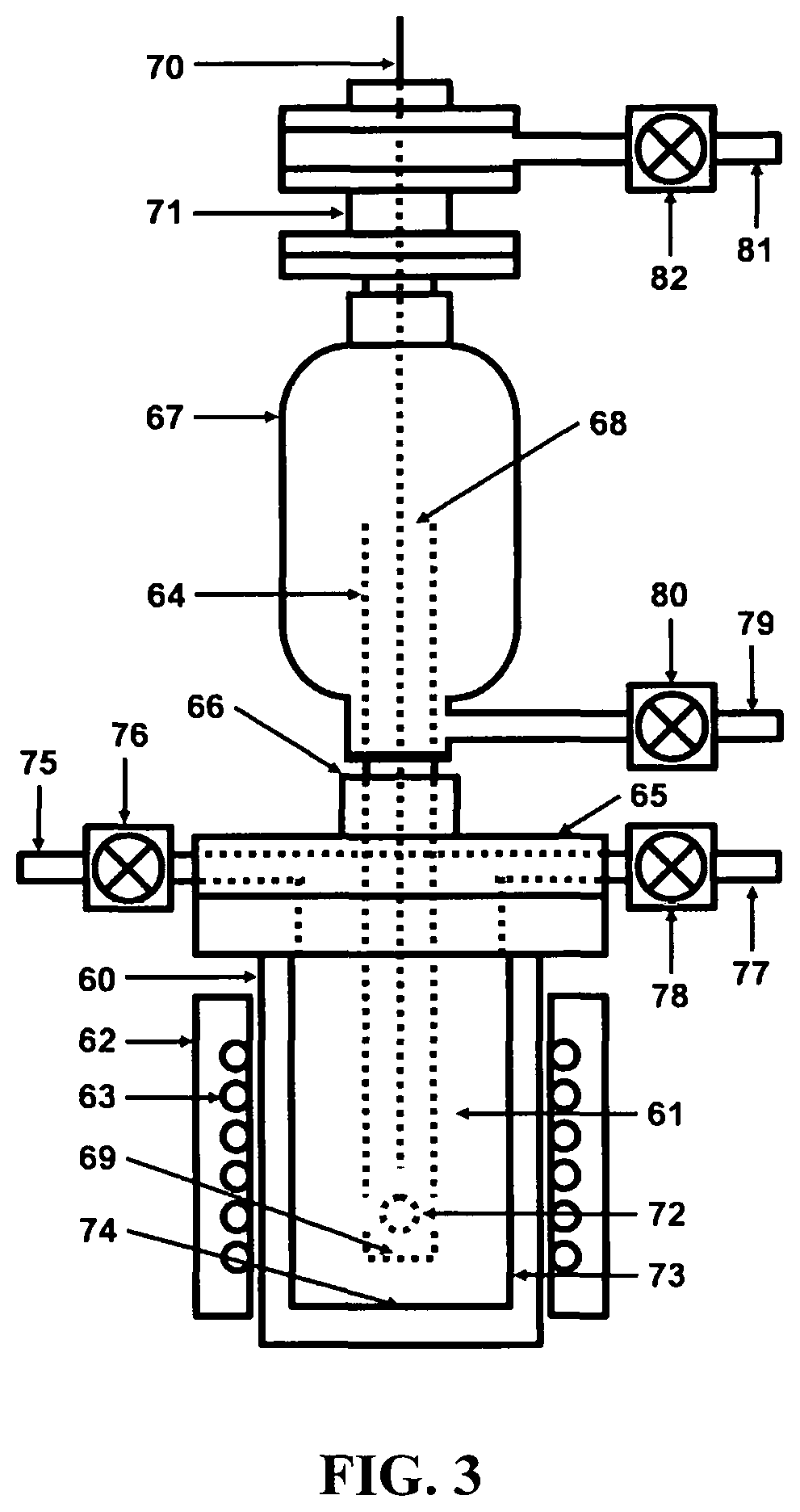

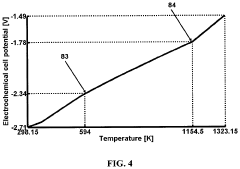

Method and molten salt electrolytic cell for implementing a hydrogen fuel, sustainable, closed clean energy cycle on a large scale

PatentActiveUS10818951B2

Innovation

- A scalable hydrogen generation apparatus using a controlled chemical reaction between sodium metal and water to produce hydrogen gas, coupled with a fuel cell system that can be powered by solar energy, enabling the creation of a sustainable, closed clean energy cycle that avoids carbon-based fossil fuels and reduces emissions by utilizing seawater or freshwater and recycling sodium metal.

Environmental Impact

The environmental impact of harnessing alkyls for sustainable energy production is a critical consideration in the development and implementation of this technology. Alkyls, which are hydrocarbon groups derived from alkanes, have the potential to contribute significantly to renewable energy solutions. However, their utilization also raises important environmental concerns that must be carefully addressed.

One of the primary environmental benefits of using alkyls in sustainable energy production is the potential reduction in greenhouse gas emissions compared to traditional fossil fuel-based energy sources. Alkyls can be derived from renewable sources, such as biomass or waste materials, which can lead to a lower carbon footprint throughout the energy production lifecycle. This aspect aligns well with global efforts to mitigate climate change and transition towards cleaner energy alternatives.

However, the production and processing of alkyls may still have environmental implications that need to be managed. The extraction and refinement of alkyls from their source materials can require significant energy inputs and potentially generate pollutants. It is crucial to develop and implement efficient, low-impact extraction methods to minimize these negative effects. Additionally, the disposal or recycling of byproducts and waste materials from alkyl-based energy production must be carefully considered to prevent soil and water contamination.

The use of alkyls in energy production can also have implications for land use and biodiversity. If alkyls are sourced from biomass, there may be concerns about competition with food crops for agricultural land or the potential for deforestation to create more cultivation areas. Sustainable land management practices and careful selection of feedstock sources are essential to mitigate these risks and ensure that alkyl production does not negatively impact ecosystems or food security.

Water usage is another environmental factor to consider in alkyl-based energy production. Depending on the specific processes involved, significant amounts of water may be required for extraction, processing, or cooling. In water-stressed regions, this could lead to competition with other essential water needs. Implementing water-efficient technologies and exploring alternative cooling methods can help address this concern.

Air quality is also an important consideration. While alkyl-based energy production may result in lower overall emissions compared to fossil fuels, it is still necessary to monitor and control any potential air pollutants released during the production and combustion processes. This includes volatile organic compounds (VOCs) and particulate matter, which can have localized impacts on air quality and human health.

In conclusion, while harnessing alkyls for sustainable energy production offers promising environmental benefits, particularly in terms of reducing greenhouse gas emissions, it is crucial to adopt a holistic approach to environmental management. This involves carefully assessing and mitigating potential impacts on land use, water resources, air quality, and ecosystems throughout the entire production and utilization cycle. By addressing these environmental considerations proactively, the development of alkyl-based sustainable energy solutions can contribute positively to global environmental goals while minimizing negative impacts.

One of the primary environmental benefits of using alkyls in sustainable energy production is the potential reduction in greenhouse gas emissions compared to traditional fossil fuel-based energy sources. Alkyls can be derived from renewable sources, such as biomass or waste materials, which can lead to a lower carbon footprint throughout the energy production lifecycle. This aspect aligns well with global efforts to mitigate climate change and transition towards cleaner energy alternatives.

However, the production and processing of alkyls may still have environmental implications that need to be managed. The extraction and refinement of alkyls from their source materials can require significant energy inputs and potentially generate pollutants. It is crucial to develop and implement efficient, low-impact extraction methods to minimize these negative effects. Additionally, the disposal or recycling of byproducts and waste materials from alkyl-based energy production must be carefully considered to prevent soil and water contamination.

The use of alkyls in energy production can also have implications for land use and biodiversity. If alkyls are sourced from biomass, there may be concerns about competition with food crops for agricultural land or the potential for deforestation to create more cultivation areas. Sustainable land management practices and careful selection of feedstock sources are essential to mitigate these risks and ensure that alkyl production does not negatively impact ecosystems or food security.

Water usage is another environmental factor to consider in alkyl-based energy production. Depending on the specific processes involved, significant amounts of water may be required for extraction, processing, or cooling. In water-stressed regions, this could lead to competition with other essential water needs. Implementing water-efficient technologies and exploring alternative cooling methods can help address this concern.

Air quality is also an important consideration. While alkyl-based energy production may result in lower overall emissions compared to fossil fuels, it is still necessary to monitor and control any potential air pollutants released during the production and combustion processes. This includes volatile organic compounds (VOCs) and particulate matter, which can have localized impacts on air quality and human health.

In conclusion, while harnessing alkyls for sustainable energy production offers promising environmental benefits, particularly in terms of reducing greenhouse gas emissions, it is crucial to adopt a holistic approach to environmental management. This involves carefully assessing and mitigating potential impacts on land use, water resources, air quality, and ecosystems throughout the entire production and utilization cycle. By addressing these environmental considerations proactively, the development of alkyl-based sustainable energy solutions can contribute positively to global environmental goals while minimizing negative impacts.

Policy and Regulations

The development of sustainable energy production through the harnessing of alkyls is subject to a complex web of policies and regulations at both national and international levels. These frameworks are designed to ensure the safe and responsible utilization of alkyl compounds while promoting the transition towards cleaner energy sources. Many countries have implemented stringent environmental regulations that impact the use of alkyls in energy production, focusing on emissions control, waste management, and overall environmental impact.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of alkyls and other hydrocarbons in energy production. The Clean Air Act and the Resource Conservation and Recovery Act provide the legal basis for many of these regulations, setting standards for air quality and waste disposal. Similarly, the European Union has established the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the production and use of alkyl compounds in energy applications.

International agreements, such as the Paris Agreement, indirectly influence the use of alkyls in energy production by setting targets for greenhouse gas emissions reduction. This has led to increased support for research and development in sustainable alkyl-based energy technologies that can contribute to meeting these targets. Additionally, the United Nations' Sustainable Development Goals have further emphasized the need for clean and affordable energy, driving policy changes that favor innovative approaches to alkyl utilization.

Many governments have implemented incentive programs and subsidies to encourage the development and adoption of sustainable energy technologies, including those involving alkyls. These may include tax credits, grants, or preferential treatment in energy markets. However, these policies often need to balance the promotion of new technologies with the interests of established energy industries, leading to complex regulatory landscapes.

Safety regulations also play a significant role in shaping the use of alkyls for energy production. Given the potential hazards associated with alkyl compounds, strict safety protocols and standards are enforced in their handling, storage, and use. These regulations often require extensive risk assessments, safety training for personnel, and the implementation of advanced monitoring and control systems.

As the field of sustainable energy production evolves, policies and regulations continue to adapt. There is an increasing trend towards performance-based regulations that focus on outcomes rather than prescriptive methods, allowing for greater innovation in alkyl utilization techniques. This regulatory flexibility, combined with ongoing scientific advancements, is expected to pave the way for more efficient and environmentally friendly alkyl-based energy solutions in the future.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of alkyls and other hydrocarbons in energy production. The Clean Air Act and the Resource Conservation and Recovery Act provide the legal basis for many of these regulations, setting standards for air quality and waste disposal. Similarly, the European Union has established the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the production and use of alkyl compounds in energy applications.

International agreements, such as the Paris Agreement, indirectly influence the use of alkyls in energy production by setting targets for greenhouse gas emissions reduction. This has led to increased support for research and development in sustainable alkyl-based energy technologies that can contribute to meeting these targets. Additionally, the United Nations' Sustainable Development Goals have further emphasized the need for clean and affordable energy, driving policy changes that favor innovative approaches to alkyl utilization.

Many governments have implemented incentive programs and subsidies to encourage the development and adoption of sustainable energy technologies, including those involving alkyls. These may include tax credits, grants, or preferential treatment in energy markets. However, these policies often need to balance the promotion of new technologies with the interests of established energy industries, leading to complex regulatory landscapes.

Safety regulations also play a significant role in shaping the use of alkyls for energy production. Given the potential hazards associated with alkyl compounds, strict safety protocols and standards are enforced in their handling, storage, and use. These regulations often require extensive risk assessments, safety training for personnel, and the implementation of advanced monitoring and control systems.

As the field of sustainable energy production evolves, policies and regulations continue to adapt. There is an increasing trend towards performance-based regulations that focus on outcomes rather than prescriptive methods, allowing for greater innovation in alkyl utilization techniques. This regulatory flexibility, combined with ongoing scientific advancements, is expected to pave the way for more efficient and environmentally friendly alkyl-based energy solutions in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!