Innovation in Alkyl Chemistry and Its Industry Implications

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Chemistry Evolution and Objectives

Alkyl chemistry has undergone significant evolution since its inception in the early 20th century. The field has progressed from basic understanding of carbon-carbon bond formation to sophisticated methodologies for creating complex molecular structures. This journey has been marked by several key milestones, including the development of organometallic reagents, cross-coupling reactions, and asymmetric synthesis techniques.

The primary objective of modern alkyl chemistry is to develop more efficient, sustainable, and selective methods for carbon-carbon bond formation. This goal is driven by the increasing demand for complex organic molecules in various industries, including pharmaceuticals, agrochemicals, and materials science. Researchers are focusing on creating new catalytic systems that can operate under milder conditions, use less toxic reagents, and produce fewer by-products.

One of the key trends in alkyl chemistry is the shift towards greener and more sustainable practices. This includes the development of bio-based alkyl compounds, the use of renewable feedstocks, and the implementation of atom-economical reactions. These efforts align with the broader objectives of reducing the environmental impact of chemical processes and moving towards a circular economy.

Another important objective is the development of novel alkylation methods that can functionalize previously unreactive C-H bonds. This area of research has the potential to revolutionize synthetic strategies by enabling late-stage functionalization of complex molecules. Such advancements could significantly streamline the synthesis of pharmaceuticals and other high-value compounds.

The field is also witnessing a growing interest in photoredox catalysis and electrochemistry as tools for alkyl radical generation and subsequent C-C bond formation. These approaches offer new possibilities for conducting alkylation reactions under mild conditions and with high functional group tolerance.

In the realm of industrial applications, there is a strong focus on developing scalable and cost-effective alkylation processes. This includes the optimization of existing methodologies for large-scale production and the exploration of continuous flow chemistry techniques. The ultimate goal is to bridge the gap between academic research and industrial implementation, ensuring that innovative alkyl chemistry methods can be effectively translated into commercial processes.

As we look to the future, the objectives of alkyl chemistry research are likely to include the development of more selective and controllable alkylation methods, the exploration of novel catalyst designs, and the integration of artificial intelligence and machine learning to accelerate discovery and optimization processes. These advancements will continue to push the boundaries of what is possible in organic synthesis and drive innovation across multiple industries.

The primary objective of modern alkyl chemistry is to develop more efficient, sustainable, and selective methods for carbon-carbon bond formation. This goal is driven by the increasing demand for complex organic molecules in various industries, including pharmaceuticals, agrochemicals, and materials science. Researchers are focusing on creating new catalytic systems that can operate under milder conditions, use less toxic reagents, and produce fewer by-products.

One of the key trends in alkyl chemistry is the shift towards greener and more sustainable practices. This includes the development of bio-based alkyl compounds, the use of renewable feedstocks, and the implementation of atom-economical reactions. These efforts align with the broader objectives of reducing the environmental impact of chemical processes and moving towards a circular economy.

Another important objective is the development of novel alkylation methods that can functionalize previously unreactive C-H bonds. This area of research has the potential to revolutionize synthetic strategies by enabling late-stage functionalization of complex molecules. Such advancements could significantly streamline the synthesis of pharmaceuticals and other high-value compounds.

The field is also witnessing a growing interest in photoredox catalysis and electrochemistry as tools for alkyl radical generation and subsequent C-C bond formation. These approaches offer new possibilities for conducting alkylation reactions under mild conditions and with high functional group tolerance.

In the realm of industrial applications, there is a strong focus on developing scalable and cost-effective alkylation processes. This includes the optimization of existing methodologies for large-scale production and the exploration of continuous flow chemistry techniques. The ultimate goal is to bridge the gap between academic research and industrial implementation, ensuring that innovative alkyl chemistry methods can be effectively translated into commercial processes.

As we look to the future, the objectives of alkyl chemistry research are likely to include the development of more selective and controllable alkylation methods, the exploration of novel catalyst designs, and the integration of artificial intelligence and machine learning to accelerate discovery and optimization processes. These advancements will continue to push the boundaries of what is possible in organic synthesis and drive innovation across multiple industries.

Market Demand for Alkyl Compounds

The market demand for alkyl compounds has been experiencing significant growth across various industries, driven by their versatile applications and unique chemical properties. These compounds, characterized by their carbon-hydrogen bonds, play crucial roles in numerous industrial processes and end-products.

In the petrochemical industry, alkyl compounds are essential components in the production of fuels, lubricants, and various petroleum-based products. The increasing global energy demand, particularly in emerging economies, continues to drive the market for alkyl-based fuel additives and lubricant formulations. These compounds enhance fuel efficiency and reduce engine wear, aligning with the industry's focus on sustainability and performance optimization.

The polymer and plastics sector represents another major market for alkyl compounds. They are widely used as monomers, co-monomers, and additives in the production of various plastics and synthetic materials. The growing demand for lightweight, durable, and eco-friendly materials in automotive, packaging, and construction industries has led to increased consumption of alkyl-based polymers and plastics.

In the pharmaceutical and personal care industries, alkyl compounds serve as key intermediates and active ingredients in drug synthesis and formulation of cosmetics. The rising health awareness and expanding personal care market, especially in developing regions, have bolstered the demand for alkyl-based pharmaceutical precursors and cosmetic ingredients.

The agricultural sector also contributes significantly to the market demand for alkyl compounds. They are extensively used in the production of pesticides, herbicides, and fertilizers. As global food demand increases and agricultural practices evolve, the need for efficient crop protection and yield enhancement solutions continues to drive the consumption of alkyl-based agrochemicals.

Furthermore, the textile industry utilizes alkyl compounds in various processes, including dyeing, finishing, and fabric treatment. The growing textile market, particularly in Asia-Pacific regions, has led to increased demand for alkyl-based surfactants and finishing agents.

The electronics industry represents an emerging market for specialized alkyl compounds. These materials find applications in semiconductor manufacturing, printed circuit boards, and advanced electronic components. As the electronics industry continues to innovate and expand, the demand for high-purity alkyl compounds is expected to grow.

Overall, the market demand for alkyl compounds is projected to maintain a steady growth trajectory, driven by technological advancements, industrial expansion, and evolving consumer preferences across multiple sectors. The versatility and indispensable nature of these compounds in various applications ensure their continued relevance in the global chemical industry landscape.

In the petrochemical industry, alkyl compounds are essential components in the production of fuels, lubricants, and various petroleum-based products. The increasing global energy demand, particularly in emerging economies, continues to drive the market for alkyl-based fuel additives and lubricant formulations. These compounds enhance fuel efficiency and reduce engine wear, aligning with the industry's focus on sustainability and performance optimization.

The polymer and plastics sector represents another major market for alkyl compounds. They are widely used as monomers, co-monomers, and additives in the production of various plastics and synthetic materials. The growing demand for lightweight, durable, and eco-friendly materials in automotive, packaging, and construction industries has led to increased consumption of alkyl-based polymers and plastics.

In the pharmaceutical and personal care industries, alkyl compounds serve as key intermediates and active ingredients in drug synthesis and formulation of cosmetics. The rising health awareness and expanding personal care market, especially in developing regions, have bolstered the demand for alkyl-based pharmaceutical precursors and cosmetic ingredients.

The agricultural sector also contributes significantly to the market demand for alkyl compounds. They are extensively used in the production of pesticides, herbicides, and fertilizers. As global food demand increases and agricultural practices evolve, the need for efficient crop protection and yield enhancement solutions continues to drive the consumption of alkyl-based agrochemicals.

Furthermore, the textile industry utilizes alkyl compounds in various processes, including dyeing, finishing, and fabric treatment. The growing textile market, particularly in Asia-Pacific regions, has led to increased demand for alkyl-based surfactants and finishing agents.

The electronics industry represents an emerging market for specialized alkyl compounds. These materials find applications in semiconductor manufacturing, printed circuit boards, and advanced electronic components. As the electronics industry continues to innovate and expand, the demand for high-purity alkyl compounds is expected to grow.

Overall, the market demand for alkyl compounds is projected to maintain a steady growth trajectory, driven by technological advancements, industrial expansion, and evolving consumer preferences across multiple sectors. The versatility and indispensable nature of these compounds in various applications ensure their continued relevance in the global chemical industry landscape.

Alkyl Chemistry Challenges and Limitations

Alkyl chemistry, while fundamental to organic synthesis and industrial processes, faces several significant challenges and limitations that hinder its further development and application. One of the primary obstacles is the selective functionalization of unactivated C-H bonds. Despite recent advancements, achieving high levels of regioselectivity and stereoselectivity in alkyl C-H activation remains a formidable task, particularly for complex molecules with multiple potential reaction sites.

The stability and reactivity of alkyl intermediates pose another major challenge. Alkyl radicals and carbanions are often highly reactive and prone to undesired side reactions, making it difficult to control their behavior in complex reaction environments. This instability can lead to low yields, poor selectivity, and the formation of unwanted by-products, limiting the efficiency and applicability of alkyl chemistry in industrial settings.

Environmental concerns and sustainability issues also present significant limitations to traditional alkyl chemistry. Many conventional alkylation processes rely on toxic reagents, harsh reaction conditions, or generate substantial amounts of waste. The need for greener and more sustainable alkylation methods is becoming increasingly urgent, driving research towards more environmentally friendly alternatives.

The scalability of alkyl chemistry processes is another critical limitation, particularly in industrial applications. Many laboratory-scale reactions fail to translate effectively to large-scale production due to issues such as heat transfer, mixing efficiency, and reagent handling. This scale-up challenge often necessitates extensive process optimization and sometimes complete redesign of synthetic routes, adding significant costs and time to industrial implementation.

Furthermore, the limited availability and high cost of certain alkyl precursors and catalysts can restrict the widespread adoption of advanced alkylation techniques. Rare and expensive transition metal catalysts, while effective in academic research, may prove economically unfeasible for large-scale industrial processes. This economic barrier often forces industries to rely on less efficient but more cost-effective traditional methods.

Lastly, the complexity of mechanistic understanding in alkyl chemistry poses a significant challenge to rational reaction design and optimization. Many alkylation reactions involve intricate radical or ionic pathways that are not fully elucidated, making it difficult to predict outcomes and design new reactions with high precision. This knowledge gap hampers the development of novel, more efficient alkylation strategies and limits the ability to tailor reactions for specific industrial needs.

The stability and reactivity of alkyl intermediates pose another major challenge. Alkyl radicals and carbanions are often highly reactive and prone to undesired side reactions, making it difficult to control their behavior in complex reaction environments. This instability can lead to low yields, poor selectivity, and the formation of unwanted by-products, limiting the efficiency and applicability of alkyl chemistry in industrial settings.

Environmental concerns and sustainability issues also present significant limitations to traditional alkyl chemistry. Many conventional alkylation processes rely on toxic reagents, harsh reaction conditions, or generate substantial amounts of waste. The need for greener and more sustainable alkylation methods is becoming increasingly urgent, driving research towards more environmentally friendly alternatives.

The scalability of alkyl chemistry processes is another critical limitation, particularly in industrial applications. Many laboratory-scale reactions fail to translate effectively to large-scale production due to issues such as heat transfer, mixing efficiency, and reagent handling. This scale-up challenge often necessitates extensive process optimization and sometimes complete redesign of synthetic routes, adding significant costs and time to industrial implementation.

Furthermore, the limited availability and high cost of certain alkyl precursors and catalysts can restrict the widespread adoption of advanced alkylation techniques. Rare and expensive transition metal catalysts, while effective in academic research, may prove economically unfeasible for large-scale industrial processes. This economic barrier often forces industries to rely on less efficient but more cost-effective traditional methods.

Lastly, the complexity of mechanistic understanding in alkyl chemistry poses a significant challenge to rational reaction design and optimization. Many alkylation reactions involve intricate radical or ionic pathways that are not fully elucidated, making it difficult to predict outcomes and design new reactions with high precision. This knowledge gap hampers the development of novel, more efficient alkylation strategies and limits the ability to tailor reactions for specific industrial needs.

Current Alkyl Synthesis Methodologies

01 Alkyl-based chemical synthesis and modifications

This category focuses on the synthesis and modification of alkyl compounds, including various chemical reactions and processes involving alkyl groups. It encompasses the creation of new alkyl-based materials and the alteration of existing compounds through alkylation or other related chemical transformations.- Alkyl-based chemical reactions and synthesis: This category focuses on various chemical reactions and synthesis methods involving alkyl groups. It includes processes for creating alkyl compounds, modifying existing molecules with alkyl groups, and studying the reactivity of alkyl-containing substances. These reactions are fundamental in organic chemistry and have applications in pharmaceuticals, materials science, and industrial processes.

- Alkyl-functionalized materials and coatings: This area explores the development and application of materials and coatings that incorporate alkyl groups. These functionalized materials often exhibit unique properties such as improved hydrophobicity, chemical resistance, or surface interactions. Applications range from protective coatings to advanced materials for electronics and biomedical devices.

- Alkyl-based surfactants and emulsifiers: This category covers the formulation and use of alkyl-based surfactants and emulsifiers. These compounds play crucial roles in various industries, including personal care, cleaning products, and food processing. The research focuses on developing new alkyl-based surfactants with improved performance, biodegradability, and specific functionalities.

- Alkyl group analysis and characterization techniques: This area involves the development and application of analytical methods for identifying, quantifying, and characterizing alkyl groups in various compounds and materials. It includes spectroscopic techniques, chromatography, and advanced imaging methods that allow researchers to study the structure, composition, and behavior of alkyl-containing substances.

- Alkyl-based polymers and copolymers: This category focuses on the synthesis, characterization, and application of polymers and copolymers containing alkyl groups. These materials often exhibit unique properties such as thermal stability, chemical resistance, or specific mechanical characteristics. Research in this area aims to develop new alkyl-based polymers for applications in packaging, textiles, and advanced materials.

02 Applications of alkyl compounds in electronic devices

Alkyl compounds play a significant role in the development and improvement of electronic devices. This includes their use in semiconductor manufacturing, display technologies, and other electronic components where alkyl-based materials contribute to enhanced performance or specific functionalities.Expand Specific Solutions03 Alkyl-based materials in biotechnology and medical applications

This area explores the use of alkyl compounds and their derivatives in biotechnology and medical fields. It includes applications in drug delivery systems, biocompatible materials, and diagnostic tools where alkyl chemistry plays a crucial role in achieving desired biological interactions or properties.Expand Specific Solutions04 Environmental and industrial applications of alkyl chemistry

Alkyl compounds find applications in various environmental and industrial processes. This includes their use in waste treatment, pollution control, and as components in industrial products such as lubricants, surfactants, and polymers. The focus is on leveraging alkyl chemistry for improved efficiency and environmental sustainability.Expand Specific Solutions05 Analytical methods and characterization of alkyl compounds

This category covers analytical techniques and methods used for the characterization and study of alkyl compounds. It includes spectroscopic methods, chromatography, and other analytical approaches specifically tailored for alkyl-based materials, aiding in their identification, purity assessment, and structural analysis.Expand Specific Solutions

Key Players in Alkyl Chemistry Industry

The innovation in alkyl chemistry is currently in a growth phase, with increasing market size and technological advancements. The global market for alkyl chemistry products is expanding, driven by demand in various industries such as pharmaceuticals, petrochemicals, and materials science. Key players like China Petroleum & Chemical Corp., Novartis AG, and ExxonMobil Chemical Patents Inc. are investing heavily in R&D to develop novel alkyl compounds and processes. The technology is maturing rapidly, with companies like 3M Innovative Properties Co. and DuPont de Nemours Inc. focusing on improving efficiency and sustainability. Academic institutions such as MIT and the National University of Singapore are also contributing significantly to the field, pushing the boundaries of alkyl chemistry applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in alkyl chemistry innovation, particularly in the field of alkylation for clean fuels. They have developed a solid acid alkylation technology that produces high-quality alkylate without the use of corrosive liquid acids[4]. This process achieves a conversion rate of over 95% for C4 olefins and yields an alkylate with a research octane number (RON) exceeding 96[5]. Sinopec has also pioneered advancements in alkyl benzene production, utilizing a fixed-bed alkylation process that improves product quality and reduces energy consumption by approximately 20% compared to traditional methods[6].

Strengths: High conversion rates, improved product quality, and reduced environmental impact. Weaknesses: May face challenges in scaling up the technology for widespread implementation across all refineries.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed innovative alkylation processes for producing high-octane gasoline blending components. Their AlkyMax™ technology uses a proprietary solid acid catalyst that eliminates the need for liquid acids, improving safety and reducing environmental impact[1]. The process operates at lower temperatures and pressures compared to conventional alkylation, resulting in energy savings of up to 50%[2]. ExxonMobil has also made advancements in alkyl aromatics production, using zeolite catalysts for selective para-xylene formation, which is crucial for polyester manufacturing[3].

Strengths: Improved safety and environmental profile, significant energy savings, and high selectivity in alkyl aromatic production. Weaknesses: May require substantial capital investment for implementation in existing refineries.

Breakthrough Alkyl Chemistry Innovations

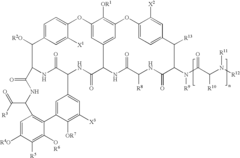

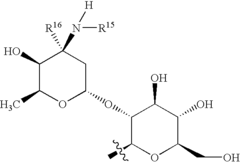

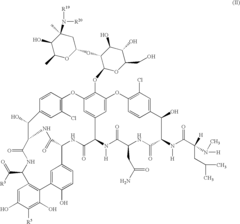

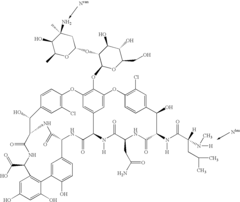

Glycopeptide phosphonate derivatives

PatentInactiveUS20040063916A1

Innovation

- The development of glycopeptide phosphonate derivatives with phosphono groups attached through amide, ester, or thioester bonds at specific positions, such as the C-terminus or R-terminus, to enhance antibacterial efficacy while reducing tissue accumulation and nephrotoxicity.

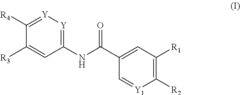

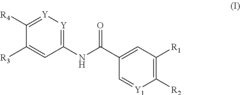

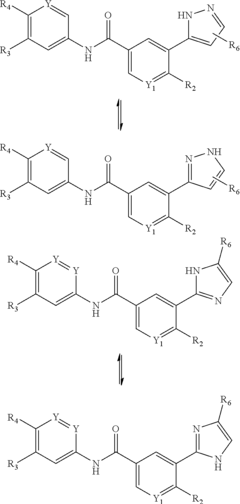

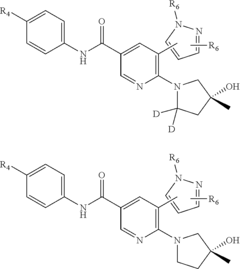

Compounds and compositions for inhibiting the activity of ABL1, ABL2 and BCR-ABL1

PatentInactiveUS20180134695A1

Innovation

- Development of specific compounds of formula (I) that target the allosteric myristoyl binding site of BCR-ABL1, potentially combined with ATP-competitive inhibitors, to inhibit the tyrosine kinase activity of BCR-ABL1 and its mutants, including the T315I mutation, thereby delaying resistance and treating CML and other related disorders.

Environmental Impact of Alkyl Chemistry

Alkyl chemistry, while essential for numerous industrial processes and consumer products, has significant environmental implications that warrant careful consideration. The production and use of alkyl compounds contribute to various forms of pollution, including air, water, and soil contamination. Volatile organic compounds (VOCs) released during manufacturing processes and product use can lead to the formation of ground-level ozone, a major component of smog that negatively impacts air quality and human health.

Water pollution is another critical concern, as many alkyl compounds are not readily biodegradable and can persist in aquatic environments. This persistence can lead to bioaccumulation in marine organisms and potentially enter the food chain, posing risks to ecosystem health and human consumers. Accidental spills or improper disposal of alkyl-based products can result in soil contamination, affecting local flora and fauna and potentially leaching into groundwater supplies.

The petrochemical industry, a major source of alkyl compounds, is also associated with significant greenhouse gas emissions, contributing to global climate change. The extraction and refining processes required for producing alkyl precursors are energy-intensive and often rely on fossil fuels, further exacerbating the carbon footprint of these chemicals.

However, recent innovations in alkyl chemistry are addressing these environmental concerns. Green chemistry initiatives are focusing on developing more sustainable production methods, such as using renewable feedstocks and catalysts to reduce reliance on petroleum-based raw materials. Biodegradable alkyl compounds are being researched and developed to minimize long-term environmental persistence.

Advanced waste treatment technologies are being implemented to reduce the release of harmful alkyl compounds into the environment. These include improved filtration systems, chemical oxidation processes, and bioremediation techniques that can break down alkyl pollutants more effectively.

The shift towards circular economy principles is also influencing alkyl chemistry, with increased emphasis on recycling and reusing alkyl-based products. This approach aims to reduce the overall environmental impact by minimizing waste and conserving resources.

As regulatory pressures increase and consumer demand for environmentally friendly products grows, the alkyl chemistry industry is adapting. Companies are investing in research and development to create safer alternatives and more sustainable production processes. This includes exploring bio-based alkyl compounds and developing more efficient, less polluting manufacturing methods.

While challenges remain, the ongoing innovation in alkyl chemistry is gradually reducing its environmental footprint. As the industry continues to evolve, balancing economic needs with environmental stewardship will be crucial for sustainable growth and responsible chemical production.

Water pollution is another critical concern, as many alkyl compounds are not readily biodegradable and can persist in aquatic environments. This persistence can lead to bioaccumulation in marine organisms and potentially enter the food chain, posing risks to ecosystem health and human consumers. Accidental spills or improper disposal of alkyl-based products can result in soil contamination, affecting local flora and fauna and potentially leaching into groundwater supplies.

The petrochemical industry, a major source of alkyl compounds, is also associated with significant greenhouse gas emissions, contributing to global climate change. The extraction and refining processes required for producing alkyl precursors are energy-intensive and often rely on fossil fuels, further exacerbating the carbon footprint of these chemicals.

However, recent innovations in alkyl chemistry are addressing these environmental concerns. Green chemistry initiatives are focusing on developing more sustainable production methods, such as using renewable feedstocks and catalysts to reduce reliance on petroleum-based raw materials. Biodegradable alkyl compounds are being researched and developed to minimize long-term environmental persistence.

Advanced waste treatment technologies are being implemented to reduce the release of harmful alkyl compounds into the environment. These include improved filtration systems, chemical oxidation processes, and bioremediation techniques that can break down alkyl pollutants more effectively.

The shift towards circular economy principles is also influencing alkyl chemistry, with increased emphasis on recycling and reusing alkyl-based products. This approach aims to reduce the overall environmental impact by minimizing waste and conserving resources.

As regulatory pressures increase and consumer demand for environmentally friendly products grows, the alkyl chemistry industry is adapting. Companies are investing in research and development to create safer alternatives and more sustainable production processes. This includes exploring bio-based alkyl compounds and developing more efficient, less polluting manufacturing methods.

While challenges remain, the ongoing innovation in alkyl chemistry is gradually reducing its environmental footprint. As the industry continues to evolve, balancing economic needs with environmental stewardship will be crucial for sustainable growth and responsible chemical production.

Alkyl Chemistry Safety Regulations

The safety regulations governing alkyl chemistry have evolved significantly in recent years, reflecting the growing awareness of potential hazards and the need for stringent safety measures in the industry. These regulations encompass a wide range of aspects, from handling and storage of alkyl compounds to waste management and emergency response protocols.

One of the primary focuses of alkyl chemistry safety regulations is the prevention of fires and explosions. Many alkyl compounds are highly flammable and can form explosive mixtures with air. As a result, regulations mandate the use of specialized equipment and facilities designed to minimize the risk of ignition. This includes the implementation of intrinsically safe electrical systems, proper ventilation, and the use of inert atmospheres in storage and handling areas.

Personal protective equipment (PPE) requirements have also become more stringent. Workers handling alkyl compounds are required to wear appropriate chemical-resistant gloves, protective clothing, and respiratory protection. The selection of PPE is based on the specific properties of the alkyl compounds being handled and the nature of the work being performed.

Environmental protection is another crucial aspect of alkyl chemistry safety regulations. Strict guidelines have been established for the disposal of alkyl waste products and the prevention of environmental contamination. Companies are required to implement comprehensive waste management plans and to use approved methods for the treatment and disposal of alkyl-containing waste.

Transportation of alkyl compounds is subject to rigorous safety regulations. These include specific packaging requirements, labeling standards, and transportation protocols designed to minimize the risk of accidents during transit. Drivers and handlers involved in the transportation of alkyl compounds must undergo specialized training and certification.

Emergency response planning has become a mandatory component of alkyl chemistry safety regulations. Companies are required to develop and maintain detailed emergency response plans, including procedures for spill containment, fire suppression, and evacuation. Regular drills and training exercises are mandated to ensure that all personnel are prepared to respond effectively in the event of an emergency.

Regulatory bodies have also implemented more stringent reporting and documentation requirements. Companies engaged in alkyl chemistry are required to maintain detailed records of their safety procedures, incident reports, and compliance with regulatory standards. Regular inspections and audits are conducted to ensure ongoing compliance with these regulations.

As innovations in alkyl chemistry continue to emerge, safety regulations are expected to evolve further. Regulatory bodies are increasingly focusing on proactive risk assessment and management strategies, encouraging companies to adopt advanced technologies and methodologies to enhance safety in alkyl chemistry operations. This ongoing evolution of safety regulations reflects the industry's commitment to protecting workers, the environment, and the public while fostering continued innovation in this critical field of chemistry.

One of the primary focuses of alkyl chemistry safety regulations is the prevention of fires and explosions. Many alkyl compounds are highly flammable and can form explosive mixtures with air. As a result, regulations mandate the use of specialized equipment and facilities designed to minimize the risk of ignition. This includes the implementation of intrinsically safe electrical systems, proper ventilation, and the use of inert atmospheres in storage and handling areas.

Personal protective equipment (PPE) requirements have also become more stringent. Workers handling alkyl compounds are required to wear appropriate chemical-resistant gloves, protective clothing, and respiratory protection. The selection of PPE is based on the specific properties of the alkyl compounds being handled and the nature of the work being performed.

Environmental protection is another crucial aspect of alkyl chemistry safety regulations. Strict guidelines have been established for the disposal of alkyl waste products and the prevention of environmental contamination. Companies are required to implement comprehensive waste management plans and to use approved methods for the treatment and disposal of alkyl-containing waste.

Transportation of alkyl compounds is subject to rigorous safety regulations. These include specific packaging requirements, labeling standards, and transportation protocols designed to minimize the risk of accidents during transit. Drivers and handlers involved in the transportation of alkyl compounds must undergo specialized training and certification.

Emergency response planning has become a mandatory component of alkyl chemistry safety regulations. Companies are required to develop and maintain detailed emergency response plans, including procedures for spill containment, fire suppression, and evacuation. Regular drills and training exercises are mandated to ensure that all personnel are prepared to respond effectively in the event of an emergency.

Regulatory bodies have also implemented more stringent reporting and documentation requirements. Companies engaged in alkyl chemistry are required to maintain detailed records of their safety procedures, incident reports, and compliance with regulatory standards. Regular inspections and audits are conducted to ensure ongoing compliance with these regulations.

As innovations in alkyl chemistry continue to emerge, safety regulations are expected to evolve further. Regulatory bodies are increasingly focusing on proactive risk assessment and management strategies, encouraging companies to adopt advanced technologies and methodologies to enhance safety in alkyl chemistry operations. This ongoing evolution of safety regulations reflects the industry's commitment to protecting workers, the environment, and the public while fostering continued innovation in this critical field of chemistry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!