Alkyl's Role in the Evolution of Chemical Engineering

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl's Historical Context

Alkyl groups have played a pivotal role in the evolution of chemical engineering, with their historical context deeply rooted in the development of organic chemistry and industrial processes. The study of alkyl compounds can be traced back to the early 19th century when chemists began to investigate the nature of organic substances. Friedrich Wöhler's synthesis of urea in 1828 marked a significant milestone, challenging the prevailing belief in vitalism and paving the way for the systematic study of organic compounds, including alkyl groups.

The industrial revolution of the 19th century further accelerated the importance of alkyl chemistry. As the demand for petroleum-based products grew, the need to understand and manipulate alkyl compounds became increasingly critical. The discovery of the Wurtz reaction in 1855 by Charles-Adolphe Wurtz provided a method for synthesizing alkanes, which proved instrumental in the development of petrochemical industries.

The early 20th century saw rapid advancements in the understanding of alkyl groups and their reactions. The work of Victor Grignard on organomagnesium compounds, which led to the Nobel Prize in Chemistry in 1912, opened new avenues for alkyl group manipulations in organic synthesis. This period also witnessed the rise of the petrochemical industry, where alkyl groups became central to the production of fuels, plastics, and a wide array of industrial chemicals.

The mid-20th century brought about significant technological advancements that further enhanced the role of alkyl groups in chemical engineering. The development of chromatography techniques, particularly gas chromatography in the 1950s, revolutionized the analysis and separation of alkyl compounds. This technology enabled more precise control and optimization of industrial processes involving alkyl groups.

Concurrently, the petrochemical industry experienced exponential growth, driven by the increasing demand for alkyl-based products. The cracking of petroleum to produce smaller alkyl molecules became a cornerstone of the industry, leading to the development of more efficient catalytic processes. The Ziegler-Natta catalysts, discovered in the 1950s, revolutionized the polymerization of alkenes, significantly impacting the production of plastics and synthetic rubbers.

As environmental concerns gained prominence in the latter half of the 20th century, chemical engineers faced new challenges in alkyl chemistry. The focus shifted towards developing cleaner processes, reducing waste, and finding alternatives to petroleum-based alkyl compounds. This led to innovations in green chemistry and the exploration of bio-based sources for alkyl groups.

The historical context of alkyl groups in chemical engineering reflects a journey of scientific discovery, industrial innovation, and societal change. From their early recognition in organic chemistry to their central role in modern industrial processes, alkyl groups have been at the forefront of chemical engineering's evolution, continually adapting to meet the changing needs of society and industry.

The industrial revolution of the 19th century further accelerated the importance of alkyl chemistry. As the demand for petroleum-based products grew, the need to understand and manipulate alkyl compounds became increasingly critical. The discovery of the Wurtz reaction in 1855 by Charles-Adolphe Wurtz provided a method for synthesizing alkanes, which proved instrumental in the development of petrochemical industries.

The early 20th century saw rapid advancements in the understanding of alkyl groups and their reactions. The work of Victor Grignard on organomagnesium compounds, which led to the Nobel Prize in Chemistry in 1912, opened new avenues for alkyl group manipulations in organic synthesis. This period also witnessed the rise of the petrochemical industry, where alkyl groups became central to the production of fuels, plastics, and a wide array of industrial chemicals.

The mid-20th century brought about significant technological advancements that further enhanced the role of alkyl groups in chemical engineering. The development of chromatography techniques, particularly gas chromatography in the 1950s, revolutionized the analysis and separation of alkyl compounds. This technology enabled more precise control and optimization of industrial processes involving alkyl groups.

Concurrently, the petrochemical industry experienced exponential growth, driven by the increasing demand for alkyl-based products. The cracking of petroleum to produce smaller alkyl molecules became a cornerstone of the industry, leading to the development of more efficient catalytic processes. The Ziegler-Natta catalysts, discovered in the 1950s, revolutionized the polymerization of alkenes, significantly impacting the production of plastics and synthetic rubbers.

As environmental concerns gained prominence in the latter half of the 20th century, chemical engineers faced new challenges in alkyl chemistry. The focus shifted towards developing cleaner processes, reducing waste, and finding alternatives to petroleum-based alkyl compounds. This led to innovations in green chemistry and the exploration of bio-based sources for alkyl groups.

The historical context of alkyl groups in chemical engineering reflects a journey of scientific discovery, industrial innovation, and societal change. From their early recognition in organic chemistry to their central role in modern industrial processes, alkyl groups have been at the forefront of chemical engineering's evolution, continually adapting to meet the changing needs of society and industry.

Market Demand Analysis

The market demand for alkyl-related technologies in chemical engineering has experienced significant growth in recent years, driven by the increasing need for more efficient and sustainable processes across various industries. The petrochemical sector, in particular, has shown a strong appetite for advanced alkylation technologies to produce high-octane gasoline components and other valuable products. This demand is further fueled by stringent environmental regulations and the push for cleaner fuel alternatives.

In the pharmaceutical industry, alkyl groups play a crucial role in drug development and synthesis. The market for alkylation reagents and processes has expanded as pharmaceutical companies seek more effective ways to modify molecular structures and enhance drug efficacy. This trend is expected to continue as personalized medicine and targeted therapies gain prominence, requiring more sophisticated chemical engineering solutions.

The polymer industry has also contributed to the growing demand for alkyl-based technologies. With the increasing focus on sustainable materials, there is a rising interest in bio-based alkyl compounds for the production of biodegradable plastics and other environmentally friendly polymers. This shift has opened up new opportunities for chemical engineers to develop innovative alkylation processes that utilize renewable feedstocks.

In the field of agrochemicals, the demand for alkyl-containing pesticides and herbicides remains strong, driven by the need to improve crop yields and food security. However, there is a growing emphasis on developing more environmentally benign formulations, which has spurred research into novel alkylation methods that reduce the environmental impact of these products.

The electronics industry has emerged as another significant driver of alkyl-related market demand. The production of advanced semiconductors and display technologies often requires precise control of surface properties, where alkyl-based treatments play a crucial role. As the demand for smaller, more efficient electronic devices continues to grow, so does the need for specialized alkylation processes in chemical engineering.

The global market for alkylation technologies is projected to expand at a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth is attributed to the increasing industrialization in developing economies, the ongoing transition towards cleaner energy sources, and the continuous innovation in chemical processes. North America and Europe currently dominate the market, but Asia-Pacific is expected to witness the fastest growth due to rapid industrialization and increasing investments in chemical manufacturing infrastructure.

As the chemical engineering landscape evolves, the role of alkyl groups in various processes is likely to become even more critical. The market demand analysis suggests a continued focus on developing more efficient, selective, and environmentally friendly alkylation technologies. This trend presents both challenges and opportunities for chemical engineers to innovate and address the complex needs of diverse industries relying on alkyl-based processes and products.

In the pharmaceutical industry, alkyl groups play a crucial role in drug development and synthesis. The market for alkylation reagents and processes has expanded as pharmaceutical companies seek more effective ways to modify molecular structures and enhance drug efficacy. This trend is expected to continue as personalized medicine and targeted therapies gain prominence, requiring more sophisticated chemical engineering solutions.

The polymer industry has also contributed to the growing demand for alkyl-based technologies. With the increasing focus on sustainable materials, there is a rising interest in bio-based alkyl compounds for the production of biodegradable plastics and other environmentally friendly polymers. This shift has opened up new opportunities for chemical engineers to develop innovative alkylation processes that utilize renewable feedstocks.

In the field of agrochemicals, the demand for alkyl-containing pesticides and herbicides remains strong, driven by the need to improve crop yields and food security. However, there is a growing emphasis on developing more environmentally benign formulations, which has spurred research into novel alkylation methods that reduce the environmental impact of these products.

The electronics industry has emerged as another significant driver of alkyl-related market demand. The production of advanced semiconductors and display technologies often requires precise control of surface properties, where alkyl-based treatments play a crucial role. As the demand for smaller, more efficient electronic devices continues to grow, so does the need for specialized alkylation processes in chemical engineering.

The global market for alkylation technologies is projected to expand at a compound annual growth rate (CAGR) of several percentage points over the next five years. This growth is attributed to the increasing industrialization in developing economies, the ongoing transition towards cleaner energy sources, and the continuous innovation in chemical processes. North America and Europe currently dominate the market, but Asia-Pacific is expected to witness the fastest growth due to rapid industrialization and increasing investments in chemical manufacturing infrastructure.

As the chemical engineering landscape evolves, the role of alkyl groups in various processes is likely to become even more critical. The market demand analysis suggests a continued focus on developing more efficient, selective, and environmentally friendly alkylation technologies. This trend presents both challenges and opportunities for chemical engineers to innovate and address the complex needs of diverse industries relying on alkyl-based processes and products.

Current Challenges

The field of chemical engineering has witnessed significant advancements over the years, with alkyl compounds playing a crucial role in its evolution. However, several challenges persist in the current landscape, hindering further progress and optimal utilization of alkyl-based technologies.

One of the primary challenges is the environmental impact associated with alkyl compounds. Many alkyl-based processes and products contribute to pollution and greenhouse gas emissions. The chemical industry faces increasing pressure to develop more sustainable and eco-friendly alternatives while maintaining the efficiency and effectiveness of alkyl-based solutions.

Another significant challenge lies in the optimization of alkyl synthesis and processing techniques. While considerable progress has been made, there is still room for improvement in terms of yield, selectivity, and energy efficiency. Researchers and engineers are grappling with the task of developing more cost-effective and environmentally benign catalysts and reaction conditions for alkyl-related processes.

The complexity of alkyl chemistry poses challenges in terms of predictability and control. As the demand for more sophisticated and specialized alkyl compounds grows, scientists face difficulties in accurately predicting reaction outcomes and controlling the formation of desired products. This complexity often leads to increased production costs and reduced efficiency in industrial-scale applications.

Safety concerns associated with the handling and storage of alkyl compounds present ongoing challenges. Many alkyl compounds are highly reactive, flammable, or toxic, necessitating stringent safety protocols and specialized equipment. Developing safer alternatives or improved handling techniques remains a priority for the chemical engineering community.

The integration of alkyl-based technologies with emerging fields such as nanotechnology and biotechnology presents both opportunities and challenges. While these interdisciplinary approaches hold great promise, they also require overcoming barriers related to compatibility, scalability, and regulatory compliance.

Furthermore, the chemical engineering industry faces challenges in terms of raw material availability and supply chain management for alkyl-based processes. Fluctuations in feedstock prices and geopolitical factors can significantly impact the economic viability of alkyl-related technologies, necessitating the development of more resilient and diversified supply chains.

Lastly, the rapid pace of technological advancements in other areas of chemical engineering sometimes overshadows the continued importance of alkyl chemistry. Maintaining a balance between exploring cutting-edge technologies and refining existing alkyl-based processes poses a challenge for researchers and industry professionals alike.

One of the primary challenges is the environmental impact associated with alkyl compounds. Many alkyl-based processes and products contribute to pollution and greenhouse gas emissions. The chemical industry faces increasing pressure to develop more sustainable and eco-friendly alternatives while maintaining the efficiency and effectiveness of alkyl-based solutions.

Another significant challenge lies in the optimization of alkyl synthesis and processing techniques. While considerable progress has been made, there is still room for improvement in terms of yield, selectivity, and energy efficiency. Researchers and engineers are grappling with the task of developing more cost-effective and environmentally benign catalysts and reaction conditions for alkyl-related processes.

The complexity of alkyl chemistry poses challenges in terms of predictability and control. As the demand for more sophisticated and specialized alkyl compounds grows, scientists face difficulties in accurately predicting reaction outcomes and controlling the formation of desired products. This complexity often leads to increased production costs and reduced efficiency in industrial-scale applications.

Safety concerns associated with the handling and storage of alkyl compounds present ongoing challenges. Many alkyl compounds are highly reactive, flammable, or toxic, necessitating stringent safety protocols and specialized equipment. Developing safer alternatives or improved handling techniques remains a priority for the chemical engineering community.

The integration of alkyl-based technologies with emerging fields such as nanotechnology and biotechnology presents both opportunities and challenges. While these interdisciplinary approaches hold great promise, they also require overcoming barriers related to compatibility, scalability, and regulatory compliance.

Furthermore, the chemical engineering industry faces challenges in terms of raw material availability and supply chain management for alkyl-based processes. Fluctuations in feedstock prices and geopolitical factors can significantly impact the economic viability of alkyl-related technologies, necessitating the development of more resilient and diversified supply chains.

Lastly, the rapid pace of technological advancements in other areas of chemical engineering sometimes overshadows the continued importance of alkyl chemistry. Maintaining a balance between exploring cutting-edge technologies and refining existing alkyl-based processes poses a challenge for researchers and industry professionals alike.

Existing Alkyl Solutions

01 Alkyl halide synthesis and applications

Alkyl halides are important organic compounds with various industrial applications. They can be synthesized through different methods, including the halogenation of alkanes or the addition of hydrogen halides to alkenes. These compounds serve as key intermediates in the production of other organic chemicals and polymers.- Alkyl halide synthesis and applications: Alkyl halides are important organic compounds with various industrial applications. They can be synthesized through different methods, including the halogenation of alkanes or the addition of hydrogen halides to alkenes. These compounds serve as key intermediates in organic synthesis and are used in the production of pharmaceuticals, polymers, and other chemical products.

- Alkyl-substituted aromatic compounds: Alkyl-substituted aromatic compounds are widely used in the chemical industry. These compounds can be prepared through various methods, such as Friedel-Crafts alkylation or transition metal-catalyzed cross-coupling reactions. They find applications in the production of dyes, pharmaceuticals, and specialty chemicals.

- Alkyl-based surfactants and detergents: Alkyl-based surfactants and detergents are essential components in many cleaning and personal care products. These compounds typically consist of a hydrophobic alkyl chain and a hydrophilic head group. The synthesis and formulation of these surfactants involve various processes, including alkylation, sulfonation, and ethoxylation.

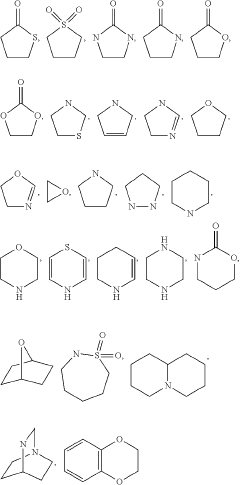

- Alkyl-substituted heterocycles: Alkyl-substituted heterocycles are important structural motifs in many biologically active compounds and materials. The synthesis of these compounds often involves alkylation of heterocyclic cores or the construction of heterocycles from alkyl-substituted precursors. These compounds have applications in pharmaceuticals, agrochemicals, and materials science.

- Alkyl-based polymers and materials: Alkyl-based polymers and materials are widely used in various industries. These materials can be synthesized through different polymerization techniques, such as free radical polymerization or coordination polymerization. The properties of these polymers can be tailored by adjusting the length and branching of the alkyl chains, making them suitable for applications in plastics, coatings, and adhesives.

02 Alkyl-substituted aromatic compounds

Alkyl-substituted aromatic compounds are widely used in the chemical industry. These compounds can be prepared through various alkylation reactions, such as Friedel-Crafts alkylation. They find applications in the production of pharmaceuticals, dyes, and other specialty chemicals.Expand Specific Solutions03 Alkyl ethers and their production

Alkyl ethers are important organic compounds used as solvents, fuel additives, and chemical intermediates. They can be synthesized through various methods, including the Williamson ether synthesis or the dehydration of alcohols. The production of alkyl ethers often involves catalytic processes to improve efficiency and selectivity.Expand Specific Solutions04 Alkyl-based surfactants and detergents

Alkyl-based surfactants and detergents are widely used in household and industrial cleaning products. These compounds typically consist of a hydrophobic alkyl chain and a hydrophilic head group. The synthesis and formulation of alkyl-based surfactants involve considerations of chain length, branching, and functional group attachment to optimize their performance.Expand Specific Solutions05 Alkyl-substituted polymers and copolymers

Alkyl-substituted polymers and copolymers have diverse applications in materials science. These polymers can be synthesized through various polymerization techniques, including free radical, anionic, or cationic polymerization. The incorporation of alkyl groups can modify the properties of the resulting polymers, such as solubility, thermal stability, and mechanical characteristics.Expand Specific Solutions

Key Industry Players

The evolution of alkyl's role in chemical engineering reflects a mature industry with significant market size and ongoing technological advancements. The competitive landscape is characterized by a mix of established pharmaceutical giants, specialized chemical companies, and emerging biotech firms. Key players like Gilead Sciences, Sanofi, and Novartis drive innovation in drug development, while companies such as LANXESS and Henkel focus on industrial applications. Research institutions like Shanghai Institute of Organic Chemistry and universities including Harvard and Sichuan University contribute to fundamental advancements. The involvement of major petrochemical corporations like Sinopec and PetroChina highlights the broad impact of alkyl chemistry across multiple sectors, indicating a well-developed but still evolving technological field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in the evolution of chemical engineering through alkyl-related processes. The company has developed advanced alkylation technologies for producing high-octane gasoline components. Their solid acid alkylation technology uses a proprietary catalyst that allows for a more environmentally friendly and cost-effective production process compared to traditional sulfuric acid alkylation [1]. This innovation has led to improved product quality and reduced environmental impact in refinery operations. Sinopec has also invested in research on alkyl-based surfactants for enhanced oil recovery (EOR) applications, which has potential to significantly improve oil extraction efficiency [2].

Strengths: Large-scale implementation capability, strong R&D infrastructure. Weaknesses: Potential overreliance on fossil fuel-based technologies, environmental concerns.

LANXESS Deutschland GmbH

Technical Solution: LANXESS has been at the forefront of alkyl-related innovations in chemical engineering, particularly in the realm of specialty chemicals. The company has developed a range of alkylphenol ethoxylates (APEs) with improved biodegradability and reduced toxicity compared to traditional APEs [3]. These products find applications in various industries, including textiles, paints, and agrochemicals. LANXESS has also made advancements in alkyl dimethyl benzyl ammonium chloride (ADBAC) production, a key ingredient in disinfectants and sanitizers, by implementing more sustainable manufacturing processes that reduce waste and energy consumption [4]. Their continuous research in alkyl-based flame retardants has led to the development of safer alternatives to traditional halogenated compounds.

Strengths: Strong focus on sustainability and eco-friendly solutions, diverse product portfolio. Weaknesses: Regulatory challenges in some markets, competition from bio-based alternatives.

Innovative Alkyl Research

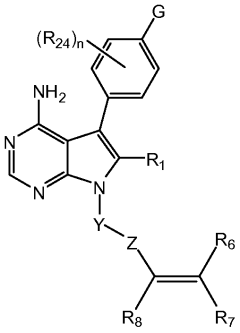

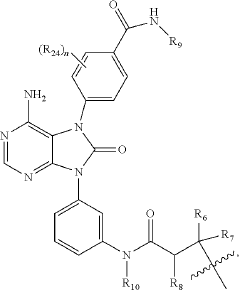

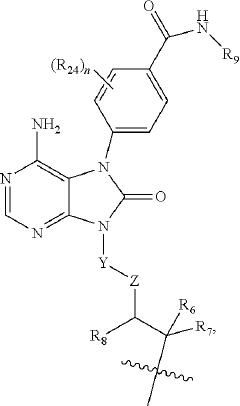

Pyrrolopyrimidine compounds as kinase inhibitors

PatentWO2014078578A1

Innovation

- Development of pyrrolopyrimidine compounds that act as irreversible or reversible inhibitors of Btk, forming covalent bonds with cysteine residues, thereby inhibiting the enzyme's activity.

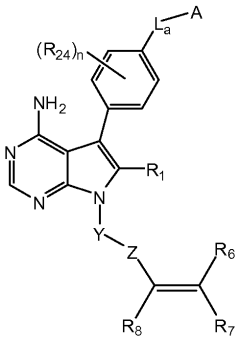

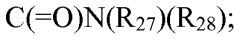

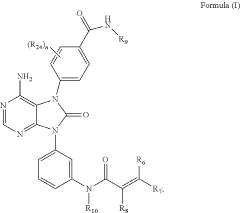

Purinone compounds as kinase inhibitors

PatentInactiveUS20190144451A1

Innovation

- Development of compounds, including reversible and irreversible inhibitors that target Btk, forming covalent bonds with cysteine residues, specifically designed to inhibit Btk activity and potentially other tyrosine kinases sharing homology, for therapeutic use in treating autoimmune diseases, cancers, and inflammatory conditions.

Environmental Impact

The environmental impact of alkyl compounds in chemical engineering has been a subject of increasing concern and scrutiny. As these compounds have played a pivotal role in the evolution of chemical processes, their effects on ecosystems and human health have become more apparent. Alkyl groups, being hydrocarbon chains, are often associated with petroleum-based products and processes, which have significant environmental implications.

One of the primary environmental concerns related to alkyl compounds is their persistence in the environment. Many alkyl-based substances, particularly those with longer carbon chains, are resistant to biodegradation. This persistence can lead to bioaccumulation in various organisms, potentially disrupting food chains and ecosystems. For instance, certain alkylphenols, used in industrial detergents and pesticides, have been found to act as endocrine disruptors in aquatic life, affecting reproductive cycles and population dynamics.

Air pollution is another critical aspect of the environmental impact of alkyl compounds. Volatile organic compounds (VOCs), many of which contain alkyl groups, contribute to the formation of ground-level ozone and smog. These air quality issues can have severe consequences for both human health and plant life. Additionally, the production and use of alkyl-based substances often involve the emission of greenhouse gases, contributing to global climate change.

Water contamination is a significant concern, particularly in areas with extensive chemical manufacturing or oil refining activities. Alkyl compounds can enter water systems through industrial effluents, spills, or leaching from contaminated soils. Once in aquatic environments, these compounds can affect water quality, harm aquatic organisms, and potentially enter drinking water supplies. The remediation of water bodies contaminated with alkyl compounds is often a complex and costly process.

The disposal and management of alkyl-containing waste present ongoing challenges. Improper disposal can lead to soil contamination, affecting soil fertility and potentially entering the food chain through agricultural products. Incineration of alkyl-rich waste, while sometimes necessary, can release harmful emissions if not properly controlled.

However, the chemical engineering industry has been making strides in addressing these environmental concerns. There is a growing focus on developing more environmentally friendly alkyl compounds and processes. This includes the use of bio-based alkyl sources, the design of more readily biodegradable compounds, and the implementation of cleaner production technologies. Green chemistry principles are increasingly being applied to minimize the environmental footprint of alkyl-based processes.

Furthermore, advancements in wastewater treatment technologies and air pollution control systems have improved the industry's ability to manage and mitigate the environmental impacts of alkyl compounds. Regulatory frameworks, such as REACH in the European Union, have also played a crucial role in driving the industry towards more sustainable practices and safer alternatives.

One of the primary environmental concerns related to alkyl compounds is their persistence in the environment. Many alkyl-based substances, particularly those with longer carbon chains, are resistant to biodegradation. This persistence can lead to bioaccumulation in various organisms, potentially disrupting food chains and ecosystems. For instance, certain alkylphenols, used in industrial detergents and pesticides, have been found to act as endocrine disruptors in aquatic life, affecting reproductive cycles and population dynamics.

Air pollution is another critical aspect of the environmental impact of alkyl compounds. Volatile organic compounds (VOCs), many of which contain alkyl groups, contribute to the formation of ground-level ozone and smog. These air quality issues can have severe consequences for both human health and plant life. Additionally, the production and use of alkyl-based substances often involve the emission of greenhouse gases, contributing to global climate change.

Water contamination is a significant concern, particularly in areas with extensive chemical manufacturing or oil refining activities. Alkyl compounds can enter water systems through industrial effluents, spills, or leaching from contaminated soils. Once in aquatic environments, these compounds can affect water quality, harm aquatic organisms, and potentially enter drinking water supplies. The remediation of water bodies contaminated with alkyl compounds is often a complex and costly process.

The disposal and management of alkyl-containing waste present ongoing challenges. Improper disposal can lead to soil contamination, affecting soil fertility and potentially entering the food chain through agricultural products. Incineration of alkyl-rich waste, while sometimes necessary, can release harmful emissions if not properly controlled.

However, the chemical engineering industry has been making strides in addressing these environmental concerns. There is a growing focus on developing more environmentally friendly alkyl compounds and processes. This includes the use of bio-based alkyl sources, the design of more readily biodegradable compounds, and the implementation of cleaner production technologies. Green chemistry principles are increasingly being applied to minimize the environmental footprint of alkyl-based processes.

Furthermore, advancements in wastewater treatment technologies and air pollution control systems have improved the industry's ability to manage and mitigate the environmental impacts of alkyl compounds. Regulatory frameworks, such as REACH in the European Union, have also played a crucial role in driving the industry towards more sustainable practices and safer alternatives.

Safety Regulations

The evolution of chemical engineering has been significantly influenced by the development and implementation of safety regulations, particularly in relation to alkyl compounds. These regulations have played a crucial role in shaping industry practices, research directions, and technological advancements.

In the early stages of chemical engineering, safety considerations were often secondary to production efficiency. However, as the industry grew and the potential hazards of alkyl compounds became more apparent, regulatory bodies began to implement stricter safety measures. The introduction of the Occupational Safety and Health Administration (OSHA) in the United States in 1970 marked a turning point in safety regulations for the chemical industry.

Alkyl compounds, being highly reactive and often flammable, posed significant risks in chemical processes. This led to the development of specific safety protocols for handling, storing, and transporting these substances. The implementation of these regulations necessitated innovations in process design, equipment engineering, and monitoring systems.

One of the key areas of focus in safety regulations has been the prevention and mitigation of fires and explosions related to alkyl compounds. This has led to the development of advanced fire suppression systems, explosion-proof equipment, and improved ventilation systems in chemical plants. Additionally, regulations mandating the use of personal protective equipment (PPE) when handling alkyl compounds have significantly reduced the incidence of workplace injuries.

The introduction of process safety management (PSM) regulations in the 1990s further transformed the chemical engineering landscape. These regulations required comprehensive hazard analyses, rigorous operating procedures, and regular safety audits for processes involving highly hazardous chemicals, including many alkyl compounds. This systemic approach to safety has driven innovations in process control, automation, and risk assessment methodologies.

Environmental regulations have also played a significant role in shaping the use of alkyl compounds in chemical engineering. Stricter emissions controls and waste management regulations have led to the development of more efficient and environmentally friendly processes. This has spurred research into green chemistry principles and the development of alternative, less hazardous substances to replace certain alkyl compounds.

The impact of safety regulations on the evolution of chemical engineering extends beyond operational practices. They have influenced education and training programs, with increased emphasis on safety principles in chemical engineering curricula. This has led to a new generation of engineers with a strong foundation in process safety and risk management.

In conclusion, safety regulations, particularly those related to alkyl compounds, have been a driving force in the evolution of chemical engineering. They have not only improved workplace safety but also catalyzed technological advancements, process innovations, and a shift towards more sustainable practices in the industry.

In the early stages of chemical engineering, safety considerations were often secondary to production efficiency. However, as the industry grew and the potential hazards of alkyl compounds became more apparent, regulatory bodies began to implement stricter safety measures. The introduction of the Occupational Safety and Health Administration (OSHA) in the United States in 1970 marked a turning point in safety regulations for the chemical industry.

Alkyl compounds, being highly reactive and often flammable, posed significant risks in chemical processes. This led to the development of specific safety protocols for handling, storing, and transporting these substances. The implementation of these regulations necessitated innovations in process design, equipment engineering, and monitoring systems.

One of the key areas of focus in safety regulations has been the prevention and mitigation of fires and explosions related to alkyl compounds. This has led to the development of advanced fire suppression systems, explosion-proof equipment, and improved ventilation systems in chemical plants. Additionally, regulations mandating the use of personal protective equipment (PPE) when handling alkyl compounds have significantly reduced the incidence of workplace injuries.

The introduction of process safety management (PSM) regulations in the 1990s further transformed the chemical engineering landscape. These regulations required comprehensive hazard analyses, rigorous operating procedures, and regular safety audits for processes involving highly hazardous chemicals, including many alkyl compounds. This systemic approach to safety has driven innovations in process control, automation, and risk assessment methodologies.

Environmental regulations have also played a significant role in shaping the use of alkyl compounds in chemical engineering. Stricter emissions controls and waste management regulations have led to the development of more efficient and environmentally friendly processes. This has spurred research into green chemistry principles and the development of alternative, less hazardous substances to replace certain alkyl compounds.

The impact of safety regulations on the evolution of chemical engineering extends beyond operational practices. They have influenced education and training programs, with increased emphasis on safety principles in chemical engineering curricula. This has led to a new generation of engineers with a strong foundation in process safety and risk management.

In conclusion, safety regulations, particularly those related to alkyl compounds, have been a driving force in the evolution of chemical engineering. They have not only improved workplace safety but also catalyzed technological advancements, process innovations, and a shift towards more sustainable practices in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!