Borosilicate Glass in Aerospace Structural Applications

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Glass Evolution

The evolution of aerospace glass has been a critical factor in the advancement of aircraft and spacecraft design. In the early days of aviation, glass was primarily used for windshields and small windows, with limited structural applications. The introduction of borosilicate glass in the mid-20th century marked a significant turning point in aerospace glass technology.

Borosilicate glass, known for its low thermal expansion coefficient and high resistance to thermal shock, quickly gained prominence in aerospace applications. Its superior properties allowed for larger and more complex glass structures in aircraft, improving visibility and reducing overall weight. The 1960s and 1970s saw a rapid increase in the use of borosilicate glass in cockpit windows and passenger cabin windows, enhancing both safety and passenger experience.

As space exploration began to take off, borosilicate glass found new applications in spacecraft design. It was used in viewing ports, protective shields, and even in the construction of space station windows. The ability of borosilicate glass to withstand extreme temperature fluctuations and resist radiation made it an ideal material for these challenging environments.

The 1980s and 1990s brought further advancements in glass technology for aerospace applications. Chemically strengthened borosilicate glass was developed, offering even greater strength and impact resistance. This innovation allowed for the design of larger, more aerodynamic windshields and reduced the need for heavy supporting structures.

In recent years, the focus has shifted towards developing multi-functional aerospace glass. Modern borosilicate glass compositions incorporate additional properties such as electromagnetic shielding, de-icing capabilities, and even display integration. These advancements have led to the creation of "smart" windows that can adjust their transparency or display flight information directly on the glass surface.

The ongoing evolution of aerospace glass continues to push the boundaries of what is possible in aircraft and spacecraft design. Current research is exploring the potential of ultra-thin borosilicate glass laminates that offer exceptional strength-to-weight ratios, as well as the integration of advanced coatings to enhance durability and functionality. As aerospace technology progresses, the role of borosilicate glass in structural applications is expected to expand further, contributing to lighter, safer, and more efficient aerospace vehicles.

Borosilicate glass, known for its low thermal expansion coefficient and high resistance to thermal shock, quickly gained prominence in aerospace applications. Its superior properties allowed for larger and more complex glass structures in aircraft, improving visibility and reducing overall weight. The 1960s and 1970s saw a rapid increase in the use of borosilicate glass in cockpit windows and passenger cabin windows, enhancing both safety and passenger experience.

As space exploration began to take off, borosilicate glass found new applications in spacecraft design. It was used in viewing ports, protective shields, and even in the construction of space station windows. The ability of borosilicate glass to withstand extreme temperature fluctuations and resist radiation made it an ideal material for these challenging environments.

The 1980s and 1990s brought further advancements in glass technology for aerospace applications. Chemically strengthened borosilicate glass was developed, offering even greater strength and impact resistance. This innovation allowed for the design of larger, more aerodynamic windshields and reduced the need for heavy supporting structures.

In recent years, the focus has shifted towards developing multi-functional aerospace glass. Modern borosilicate glass compositions incorporate additional properties such as electromagnetic shielding, de-icing capabilities, and even display integration. These advancements have led to the creation of "smart" windows that can adjust their transparency or display flight information directly on the glass surface.

The ongoing evolution of aerospace glass continues to push the boundaries of what is possible in aircraft and spacecraft design. Current research is exploring the potential of ultra-thin borosilicate glass laminates that offer exceptional strength-to-weight ratios, as well as the integration of advanced coatings to enhance durability and functionality. As aerospace technology progresses, the role of borosilicate glass in structural applications is expected to expand further, contributing to lighter, safer, and more efficient aerospace vehicles.

Market Demand Analysis

The aerospace industry has shown a growing demand for advanced materials that can withstand extreme conditions while offering superior performance characteristics. Borosilicate glass, with its unique properties, has emerged as a promising candidate for structural applications in aerospace engineering. The market for borosilicate glass in this sector is driven by several key factors.

Firstly, the increasing focus on lightweight materials in aerospace design has created a significant opportunity for borosilicate glass. As aircraft manufacturers strive to improve fuel efficiency and reduce emissions, the low density of borosilicate glass compared to traditional structural materials makes it an attractive option. This trend is expected to continue, with the global market for lightweight materials in aerospace projected to grow steadily over the next decade.

Secondly, the thermal properties of borosilicate glass align well with the demanding requirements of aerospace applications. Its low coefficient of thermal expansion and excellent resistance to thermal shock make it suitable for components exposed to rapid temperature changes, such as windows, sensor housings, and heat shields. The increasing use of advanced avionics and sensor systems in modern aircraft and spacecraft is likely to drive further demand for borosilicate glass in these applications.

The space exploration sector represents another significant market opportunity for borosilicate glass. As both government space agencies and private companies invest in new missions and technologies, the demand for materials that can withstand the harsh conditions of space is expected to rise. Borosilicate glass's resistance to radiation and its ability to maintain optical clarity in extreme environments make it a valuable material for spacecraft windows, optical systems, and scientific instruments.

In the commercial aviation sector, the growing emphasis on passenger comfort and experience is creating new applications for borosilicate glass. Its use in larger, more complex window designs and in-flight entertainment systems is expected to increase, driven by airlines' efforts to differentiate their offerings and improve the overall flying experience.

The defense aerospace market also presents substantial opportunities for borosilicate glass applications. The material's durability and resistance to chemical attack make it suitable for use in military aircraft, unmanned aerial vehicles (UAVs), and missile systems. As defense budgets in many countries continue to prioritize advanced aerospace technologies, the demand for high-performance materials like borosilicate glass is likely to grow.

However, it's important to note that the market for borosilicate glass in aerospace structural applications faces competition from other advanced materials, such as advanced composites and ceramics. The ability of borosilicate glass to compete effectively will depend on ongoing research and development efforts to enhance its properties and develop new manufacturing techniques that can reduce production costs and improve scalability.

Firstly, the increasing focus on lightweight materials in aerospace design has created a significant opportunity for borosilicate glass. As aircraft manufacturers strive to improve fuel efficiency and reduce emissions, the low density of borosilicate glass compared to traditional structural materials makes it an attractive option. This trend is expected to continue, with the global market for lightweight materials in aerospace projected to grow steadily over the next decade.

Secondly, the thermal properties of borosilicate glass align well with the demanding requirements of aerospace applications. Its low coefficient of thermal expansion and excellent resistance to thermal shock make it suitable for components exposed to rapid temperature changes, such as windows, sensor housings, and heat shields. The increasing use of advanced avionics and sensor systems in modern aircraft and spacecraft is likely to drive further demand for borosilicate glass in these applications.

The space exploration sector represents another significant market opportunity for borosilicate glass. As both government space agencies and private companies invest in new missions and technologies, the demand for materials that can withstand the harsh conditions of space is expected to rise. Borosilicate glass's resistance to radiation and its ability to maintain optical clarity in extreme environments make it a valuable material for spacecraft windows, optical systems, and scientific instruments.

In the commercial aviation sector, the growing emphasis on passenger comfort and experience is creating new applications for borosilicate glass. Its use in larger, more complex window designs and in-flight entertainment systems is expected to increase, driven by airlines' efforts to differentiate their offerings and improve the overall flying experience.

The defense aerospace market also presents substantial opportunities for borosilicate glass applications. The material's durability and resistance to chemical attack make it suitable for use in military aircraft, unmanned aerial vehicles (UAVs), and missile systems. As defense budgets in many countries continue to prioritize advanced aerospace technologies, the demand for high-performance materials like borosilicate glass is likely to grow.

However, it's important to note that the market for borosilicate glass in aerospace structural applications faces competition from other advanced materials, such as advanced composites and ceramics. The ability of borosilicate glass to compete effectively will depend on ongoing research and development efforts to enhance its properties and develop new manufacturing techniques that can reduce production costs and improve scalability.

Borosilicate Challenges

Despite the numerous advantages of borosilicate glass in aerospace applications, several significant challenges persist in its widespread adoption and optimal utilization. One of the primary concerns is the material's inherent brittleness, which makes it susceptible to sudden failure under extreme stress conditions often encountered in aerospace environments. This characteristic necessitates careful design considerations and protective measures to mitigate the risk of catastrophic failure during mission-critical operations.

Another challenge lies in the manufacturing process of borosilicate glass components for aerospace structures. The production of large, complex shapes with consistent properties and minimal defects remains a technical hurdle. Achieving the required precision and uniformity in thickness, composition, and thermal properties across sizeable glass components is particularly demanding. This challenge is further compounded by the need for scalable and cost-effective manufacturing techniques that can meet the stringent quality standards of the aerospace industry.

The integration of borosilicate glass with other materials in composite structures presents additional complexities. Ensuring strong and durable bonds between glass and metal or polymer components, while accommodating differences in thermal expansion coefficients, is a significant engineering challenge. This integration issue extends to the development of effective sealing and joining techniques that can withstand the extreme temperature fluctuations and mechanical stresses typical in aerospace applications.

Thermal management is another critical challenge in the use of borosilicate glass for aerospace structures. While the material exhibits excellent thermal shock resistance, managing heat distribution and dissipation in complex glass structures under varying operational conditions remains a complex task. Engineers must develop innovative solutions to prevent localized thermal stresses that could compromise the integrity of the glass components.

Furthermore, the long-term durability and reliability of borosilicate glass in the harsh space environment pose ongoing challenges. Exposure to radiation, micrometeoroid impacts, and atomic oxygen can potentially degrade the material's properties over time. Developing protective coatings or surface treatments that can enhance the glass's resistance to these environmental factors without compromising its optical and structural properties is an area of active research and development.

Lastly, the aerospace industry faces challenges in standardization and certification processes for borosilicate glass components. Establishing comprehensive testing protocols and performance criteria that accurately predict the behavior of glass structures under the full range of operational conditions is crucial for widespread adoption. This includes developing non-destructive evaluation techniques for quality assurance and in-service inspection of glass components in aerospace structures.

Another challenge lies in the manufacturing process of borosilicate glass components for aerospace structures. The production of large, complex shapes with consistent properties and minimal defects remains a technical hurdle. Achieving the required precision and uniformity in thickness, composition, and thermal properties across sizeable glass components is particularly demanding. This challenge is further compounded by the need for scalable and cost-effective manufacturing techniques that can meet the stringent quality standards of the aerospace industry.

The integration of borosilicate glass with other materials in composite structures presents additional complexities. Ensuring strong and durable bonds between glass and metal or polymer components, while accommodating differences in thermal expansion coefficients, is a significant engineering challenge. This integration issue extends to the development of effective sealing and joining techniques that can withstand the extreme temperature fluctuations and mechanical stresses typical in aerospace applications.

Thermal management is another critical challenge in the use of borosilicate glass for aerospace structures. While the material exhibits excellent thermal shock resistance, managing heat distribution and dissipation in complex glass structures under varying operational conditions remains a complex task. Engineers must develop innovative solutions to prevent localized thermal stresses that could compromise the integrity of the glass components.

Furthermore, the long-term durability and reliability of borosilicate glass in the harsh space environment pose ongoing challenges. Exposure to radiation, micrometeoroid impacts, and atomic oxygen can potentially degrade the material's properties over time. Developing protective coatings or surface treatments that can enhance the glass's resistance to these environmental factors without compromising its optical and structural properties is an area of active research and development.

Lastly, the aerospace industry faces challenges in standardization and certification processes for borosilicate glass components. Establishing comprehensive testing protocols and performance criteria that accurately predict the behavior of glass structures under the full range of operational conditions is crucial for widespread adoption. This includes developing non-destructive evaluation techniques for quality assurance and in-service inspection of glass components in aerospace structures.

Current Glass Solutions

01 Composition and properties of borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.

- Applications of borosilicate glass in laboratory and industrial settings: Borosilicate glass finds extensive use in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also used in industrial applications, including sight glasses, level gauges, and process vessels in chemical and pharmaceutical industries.

- Borosilicate glass in consumer products: Borosilicate glass is widely used in consumer products, particularly in cookware and bakeware. Its low thermal expansion makes it resistant to thermal shock, allowing it to go from freezer to oven safely. It is also used in high-quality drinking glasses, coffee makers, and storage containers.

- Innovations and modifications in borosilicate glass: Ongoing research and development in borosilicate glass focus on improving its properties and expanding its applications. This includes developing specialized coatings, creating composite materials, and modifying the glass composition to enhance specific characteristics such as optical properties, strength, or biocompatibility.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process can be optimized to enhance specific properties of the glass.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and industrial settings

Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including chemical processing equipment, sight glasses, and high-temperature windows. The glass's durability and transparency make it ideal for these demanding environments.Expand Specific Solutions04 Borosilicate glass in consumer products

Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and home appliances. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The glass is also used in lighting fixtures and solar energy applications due to its optical properties and thermal performance.Expand Specific Solutions05 Innovations and modifications in borosilicate glass

Ongoing research focuses on improving the properties of borosilicate glass through composition modifications and novel processing techniques. This includes developing specialized coatings, enhancing strength and impact resistance, and creating composite materials. These innovations aim to expand the glass's applications in areas such as electronics, aerospace, and medical devices.Expand Specific Solutions

Aerospace Glass Players

The research on borosilicate glass in aerospace structural applications is in a mature stage, with a significant market presence and ongoing innovation. The global market for aerospace-grade borosilicate glass is substantial, driven by the material's unique properties such as thermal stability and low coefficient of expansion. Key players like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. have established themselves as industry leaders, leveraging decades of experience in glass technology. These companies are continuously advancing the material's capabilities, focusing on improving strength, durability, and weight reduction for aerospace applications. The competitive landscape is characterized by a mix of established glass manufacturers and specialized aerospace material suppliers, with ongoing research and development efforts to meet the evolving demands of the aerospace industry.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass solutions for aerospace applications, focusing on high-performance materials that can withstand extreme conditions. Their BOROFLOAT® glass, a borosilicate float glass, offers exceptional thermal and chemical resistance, making it suitable for aerospace structural components[1]. SCHOTT has also engineered specialized coatings and surface treatments to enhance the glass's mechanical strength and optical properties. The company's research includes developing glass-ceramic composites that combine the transparency of glass with the durability of ceramics, potentially revolutionizing aerospace window and sensor cover designs[2].

Strengths: Extensive experience in specialized glass manufacturing, strong R&D capabilities, and a wide range of aerospace-specific products. Weaknesses: High production costs and potential limitations in scaling up production for large aerospace structures.

Corning, Inc.

Technical Solution: Corning has made significant strides in borosilicate glass research for aerospace applications, leveraging its expertise in glass science and ceramic technologies. The company has developed Corning® Gorilla® Glass for Aerospace, a chemically strengthened glass that offers superior damage resistance and optical clarity[3]. Corning's research focuses on improving the glass's strength-to-weight ratio, crucial for aerospace applications. They have also explored innovative forming techniques to create complex shapes while maintaining the glass's structural integrity. Additionally, Corning is investigating the integration of smart glass technologies, such as electrochromic properties, into aerospace-grade borosilicate glass for advanced cockpit displays and windows[4].

Strengths: Strong brand recognition, extensive R&D resources, and a history of innovation in glass technologies. Weaknesses: May face challenges in adapting consumer-focused technologies to meet stringent aerospace standards.

Key Borosilicate Patents

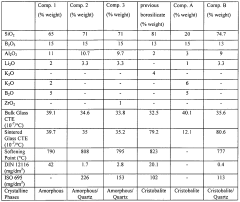

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

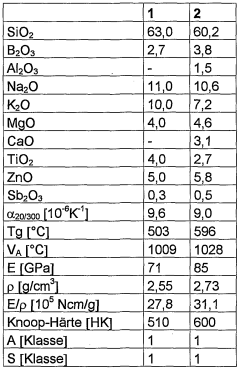

Borosilicate glass containing zinc oxide

PatentWO2002051764A2

Innovation

- Borosilicate glasses containing specific compositions such as 58-67% SiO2, 1-5% B2O3, up to 5% Al2O3, 8-17% Na2O, 3-12% MgO, 1-5% TiO2, and 2-8% ZnO, without Li2O, BaO, or P2O5, which enhance mechanical strength, chemical resistance, and crystallization stability, allowing for economical production and high-quality surface finishing.

Aerospace Regulations

The aerospace industry operates under stringent regulations to ensure the safety and reliability of aircraft and spacecraft. When considering the use of borosilicate glass in aerospace structural applications, it is crucial to understand and comply with the relevant regulatory frameworks. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are two primary regulatory bodies that oversee aerospace safety standards.

FAA regulations, particularly those outlined in Title 14 of the Code of Federal Regulations (14 CFR), provide comprehensive guidelines for aircraft design, manufacturing, and maintenance. Part 25 of 14 CFR specifically addresses airworthiness standards for transport category airplanes. When incorporating borosilicate glass into aerospace structures, manufacturers must demonstrate compliance with these regulations, including requirements for structural integrity, fire resistance, and impact resistance.

EASA regulations, similarly, set forth certification specifications (CS) for various aircraft categories. CS-25 for large aeroplanes contains requirements applicable to the use of materials in aircraft structures. Borosilicate glass applications must meet these standards, which cover aspects such as material properties, durability, and performance under various environmental conditions.

In addition to these general regulations, specific standards related to transparent materials in aerospace applications are relevant. For instance, MIL-G-25871 provides military specifications for glass windshields used in aircraft. While this standard primarily focuses on laminated glass, it offers insights into the performance requirements that borosilicate glass may need to meet in certain applications.

The SAE International, formerly known as the Society of Automotive Engineers, has developed aerospace material specifications (AMS) that are widely recognized in the industry. AMS 2180 addresses heat-resistant glasses, which may be applicable to borosilicate glass used in high-temperature aerospace environments.

Compliance with these regulations and standards requires extensive testing and documentation. Manufacturers must conduct a range of tests to verify the material's properties and performance under various conditions, including extreme temperatures, pressure differentials, and impact scenarios. The results of these tests must be thoroughly documented and submitted to the relevant regulatory authorities as part of the certification process.

It is important to note that regulations are subject to periodic updates and revisions. Aerospace companies and researchers working with borosilicate glass must stay informed about any changes in regulatory requirements and adjust their development and certification processes accordingly. This ongoing compliance ensures that the use of borosilicate glass in aerospace structural applications meets the highest safety standards and contributes to the overall reliability of aircraft and spacecraft.

FAA regulations, particularly those outlined in Title 14 of the Code of Federal Regulations (14 CFR), provide comprehensive guidelines for aircraft design, manufacturing, and maintenance. Part 25 of 14 CFR specifically addresses airworthiness standards for transport category airplanes. When incorporating borosilicate glass into aerospace structures, manufacturers must demonstrate compliance with these regulations, including requirements for structural integrity, fire resistance, and impact resistance.

EASA regulations, similarly, set forth certification specifications (CS) for various aircraft categories. CS-25 for large aeroplanes contains requirements applicable to the use of materials in aircraft structures. Borosilicate glass applications must meet these standards, which cover aspects such as material properties, durability, and performance under various environmental conditions.

In addition to these general regulations, specific standards related to transparent materials in aerospace applications are relevant. For instance, MIL-G-25871 provides military specifications for glass windshields used in aircraft. While this standard primarily focuses on laminated glass, it offers insights into the performance requirements that borosilicate glass may need to meet in certain applications.

The SAE International, formerly known as the Society of Automotive Engineers, has developed aerospace material specifications (AMS) that are widely recognized in the industry. AMS 2180 addresses heat-resistant glasses, which may be applicable to borosilicate glass used in high-temperature aerospace environments.

Compliance with these regulations and standards requires extensive testing and documentation. Manufacturers must conduct a range of tests to verify the material's properties and performance under various conditions, including extreme temperatures, pressure differentials, and impact scenarios. The results of these tests must be thoroughly documented and submitted to the relevant regulatory authorities as part of the certification process.

It is important to note that regulations are subject to periodic updates and revisions. Aerospace companies and researchers working with borosilicate glass must stay informed about any changes in regulatory requirements and adjust their development and certification processes accordingly. This ongoing compliance ensures that the use of borosilicate glass in aerospace structural applications meets the highest safety standards and contributes to the overall reliability of aircraft and spacecraft.

Environmental Impact

The environmental impact of borosilicate glass in aerospace structural applications is a critical consideration in the industry's pursuit of sustainable and eco-friendly technologies. Borosilicate glass, known for its exceptional thermal and chemical resistance, offers significant advantages in aerospace applications. However, its production and lifecycle present both challenges and opportunities from an environmental perspective.

The manufacturing process of borosilicate glass requires high temperatures, typically around 1,600°C, which results in substantial energy consumption and associated greenhouse gas emissions. This energy-intensive production contributes to the carbon footprint of aerospace components. However, when compared to alternative materials like certain metals or advanced composites, borosilicate glass often has a lower overall environmental impact due to its longevity and recyclability.

Borosilicate glass's durability and resistance to thermal shock make it an excellent choice for long-lasting aerospace components. This extended lifespan reduces the need for frequent replacements, ultimately decreasing waste generation and resource consumption over time. Additionally, the material's ability to withstand extreme temperatures and harsh environments contributes to improved fuel efficiency in aerospace vehicles, indirectly reducing emissions during operation.

The recyclability of borosilicate glass is another significant environmental advantage. Unlike some composite materials used in aerospace, borosilicate glass can be fully recycled without loss of quality. This closed-loop recycling potential minimizes waste and reduces the demand for raw materials in future production cycles. However, the specialized nature of aerospace components may present challenges in establishing efficient recycling streams within the industry.

In terms of raw material extraction, borosilicate glass primarily consists of silica, boron oxide, and other minerals. While these materials are generally abundant, their mining and processing can have localized environmental impacts, including habitat disruption and water usage. Responsible sourcing and sustainable mining practices are crucial to mitigate these effects.

The use of borosilicate glass in aerospace applications also contributes to weight reduction in aircraft and spacecraft. Lighter vehicles require less fuel, leading to reduced emissions during operation. This indirect environmental benefit is particularly significant given the long operational life of aerospace vehicles.

As the aerospace industry continues to prioritize sustainability, ongoing research focuses on improving the energy efficiency of borosilicate glass production and exploring bio-based alternatives for certain components. These efforts aim to further reduce the environmental footprint of aerospace materials while maintaining the high performance standards required in this demanding sector.

The manufacturing process of borosilicate glass requires high temperatures, typically around 1,600°C, which results in substantial energy consumption and associated greenhouse gas emissions. This energy-intensive production contributes to the carbon footprint of aerospace components. However, when compared to alternative materials like certain metals or advanced composites, borosilicate glass often has a lower overall environmental impact due to its longevity and recyclability.

Borosilicate glass's durability and resistance to thermal shock make it an excellent choice for long-lasting aerospace components. This extended lifespan reduces the need for frequent replacements, ultimately decreasing waste generation and resource consumption over time. Additionally, the material's ability to withstand extreme temperatures and harsh environments contributes to improved fuel efficiency in aerospace vehicles, indirectly reducing emissions during operation.

The recyclability of borosilicate glass is another significant environmental advantage. Unlike some composite materials used in aerospace, borosilicate glass can be fully recycled without loss of quality. This closed-loop recycling potential minimizes waste and reduces the demand for raw materials in future production cycles. However, the specialized nature of aerospace components may present challenges in establishing efficient recycling streams within the industry.

In terms of raw material extraction, borosilicate glass primarily consists of silica, boron oxide, and other minerals. While these materials are generally abundant, their mining and processing can have localized environmental impacts, including habitat disruption and water usage. Responsible sourcing and sustainable mining practices are crucial to mitigate these effects.

The use of borosilicate glass in aerospace applications also contributes to weight reduction in aircraft and spacecraft. Lighter vehicles require less fuel, leading to reduced emissions during operation. This indirect environmental benefit is particularly significant given the long operational life of aerospace vehicles.

As the aerospace industry continues to prioritize sustainability, ongoing research focuses on improving the energy efficiency of borosilicate glass production and exploring bio-based alternatives for certain components. These efforts aim to further reduce the environmental footprint of aerospace materials while maintaining the high performance standards required in this demanding sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!