Graphene Battery as an Enabler of Clean Technology

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a significant leap forward in energy storage technology, marking a crucial milestone in the evolution of clean energy solutions. The development of graphene-based batteries can be traced back to the early 2010s when researchers first began exploring the potential of this two-dimensional carbon material in energy storage applications. Since then, the field has witnessed rapid advancements, driven by the unique properties of graphene, including its exceptional electrical conductivity, mechanical strength, and high surface area.

The evolution of graphene batteries has been characterized by several key phases. Initially, researchers focused on incorporating graphene as an additive in traditional lithium-ion battery electrodes to enhance their performance. This approach led to improvements in energy density and charging speeds. As the technology progressed, scientists began developing graphene-dominant electrodes, which promised even greater enhancements in battery performance.

More recently, the focus has shifted towards developing all-graphene batteries, where both electrodes and electrolytes are graphene-based. This approach aims to fully leverage the material's extraordinary properties to create batteries with unprecedented energy density, charging speeds, and cycle life. The evolution of graphene batteries has been closely tied to advancements in graphene production techniques, as the availability of high-quality, large-scale graphene is crucial for commercial viability.

The primary objectives of graphene battery research are multifaceted and ambitious. Foremost among these is the goal of significantly increasing energy density, with some researchers aiming to achieve up to ten times the capacity of current lithium-ion batteries. This would revolutionize electric vehicle technology, potentially extending driving ranges to over 1000 kilometers on a single charge.

Another critical objective is to dramatically reduce charging times. Researchers are working towards developing graphene batteries that can be fully charged in minutes rather than hours, addressing one of the main barriers to widespread electric vehicle adoption. Additionally, improving the cycle life of batteries is a key focus, with the aim of creating batteries that can withstand thousands of charge-discharge cycles without significant degradation.

Safety is another paramount concern, and graphene batteries are expected to offer improved thermal management and reduced risk of thermal runaway compared to conventional lithium-ion batteries. This could lead to safer and more reliable energy storage solutions for a wide range of applications, from consumer electronics to grid-scale energy storage.

Ultimately, the overarching goal of graphene battery research is to enable a new generation of clean technologies. By providing more efficient, powerful, and sustainable energy storage solutions, graphene batteries have the potential to accelerate the transition to renewable energy sources and electric transportation, playing a crucial role in addressing global climate challenges.

The evolution of graphene batteries has been characterized by several key phases. Initially, researchers focused on incorporating graphene as an additive in traditional lithium-ion battery electrodes to enhance their performance. This approach led to improvements in energy density and charging speeds. As the technology progressed, scientists began developing graphene-dominant electrodes, which promised even greater enhancements in battery performance.

More recently, the focus has shifted towards developing all-graphene batteries, where both electrodes and electrolytes are graphene-based. This approach aims to fully leverage the material's extraordinary properties to create batteries with unprecedented energy density, charging speeds, and cycle life. The evolution of graphene batteries has been closely tied to advancements in graphene production techniques, as the availability of high-quality, large-scale graphene is crucial for commercial viability.

The primary objectives of graphene battery research are multifaceted and ambitious. Foremost among these is the goal of significantly increasing energy density, with some researchers aiming to achieve up to ten times the capacity of current lithium-ion batteries. This would revolutionize electric vehicle technology, potentially extending driving ranges to over 1000 kilometers on a single charge.

Another critical objective is to dramatically reduce charging times. Researchers are working towards developing graphene batteries that can be fully charged in minutes rather than hours, addressing one of the main barriers to widespread electric vehicle adoption. Additionally, improving the cycle life of batteries is a key focus, with the aim of creating batteries that can withstand thousands of charge-discharge cycles without significant degradation.

Safety is another paramount concern, and graphene batteries are expected to offer improved thermal management and reduced risk of thermal runaway compared to conventional lithium-ion batteries. This could lead to safer and more reliable energy storage solutions for a wide range of applications, from consumer electronics to grid-scale energy storage.

Ultimately, the overarching goal of graphene battery research is to enable a new generation of clean technologies. By providing more efficient, powerful, and sustainable energy storage solutions, graphene batteries have the potential to accelerate the transition to renewable energy sources and electric transportation, playing a crucial role in addressing global climate challenges.

Clean Energy Market Demand Analysis

The clean energy market has experienced significant growth in recent years, driven by increasing environmental concerns, government policies, and technological advancements. The demand for clean energy solutions, including advanced energy storage technologies like graphene batteries, is expected to continue its upward trajectory in the coming decades.

Global efforts to combat climate change and reduce carbon emissions have led to a surge in renewable energy adoption. This shift towards cleaner energy sources has created a substantial market for efficient energy storage solutions. Graphene batteries, with their potential for high energy density, rapid charging capabilities, and longer lifespan, are positioned to play a crucial role in addressing the intermittency challenges associated with renewable energy sources.

The electric vehicle (EV) sector represents a major driver for advanced battery technologies. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance batteries continues to grow. Graphene batteries could potentially overcome the limitations of current lithium-ion batteries, offering faster charging times and increased range, which are critical factors for widespread EV adoption.

In the consumer electronics market, there is a constant demand for devices with longer battery life and faster charging capabilities. Graphene batteries have the potential to revolutionize this sector by providing significantly improved performance over existing battery technologies. This could lead to a new generation of mobile devices, laptops, and wearables with extended usage times and reduced charging frequency.

The grid energy storage market is another area where graphene batteries could make a substantial impact. As power grids integrate more renewable energy sources, the need for efficient and large-scale energy storage solutions becomes increasingly critical. Graphene batteries' potential for high power density and long cycle life makes them attractive for grid-scale applications, potentially enabling more stable and reliable renewable energy integration.

Industrial and aerospace sectors also present significant opportunities for graphene battery technology. The demand for lightweight, high-performance energy storage solutions in these industries could drive further development and adoption of graphene-based batteries.

While the market potential for graphene batteries is substantial, it's important to note that the technology is still in its early stages of development. Overcoming technical challenges and scaling up production will be crucial for graphene batteries to capture a significant share of the clean energy market. However, the growing emphasis on sustainability and the increasing investment in clean technologies provide a favorable environment for the continued development and eventual commercialization of graphene battery technology.

Global efforts to combat climate change and reduce carbon emissions have led to a surge in renewable energy adoption. This shift towards cleaner energy sources has created a substantial market for efficient energy storage solutions. Graphene batteries, with their potential for high energy density, rapid charging capabilities, and longer lifespan, are positioned to play a crucial role in addressing the intermittency challenges associated with renewable energy sources.

The electric vehicle (EV) sector represents a major driver for advanced battery technologies. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance batteries continues to grow. Graphene batteries could potentially overcome the limitations of current lithium-ion batteries, offering faster charging times and increased range, which are critical factors for widespread EV adoption.

In the consumer electronics market, there is a constant demand for devices with longer battery life and faster charging capabilities. Graphene batteries have the potential to revolutionize this sector by providing significantly improved performance over existing battery technologies. This could lead to a new generation of mobile devices, laptops, and wearables with extended usage times and reduced charging frequency.

The grid energy storage market is another area where graphene batteries could make a substantial impact. As power grids integrate more renewable energy sources, the need for efficient and large-scale energy storage solutions becomes increasingly critical. Graphene batteries' potential for high power density and long cycle life makes them attractive for grid-scale applications, potentially enabling more stable and reliable renewable energy integration.

Industrial and aerospace sectors also present significant opportunities for graphene battery technology. The demand for lightweight, high-performance energy storage solutions in these industries could drive further development and adoption of graphene-based batteries.

While the market potential for graphene batteries is substantial, it's important to note that the technology is still in its early stages of development. Overcoming technical challenges and scaling up production will be crucial for graphene batteries to capture a significant share of the clean energy market. However, the growing emphasis on sustainability and the increasing investment in clean technologies provide a favorable environment for the continued development and eventual commercialization of graphene battery technology.

Graphene Battery Technology Status and Challenges

Graphene battery technology has made significant strides in recent years, positioning itself as a promising enabler of clean energy solutions. However, the current state of development presents both exciting advancements and formidable challenges. The unique properties of graphene, including its high electrical conductivity, mechanical strength, and large surface area, have sparked intense research interest in its application to battery technology.

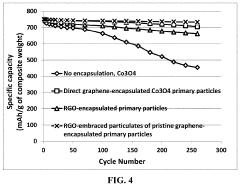

One of the primary areas of focus has been the integration of graphene into lithium-ion batteries. Researchers have demonstrated that graphene-enhanced electrodes can significantly improve battery performance, including faster charging times, increased energy density, and extended cycle life. Some studies have reported up to 45% increase in energy density and charging speeds up to five times faster than conventional lithium-ion batteries.

Despite these promising results, several technical hurdles remain. The mass production of high-quality graphene at a cost-effective scale continues to be a significant challenge. Current manufacturing processes are often energy-intensive and expensive, limiting widespread commercial adoption. Additionally, ensuring consistent quality and purity of graphene materials across large-scale production batches poses difficulties.

Another critical challenge lies in the integration of graphene into existing battery architectures. While graphene shows excellent potential as an additive or replacement for traditional electrode materials, optimizing its incorporation without compromising other battery components or overall performance remains complex. Issues such as electrolyte compatibility, electrode stability, and long-term cycling performance need further investigation.

The development of graphene-based solid-state electrolytes represents another frontier in battery technology. These materials could potentially address safety concerns associated with liquid electrolytes while improving energy density. However, challenges in ionic conductivity and interfacial resistance between the electrolyte and electrodes persist.

Geographically, research and development efforts in graphene battery technology are distributed globally, with significant contributions from Asia, North America, and Europe. China, in particular, has emerged as a leader in graphene production and battery research, with substantial government support and industrial investment.

As the technology progresses, addressing environmental and sustainability concerns becomes increasingly important. While graphene batteries hold promise for clean energy applications, the environmental impact of graphene production and end-of-life recycling processes requires careful consideration and further development of eco-friendly manufacturing methods.

One of the primary areas of focus has been the integration of graphene into lithium-ion batteries. Researchers have demonstrated that graphene-enhanced electrodes can significantly improve battery performance, including faster charging times, increased energy density, and extended cycle life. Some studies have reported up to 45% increase in energy density and charging speeds up to five times faster than conventional lithium-ion batteries.

Despite these promising results, several technical hurdles remain. The mass production of high-quality graphene at a cost-effective scale continues to be a significant challenge. Current manufacturing processes are often energy-intensive and expensive, limiting widespread commercial adoption. Additionally, ensuring consistent quality and purity of graphene materials across large-scale production batches poses difficulties.

Another critical challenge lies in the integration of graphene into existing battery architectures. While graphene shows excellent potential as an additive or replacement for traditional electrode materials, optimizing its incorporation without compromising other battery components or overall performance remains complex. Issues such as electrolyte compatibility, electrode stability, and long-term cycling performance need further investigation.

The development of graphene-based solid-state electrolytes represents another frontier in battery technology. These materials could potentially address safety concerns associated with liquid electrolytes while improving energy density. However, challenges in ionic conductivity and interfacial resistance between the electrolyte and electrodes persist.

Geographically, research and development efforts in graphene battery technology are distributed globally, with significant contributions from Asia, North America, and Europe. China, in particular, has emerged as a leader in graphene production and battery research, with substantial government support and industrial investment.

As the technology progresses, addressing environmental and sustainability concerns becomes increasingly important. While graphene batteries hold promise for clean energy applications, the environmental impact of graphene production and end-of-life recycling processes requires careful consideration and further development of eco-friendly manufacturing methods.

Current Graphene Battery Solutions

01 Graphene-based electrode materials

Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. It can be incorporated into both anodes and cathodes to improve battery performance, including increased capacity and faster charging rates.- Graphene-based electrode materials: Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. It can be incorporated into both anodes and cathodes to improve battery performance, including increased capacity and faster charging rates.

- Graphene-enhanced electrolytes: Graphene can be used to enhance battery electrolytes, improving ionic conductivity and stability. This can lead to better overall battery performance, including increased energy density and longer cycle life.

- Graphene-based composite materials: Composite materials incorporating graphene are developed for battery applications. These composites can combine the benefits of graphene with other materials to create high-performance electrodes or other battery components.

- Graphene production methods for battery applications: Specialized methods for producing graphene tailored for battery applications are developed. These methods focus on creating graphene with specific properties that enhance battery performance, such as controlled porosity or functionalization.

- Graphene-based flexible and wearable batteries: Graphene is utilized in the development of flexible and wearable battery technologies. Its unique properties allow for the creation of thin, lightweight, and bendable batteries suitable for integration into wearable devices and flexible electronics.

02 Graphene-enhanced electrolytes

Graphene can be used to enhance battery electrolytes, improving ionic conductivity and stability. This can lead to better overall battery performance, including increased energy density and longer cycle life.Expand Specific Solutions03 Graphene composite materials

Composite materials combining graphene with other substances, such as metal oxides or polymers, are developed to create advanced battery components. These composites can offer improved mechanical properties and enhanced electrochemical performance.Expand Specific Solutions04 Graphene-based flexible batteries

Graphene's flexibility and strength make it suitable for developing flexible and wearable battery technologies. These batteries can be integrated into various devices and applications where traditional rigid batteries are not suitable.Expand Specific Solutions05 Graphene production and modification for battery applications

Various methods for producing and modifying graphene specifically for battery applications are developed. These include techniques for controlling graphene structure, doping, and functionalization to optimize its properties for use in batteries.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market is in its early growth stage, characterized by intensive research and development efforts across academia and industry. The market size is projected to expand significantly due to the increasing demand for high-performance energy storage solutions in clean technology applications. While the technology is not yet fully mature, several key players are making substantial progress. Companies like Honeycomb Battery Co., Apple Inc., and Samsung Electronics are investing heavily in graphene battery research, leveraging their resources and expertise to accelerate development. Academic institutions such as Northwestern University, Peking University, and the University of Manchester are contributing fundamental research, collaborating with industry partners to bridge the gap between laboratory discoveries and commercial applications. The competitive landscape is dynamic, with both established tech giants and specialized startups vying for leadership in this promising field.

Apple, Inc.

Technical Solution: Apple's approach to graphene battery technology focuses on enhancing the performance and sustainability of their mobile devices. They have patented a graphene-based heat dissipation system for batteries, which addresses the issue of thermal management in high-performance electronics[4]. This system utilizes graphene's excellent thermal conductivity to efficiently distribute heat, potentially allowing for faster charging and longer battery life. Apple is also exploring the use of graphene as a protective coating for battery electrodes, which could significantly improve the cycle life and stability of lithium-ion batteries[5]. Additionally, the company is investigating graphene-based flexible batteries that could be integrated into wearable devices, offering improved energy density and form factor flexibility[6].

Strengths: Vast resources for R&D, strong integration capabilities with existing product lines, and a global supply chain for potential commercialization. Weaknesses: Primarily focused on consumer electronics applications, which may limit broader clean technology applications.

Beijing Graphene Research Institute

Technical Solution: The Beijing Graphene Research Institute is focusing on developing large-scale production methods for high-quality graphene materials suitable for battery applications. Their approach includes the synthesis of graphene through chemical vapor deposition (CVD) and the exfoliation of graphite, optimized for energy storage applications[10]. The institute has made progress in creating graphene-based composite materials that can be used as battery electrodes, offering improved conductivity and surface area compared to traditional materials. They are also exploring the use of graphene in lithium-sulfur batteries, which have the potential for much higher energy density than current lithium-ion batteries[11]. Additionally, the institute is researching graphene's role in enhancing the performance of sodium-ion batteries, which could provide a more sustainable alternative to lithium-based technologies[12].

Strengths: Strong government support, access to a large pool of skilled researchers, and focus on scalable production methods. Weaknesses: Potential challenges in international collaboration and technology transfer due to geopolitical factors.

Core Graphene Battery Innovations

Method of producing multi-level graphene-protected cathode active material particles for battery applications

PatentActiveUS20190372100A1

Innovation

- The use of graphene-embraced particulates, where primary particles of anode or cathode active materials are encapsulated with multiple sheets of graphene, providing mechanical protection and conductivity, and optionally combined with a conductive additive, to enhance cycle stability and capacity.

Method for preparing graphene by using waste negative electrode graphite of lithium battery and graphene

PatentWO2022183585A1

Innovation

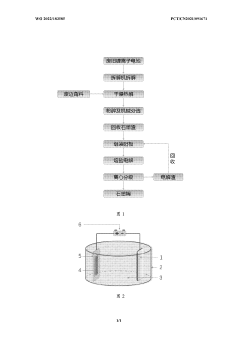

- Using the confined-molten salt electrolysis method, the graphite powder recovered from used batteries is clamped in a conductive mesh, and DC electrolysis is performed. The molten electrolyte and external voltage are used to drive anions to embed between the graphite layers, and graphene is prepared through oxidative exfoliation. Simplify processes and increase recovery and conversion rates.

Environmental Impact Assessment

The environmental impact assessment of graphene batteries as an enabler of clean technology reveals both promising benefits and potential concerns. On the positive side, graphene batteries have the potential to significantly reduce greenhouse gas emissions associated with energy storage and transportation. Their high energy density and rapid charging capabilities could accelerate the adoption of electric vehicles, reducing reliance on fossil fuels in the transportation sector. Additionally, the improved efficiency and longer lifespan of graphene batteries could lead to a reduction in electronic waste, addressing a growing environmental challenge.

However, the production of graphene itself raises some environmental considerations. The extraction and processing of graphite, the primary raw material for graphene, can have localized environmental impacts, including land disturbance and water pollution if not properly managed. The energy-intensive nature of some graphene production methods also needs to be addressed to ensure a net positive environmental impact.

The use of graphene batteries in renewable energy systems presents a significant opportunity for environmental improvement. Their ability to store and distribute energy more efficiently could enhance the viability of intermittent renewable sources like solar and wind power, potentially accelerating the transition away from fossil fuel-based electricity generation.

From a lifecycle perspective, graphene batteries show promise in terms of recyclability and resource conservation. The materials used in graphene batteries are generally more recyclable than those in conventional lithium-ion batteries, potentially reducing the environmental burden at the end of their life cycle. Furthermore, the extended lifespan of graphene batteries could lead to a reduction in the overall demand for battery production, conserving resources and energy in the long term.

It's important to note that the full environmental impact of graphene batteries will depend on the scale of their adoption and the specific manufacturing processes used. As the technology matures, ongoing assessment and optimization of production methods will be crucial to maximize the environmental benefits while minimizing potential negative impacts. This includes developing sustainable sourcing practices for raw materials and implementing energy-efficient manufacturing processes.

In conclusion, while graphene batteries show significant potential as an enabler of clean technology, realizing their full environmental benefits will require careful consideration of the entire lifecycle, from production to disposal. Continued research and development efforts should focus not only on enhancing performance but also on minimizing the environmental footprint of graphene battery technology.

However, the production of graphene itself raises some environmental considerations. The extraction and processing of graphite, the primary raw material for graphene, can have localized environmental impacts, including land disturbance and water pollution if not properly managed. The energy-intensive nature of some graphene production methods also needs to be addressed to ensure a net positive environmental impact.

The use of graphene batteries in renewable energy systems presents a significant opportunity for environmental improvement. Their ability to store and distribute energy more efficiently could enhance the viability of intermittent renewable sources like solar and wind power, potentially accelerating the transition away from fossil fuel-based electricity generation.

From a lifecycle perspective, graphene batteries show promise in terms of recyclability and resource conservation. The materials used in graphene batteries are generally more recyclable than those in conventional lithium-ion batteries, potentially reducing the environmental burden at the end of their life cycle. Furthermore, the extended lifespan of graphene batteries could lead to a reduction in the overall demand for battery production, conserving resources and energy in the long term.

It's important to note that the full environmental impact of graphene batteries will depend on the scale of their adoption and the specific manufacturing processes used. As the technology matures, ongoing assessment and optimization of production methods will be crucial to maximize the environmental benefits while minimizing potential negative impacts. This includes developing sustainable sourcing practices for raw materials and implementing energy-efficient manufacturing processes.

In conclusion, while graphene batteries show significant potential as an enabler of clean technology, realizing their full environmental benefits will require careful consideration of the entire lifecycle, from production to disposal. Continued research and development efforts should focus not only on enhancing performance but also on minimizing the environmental footprint of graphene battery technology.

Graphene Battery Manufacturing Processes

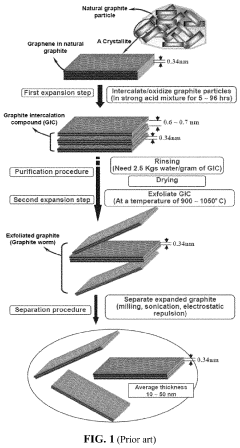

The manufacturing processes for graphene batteries involve several key steps, each crucial for the production of high-quality, efficient energy storage devices. The process typically begins with the synthesis of graphene, which can be achieved through various methods such as chemical vapor deposition (CVD), exfoliation of graphite, or reduction of graphene oxide. Each method has its advantages and challenges, impacting the final battery performance and production scalability.

Once the graphene is produced, it undergoes a series of treatments to enhance its properties for battery applications. This may include surface functionalization to improve its interaction with electrolytes or doping with other elements to modify its electronic properties. The treated graphene is then incorporated into the battery structure, often as part of the electrode material.

The electrode fabrication process is a critical step in graphene battery manufacturing. It involves creating a composite material that combines graphene with other active materials, such as lithium compounds for lithium-ion batteries. This composite is then coated onto current collectors, typically made of copper or aluminum foils. The coating process must ensure uniform distribution and proper adhesion of the electrode material.

Assembly of the battery components follows, where the graphene-based electrodes are combined with separators and electrolytes. This step requires precise control of environmental conditions to prevent contamination and ensure proper cell chemistry. Advanced manufacturing techniques, such as roll-to-roll processing, are being developed to enable large-scale production of graphene batteries.

Quality control and testing are integral parts of the manufacturing process. Each battery undergoes rigorous testing to ensure it meets performance and safety standards. This includes cycling tests to evaluate capacity retention, rate capability tests, and safety tests under various conditions.

The final stages of production involve packaging the batteries into their final form factor, whether as individual cells or as part of larger battery packs. This step also includes the integration of battery management systems for larger assemblies, crucial for monitoring and optimizing battery performance and safety during use.

As the technology evolves, manufacturers are continually refining these processes to improve efficiency, reduce costs, and enhance the overall performance of graphene batteries. Innovations in automation and advanced manufacturing techniques are expected to play a significant role in scaling up production to meet the growing demand for high-performance energy storage solutions in clean technology applications.

Once the graphene is produced, it undergoes a series of treatments to enhance its properties for battery applications. This may include surface functionalization to improve its interaction with electrolytes or doping with other elements to modify its electronic properties. The treated graphene is then incorporated into the battery structure, often as part of the electrode material.

The electrode fabrication process is a critical step in graphene battery manufacturing. It involves creating a composite material that combines graphene with other active materials, such as lithium compounds for lithium-ion batteries. This composite is then coated onto current collectors, typically made of copper or aluminum foils. The coating process must ensure uniform distribution and proper adhesion of the electrode material.

Assembly of the battery components follows, where the graphene-based electrodes are combined with separators and electrolytes. This step requires precise control of environmental conditions to prevent contamination and ensure proper cell chemistry. Advanced manufacturing techniques, such as roll-to-roll processing, are being developed to enable large-scale production of graphene batteries.

Quality control and testing are integral parts of the manufacturing process. Each battery undergoes rigorous testing to ensure it meets performance and safety standards. This includes cycling tests to evaluate capacity retention, rate capability tests, and safety tests under various conditions.

The final stages of production involve packaging the batteries into their final form factor, whether as individual cells or as part of larger battery packs. This step also includes the integration of battery management systems for larger assemblies, crucial for monitoring and optimizing battery performance and safety during use.

As the technology evolves, manufacturers are continually refining these processes to improve efficiency, reduce costs, and enhance the overall performance of graphene batteries. Innovations in automation and advanced manufacturing techniques are expected to play a significant role in scaling up production to meet the growing demand for high-performance energy storage solutions in clean technology applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!