Alkyl Compounds in Polymer Science: Emerging Trends

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Compound Evolution in Polymer Science

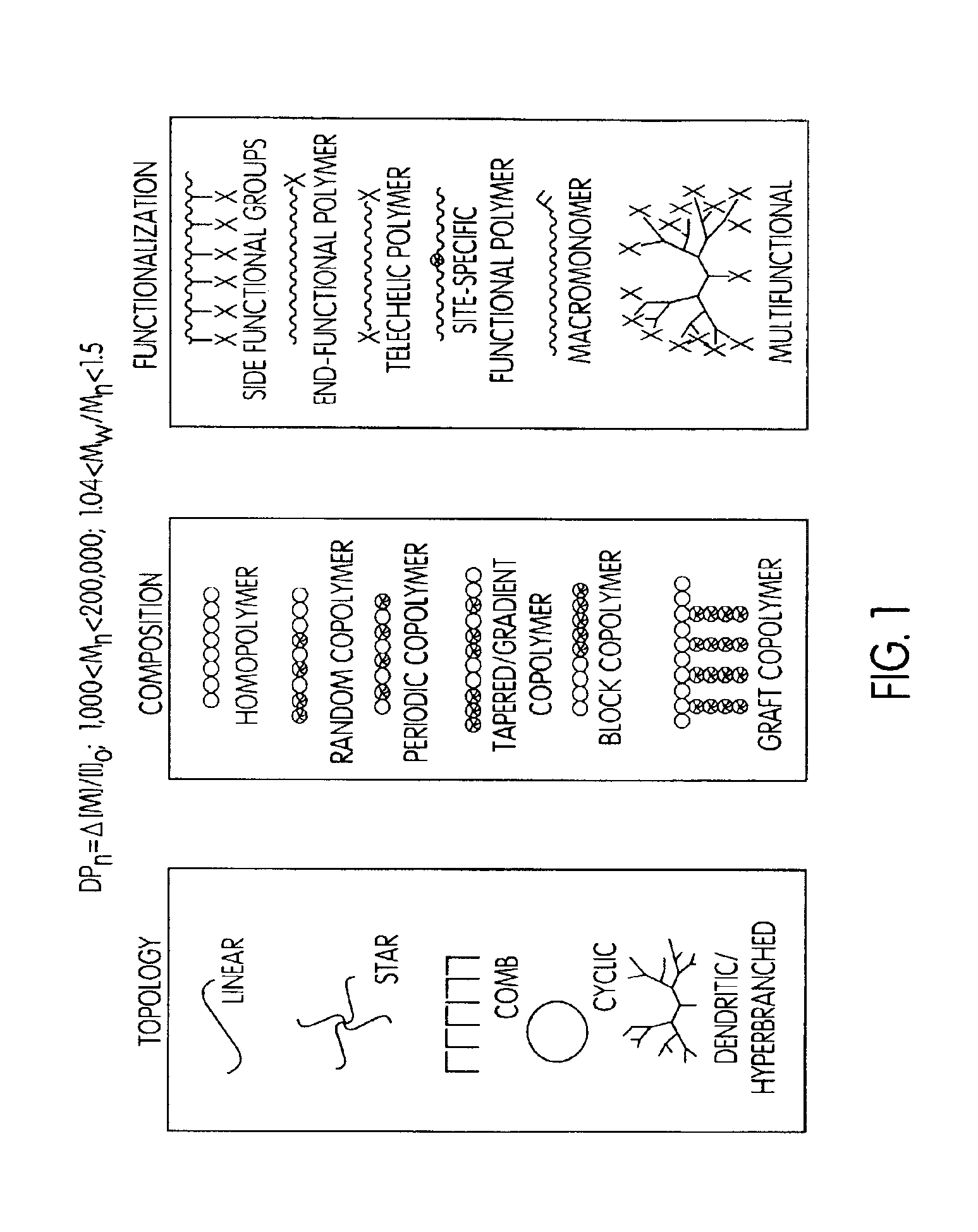

The evolution of alkyl compounds in polymer science has been a journey of continuous innovation and adaptation. In the early days of polymer chemistry, simple alkyl groups were primarily used as side chains or end groups to modify the properties of polymers. These initial applications focused on enhancing solubility, improving processability, and adjusting the glass transition temperature of polymers.

As the field progressed, researchers began to explore more complex alkyl structures and their impact on polymer performance. The introduction of branched and cyclic alkyl groups opened up new possibilities for tailoring polymer properties. These structures allowed for better control over crystallinity, thermal stability, and mechanical strength, leading to the development of high-performance polymers for specialized applications.

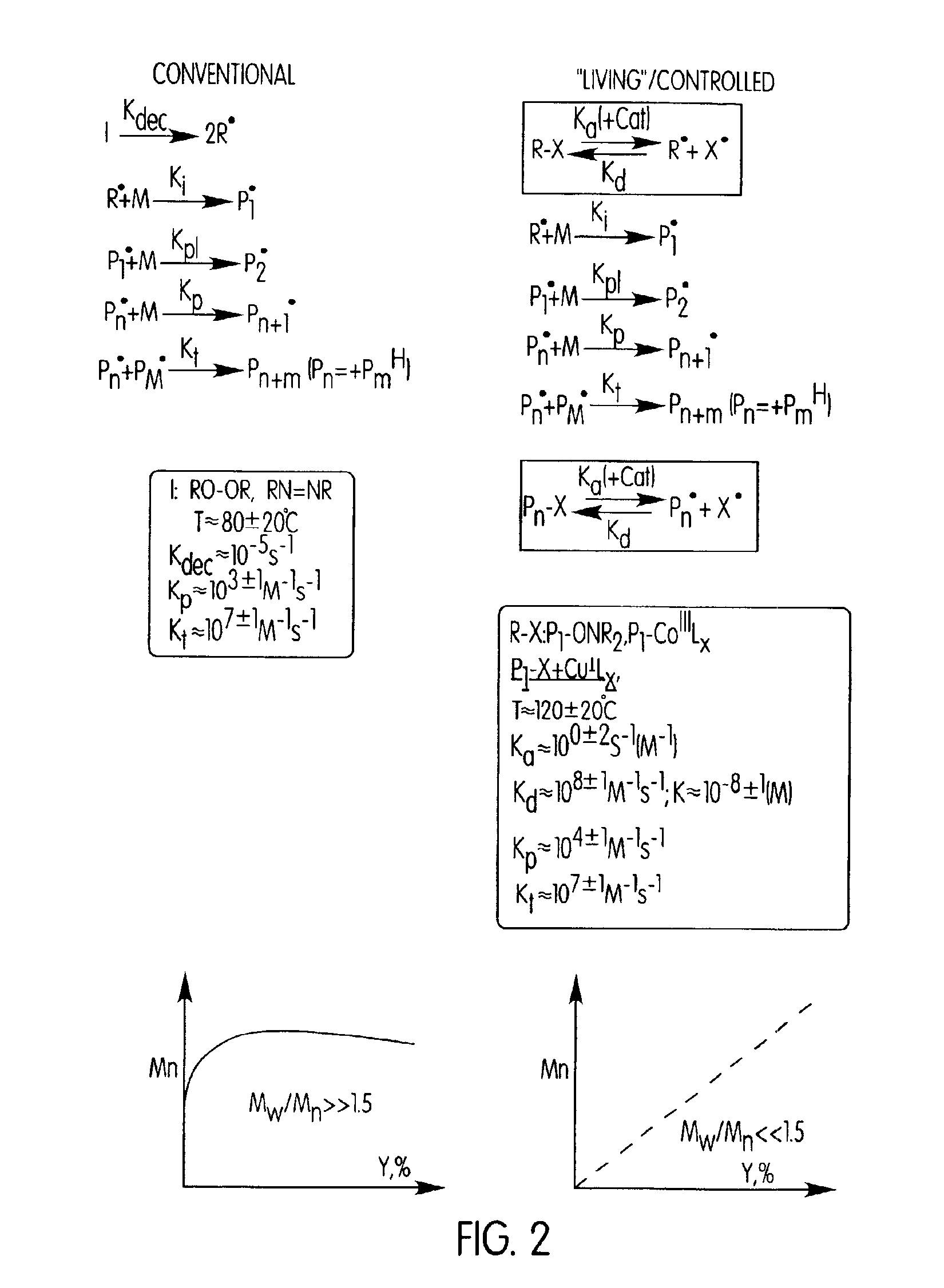

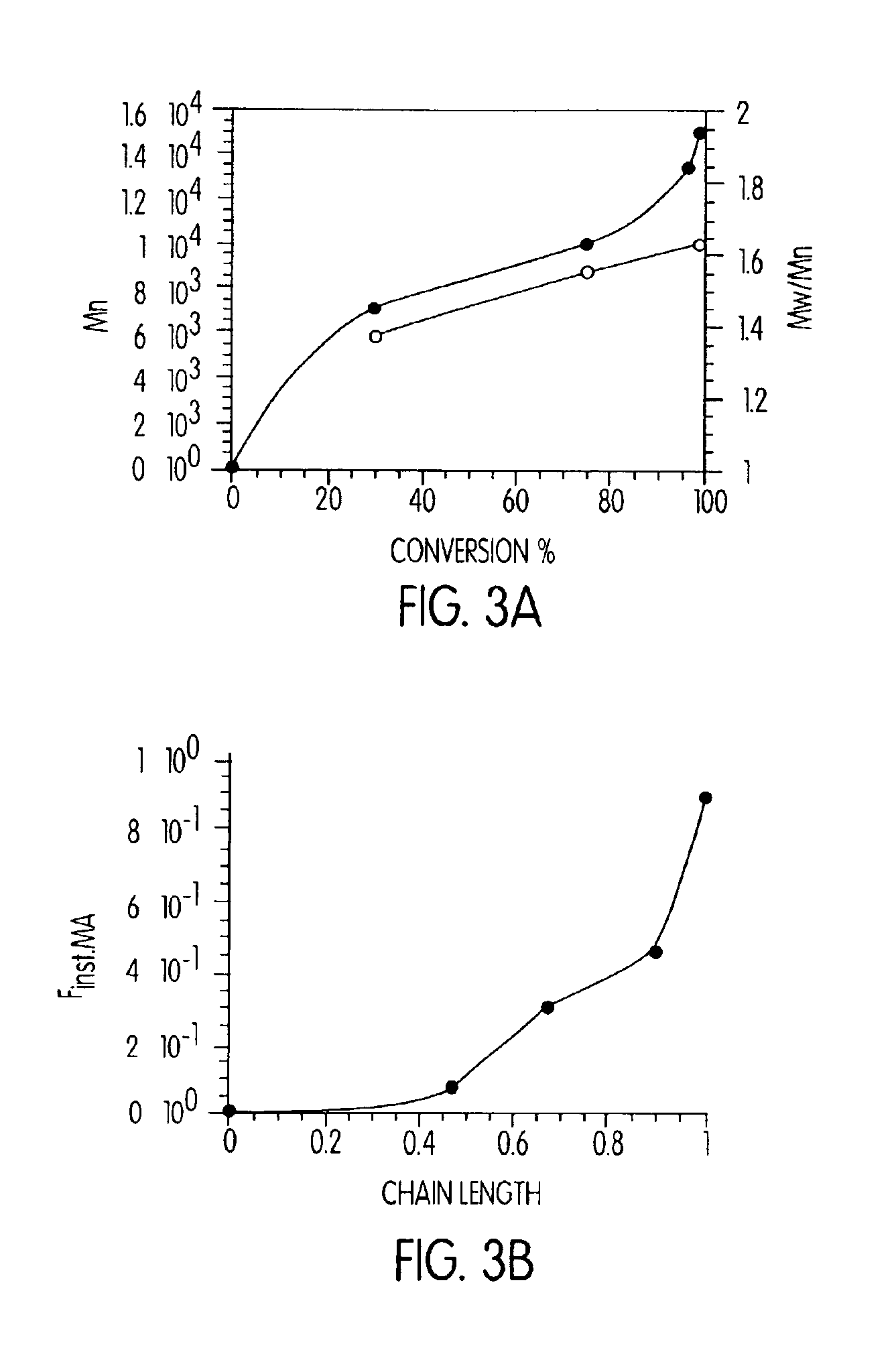

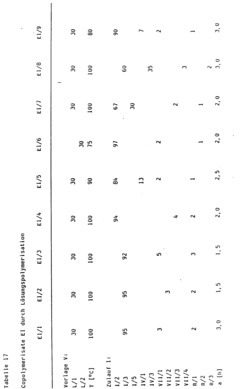

The advent of controlled polymerization techniques in the late 20th century marked a significant milestone in alkyl compound evolution. Methods such as atom transfer radical polymerization (ATRP) and reversible addition-fragmentation chain transfer (RAFT) polymerization enabled precise control over polymer architecture and composition. This breakthrough allowed for the incorporation of functional alkyl groups at specific positions along the polymer backbone, revolutionizing the design of smart and responsive materials.

In recent years, the focus has shifted towards sustainable and bio-based alkyl compounds. The growing emphasis on environmental concerns has driven research into renewable sources of alkyl groups, such as plant-based oils and fatty acids. These bio-derived alkyl compounds offer a greener alternative to petroleum-based counterparts while maintaining or even enhancing polymer performance.

The integration of alkyl compounds with advanced manufacturing techniques has further expanded their application scope. 3D printing and additive manufacturing have benefited from the development of alkyl-modified polymers with improved printability and mechanical properties. This synergy has enabled the production of complex, customized polymer structures for various industries, including aerospace, automotive, and biomedical fields.

Looking ahead, the evolution of alkyl compounds in polymer science is poised to continue its rapid pace. Emerging trends include the development of stimuli-responsive alkyl groups for smart materials, the exploration of supramolecular interactions for self-healing polymers, and the integration of alkyl compounds with nanomaterials for enhanced functionality. These advancements promise to push the boundaries of polymer science, opening up new frontiers in material design and application.

As the field progressed, researchers began to explore more complex alkyl structures and their impact on polymer performance. The introduction of branched and cyclic alkyl groups opened up new possibilities for tailoring polymer properties. These structures allowed for better control over crystallinity, thermal stability, and mechanical strength, leading to the development of high-performance polymers for specialized applications.

The advent of controlled polymerization techniques in the late 20th century marked a significant milestone in alkyl compound evolution. Methods such as atom transfer radical polymerization (ATRP) and reversible addition-fragmentation chain transfer (RAFT) polymerization enabled precise control over polymer architecture and composition. This breakthrough allowed for the incorporation of functional alkyl groups at specific positions along the polymer backbone, revolutionizing the design of smart and responsive materials.

In recent years, the focus has shifted towards sustainable and bio-based alkyl compounds. The growing emphasis on environmental concerns has driven research into renewable sources of alkyl groups, such as plant-based oils and fatty acids. These bio-derived alkyl compounds offer a greener alternative to petroleum-based counterparts while maintaining or even enhancing polymer performance.

The integration of alkyl compounds with advanced manufacturing techniques has further expanded their application scope. 3D printing and additive manufacturing have benefited from the development of alkyl-modified polymers with improved printability and mechanical properties. This synergy has enabled the production of complex, customized polymer structures for various industries, including aerospace, automotive, and biomedical fields.

Looking ahead, the evolution of alkyl compounds in polymer science is poised to continue its rapid pace. Emerging trends include the development of stimuli-responsive alkyl groups for smart materials, the exploration of supramolecular interactions for self-healing polymers, and the integration of alkyl compounds with nanomaterials for enhanced functionality. These advancements promise to push the boundaries of polymer science, opening up new frontiers in material design and application.

Market Demand for Advanced Polymer Materials

The demand for advanced polymer materials has been steadily increasing across various industries, driven by the need for innovative solutions to complex challenges. In the automotive sector, lightweight and high-strength polymers are sought after to improve fuel efficiency and reduce emissions. These materials offer significant advantages over traditional metals, including reduced weight, enhanced durability, and improved design flexibility. The aerospace industry also shows a growing interest in advanced polymers, particularly for their ability to withstand extreme temperatures and harsh environments while maintaining structural integrity.

In the electronics and telecommunications sectors, the market for advanced polymer materials is expanding rapidly. With the advent of 5G technology and the Internet of Things (IoT), there is a pressing need for materials that can support high-frequency applications and miniaturization. Polymers with enhanced dielectric properties and thermal management capabilities are in high demand for use in circuit boards, connectors, and other electronic components.

The healthcare and medical device industry represents another significant market for advanced polymer materials. Biocompatible polymers are essential for developing implants, drug delivery systems, and tissue engineering scaffolds. The aging population and increasing prevalence of chronic diseases are driving the demand for innovative medical solutions, many of which rely on advanced polymer technologies.

Environmental concerns and sustainability initiatives are also shaping the market demand for advanced polymer materials. There is a growing interest in biodegradable and recyclable polymers that can reduce the environmental impact of plastic waste. Industries are seeking materials that can maintain high performance while offering improved end-of-life options, such as easier recycling or composting.

The packaging industry is another key driver of demand for advanced polymer materials. With the rise of e-commerce and changing consumer preferences, there is a need for packaging solutions that are lightweight, durable, and environmentally friendly. Advanced polymers that offer improved barrier properties, extended shelf life, and reduced material usage are highly sought after in this sector.

In the construction and infrastructure sectors, advanced polymer materials are gaining traction for their ability to enhance building performance and longevity. Polymers with improved fire resistance, weatherability, and structural properties are being used in applications ranging from insulation to reinforcement in concrete structures.

The global market for advanced polymer materials is expected to continue its growth trajectory, with emerging economies playing an increasingly important role. As industries across the board seek to innovate and improve their products and processes, the demand for specialized, high-performance polymers is likely to intensify, driving further research and development in this field.

In the electronics and telecommunications sectors, the market for advanced polymer materials is expanding rapidly. With the advent of 5G technology and the Internet of Things (IoT), there is a pressing need for materials that can support high-frequency applications and miniaturization. Polymers with enhanced dielectric properties and thermal management capabilities are in high demand for use in circuit boards, connectors, and other electronic components.

The healthcare and medical device industry represents another significant market for advanced polymer materials. Biocompatible polymers are essential for developing implants, drug delivery systems, and tissue engineering scaffolds. The aging population and increasing prevalence of chronic diseases are driving the demand for innovative medical solutions, many of which rely on advanced polymer technologies.

Environmental concerns and sustainability initiatives are also shaping the market demand for advanced polymer materials. There is a growing interest in biodegradable and recyclable polymers that can reduce the environmental impact of plastic waste. Industries are seeking materials that can maintain high performance while offering improved end-of-life options, such as easier recycling or composting.

The packaging industry is another key driver of demand for advanced polymer materials. With the rise of e-commerce and changing consumer preferences, there is a need for packaging solutions that are lightweight, durable, and environmentally friendly. Advanced polymers that offer improved barrier properties, extended shelf life, and reduced material usage are highly sought after in this sector.

In the construction and infrastructure sectors, advanced polymer materials are gaining traction for their ability to enhance building performance and longevity. Polymers with improved fire resistance, weatherability, and structural properties are being used in applications ranging from insulation to reinforcement in concrete structures.

The global market for advanced polymer materials is expected to continue its growth trajectory, with emerging economies playing an increasingly important role. As industries across the board seek to innovate and improve their products and processes, the demand for specialized, high-performance polymers is likely to intensify, driving further research and development in this field.

Current Challenges in Alkyl-based Polymer Development

The development of alkyl-based polymers faces several significant challenges that hinder their widespread adoption and limit their potential applications. One of the primary obstacles is the control of molecular weight distribution during polymerization. Achieving narrow polydispersity indices remains difficult, particularly for complex alkyl-based monomers, which can lead to inconsistent material properties and performance.

Another major challenge lies in the thermal and oxidative stability of alkyl-based polymers. Many of these materials are susceptible to degradation at elevated temperatures or in the presence of oxygen, limiting their use in high-temperature applications or environments with prolonged exposure to air. This instability often results in the loss of mechanical properties and the formation of undesirable by-products.

The environmental impact of alkyl-based polymers presents a growing concern. Many of these materials are not biodegradable and can persist in the environment for extended periods. Developing sustainable alternatives or incorporating biodegradable components into alkyl-based polymers without compromising their desirable properties remains a significant challenge for polymer scientists.

Processability issues also pose difficulties in the manufacturing of alkyl-based polymers. Some of these materials exhibit high melt viscosities or narrow processing windows, making them challenging to mold, extrude, or form into complex shapes. This limitation restricts their use in certain manufacturing processes and applications that require intricate geometries or thin-walled structures.

The compatibility of alkyl-based polymers with other materials, such as fillers, additives, or other polymers, presents another hurdle. Achieving good dispersion and strong interfacial adhesion between the polymer matrix and reinforcing agents or functional additives is crucial for developing high-performance composites. However, the hydrophobic nature of many alkyl-based polymers can lead to poor compatibility and weak interactions with polar additives or surfaces.

Lastly, the cost-effectiveness of alkyl-based polymer production remains a challenge for widespread industrial adoption. Many of these materials require expensive catalysts, complex synthesis routes, or energy-intensive processes, which can make them economically unviable for certain applications. Developing more efficient and cost-effective production methods is essential for expanding the commercial viability of alkyl-based polymers across various sectors.

Another major challenge lies in the thermal and oxidative stability of alkyl-based polymers. Many of these materials are susceptible to degradation at elevated temperatures or in the presence of oxygen, limiting their use in high-temperature applications or environments with prolonged exposure to air. This instability often results in the loss of mechanical properties and the formation of undesirable by-products.

The environmental impact of alkyl-based polymers presents a growing concern. Many of these materials are not biodegradable and can persist in the environment for extended periods. Developing sustainable alternatives or incorporating biodegradable components into alkyl-based polymers without compromising their desirable properties remains a significant challenge for polymer scientists.

Processability issues also pose difficulties in the manufacturing of alkyl-based polymers. Some of these materials exhibit high melt viscosities or narrow processing windows, making them challenging to mold, extrude, or form into complex shapes. This limitation restricts their use in certain manufacturing processes and applications that require intricate geometries or thin-walled structures.

The compatibility of alkyl-based polymers with other materials, such as fillers, additives, or other polymers, presents another hurdle. Achieving good dispersion and strong interfacial adhesion between the polymer matrix and reinforcing agents or functional additives is crucial for developing high-performance composites. However, the hydrophobic nature of many alkyl-based polymers can lead to poor compatibility and weak interactions with polar additives or surfaces.

Lastly, the cost-effectiveness of alkyl-based polymer production remains a challenge for widespread industrial adoption. Many of these materials require expensive catalysts, complex synthesis routes, or energy-intensive processes, which can make them economically unviable for certain applications. Developing more efficient and cost-effective production methods is essential for expanding the commercial viability of alkyl-based polymers across various sectors.

Existing Alkyl Compound Solutions in Polymer Science

01 Synthesis of alkyl compounds

Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl compounds efficiently.- Synthesis of alkyl compounds: Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.

- Applications of alkyl compounds in industry: Alkyl compounds find diverse applications in industrial processes, such as in the production of plastics, lubricants, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules.

- Alkyl compounds in pharmaceutical formulations: Alkyl compounds are utilized in pharmaceutical formulations as excipients, solubilizers, or active ingredients. They can enhance drug delivery, improve stability, or contribute to the therapeutic effect of medications.

- Environmental impact and biodegradation of alkyl compounds: Research focuses on the environmental fate and biodegradation of alkyl compounds, particularly in relation to their use in consumer products and industrial processes. Studies aim to develop more environmentally friendly alkyl derivatives and assess their impact on ecosystems.

- Novel alkyl compound structures and properties: Investigations into novel alkyl compound structures and their unique properties are ongoing. These studies explore the relationship between molecular structure and physical or chemical characteristics, aiming to develop compounds with enhanced performance for specific applications.

02 Applications of alkyl compounds in industrial processes

Alkyl compounds find widespread use in industrial processes, such as in the production of polymers, lubricants, and surfactants. They serve as important intermediates in the synthesis of various chemicals and materials used across different sectors.Expand Specific Solutions03 Alkyl compounds in pharmaceutical and cosmetic formulations

Alkyl compounds are utilized in the development of pharmaceutical and cosmetic products. They can act as carriers, emollients, or active ingredients in various formulations, contributing to the efficacy and stability of these products.Expand Specific Solutions04 Environmental and safety considerations of alkyl compounds

Research focuses on the environmental impact and safety aspects of alkyl compounds. This includes studies on biodegradability, toxicity, and potential alternatives to harmful alkyl compounds in various applications.Expand Specific Solutions05 Novel alkyl compound derivatives and their properties

Development of new alkyl compound derivatives with enhanced properties for specific applications. This includes modifications to improve stability, reactivity, or functionality of alkyl compounds for use in various industries.Expand Specific Solutions

Key Players in Alkyl-Polymer Research and Production

The emerging trends in alkyl compounds for polymer science are characterized by a competitive landscape in a mature yet evolving industry. The market is experiencing steady growth, driven by increasing demand for advanced polymers across various sectors. Technological maturity varies, with established players like BASF, Arkema, and Novartis leading in innovation. Newer entrants such as Global Bioenergies and Sunshine Lake Pharma are focusing on sustainable and bio-based solutions. Research institutions like Shanghai Institute of Organic Chemistry and Carnegie Mellon University contribute significantly to technological advancements. The industry is witnessing a shift towards eco-friendly and high-performance alkyl compounds, with collaborations between academia and industry driving innovation.

3M Innovative Properties Co.

Technical Solution: 3M Innovative Properties Co. has been actively researching and developing alkyl compounds for various polymer applications. Their focus has been on creating functional alkyl additives that enhance the performance of polymers in specific applications. 3M has developed alkyl-based fluoropolymers with improved chemical resistance and low surface energy, suitable for protective coatings and release liners[9]. The company has also explored the use of alkyl compounds in the development of advanced polymer membranes for separation technologies, enhancing selectivity and permeability[10]. Additionally, 3M has made progress in creating alkyl-modified adhesives with improved bonding strength and durability under extreme conditions[11].

Strengths: Diverse product portfolio, strong innovation culture, and extensive patent portfolio. Weaknesses: Complex organizational structure may slow down decision-making processes.

Arkema, Inc.

Technical Solution: Arkema, Inc. has been actively involved in developing cutting-edge alkyl compounds for polymer science applications. Their research focuses on creating high-performance materials through strategic alkylation of existing polymer structures. Arkema has developed a range of alkyl-modified acrylic polymers that offer enhanced weatherability and UV resistance for coating applications[12]. The company has also made significant progress in the field of alkyl-functionalized polyamides, which exhibit improved thermal stability and chemical resistance[13]. Arkema's innovative approach includes the development of bio-based alkyl compounds derived from renewable resources, aligning with the growing demand for sustainable polymer solutions[14].

Strengths: Strong focus on specialty chemicals and advanced materials, commitment to sustainability. Weaknesses: Potential vulnerability to fluctuations in raw material prices.

Innovative Alkyl Structures for Polymer Enhancement

Processes based on atom (or group) transfer radical polymerization and novel (co)polymers having useful structures and properties

PatentInactiveUS6887962B2

Innovation

- The development of atom transfer radical polymerization (ATRP) using a transition metal-mediated process with a reversible redox cycle and coordinating ligands to control the formation of radicals, allowing for predictable molecular weight and narrow polydispersity in polymerization.

By air humidity self-curable copolymers and mixtures

PatentInactiveEP0656369A1

Innovation

- Development of new mixtures of copolymers comprising 40-98% C₁-C₂₄ alkyl esters of acrylic and/or methacrylic acid, 0.5-10% hydroxyl-containing comonomers, and 1-30% di- or polyfunctional isocyanates and aldimines or ketimines, which are self-curable with atmospheric moisture, improving flow behavior and reducing surface tackiness.

Environmental Impact of Alkyl-based Polymers

The environmental impact of alkyl-based polymers has become a critical concern in the field of polymer science. These materials, while offering numerous benefits in various applications, pose significant challenges to ecological sustainability. The production process of alkyl-based polymers often involves the use of fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, the non-biodegradable nature of many of these polymers leads to long-term accumulation in landfills and oceans, exacerbating pollution issues.

One of the primary environmental concerns is the persistence of microplastics derived from alkyl-based polymers. These tiny particles, often less than 5mm in size, have been found in marine ecosystems, freshwater systems, and even in the air we breathe. They can adsorb toxic chemicals and potentially enter the food chain, posing risks to wildlife and human health. The full extent of their impact is still being studied, but initial findings suggest far-reaching consequences for biodiversity and ecosystem health.

In response to these challenges, there is a growing trend towards developing more environmentally friendly alternatives. Biodegradable alkyl-based polymers are gaining traction, with researchers exploring ways to incorporate easily degradable linkages into the polymer backbone. These materials are designed to break down under specific environmental conditions, reducing their long-term impact on ecosystems.

Another emerging approach is the use of bio-based alkyl compounds in polymer synthesis. By sourcing alkyl groups from renewable resources such as plant oils or agricultural waste, the carbon footprint of polymer production can be significantly reduced. This shift towards sustainable feedstocks aligns with circular economy principles and helps mitigate the reliance on fossil fuels.

Recycling technologies for alkyl-based polymers are also advancing rapidly. Chemical recycling methods, such as pyrolysis and depolymerization, are being developed to break down these polymers into their constituent monomers or other valuable chemical feedstocks. This not only reduces waste but also creates a closed-loop system for polymer production, minimizing the need for virgin materials.

The environmental impact of alkyl-based polymers extends beyond their end-of-life considerations. Energy-efficient production processes and the use of green chemistry principles in polymer synthesis are becoming increasingly important. Researchers are exploring catalytic systems that enable polymerization reactions under milder conditions, reducing energy consumption and minimizing the use of harmful solvents.

As awareness of environmental issues grows, regulatory frameworks are evolving to address the challenges posed by alkyl-based polymers. Many countries are implementing stricter regulations on single-use plastics and setting targets for recycling and biodegradability. These policy changes are driving innovation in the polymer industry, pushing for more sustainable solutions and encouraging the development of environmentally benign materials.

One of the primary environmental concerns is the persistence of microplastics derived from alkyl-based polymers. These tiny particles, often less than 5mm in size, have been found in marine ecosystems, freshwater systems, and even in the air we breathe. They can adsorb toxic chemicals and potentially enter the food chain, posing risks to wildlife and human health. The full extent of their impact is still being studied, but initial findings suggest far-reaching consequences for biodiversity and ecosystem health.

In response to these challenges, there is a growing trend towards developing more environmentally friendly alternatives. Biodegradable alkyl-based polymers are gaining traction, with researchers exploring ways to incorporate easily degradable linkages into the polymer backbone. These materials are designed to break down under specific environmental conditions, reducing their long-term impact on ecosystems.

Another emerging approach is the use of bio-based alkyl compounds in polymer synthesis. By sourcing alkyl groups from renewable resources such as plant oils or agricultural waste, the carbon footprint of polymer production can be significantly reduced. This shift towards sustainable feedstocks aligns with circular economy principles and helps mitigate the reliance on fossil fuels.

Recycling technologies for alkyl-based polymers are also advancing rapidly. Chemical recycling methods, such as pyrolysis and depolymerization, are being developed to break down these polymers into their constituent monomers or other valuable chemical feedstocks. This not only reduces waste but also creates a closed-loop system for polymer production, minimizing the need for virgin materials.

The environmental impact of alkyl-based polymers extends beyond their end-of-life considerations. Energy-efficient production processes and the use of green chemistry principles in polymer synthesis are becoming increasingly important. Researchers are exploring catalytic systems that enable polymerization reactions under milder conditions, reducing energy consumption and minimizing the use of harmful solvents.

As awareness of environmental issues grows, regulatory frameworks are evolving to address the challenges posed by alkyl-based polymers. Many countries are implementing stricter regulations on single-use plastics and setting targets for recycling and biodegradability. These policy changes are driving innovation in the polymer industry, pushing for more sustainable solutions and encouraging the development of environmentally benign materials.

Regulatory Framework for Novel Polymer Materials

The regulatory framework for novel polymer materials is evolving rapidly to keep pace with emerging trends in alkyl compounds for polymer science. As new polymeric materials incorporating innovative alkyl compounds enter the market, regulatory bodies worldwide are adapting their guidelines to ensure safety, environmental protection, and sustainable development.

In the United States, the Environmental Protection Agency (EPA) has been proactive in addressing the regulatory challenges posed by novel polymer materials. The Toxic Substances Control Act (TSCA) has been updated to include specific provisions for polymers containing new alkyl compounds. These regulations focus on assessing the potential environmental and health impacts of these materials throughout their lifecycle.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to novel polymer materials incorporating alkyl compounds. REACH requires manufacturers and importers to provide detailed information on the properties and potential risks associated with these materials. The European Chemicals Agency (ECHA) has also established specific guidelines for polymers of low concern (PLC), which may include certain alkyl-based polymers.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for novel polymer materials. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both include provisions for assessing and managing the risks associated with new polymeric substances, including those containing innovative alkyl compounds.

International organizations, such as the Organization for Economic Co-operation and Development (OECD), have been working to harmonize regulatory approaches across different countries. The OECD's Guidelines for the Testing of Chemicals provide standardized methods for assessing the safety and environmental impact of novel polymer materials, including those incorporating alkyl compounds.

As the field of polymer science continues to advance, regulatory bodies are increasingly focusing on the concept of "safe-by-design" for novel materials. This approach encourages manufacturers to consider potential regulatory requirements and safety concerns from the early stages of material development. It aims to streamline the regulatory process and ensure that new polymeric materials are inherently safer and more environmentally friendly.

The regulatory landscape also reflects growing concerns about the environmental impact of polymers, particularly in terms of biodegradability and recyclability. Many jurisdictions are implementing regulations that promote the development of sustainable polymer materials, including those derived from renewable alkyl sources. These regulations often include incentives for manufacturers to prioritize eco-friendly designs and production processes.

In the United States, the Environmental Protection Agency (EPA) has been proactive in addressing the regulatory challenges posed by novel polymer materials. The Toxic Substances Control Act (TSCA) has been updated to include specific provisions for polymers containing new alkyl compounds. These regulations focus on assessing the potential environmental and health impacts of these materials throughout their lifecycle.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to novel polymer materials incorporating alkyl compounds. REACH requires manufacturers and importers to provide detailed information on the properties and potential risks associated with these materials. The European Chemicals Agency (ECHA) has also established specific guidelines for polymers of low concern (PLC), which may include certain alkyl-based polymers.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for novel polymer materials. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both include provisions for assessing and managing the risks associated with new polymeric substances, including those containing innovative alkyl compounds.

International organizations, such as the Organization for Economic Co-operation and Development (OECD), have been working to harmonize regulatory approaches across different countries. The OECD's Guidelines for the Testing of Chemicals provide standardized methods for assessing the safety and environmental impact of novel polymer materials, including those incorporating alkyl compounds.

As the field of polymer science continues to advance, regulatory bodies are increasingly focusing on the concept of "safe-by-design" for novel materials. This approach encourages manufacturers to consider potential regulatory requirements and safety concerns from the early stages of material development. It aims to streamline the regulatory process and ensure that new polymeric materials are inherently safer and more environmentally friendly.

The regulatory landscape also reflects growing concerns about the environmental impact of polymers, particularly in terms of biodegradability and recyclability. Many jurisdictions are implementing regulations that promote the development of sustainable polymer materials, including those derived from renewable alkyl sources. These regulations often include incentives for manufacturers to prioritize eco-friendly designs and production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!