Cutting-Edge Catalysis Methods for Isocyanate Synthesis

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Catalysis Evolution and Objectives

Isocyanates have been a cornerstone in the production of polyurethanes and other essential industrial chemicals for decades. The evolution of catalysis methods for isocyanate synthesis has been driven by the need for more efficient, environmentally friendly, and cost-effective processes. This technological journey began with the traditional phosgenation route, which, despite its effectiveness, posed significant safety and environmental concerns.

The primary objective in the field of isocyanate catalysis has been to develop alternative synthesis routes that eliminate the use of highly toxic phosgene. This goal has led to the exploration of non-phosgene methods, including the use of carbon monoxide and nitro compounds. These approaches aim to maintain or improve yield and selectivity while reducing environmental impact and operational risks.

Another key focus has been the development of heterogeneous catalysts to replace homogeneous systems. Heterogeneous catalysis offers advantages in terms of catalyst recovery, product purification, and continuous processing capabilities. Researchers have investigated various support materials and metal catalysts to achieve optimal performance in isocyanate synthesis.

The quest for greener chemistry has also driven research into bio-based isocyanates and their precursors. This aligns with the broader objective of reducing dependence on fossil-based raw materials and moving towards more sustainable production methods. Catalysts that can efficiently convert bio-derived compounds into isocyanates are of particular interest in this context.

Recent years have seen a surge in interest in photocatalytic and electrochemical approaches for isocyanate synthesis. These cutting-edge methods aim to harness renewable energy sources and operate under milder conditions, potentially offering significant energy savings and improved safety profiles. The development of novel photocatalysts and electrode materials is crucial to realizing the full potential of these emerging technologies.

Nanocatalysis has emerged as a promising frontier in isocyanate synthesis. The unique properties of nanomaterials, such as high surface area and tunable electronic structures, offer opportunities for enhanced catalytic performance. Researchers are exploring various nanostructured catalysts, including metal nanoparticles, core-shell structures, and supported nanoclusters, to achieve higher activity and selectivity in isocyanate production.

The overarching goal of current research is to develop catalytic systems that not only improve the efficiency and sustainability of isocyanate synthesis but also enable the production of novel isocyanate compounds with tailored properties. This includes the synthesis of isocyanates with specific functional groups or stereochemistry, opening up new applications in materials science and pharmaceutical industries.

The primary objective in the field of isocyanate catalysis has been to develop alternative synthesis routes that eliminate the use of highly toxic phosgene. This goal has led to the exploration of non-phosgene methods, including the use of carbon monoxide and nitro compounds. These approaches aim to maintain or improve yield and selectivity while reducing environmental impact and operational risks.

Another key focus has been the development of heterogeneous catalysts to replace homogeneous systems. Heterogeneous catalysis offers advantages in terms of catalyst recovery, product purification, and continuous processing capabilities. Researchers have investigated various support materials and metal catalysts to achieve optimal performance in isocyanate synthesis.

The quest for greener chemistry has also driven research into bio-based isocyanates and their precursors. This aligns with the broader objective of reducing dependence on fossil-based raw materials and moving towards more sustainable production methods. Catalysts that can efficiently convert bio-derived compounds into isocyanates are of particular interest in this context.

Recent years have seen a surge in interest in photocatalytic and electrochemical approaches for isocyanate synthesis. These cutting-edge methods aim to harness renewable energy sources and operate under milder conditions, potentially offering significant energy savings and improved safety profiles. The development of novel photocatalysts and electrode materials is crucial to realizing the full potential of these emerging technologies.

Nanocatalysis has emerged as a promising frontier in isocyanate synthesis. The unique properties of nanomaterials, such as high surface area and tunable electronic structures, offer opportunities for enhanced catalytic performance. Researchers are exploring various nanostructured catalysts, including metal nanoparticles, core-shell structures, and supported nanoclusters, to achieve higher activity and selectivity in isocyanate production.

The overarching goal of current research is to develop catalytic systems that not only improve the efficiency and sustainability of isocyanate synthesis but also enable the production of novel isocyanate compounds with tailored properties. This includes the synthesis of isocyanates with specific functional groups or stereochemistry, opening up new applications in materials science and pharmaceutical industries.

Market Analysis for Advanced Isocyanate Synthesis

The global isocyanate market has been experiencing steady growth, driven by increasing demand from various end-use industries such as automotive, construction, and furniture. The market for advanced isocyanate synthesis methods is particularly promising, as manufacturers seek more efficient and environmentally friendly production processes.

The automotive sector remains a key driver for isocyanate demand, with polyurethane-based components being widely used in vehicle interiors, seating, and insulation. As the automotive industry continues to evolve towards electric and lightweight vehicles, the demand for high-performance isocyanates is expected to grow further.

In the construction industry, isocyanates are essential in the production of rigid foam insulation, which is crucial for improving energy efficiency in buildings. With the growing emphasis on sustainable construction practices and stringent energy regulations, the demand for advanced isocyanate-based insulation materials is projected to increase significantly.

The furniture and bedding sector also contributes substantially to the isocyanate market, with flexible foams being a primary application. As consumer preferences shift towards more comfortable and durable products, manufacturers are seeking innovative isocyanate formulations to meet these demands.

Geographically, Asia-Pacific dominates the isocyanate market, with China being the largest producer and consumer. The region's rapid industrialization, growing construction activities, and expanding automotive sector are driving the demand for isocyanates. North America and Europe follow, with mature markets focusing on high-performance and specialty isocyanates.

The market for advanced isocyanate synthesis methods is characterized by intense research and development activities. Major chemical companies are investing heavily in developing catalysts and processes that can improve yield, reduce energy consumption, and minimize environmental impact. These innovations are crucial in addressing the challenges associated with traditional isocyanate production methods, such as the use of phosgene and high energy requirements.

Emerging trends in the market include the development of bio-based isocyanates, which align with the growing demand for sustainable materials. Additionally, there is a focus on creating isocyanates with enhanced properties, such as improved thermal stability and fire resistance, to cater to specialized applications in aerospace and electronics industries.

The market for advanced isocyanate synthesis methods is expected to grow at a faster rate than the overall isocyanate market, as manufacturers seek to gain a competitive edge through improved production efficiency and product quality. This trend is likely to drive further investments in research and development, creating opportunities for innovative catalysis methods and process technologies.

The automotive sector remains a key driver for isocyanate demand, with polyurethane-based components being widely used in vehicle interiors, seating, and insulation. As the automotive industry continues to evolve towards electric and lightweight vehicles, the demand for high-performance isocyanates is expected to grow further.

In the construction industry, isocyanates are essential in the production of rigid foam insulation, which is crucial for improving energy efficiency in buildings. With the growing emphasis on sustainable construction practices and stringent energy regulations, the demand for advanced isocyanate-based insulation materials is projected to increase significantly.

The furniture and bedding sector also contributes substantially to the isocyanate market, with flexible foams being a primary application. As consumer preferences shift towards more comfortable and durable products, manufacturers are seeking innovative isocyanate formulations to meet these demands.

Geographically, Asia-Pacific dominates the isocyanate market, with China being the largest producer and consumer. The region's rapid industrialization, growing construction activities, and expanding automotive sector are driving the demand for isocyanates. North America and Europe follow, with mature markets focusing on high-performance and specialty isocyanates.

The market for advanced isocyanate synthesis methods is characterized by intense research and development activities. Major chemical companies are investing heavily in developing catalysts and processes that can improve yield, reduce energy consumption, and minimize environmental impact. These innovations are crucial in addressing the challenges associated with traditional isocyanate production methods, such as the use of phosgene and high energy requirements.

Emerging trends in the market include the development of bio-based isocyanates, which align with the growing demand for sustainable materials. Additionally, there is a focus on creating isocyanates with enhanced properties, such as improved thermal stability and fire resistance, to cater to specialized applications in aerospace and electronics industries.

The market for advanced isocyanate synthesis methods is expected to grow at a faster rate than the overall isocyanate market, as manufacturers seek to gain a competitive edge through improved production efficiency and product quality. This trend is likely to drive further investments in research and development, creating opportunities for innovative catalysis methods and process technologies.

Current Challenges in Isocyanate Catalysis

The synthesis of isocyanates, a crucial class of compounds in the chemical industry, faces several significant challenges in terms of catalysis. One of the primary issues is the development of more efficient and selective catalysts. Current catalytic systems often struggle to achieve high yields and selectivity, particularly when dealing with complex or sensitive substrates. This limitation hampers the production of specialized isocyanates required for advanced materials and applications.

Another major challenge lies in the environmental impact of traditional catalytic processes. Many existing methods rely on toxic or environmentally harmful reagents, such as phosgene or carbon monoxide. There is a pressing need to develop greener catalytic routes that minimize the use of hazardous substances and reduce waste generation. This shift towards more sustainable practices is not only environmentally beneficial but also economically advantageous in the long term.

The energy efficiency of isocyanate synthesis processes presents another significant hurdle. Current catalytic methods often require high temperatures and pressures, leading to substantial energy consumption. Developing catalysts that can operate under milder conditions without compromising yield or selectivity is a key area of research. Such advancements would not only reduce energy costs but also enable the synthesis of thermally sensitive isocyanates.

Catalyst stability and longevity pose additional challenges in isocyanate synthesis. Many catalysts suffer from deactivation or degradation during the reaction process, necessitating frequent replacement or regeneration. This issue impacts both the economics of the process and the consistency of product quality. Research into more robust catalytic systems that maintain their activity over extended periods is crucial for improving industrial-scale production.

The scalability of novel catalytic methods is another critical concern. While many innovative catalysts show promise in laboratory-scale experiments, translating these successes to industrial-scale production often proves challenging. Factors such as mass transfer limitations, heat management, and catalyst recovery become increasingly important at larger scales. Developing catalytic systems that can effectively bridge the gap between laboratory and industrial applications is essential for advancing isocyanate synthesis technology.

Lastly, the specificity of catalysts for different types of isocyanates remains a challenge. The diverse range of isocyanate products required by various industries necessitates catalysts that can be tailored for specific substrates or reaction conditions. Creating versatile catalytic systems that can be easily adapted or fine-tuned for different isocyanate syntheses would greatly enhance the flexibility and efficiency of production processes.

Another major challenge lies in the environmental impact of traditional catalytic processes. Many existing methods rely on toxic or environmentally harmful reagents, such as phosgene or carbon monoxide. There is a pressing need to develop greener catalytic routes that minimize the use of hazardous substances and reduce waste generation. This shift towards more sustainable practices is not only environmentally beneficial but also economically advantageous in the long term.

The energy efficiency of isocyanate synthesis processes presents another significant hurdle. Current catalytic methods often require high temperatures and pressures, leading to substantial energy consumption. Developing catalysts that can operate under milder conditions without compromising yield or selectivity is a key area of research. Such advancements would not only reduce energy costs but also enable the synthesis of thermally sensitive isocyanates.

Catalyst stability and longevity pose additional challenges in isocyanate synthesis. Many catalysts suffer from deactivation or degradation during the reaction process, necessitating frequent replacement or regeneration. This issue impacts both the economics of the process and the consistency of product quality. Research into more robust catalytic systems that maintain their activity over extended periods is crucial for improving industrial-scale production.

The scalability of novel catalytic methods is another critical concern. While many innovative catalysts show promise in laboratory-scale experiments, translating these successes to industrial-scale production often proves challenging. Factors such as mass transfer limitations, heat management, and catalyst recovery become increasingly important at larger scales. Developing catalytic systems that can effectively bridge the gap between laboratory and industrial applications is essential for advancing isocyanate synthesis technology.

Lastly, the specificity of catalysts for different types of isocyanates remains a challenge. The diverse range of isocyanate products required by various industries necessitates catalysts that can be tailored for specific substrates or reaction conditions. Creating versatile catalytic systems that can be easily adapted or fine-tuned for different isocyanate syntheses would greatly enhance the flexibility and efficiency of production processes.

State-of-the-Art Catalytic Methods for Isocyanates

01 Metal-based catalysts for isocyanate synthesis

Various metal-based catalysts are employed in isocyanate synthesis. These catalysts, including transition metals and their complexes, facilitate the reaction between amines and carbonyl compounds to form isocyanates. They can enhance reaction rates, improve selectivity, and operate under milder conditions compared to non-catalyzed processes.- Metal-based catalysts for isocyanate synthesis: Various metal-based catalysts are employed in isocyanate synthesis to improve reaction efficiency and selectivity. These catalysts often include transition metals such as copper, nickel, or palladium, which can facilitate the conversion of amines or other precursors to isocyanates under specific reaction conditions.

- Heterogeneous catalysis in isocyanate production: Heterogeneous catalysts, such as supported metal catalysts or zeolites, are used in isocyanate synthesis to enhance reaction rates and product yield. These catalysts offer advantages like easy separation from the reaction mixture and potential for continuous processing.

- Organocatalysts for isocyanate synthesis: Organic catalysts, including certain amines, phosphines, or carbenes, are explored for their potential in catalyzing isocyanate formation. These catalysts can offer milder reaction conditions and improved selectivity in some cases, particularly for sensitive substrates.

- Photocatalytic methods in isocyanate synthesis: Photocatalytic approaches are being investigated for isocyanate synthesis, utilizing light-activated catalysts to promote the reaction. This method can potentially offer more environmentally friendly conditions and enable new reaction pathways for isocyanate formation.

- Enzymatic catalysis for isocyanate production: Biocatalytic methods using enzymes are explored as potential alternatives for isocyanate synthesis. While still in early stages of research, enzymatic catalysis could offer highly selective and environmentally benign routes to certain isocyanates under mild conditions.

02 Heterogeneous catalysis in isocyanate production

Heterogeneous catalysts, such as supported metal catalysts or zeolites, are used in isocyanate synthesis. These solid catalysts offer advantages like easy separation from the reaction mixture, potential for continuous processes, and improved stability. They can be tailored for specific isocyanate syntheses by adjusting their composition and surface properties.Expand Specific Solutions03 Enzymatic and biocatalytic approaches

Enzymatic and biocatalytic methods are emerging as green alternatives for isocyanate synthesis. These biological catalysts can operate under mild conditions and offer high selectivity. Engineered enzymes or whole-cell biocatalysts are being explored for their potential in producing isocyanates through environmentally friendly routes.Expand Specific Solutions04 Photocatalytic isocyanate synthesis

Photocatalytic methods for isocyanate synthesis utilize light energy to drive the reaction. These processes often involve photoactive catalysts that can be activated by specific wavelengths of light. Photocatalysis can offer energy-efficient and environmentally friendly routes to isocyanate production, potentially operating at room temperature and atmospheric pressure.Expand Specific Solutions05 Organocatalysis in isocyanate production

Organocatalysts, which are small organic molecules, are being investigated for isocyanate synthesis. These metal-free catalysts can offer advantages such as low toxicity, ease of handling, and potential for asymmetric synthesis. Various classes of organocatalysts, including hydrogen-bond donors and Brønsted acids, are being explored for their efficacy in isocyanate formation reactions.Expand Specific Solutions

Key Players in Isocyanate Catalysis Research

The research on cutting-edge catalysis methods for isocyanate synthesis is in a competitive and evolving stage, with significant market potential due to the widespread use of isocyanates in various industries. The global market for isocyanates is substantial, driven by demand in polyurethane production, coatings, and adhesives. Technologically, the field is advancing rapidly, with major players like BASF, Covestro, and Wanhua Chemical Group leading innovation. These companies, along with research institutions such as the Chinese Academy of Sciences and Max Planck Society, are pushing the boundaries of catalytic efficiency, selectivity, and sustainability. The technology's maturity varies, with established processes being refined and novel approaches emerging, indicating a dynamic landscape for future developments.

BASF Corp.

Technical Solution: BASF has developed innovative catalysis methods for isocyanate synthesis, focusing on improving efficiency and sustainability. Their approach involves using novel metal-organic frameworks (MOFs) as heterogeneous catalysts, which offer high surface area and tunable pore structures[1]. This method allows for better control of the reaction kinetics and selectivity in isocyanate production. BASF has also explored the use of ionic liquids as catalysts, which can act as both solvents and catalysts, potentially simplifying the reaction process and improving yields[2]. Additionally, they have invested in research on photocatalytic methods for isocyanate synthesis, utilizing visible light to drive the reaction, which could significantly reduce energy consumption[3].

Strengths: High efficiency, improved selectivity, and potential for greener production processes. Weaknesses: May require significant changes to existing manufacturing infrastructure and potentially higher initial costs.

Covestro Deutschland AG

Technical Solution: Covestro has made significant strides in developing cutting-edge catalysis methods for isocyanate synthesis, focusing on sustainable and efficient processes. They have pioneered the use of gas-phase technology for the production of aromatic isocyanates, which reduces solvent use and energy consumption[1]. This method employs highly selective catalysts that can operate at lower temperatures, improving overall process efficiency. Covestro has also explored the use of bio-based raw materials in isocyanate production, developing catalysts that can effectively convert these renewable resources into high-quality isocyanates[2]. Furthermore, they have invested in research on microreactor technology for isocyanate synthesis, which allows for better control of reaction conditions and potentially safer production processes[3].

Strengths: Improved sustainability, reduced environmental impact, and potential for cost savings in large-scale production. Weaknesses: May require significant initial investment and adaptation of existing manufacturing processes.

Breakthrough Catalysts for Isocyanate Production

Process for preparing isocyanates

PatentInactiveUS20120253063A1

Innovation

- A phosgene-free process involving the oxydehydrogenation of formamides over noble metal catalysts at elevated temperatures, with vaporized formamides reacting with an oxygen-comprising gas, followed by quenching with an alcohol to form isocyanates, which are then dissociated from urethanes.

Method for preparing aliphatic diisocyanate

PatentInactiveUS20140303399A1

Innovation

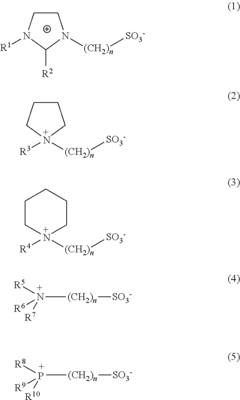

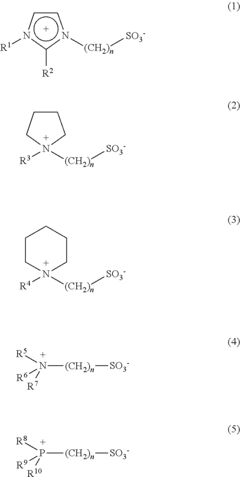

- Pyrolyzing aliphatic dicarbamates in a liquid phase with a tin (II) or (IV) compound as a catalyst and a zwitterionic compound as a stabilizer to inhibit the formation of high-boiling by-products and enhance yield.

Environmental Impact of Isocyanate Synthesis

The environmental impact of isocyanate synthesis is a critical consideration in the development and implementation of cutting-edge catalysis methods. Traditional isocyanate production processes have been associated with significant environmental concerns, primarily due to the use of phosgene as a key reagent. Phosgene is highly toxic and corrosive, posing risks to both human health and the environment.

Recent advancements in catalysis methods for isocyanate synthesis have aimed to address these environmental challenges. One promising approach involves the use of carbon dioxide as a more environmentally friendly alternative to phosgene. This method not only reduces the reliance on toxic chemicals but also contributes to carbon dioxide utilization, potentially mitigating greenhouse gas emissions.

The development of metal-organic frameworks (MOFs) as catalysts has shown potential in improving the efficiency and selectivity of isocyanate synthesis reactions. These porous materials can be designed to have specific catalytic properties, potentially reducing energy consumption and waste generation in the production process.

Another area of focus has been the exploration of continuous flow reactors for isocyanate synthesis. This technology offers better control over reaction conditions, potentially leading to improved yields and reduced byproduct formation. The enhanced efficiency of continuous flow processes can result in lower energy consumption and reduced environmental footprint compared to traditional batch processes.

The use of renewable feedstocks in isocyanate synthesis has also gained attention as a means to reduce the environmental impact. Bio-based isocyanates derived from plant oils or other renewable sources offer a more sustainable alternative to petroleum-based precursors. However, challenges remain in terms of scalability and cost-effectiveness of these bio-based approaches.

Water-based systems for isocyanate production have been investigated as a way to reduce the use of organic solvents, which can contribute to air pollution and pose health risks. While promising, these systems face challenges in terms of reaction kinetics and product stability that need to be addressed through further research and development.

The environmental impact of isocyanate synthesis extends beyond the production process to include considerations of product lifecycle and end-of-life disposal. Efforts to develop more easily recyclable or biodegradable isocyanate-based materials are ongoing, with the aim of reducing the long-term environmental impact of these widely used chemicals.

Recent advancements in catalysis methods for isocyanate synthesis have aimed to address these environmental challenges. One promising approach involves the use of carbon dioxide as a more environmentally friendly alternative to phosgene. This method not only reduces the reliance on toxic chemicals but also contributes to carbon dioxide utilization, potentially mitigating greenhouse gas emissions.

The development of metal-organic frameworks (MOFs) as catalysts has shown potential in improving the efficiency and selectivity of isocyanate synthesis reactions. These porous materials can be designed to have specific catalytic properties, potentially reducing energy consumption and waste generation in the production process.

Another area of focus has been the exploration of continuous flow reactors for isocyanate synthesis. This technology offers better control over reaction conditions, potentially leading to improved yields and reduced byproduct formation. The enhanced efficiency of continuous flow processes can result in lower energy consumption and reduced environmental footprint compared to traditional batch processes.

The use of renewable feedstocks in isocyanate synthesis has also gained attention as a means to reduce the environmental impact. Bio-based isocyanates derived from plant oils or other renewable sources offer a more sustainable alternative to petroleum-based precursors. However, challenges remain in terms of scalability and cost-effectiveness of these bio-based approaches.

Water-based systems for isocyanate production have been investigated as a way to reduce the use of organic solvents, which can contribute to air pollution and pose health risks. While promising, these systems face challenges in terms of reaction kinetics and product stability that need to be addressed through further research and development.

The environmental impact of isocyanate synthesis extends beyond the production process to include considerations of product lifecycle and end-of-life disposal. Efforts to develop more easily recyclable or biodegradable isocyanate-based materials are ongoing, with the aim of reducing the long-term environmental impact of these widely used chemicals.

Safety Considerations in Isocyanate Production

Safety considerations in isocyanate production are paramount due to the highly reactive nature of these compounds. The synthesis process involves handling toxic and potentially hazardous materials, necessitating stringent safety protocols. Proper ventilation systems are crucial to prevent the accumulation of harmful vapors and maintain a safe working environment. Personal protective equipment (PPE), including respirators, chemical-resistant gloves, and protective clothing, must be worn at all times to minimize exposure risks.

Temperature control is critical during isocyanate synthesis, as exothermic reactions can lead to runaway conditions if not properly managed. Advanced process control systems and fail-safe mechanisms should be implemented to monitor and regulate reaction temperatures. Pressure relief systems are essential to prevent equipment failure and potential explosions in case of unexpected pressure buildup.

Storage and handling of raw materials and finished products require specialized containment systems to prevent leaks and spills. Isocyanates are highly sensitive to moisture, necessitating the use of dry, inert atmospheres during storage and transportation. Regular inspection and maintenance of storage tanks, pipelines, and transfer equipment are vital to ensure their integrity and prevent accidental releases.

Emergency response planning is a crucial aspect of isocyanate production safety. Facilities must have well-defined procedures for spill containment, fire suppression, and evacuation. Regular drills and training sessions should be conducted to ensure all personnel are familiar with emergency protocols. On-site medical facilities and trained first responders are essential to provide immediate care in case of exposure incidents.

Environmental considerations are increasingly important in isocyanate production. Advanced scrubbing systems and catalytic oxidizers should be employed to minimize air emissions. Wastewater treatment facilities must be capable of handling and neutralizing any isocyanate-containing effluents before discharge. Continuous monitoring of air and water quality in and around production facilities is necessary to ensure compliance with environmental regulations and protect surrounding communities.

Cutting-edge catalysis methods for isocyanate synthesis may introduce new safety challenges. Novel catalysts or reaction conditions may require additional safety measures or modifications to existing protocols. Thorough risk assessments should be conducted for any new production methods, with particular attention to potential side reactions, byproducts, or unexpected hazards. Pilot-scale testing and gradual scale-up procedures are essential to identify and address safety concerns before full-scale implementation.

Temperature control is critical during isocyanate synthesis, as exothermic reactions can lead to runaway conditions if not properly managed. Advanced process control systems and fail-safe mechanisms should be implemented to monitor and regulate reaction temperatures. Pressure relief systems are essential to prevent equipment failure and potential explosions in case of unexpected pressure buildup.

Storage and handling of raw materials and finished products require specialized containment systems to prevent leaks and spills. Isocyanates are highly sensitive to moisture, necessitating the use of dry, inert atmospheres during storage and transportation. Regular inspection and maintenance of storage tanks, pipelines, and transfer equipment are vital to ensure their integrity and prevent accidental releases.

Emergency response planning is a crucial aspect of isocyanate production safety. Facilities must have well-defined procedures for spill containment, fire suppression, and evacuation. Regular drills and training sessions should be conducted to ensure all personnel are familiar with emergency protocols. On-site medical facilities and trained first responders are essential to provide immediate care in case of exposure incidents.

Environmental considerations are increasingly important in isocyanate production. Advanced scrubbing systems and catalytic oxidizers should be employed to minimize air emissions. Wastewater treatment facilities must be capable of handling and neutralizing any isocyanate-containing effluents before discharge. Continuous monitoring of air and water quality in and around production facilities is necessary to ensure compliance with environmental regulations and protect surrounding communities.

Cutting-edge catalysis methods for isocyanate synthesis may introduce new safety challenges. Novel catalysts or reaction conditions may require additional safety measures or modifications to existing protocols. Thorough risk assessments should be conducted for any new production methods, with particular attention to potential side reactions, byproducts, or unexpected hazards. Pilot-scale testing and gradual scale-up procedures are essential to identify and address safety concerns before full-scale implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!