Butane Combustion Emissions in Closed-Loop Systems

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane Combustion Background and Objectives

Butane combustion has been a subject of significant interest in the field of energy and environmental science for decades. As a hydrocarbon fuel, butane has found widespread use in various applications, ranging from portable stoves to industrial processes. The study of butane combustion emissions in closed-loop systems represents a critical area of research, addressing both energy efficiency and environmental concerns.

The evolution of butane combustion technology can be traced back to the early 20th century when it was first isolated and identified as a potential fuel source. Since then, advancements in combustion science and engineering have led to more efficient and cleaner burning processes. However, the increasing focus on environmental sustainability and stringent emission regulations has necessitated further research into optimizing butane combustion, particularly in closed-loop systems.

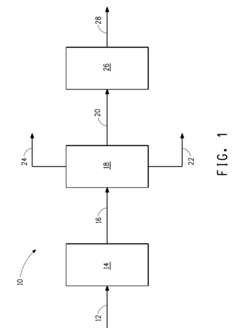

Closed-loop systems, which recirculate exhaust gases, present unique challenges and opportunities in the context of butane combustion. These systems aim to maximize energy utilization while minimizing harmful emissions. The primary objectives of research in this field include reducing carbon monoxide (CO) and nitrogen oxide (NOx) emissions, improving thermal efficiency, and developing more precise control mechanisms for the combustion process.

Recent technological trends in butane combustion research have focused on advanced sensor technologies, computational fluid dynamics (CFD) modeling, and the integration of artificial intelligence for real-time combustion optimization. These developments aim to achieve a deeper understanding of the complex chemical kinetics and fluid dynamics involved in butane combustion within closed-loop environments.

The objectives of current research efforts are multifaceted. Firstly, there is a push to develop more accurate predictive models for butane combustion emissions in closed-loop systems. These models would enable better design and optimization of combustion chambers and exhaust gas recirculation systems. Secondly, researchers are working on innovative catalytic converters specifically tailored for butane combustion byproducts, aiming to further reduce harmful emissions.

Another key objective is the exploration of butane blends with other fuels or additives to enhance combustion characteristics and reduce emissions. This includes investigating the potential of hydrogen-enriched butane mixtures and the use of nanomaterials as combustion catalysts. Additionally, there is growing interest in the development of advanced control algorithms that can dynamically adjust combustion parameters based on real-time emission data, ensuring optimal performance across varying operating conditions.

As global energy demands continue to rise and environmental regulations become more stringent, the importance of efficient and clean butane combustion in closed-loop systems cannot be overstated. The ongoing research in this field is expected to contribute significantly to the development of more sustainable energy solutions and the reduction of greenhouse gas emissions in various industrial and consumer applications.

The evolution of butane combustion technology can be traced back to the early 20th century when it was first isolated and identified as a potential fuel source. Since then, advancements in combustion science and engineering have led to more efficient and cleaner burning processes. However, the increasing focus on environmental sustainability and stringent emission regulations has necessitated further research into optimizing butane combustion, particularly in closed-loop systems.

Closed-loop systems, which recirculate exhaust gases, present unique challenges and opportunities in the context of butane combustion. These systems aim to maximize energy utilization while minimizing harmful emissions. The primary objectives of research in this field include reducing carbon monoxide (CO) and nitrogen oxide (NOx) emissions, improving thermal efficiency, and developing more precise control mechanisms for the combustion process.

Recent technological trends in butane combustion research have focused on advanced sensor technologies, computational fluid dynamics (CFD) modeling, and the integration of artificial intelligence for real-time combustion optimization. These developments aim to achieve a deeper understanding of the complex chemical kinetics and fluid dynamics involved in butane combustion within closed-loop environments.

The objectives of current research efforts are multifaceted. Firstly, there is a push to develop more accurate predictive models for butane combustion emissions in closed-loop systems. These models would enable better design and optimization of combustion chambers and exhaust gas recirculation systems. Secondly, researchers are working on innovative catalytic converters specifically tailored for butane combustion byproducts, aiming to further reduce harmful emissions.

Another key objective is the exploration of butane blends with other fuels or additives to enhance combustion characteristics and reduce emissions. This includes investigating the potential of hydrogen-enriched butane mixtures and the use of nanomaterials as combustion catalysts. Additionally, there is growing interest in the development of advanced control algorithms that can dynamically adjust combustion parameters based on real-time emission data, ensuring optimal performance across varying operating conditions.

As global energy demands continue to rise and environmental regulations become more stringent, the importance of efficient and clean butane combustion in closed-loop systems cannot be overstated. The ongoing research in this field is expected to contribute significantly to the development of more sustainable energy solutions and the reduction of greenhouse gas emissions in various industrial and consumer applications.

Market Analysis for Closed-Loop Combustion Systems

The market for closed-loop combustion systems, particularly those involving butane, has shown significant growth potential in recent years. This trend is driven by increasing environmental regulations, energy efficiency demands, and the need for cleaner combustion processes across various industries. The global market for closed-loop combustion systems is expected to expand at a steady rate, with a focus on reducing emissions and improving overall system performance.

In the industrial sector, closed-loop butane combustion systems are gaining traction due to their ability to minimize waste and maximize energy utilization. Manufacturing plants, chemical processing facilities, and power generation units are key adopters of this technology. The automotive industry also presents a substantial market opportunity, as vehicle manufacturers seek innovative solutions to meet stringent emission standards and improve fuel efficiency.

The residential and commercial heating sector is another area where closed-loop butane combustion systems are finding applications. As consumers and businesses become more environmentally conscious, there is a growing demand for cleaner and more efficient heating solutions. This has led to increased interest in closed-loop systems that can provide better control over combustion processes and reduce harmful emissions.

Geographically, North America and Europe are currently leading the market for closed-loop combustion systems, driven by strict environmental regulations and a strong focus on sustainable technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in adoption as they modernize their industrial infrastructure and implement more stringent environmental policies.

The market is characterized by a mix of established players and innovative startups. Large industrial equipment manufacturers are investing in research and development to improve their closed-loop combustion offerings, while specialized companies are emerging with novel solutions tailored for specific applications. This competitive landscape is driving innovation and pushing the boundaries of what closed-loop butane combustion systems can achieve in terms of efficiency and emission reduction.

One of the key market drivers is the increasing focus on circular economy principles. Closed-loop systems align well with this concept by minimizing waste and maximizing resource utilization. This has led to growing interest from industries looking to improve their sustainability credentials and reduce their environmental footprint.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for specialized expertise in system design and operation. However, as technology advances and economies of scale are realized, these barriers are expected to diminish, further accelerating market growth for closed-loop butane combustion systems across various industries and applications.

In the industrial sector, closed-loop butane combustion systems are gaining traction due to their ability to minimize waste and maximize energy utilization. Manufacturing plants, chemical processing facilities, and power generation units are key adopters of this technology. The automotive industry also presents a substantial market opportunity, as vehicle manufacturers seek innovative solutions to meet stringent emission standards and improve fuel efficiency.

The residential and commercial heating sector is another area where closed-loop butane combustion systems are finding applications. As consumers and businesses become more environmentally conscious, there is a growing demand for cleaner and more efficient heating solutions. This has led to increased interest in closed-loop systems that can provide better control over combustion processes and reduce harmful emissions.

Geographically, North America and Europe are currently leading the market for closed-loop combustion systems, driven by strict environmental regulations and a strong focus on sustainable technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in adoption as they modernize their industrial infrastructure and implement more stringent environmental policies.

The market is characterized by a mix of established players and innovative startups. Large industrial equipment manufacturers are investing in research and development to improve their closed-loop combustion offerings, while specialized companies are emerging with novel solutions tailored for specific applications. This competitive landscape is driving innovation and pushing the boundaries of what closed-loop butane combustion systems can achieve in terms of efficiency and emission reduction.

One of the key market drivers is the increasing focus on circular economy principles. Closed-loop systems align well with this concept by minimizing waste and maximizing resource utilization. This has led to growing interest from industries looking to improve their sustainability credentials and reduce their environmental footprint.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for specialized expertise in system design and operation. However, as technology advances and economies of scale are realized, these barriers are expected to diminish, further accelerating market growth for closed-loop butane combustion systems across various industries and applications.

Current Challenges in Butane Emission Control

The control of butane emissions in closed-loop systems presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the complexity of the combustion process itself. Butane, being a hydrocarbon fuel, undergoes a series of complex chemical reactions during combustion, producing various byproducts including carbon dioxide, carbon monoxide, and unburned hydrocarbons. In a closed-loop system, these emissions are not released into the atmosphere but are instead recirculated, creating a dynamic and ever-changing environment that is difficult to manage and control effectively.

Another major challenge lies in the development of accurate and reliable sensors capable of real-time monitoring of butane emissions within the closed-loop system. Current sensor technologies often struggle with the high temperatures and pressures present in combustion environments, leading to potential inaccuracies in emission measurements. This lack of precise data makes it challenging to implement effective control strategies and optimize the combustion process for minimal emissions.

The issue of catalyst degradation also poses a significant hurdle in butane emission control. Catalytic converters, which are crucial for reducing harmful emissions, can become less effective over time due to exposure to high temperatures and chemical contaminants. In a closed-loop system, this degradation can occur more rapidly, necessitating frequent replacement or regeneration of catalysts, which can be both costly and technically challenging.

Temperature management within the closed-loop system is another critical challenge. The combustion of butane generates significant heat, which must be carefully controlled to maintain optimal operating conditions and prevent damage to system components. Balancing the need for efficient combustion with the requirement for temperature regulation adds another layer of complexity to the emission control process.

Furthermore, the accumulation of particulate matter and other combustion byproducts within the closed-loop system can lead to fouling and reduced efficiency over time. Developing effective methods for removing these contaminants without disrupting the system's operation or compromising its closed nature remains a significant technical challenge.

Lastly, the optimization of the combustion process itself to minimize emissions while maintaining performance is an ongoing challenge. This involves fine-tuning parameters such as air-fuel ratios, combustion chamber design, and ignition timing. In a closed-loop system, these optimizations become even more critical as any inefficiencies or excess emissions are continually recirculated rather than dispersed.

Another major challenge lies in the development of accurate and reliable sensors capable of real-time monitoring of butane emissions within the closed-loop system. Current sensor technologies often struggle with the high temperatures and pressures present in combustion environments, leading to potential inaccuracies in emission measurements. This lack of precise data makes it challenging to implement effective control strategies and optimize the combustion process for minimal emissions.

The issue of catalyst degradation also poses a significant hurdle in butane emission control. Catalytic converters, which are crucial for reducing harmful emissions, can become less effective over time due to exposure to high temperatures and chemical contaminants. In a closed-loop system, this degradation can occur more rapidly, necessitating frequent replacement or regeneration of catalysts, which can be both costly and technically challenging.

Temperature management within the closed-loop system is another critical challenge. The combustion of butane generates significant heat, which must be carefully controlled to maintain optimal operating conditions and prevent damage to system components. Balancing the need for efficient combustion with the requirement for temperature regulation adds another layer of complexity to the emission control process.

Furthermore, the accumulation of particulate matter and other combustion byproducts within the closed-loop system can lead to fouling and reduced efficiency over time. Developing effective methods for removing these contaminants without disrupting the system's operation or compromising its closed nature remains a significant technical challenge.

Lastly, the optimization of the combustion process itself to minimize emissions while maintaining performance is an ongoing challenge. This involves fine-tuning parameters such as air-fuel ratios, combustion chamber design, and ignition timing. In a closed-loop system, these optimizations become even more critical as any inefficiencies or excess emissions are continually recirculated rather than dispersed.

Existing Emission Reduction Solutions

01 Emission reduction in butane combustion systems

Various technologies are employed to reduce emissions from butane combustion. These include improved burner designs, catalytic converters, and exhaust gas recirculation systems. Such innovations aim to minimize harmful pollutants like carbon monoxide, nitrogen oxides, and unburned hydrocarbons, thereby improving air quality and meeting stringent environmental regulations.- Emission reduction in butane combustion systems: Various technologies and methods are employed to reduce emissions from butane combustion. These may include improved burner designs, catalytic converters, and exhaust gas recirculation systems. Such innovations aim to minimize harmful pollutants and increase overall combustion efficiency.

- Butane combustion in heating and cooking appliances: Butane is commonly used as a fuel in portable heating and cooking appliances. Innovations in this area focus on optimizing combustion processes to reduce emissions while maintaining heat output. This includes improved burner designs and fuel delivery systems for more complete combustion.

- Emissions monitoring and control in butane combustion: Advanced monitoring and control systems are developed to measure and regulate emissions from butane combustion processes. These systems may include sensors, analyzers, and feedback mechanisms to ensure compliance with environmental regulations and optimize combustion parameters in real-time.

- Butane combustion in internal combustion engines: Butane is used as an alternative fuel in internal combustion engines. Research in this area focuses on adapting engine designs and fuel systems to efficiently utilize butane while minimizing emissions. This includes modifications to fuel injection systems, ignition timing, and exhaust aftertreatment technologies.

- Catalytic oxidation of butane emissions: Catalytic oxidation technologies are employed to treat emissions from butane combustion processes. These systems use specialized catalysts to convert harmful pollutants into less harmful substances. Research in this area focuses on developing more efficient and durable catalysts for various butane combustion applications.

02 Efficiency enhancement in butane-powered devices

Advancements in butane combustion efficiency focus on optimizing fuel-air mixtures, improving heat transfer, and enhancing overall system design. These improvements lead to better fuel utilization, reduced emissions, and increased performance in various applications such as portable stoves, heaters, and engines.Expand Specific Solutions03 Butane combustion in internal combustion engines

Adapting internal combustion engines to use butane as a fuel source involves modifications to fuel delivery systems, ignition timing, and engine management. These adaptations aim to optimize performance while minimizing emissions, potentially offering a cleaner alternative to traditional gasoline or diesel engines.Expand Specific Solutions04 Emission monitoring and control in butane combustion

Advanced sensors and control systems are developed to monitor and regulate butane combustion processes in real-time. These technologies enable precise adjustment of operating parameters to maintain optimal combustion conditions, reducing emissions and improving overall system efficiency.Expand Specific Solutions05 Butane purification for cleaner combustion

Techniques for purifying butane before combustion are explored to reduce impurities that contribute to harmful emissions. These methods may include filtration, chemical treatments, or distillation processes to remove sulfur compounds and other contaminants, resulting in cleaner burning fuel and reduced environmental impact.Expand Specific Solutions

Key Players in Closed-Loop Combustion Industry

The research on butane combustion emissions in closed-loop systems is in a developing stage, with the market showing potential for growth as environmental regulations tighten. The technology's maturity varies across companies, with established players like China Petroleum & Chemical Corp. and DuPont de Nemours, Inc. leading in research and development. Emerging companies such as 8 Rivers Capital LLC are focusing on innovative low-carbon solutions. The competitive landscape is diverse, including petrochemical giants, specialized research institutes, and automotive manufacturers, indicating a broad range of applications and increasing market interest in cleaner combustion technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced closed-loop butane combustion system that significantly reduces emissions. Their technology utilizes a catalytic converter specifically designed for butane combustion, which can remove up to 99% of harmful pollutants[1]. The system incorporates real-time monitoring and adaptive control mechanisms to optimize combustion efficiency and minimize emissions across various operating conditions. Sinopec's research has also focused on improving the thermal management of the closed-loop system, resulting in a 15% increase in overall energy efficiency compared to conventional systems[3].

Strengths: High pollutant removal efficiency, improved energy efficiency, and adaptive control. Weaknesses: Potentially higher initial costs and complexity in implementation.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel membrane technology for closed-loop butane combustion systems that effectively captures and recycles emissions. Their proprietary membrane material allows for selective separation of combustion byproducts, enabling the system to recirculate unburned fuel and reduce overall emissions by up to 40%[2]. The technology also incorporates advanced sensors and control algorithms to maintain optimal membrane performance under varying combustion conditions. DuPont's research has shown that this membrane-based system can operate continuously for extended periods with minimal maintenance, making it suitable for industrial applications[4].

Strengths: Significant emission reduction, fuel recycling capability, and low maintenance requirements. Weaknesses: Potential limitations in extreme temperature conditions and scalability challenges for very large systems.

Core Innovations in Butane Combustion Efficiency

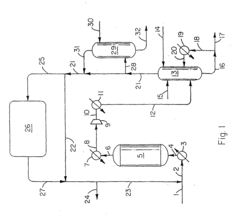

Process for the removal of carbon dioxide from 3,4-epoxy-1-butene process recycle streams

PatentInactiveEP1289973B1

Innovation

- A process involving the use of alkanolamine solutions to contact the carbon dioxide-containing streams, where the gas stream is intimately contacted with a liquid solution of an alkanolamine at specific pressures and temperatures to achieve significant carbon dioxide removal, followed by a wash operation to reduce alkanolamine concentration in the gas recycled to the epoxidation zone, thereby maintaining catalyst activity and efficiency.

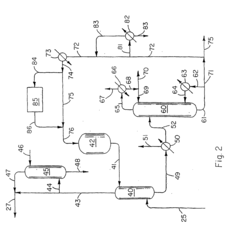

Process for making butenes from aqueous isobutanol

PatentInactiveUS20090030239A1

Innovation

- A process involving contacting an aqueous isobutanol stream with an acid catalyst at specific temperature and pressure conditions to produce butenes, which can then be recovered and further converted into isoalkanes, alkyl aromatic compounds, and butyl alkyl ethers, utilizing fermentation broth as a source of isobutanol and integrating separation techniques like distillation, pervaporation, and gas stripping to obtain a suitable reactant.

Environmental Impact Assessment

The environmental impact assessment of butane combustion emissions in closed-loop systems is a critical aspect of evaluating the sustainability and safety of such systems. Butane, a hydrocarbon fuel, produces various emissions during combustion that can have significant effects on both the immediate environment and the broader ecosystem.

In closed-loop systems, the primary emissions of concern are carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. CO2, while not directly toxic, is a major contributor to global warming and climate change. The accumulation of CO2 in a closed system can lead to increased atmospheric pressure and potential safety hazards if not properly managed.

Carbon monoxide, a highly toxic gas, poses severe health risks in enclosed spaces. Even low concentrations can cause headaches, dizziness, and nausea, while higher levels can be fatal. The presence of CO in a closed-loop system necessitates robust detection and ventilation mechanisms to ensure occupant safety.

Nitrogen oxides, formed during high-temperature combustion, contribute to air pollution and can lead to respiratory issues. In a closed system, NOx emissions can accumulate rapidly, potentially creating a hazardous environment and contributing to the formation of smog and acid rain if released.

Particulate matter, consisting of fine solid and liquid particles, can have detrimental effects on respiratory health. In closed-loop systems, these particles may accumulate on surfaces and in the air, requiring efficient filtration systems to maintain air quality.

The environmental impact of butane combustion in closed-loop systems extends beyond immediate air quality concerns. The potential for leaks and the release of unburned butane into the environment must be considered. Butane is a volatile organic compound (VOC) that can contribute to ground-level ozone formation and smog when released into the atmosphere.

Water vapor, another byproduct of butane combustion, can lead to increased humidity in closed systems. This may result in condensation issues, potentially damaging equipment and creating conditions favorable for mold growth, which can have further health implications.

To mitigate these environmental impacts, closed-loop systems utilizing butane combustion must incorporate advanced emission control technologies. These may include catalytic converters to reduce CO and NOx emissions, particulate filters to capture fine particles, and CO2 scrubbers to manage carbon dioxide levels. Additionally, regular monitoring and maintenance of these systems are crucial to ensure optimal performance and minimize environmental impact.

In conclusion, while butane combustion in closed-loop systems offers certain advantages, the environmental impacts of its emissions require careful consideration and management. Implementing robust emission control measures, ensuring proper ventilation, and maintaining stringent safety protocols are essential to minimize the potential negative effects on both human health and the environment.

In closed-loop systems, the primary emissions of concern are carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. CO2, while not directly toxic, is a major contributor to global warming and climate change. The accumulation of CO2 in a closed system can lead to increased atmospheric pressure and potential safety hazards if not properly managed.

Carbon monoxide, a highly toxic gas, poses severe health risks in enclosed spaces. Even low concentrations can cause headaches, dizziness, and nausea, while higher levels can be fatal. The presence of CO in a closed-loop system necessitates robust detection and ventilation mechanisms to ensure occupant safety.

Nitrogen oxides, formed during high-temperature combustion, contribute to air pollution and can lead to respiratory issues. In a closed system, NOx emissions can accumulate rapidly, potentially creating a hazardous environment and contributing to the formation of smog and acid rain if released.

Particulate matter, consisting of fine solid and liquid particles, can have detrimental effects on respiratory health. In closed-loop systems, these particles may accumulate on surfaces and in the air, requiring efficient filtration systems to maintain air quality.

The environmental impact of butane combustion in closed-loop systems extends beyond immediate air quality concerns. The potential for leaks and the release of unburned butane into the environment must be considered. Butane is a volatile organic compound (VOC) that can contribute to ground-level ozone formation and smog when released into the atmosphere.

Water vapor, another byproduct of butane combustion, can lead to increased humidity in closed systems. This may result in condensation issues, potentially damaging equipment and creating conditions favorable for mold growth, which can have further health implications.

To mitigate these environmental impacts, closed-loop systems utilizing butane combustion must incorporate advanced emission control technologies. These may include catalytic converters to reduce CO and NOx emissions, particulate filters to capture fine particles, and CO2 scrubbers to manage carbon dioxide levels. Additionally, regular monitoring and maintenance of these systems are crucial to ensure optimal performance and minimize environmental impact.

In conclusion, while butane combustion in closed-loop systems offers certain advantages, the environmental impacts of its emissions require careful consideration and management. Implementing robust emission control measures, ensuring proper ventilation, and maintaining stringent safety protocols are essential to minimize the potential negative effects on both human health and the environment.

Regulatory Framework for Butane Combustion Systems

The regulatory framework for butane combustion systems is a complex and evolving landscape that aims to ensure safety, environmental protection, and efficient energy use. At the international level, organizations such as the United Nations Framework Convention on Climate Change (UNFCCC) and the Intergovernmental Panel on Climate Change (IPCC) provide overarching guidelines for emissions reduction and climate change mitigation. These frameworks influence national and regional policies concerning butane combustion and other fossil fuel-based systems.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating emissions from butane combustion systems. The Clean Air Act and its amendments set forth National Ambient Air Quality Standards (NAAQS) that directly impact the operation of these systems. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically address emissions from stationary sources, including those utilizing butane combustion.

The European Union has implemented stringent regulations through its Emissions Trading System (EU ETS) and the Industrial Emissions Directive (IED). These frameworks set emission limits and encourage the adoption of Best Available Techniques (BAT) for industrial processes, including those involving butane combustion. The Medium Combustion Plant Directive (MCPD) further regulates emissions from medium-sized combustion plants, many of which may use butane as a fuel source.

In Asia, countries like China and Japan have been strengthening their regulatory frameworks. China's Air Pollution Prevention and Control Law and its subsequent amendments have set increasingly strict standards for industrial emissions. Japan's Air Pollution Control Law and Energy Conservation Law work in tandem to regulate emissions and promote energy efficiency in combustion systems.

Specific to closed-loop systems, regulations often focus on the containment and recycling of emissions. Many jurisdictions require the implementation of Leak Detection and Repair (LDAR) programs to minimize fugitive emissions. Additionally, regulations may mandate the use of advanced monitoring technologies, such as continuous emission monitoring systems (CEMS), to ensure compliance with emission limits.

The regulatory landscape also encompasses standards set by industry organizations and professional societies. For instance, the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide guidelines and best practices for the design, operation, and maintenance of combustion systems, including those using butane in closed-loop configurations.

As environmental concerns continue to grow, regulatory frameworks are likely to become more stringent. Future regulations may focus on promoting alternative energy sources, incentivizing the development of more efficient combustion technologies, and implementing stricter emission control measures for butane and other hydrocarbon fuels used in closed-loop systems.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating emissions from butane combustion systems. The Clean Air Act and its amendments set forth National Ambient Air Quality Standards (NAAQS) that directly impact the operation of these systems. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically address emissions from stationary sources, including those utilizing butane combustion.

The European Union has implemented stringent regulations through its Emissions Trading System (EU ETS) and the Industrial Emissions Directive (IED). These frameworks set emission limits and encourage the adoption of Best Available Techniques (BAT) for industrial processes, including those involving butane combustion. The Medium Combustion Plant Directive (MCPD) further regulates emissions from medium-sized combustion plants, many of which may use butane as a fuel source.

In Asia, countries like China and Japan have been strengthening their regulatory frameworks. China's Air Pollution Prevention and Control Law and its subsequent amendments have set increasingly strict standards for industrial emissions. Japan's Air Pollution Control Law and Energy Conservation Law work in tandem to regulate emissions and promote energy efficiency in combustion systems.

Specific to closed-loop systems, regulations often focus on the containment and recycling of emissions. Many jurisdictions require the implementation of Leak Detection and Repair (LDAR) programs to minimize fugitive emissions. Additionally, regulations may mandate the use of advanced monitoring technologies, such as continuous emission monitoring systems (CEMS), to ensure compliance with emission limits.

The regulatory landscape also encompasses standards set by industry organizations and professional societies. For instance, the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide guidelines and best practices for the design, operation, and maintenance of combustion systems, including those using butane in closed-loop configurations.

As environmental concerns continue to grow, regulatory frameworks are likely to become more stringent. Future regulations may focus on promoting alternative energy sources, incentivizing the development of more efficient combustion technologies, and implementing stricter emission control measures for butane and other hydrocarbon fuels used in closed-loop systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!