Graphene Battery: Integrating Renewable Energy and Storage

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a revolutionary advancement in energy storage technology, marking a significant milestone in the evolution of battery systems. The journey of graphene batteries began with the discovery of graphene in 2004, which opened up new possibilities in various fields, including energy storage. Since then, researchers and engineers have been exploring ways to harness the unique properties of graphene to enhance battery performance.

The primary objective of graphene battery research is to develop a high-capacity, fast-charging, and long-lasting energy storage solution that can effectively integrate with renewable energy systems. This goal aligns with the growing global demand for sustainable energy solutions and the need to overcome the limitations of traditional lithium-ion batteries.

One of the key evolutionary steps in graphene battery development has been the integration of graphene into existing battery architectures. Initially, researchers focused on incorporating graphene as an additive to enhance the conductivity and stability of conventional electrode materials. This approach led to incremental improvements in battery performance, setting the stage for more ambitious innovations.

As the field progressed, scientists began exploring the potential of graphene as a primary component in battery electrodes. This shift in focus aimed to leverage graphene's exceptional electrical conductivity, mechanical strength, and high surface area to create batteries with superior energy density and faster charging capabilities. The development of graphene-based anodes and cathodes has been a critical milestone in this evolutionary process.

Recent advancements have seen the emergence of all-graphene batteries, where both electrodes and even the electrolyte are composed of graphene-based materials. This represents a paradigm shift in battery design, promising unprecedented levels of performance and efficiency. The ultimate objective is to create a battery that can store large amounts of energy, charge in minutes, and maintain its capacity over thousands of cycles.

The integration of graphene batteries with renewable energy systems is another crucial aspect of their evolution. Researchers are working on developing graphene-based supercapacitors and hybrid energy storage devices that can efficiently capture and store energy from intermittent sources like solar and wind power. This integration aims to address one of the main challenges in renewable energy adoption: the need for reliable and efficient energy storage solutions.

Looking ahead, the objectives for graphene battery research include further improving energy density, enhancing cycle life, and reducing production costs. There is also a strong focus on scaling up manufacturing processes to enable mass production of graphene batteries, making them commercially viable for a wide range of applications, from portable electronics to electric vehicles and grid-scale energy storage.

The primary objective of graphene battery research is to develop a high-capacity, fast-charging, and long-lasting energy storage solution that can effectively integrate with renewable energy systems. This goal aligns with the growing global demand for sustainable energy solutions and the need to overcome the limitations of traditional lithium-ion batteries.

One of the key evolutionary steps in graphene battery development has been the integration of graphene into existing battery architectures. Initially, researchers focused on incorporating graphene as an additive to enhance the conductivity and stability of conventional electrode materials. This approach led to incremental improvements in battery performance, setting the stage for more ambitious innovations.

As the field progressed, scientists began exploring the potential of graphene as a primary component in battery electrodes. This shift in focus aimed to leverage graphene's exceptional electrical conductivity, mechanical strength, and high surface area to create batteries with superior energy density and faster charging capabilities. The development of graphene-based anodes and cathodes has been a critical milestone in this evolutionary process.

Recent advancements have seen the emergence of all-graphene batteries, where both electrodes and even the electrolyte are composed of graphene-based materials. This represents a paradigm shift in battery design, promising unprecedented levels of performance and efficiency. The ultimate objective is to create a battery that can store large amounts of energy, charge in minutes, and maintain its capacity over thousands of cycles.

The integration of graphene batteries with renewable energy systems is another crucial aspect of their evolution. Researchers are working on developing graphene-based supercapacitors and hybrid energy storage devices that can efficiently capture and store energy from intermittent sources like solar and wind power. This integration aims to address one of the main challenges in renewable energy adoption: the need for reliable and efficient energy storage solutions.

Looking ahead, the objectives for graphene battery research include further improving energy density, enhancing cycle life, and reducing production costs. There is also a strong focus on scaling up manufacturing processes to enable mass production of graphene batteries, making them commercially viable for a wide range of applications, from portable electronics to electric vehicles and grid-scale energy storage.

Renewable Energy Storage Market Analysis

The renewable energy storage market has experienced significant growth in recent years, driven by the increasing adoption of renewable energy sources and the need for efficient energy management systems. As countries worldwide strive to reduce their carbon footprint and transition towards cleaner energy solutions, the demand for advanced energy storage technologies has surged. This market encompasses various storage solutions, including batteries, pumped hydro storage, compressed air energy storage, and thermal energy storage systems.

The global renewable energy storage market was valued at approximately $11 billion in 2020 and is projected to reach $30 billion by 2025, growing at a compound annual growth rate (CAGR) of 21%. This robust growth is attributed to several factors, including declining costs of renewable energy technologies, supportive government policies, and increasing investments in grid modernization.

Lithium-ion batteries currently dominate the market, accounting for over 90% of grid battery storage installations. However, emerging technologies like flow batteries and solid-state batteries are gaining traction due to their potential for longer duration storage and improved safety profiles. The integration of graphene in battery technologies presents a promising avenue for enhancing energy storage capabilities and addressing some of the limitations of current battery systems.

The market for renewable energy storage is geographically diverse, with Asia-Pacific leading in terms of installed capacity and market share. China, in particular, has emerged as a key player, driven by its ambitious renewable energy targets and substantial investments in energy storage infrastructure. North America and Europe follow closely, with growing installations of grid-scale battery storage systems to support their renewable energy integration efforts.

Key market drivers include the increasing penetration of variable renewable energy sources, such as solar and wind, which necessitate efficient storage solutions to manage intermittency issues. Additionally, the electrification of transportation and the growing demand for off-grid and microgrid solutions in remote areas are fueling market growth.

However, the market faces challenges, including high initial costs, regulatory barriers, and technical limitations of current storage technologies. The development of more cost-effective and efficient storage solutions, such as graphene-enhanced batteries, could potentially address these challenges and further accelerate market growth.

In conclusion, the renewable energy storage market presents significant opportunities for innovation and growth, with graphene-based technologies poised to play a crucial role in shaping the future of energy storage systems. As the market continues to evolve, advancements in storage technologies will be critical in enabling the widespread adoption of renewable energy sources and facilitating the transition to a more sustainable energy landscape.

The global renewable energy storage market was valued at approximately $11 billion in 2020 and is projected to reach $30 billion by 2025, growing at a compound annual growth rate (CAGR) of 21%. This robust growth is attributed to several factors, including declining costs of renewable energy technologies, supportive government policies, and increasing investments in grid modernization.

Lithium-ion batteries currently dominate the market, accounting for over 90% of grid battery storage installations. However, emerging technologies like flow batteries and solid-state batteries are gaining traction due to their potential for longer duration storage and improved safety profiles. The integration of graphene in battery technologies presents a promising avenue for enhancing energy storage capabilities and addressing some of the limitations of current battery systems.

The market for renewable energy storage is geographically diverse, with Asia-Pacific leading in terms of installed capacity and market share. China, in particular, has emerged as a key player, driven by its ambitious renewable energy targets and substantial investments in energy storage infrastructure. North America and Europe follow closely, with growing installations of grid-scale battery storage systems to support their renewable energy integration efforts.

Key market drivers include the increasing penetration of variable renewable energy sources, such as solar and wind, which necessitate efficient storage solutions to manage intermittency issues. Additionally, the electrification of transportation and the growing demand for off-grid and microgrid solutions in remote areas are fueling market growth.

However, the market faces challenges, including high initial costs, regulatory barriers, and technical limitations of current storage technologies. The development of more cost-effective and efficient storage solutions, such as graphene-enhanced batteries, could potentially address these challenges and further accelerate market growth.

In conclusion, the renewable energy storage market presents significant opportunities for innovation and growth, with graphene-based technologies poised to play a crucial role in shaping the future of energy storage systems. As the market continues to evolve, advancements in storage technologies will be critical in enabling the widespread adoption of renewable energy sources and facilitating the transition to a more sustainable energy landscape.

Graphene Battery Technology: Current Status and Challenges

Graphene battery technology has emerged as a promising solution for integrating renewable energy and storage systems. The current status of graphene batteries showcases significant advancements, yet it also faces several challenges that need to be addressed for widespread adoption.

One of the primary advantages of graphene batteries is their high energy density and rapid charging capabilities. Researchers have demonstrated that graphene-enhanced electrodes can significantly increase the surface area for energy storage, potentially leading to batteries with up to five times the energy density of traditional lithium-ion batteries. This breakthrough could revolutionize electric vehicle technology and grid-scale energy storage systems.

However, the scalability of graphene production remains a significant hurdle. While laboratory-scale synthesis of high-quality graphene has been achieved, translating this to industrial-scale production while maintaining consistent quality and properties is challenging. The cost of production is another factor limiting widespread adoption, as current methods are still relatively expensive compared to traditional battery materials.

Stability and longevity of graphene batteries are areas of ongoing research. While graphene's excellent conductivity and mechanical strength contribute to improved cycle life, issues such as electrolyte degradation and unwanted side reactions still need to be fully addressed. Scientists are exploring various graphene composites and hybrid materials to enhance stability without compromising performance.

Integration with renewable energy systems presents both opportunities and challenges. Graphene batteries' fast charging and high power density make them ideal for smoothing out the intermittent nature of renewable sources like solar and wind. However, optimizing the interface between these energy sources and graphene-based storage systems requires further development in power electronics and energy management systems.

Safety concerns, particularly in high-energy-density applications, remain a critical focus. While graphene's thermal conductivity can help in heat dissipation, the potential for thermal runaway in large-scale systems needs thorough investigation and mitigation strategies.

Environmental impact and recyclability are becoming increasingly important considerations. While graphene itself is non-toxic, the long-term environmental effects of graphene-based batteries and their disposal or recycling processes are still being studied. Developing eco-friendly production methods and establishing efficient recycling protocols are crucial for the sustainable adoption of this technology.

In conclusion, graphene battery technology shows immense promise but faces multifaceted challenges. Overcoming these hurdles requires collaborative efforts across materials science, engineering, and environmental studies to fully harness the potential of graphene in revolutionizing energy storage and renewable integration.

One of the primary advantages of graphene batteries is their high energy density and rapid charging capabilities. Researchers have demonstrated that graphene-enhanced electrodes can significantly increase the surface area for energy storage, potentially leading to batteries with up to five times the energy density of traditional lithium-ion batteries. This breakthrough could revolutionize electric vehicle technology and grid-scale energy storage systems.

However, the scalability of graphene production remains a significant hurdle. While laboratory-scale synthesis of high-quality graphene has been achieved, translating this to industrial-scale production while maintaining consistent quality and properties is challenging. The cost of production is another factor limiting widespread adoption, as current methods are still relatively expensive compared to traditional battery materials.

Stability and longevity of graphene batteries are areas of ongoing research. While graphene's excellent conductivity and mechanical strength contribute to improved cycle life, issues such as electrolyte degradation and unwanted side reactions still need to be fully addressed. Scientists are exploring various graphene composites and hybrid materials to enhance stability without compromising performance.

Integration with renewable energy systems presents both opportunities and challenges. Graphene batteries' fast charging and high power density make them ideal for smoothing out the intermittent nature of renewable sources like solar and wind. However, optimizing the interface between these energy sources and graphene-based storage systems requires further development in power electronics and energy management systems.

Safety concerns, particularly in high-energy-density applications, remain a critical focus. While graphene's thermal conductivity can help in heat dissipation, the potential for thermal runaway in large-scale systems needs thorough investigation and mitigation strategies.

Environmental impact and recyclability are becoming increasingly important considerations. While graphene itself is non-toxic, the long-term environmental effects of graphene-based batteries and their disposal or recycling processes are still being studied. Developing eco-friendly production methods and establishing efficient recycling protocols are crucial for the sustainable adoption of this technology.

In conclusion, graphene battery technology shows immense promise but faces multifaceted challenges. Overcoming these hurdles requires collaborative efforts across materials science, engineering, and environmental studies to fully harness the potential of graphene in revolutionizing energy storage and renewable integration.

Existing Graphene Battery Solutions

01 Graphene-based electrode materials

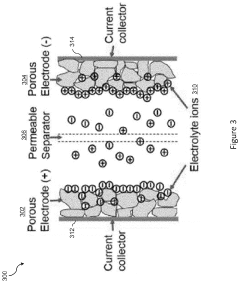

Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This can improve the battery's energy density, charge/discharge rates, and overall performance. Various forms of graphene, such as graphene oxide or reduced graphene oxide, may be incorporated into electrode structures.- Graphene-based electrode materials: Graphene is used as an electrode material in batteries due to its high conductivity and large surface area. This can enhance the battery's performance, including increased energy density and faster charging rates. Graphene-based electrodes can be used in various types of batteries, including lithium-ion batteries.

- Graphene composite materials for battery components: Composite materials incorporating graphene are developed for use in battery components such as electrodes and separators. These composites can combine the beneficial properties of graphene with other materials to improve overall battery performance, stability, and lifespan.

- Graphene-enhanced electrolytes: Graphene or graphene derivatives are incorporated into battery electrolytes to improve ionic conductivity and overall battery efficiency. This can lead to better performance in terms of power output and charging speed, as well as potentially enhancing the safety of the battery.

- Manufacturing processes for graphene-based battery components: Novel manufacturing techniques are developed to produce graphene-based materials and components for batteries. These processes aim to improve the quality, consistency, and scalability of graphene production for battery applications, potentially reducing costs and enhancing commercial viability.

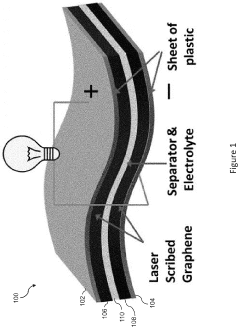

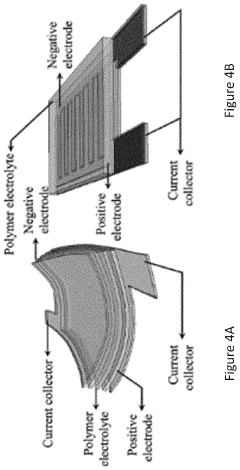

- Graphene-enabled flexible and wearable batteries: Graphene's unique properties are utilized to create flexible and wearable battery designs. These batteries can be integrated into various devices and applications, offering improved energy storage capabilities while maintaining flexibility and durability.

02 Graphene-enhanced electrolytes

Graphene or graphene derivatives are incorporated into battery electrolytes to enhance ionic conductivity and stability. This can lead to improved battery performance, longer cycle life, and better safety characteristics. The graphene materials may be dispersed in liquid electrolytes or used in solid-state electrolyte systems.Expand Specific Solutions03 Graphene-based composite materials

Composite materials combining graphene with other active materials are developed for battery applications. These composites can enhance the mechanical and electrochemical properties of battery components, leading to improved capacity, cycling stability, and rate capability. Examples include graphene-metal oxide composites for cathodes or graphene-silicon composites for anodes.Expand Specific Solutions04 Graphene production and modification for battery applications

Specialized methods for producing and modifying graphene materials tailored for battery applications are developed. These may include techniques for controlling graphene sheet size, functionalization, doping, or creating 3D graphene structures. The goal is to optimize graphene properties for specific battery components and enhance overall battery performance.Expand Specific Solutions05 Graphene-based flexible and wearable batteries

Graphene's unique properties are utilized to develop flexible and wearable battery technologies. These batteries incorporate graphene-based components to achieve high flexibility, stretchability, and durability while maintaining good electrochemical performance. Applications include powering wearable electronics and integrating energy storage into textiles or other flexible substrates.Expand Specific Solutions

Key Players in Graphene Battery Research

The graphene battery market is in an early growth stage, with significant potential for integration with renewable energy storage. The market size is expanding rapidly, driven by increasing demand for high-performance energy storage solutions. Technologically, graphene batteries are still evolving, with various research institutions and companies working on advancements. Key players like Northwestern University, Semiconductor Energy Laboratory, and Honeycomb Battery Co. are at the forefront of research and development. Universities such as The University of Queensland and Tongji University are contributing to fundamental research, while companies like Samsung Electronics and Vorbeck Materials Corp. are focusing on commercial applications. The competitive landscape is diverse, with a mix of academic institutions, established tech giants, and specialized startups all vying to unlock the full potential of graphene in battery technology.

Northwestern University

Technical Solution: Northwestern University has developed a graphene-based battery technology that combines high energy density with fast charging capabilities. Their approach involves creating a three-dimensional graphene foam structure that serves as a highly conductive scaffold for the battery's active materials. This 3D graphene framework allows for improved electron and ion transport, resulting in enhanced energy storage capacity and faster charge/discharge rates [1][3]. The university's research team has also explored the integration of graphene with silicon anodes, which has shown promise in increasing the battery's overall capacity while maintaining structural stability during cycling [2]. Additionally, they have investigated the use of graphene oxide as a coating material for conventional lithium-ion battery electrodes, demonstrating improved cycling stability and reduced capacity fade over time [4].

Strengths: High energy density, fast charging capabilities, improved electron and ion transport. Weaknesses: Potential scalability issues for mass production, higher production costs compared to conventional batteries.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory Co., Ltd. has developed a graphene-based battery technology that focuses on improving the stability and longevity of lithium-ion batteries. Their approach involves using graphene as a protective coating for the battery electrodes, particularly the anode. This graphene coating helps to prevent the formation of dendrites, which can cause short circuits and reduce battery life [1]. The company has also explored the use of graphene oxide in the electrolyte to enhance ion conductivity and reduce internal resistance [2]. Their research has shown that graphene-enhanced batteries can maintain over 80% of their initial capacity after 1000 charge-discharge cycles, a significant improvement over conventional lithium-ion batteries [3]. Additionally, they have investigated the potential of graphene in solid-state batteries, aiming to create safer and more energy-dense power sources for electric vehicles and renewable energy storage systems [4].

Strengths: Improved battery stability and longevity, enhanced safety through dendrite prevention. Weaknesses: Potentially higher production costs, challenges in large-scale manufacturing of graphene-enhanced components.

Breakthrough Graphene Battery Patents

Graphene battery as energy storage for appliances

PatentInactiveUS20220416568A1

Innovation

- The implementation of graphene batteries as a powerwall solution for homes and businesses, which can store energy from solar or other sources, providing backup power during outages and reducing energy costs by charging at night or through solar power, and utilizing energy storage to smooth out variable energy resources.

Batteries incorporating graphene membranes for extending the cycle-life of lithium-ion batteries

PatentWO2015192008A3

Innovation

- Incorporation of a selectively permeable graphene-based membrane near the anode to reduce electrolyte component contact and anode degradation.

- Use of graphene-based material as a protective barrier in lithium-ion batteries to extend cycle life.

- Novel approach to address anode degradation in lithium-ion batteries through selective filtration of electrolyte components.

Environmental Impact of Graphene Batteries

The environmental impact of graphene batteries is a critical consideration in the development and adoption of this emerging technology. As graphene batteries integrate renewable energy and storage solutions, their potential to reduce carbon emissions and promote sustainable energy practices is significant. However, a comprehensive assessment of their environmental footprint throughout their lifecycle is essential.

Graphene batteries offer several environmental advantages over traditional lithium-ion batteries. Their higher energy density and faster charging capabilities can lead to reduced energy consumption during use. This efficiency translates to lower greenhouse gas emissions associated with battery charging and operation. Additionally, the longer lifespan of graphene batteries means fewer replacements are needed, potentially reducing electronic waste.

The production of graphene batteries, however, raises some environmental concerns. The extraction and processing of raw materials, particularly graphene, can be energy-intensive and may involve the use of harmful chemicals. As the technology scales up, it is crucial to develop and implement sustainable manufacturing processes that minimize environmental impact. This includes optimizing resource use, reducing waste, and exploring eco-friendly synthesis methods for graphene production.

End-of-life management for graphene batteries is another important environmental consideration. While these batteries are expected to last longer than conventional alternatives, proper recycling and disposal methods must be established to prevent potential environmental contamination. The recyclability of graphene batteries is an area of ongoing research, with efforts focused on developing efficient recycling processes to recover valuable materials and minimize waste.

The integration of graphene batteries with renewable energy systems presents opportunities for significant environmental benefits. By enhancing the storage capacity and efficiency of renewable energy sources like solar and wind power, graphene batteries can contribute to the broader adoption of clean energy technologies. This synergy has the potential to accelerate the transition away from fossil fuels, leading to substantial reductions in greenhouse gas emissions and air pollution.

As research on graphene batteries progresses, it is essential to conduct comprehensive life cycle assessments to fully understand their environmental impact. These assessments should consider factors such as raw material sourcing, manufacturing processes, energy consumption during use, and end-of-life management. By identifying areas for improvement and implementing sustainable practices throughout the battery lifecycle, the environmental benefits of graphene batteries can be maximized while minimizing potential negative impacts.

Graphene batteries offer several environmental advantages over traditional lithium-ion batteries. Their higher energy density and faster charging capabilities can lead to reduced energy consumption during use. This efficiency translates to lower greenhouse gas emissions associated with battery charging and operation. Additionally, the longer lifespan of graphene batteries means fewer replacements are needed, potentially reducing electronic waste.

The production of graphene batteries, however, raises some environmental concerns. The extraction and processing of raw materials, particularly graphene, can be energy-intensive and may involve the use of harmful chemicals. As the technology scales up, it is crucial to develop and implement sustainable manufacturing processes that minimize environmental impact. This includes optimizing resource use, reducing waste, and exploring eco-friendly synthesis methods for graphene production.

End-of-life management for graphene batteries is another important environmental consideration. While these batteries are expected to last longer than conventional alternatives, proper recycling and disposal methods must be established to prevent potential environmental contamination. The recyclability of graphene batteries is an area of ongoing research, with efforts focused on developing efficient recycling processes to recover valuable materials and minimize waste.

The integration of graphene batteries with renewable energy systems presents opportunities for significant environmental benefits. By enhancing the storage capacity and efficiency of renewable energy sources like solar and wind power, graphene batteries can contribute to the broader adoption of clean energy technologies. This synergy has the potential to accelerate the transition away from fossil fuels, leading to substantial reductions in greenhouse gas emissions and air pollution.

As research on graphene batteries progresses, it is essential to conduct comprehensive life cycle assessments to fully understand their environmental impact. These assessments should consider factors such as raw material sourcing, manufacturing processes, energy consumption during use, and end-of-life management. By identifying areas for improvement and implementing sustainable practices throughout the battery lifecycle, the environmental benefits of graphene batteries can be maximized while minimizing potential negative impacts.

Graphene Battery Manufacturing Processes

The manufacturing processes for graphene batteries represent a critical aspect of their development and commercialization. These processes involve several key steps, each requiring precise control and optimization to ensure the production of high-quality, efficient batteries.

The first stage in graphene battery manufacturing is the synthesis of graphene itself. This can be achieved through various methods, including chemical vapor deposition (CVD), liquid-phase exfoliation, and reduction of graphene oxide. Each method has its advantages and challenges, with CVD offering high-quality graphene but at a higher cost, while liquid-phase exfoliation provides scalability but may result in lower-quality graphene.

Once the graphene is produced, it must be incorporated into the battery structure. This typically involves creating a composite material by combining graphene with other battery components such as lithium, sulfur, or metal oxides. The precise mixing and blending of these materials are crucial to achieve the desired electrochemical properties and performance characteristics of the battery.

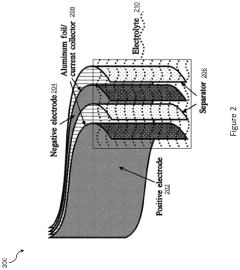

The next step in the manufacturing process is the fabrication of electrodes. This involves coating or depositing the graphene-based composite onto current collectors, usually made of copper or aluminum foils. Advanced coating techniques, such as roll-to-roll processing, are being developed to enable large-scale, continuous production of graphene-enhanced electrodes.

Assembly of the battery cells follows electrode fabrication. This step includes stacking or winding the electrodes with separators and electrolytes to form the core of the battery. The integration of graphene into this process requires careful consideration of factors such as electrode thickness, porosity, and uniformity to maximize the benefits of graphene's unique properties.

Encapsulation and sealing of the battery cells are critical to ensure their longevity and safety. This process must be carried out in controlled environments to prevent contamination and moisture ingress, which can significantly impact battery performance and lifespan.

Quality control and testing are integral parts of the manufacturing process. Each stage of production must be monitored and validated to ensure consistency and adherence to specifications. Advanced characterization techniques, including electron microscopy and spectroscopy, are employed to assess the structure and composition of graphene-enhanced battery components.

As the field of graphene batteries continues to evolve, researchers and manufacturers are focusing on developing more efficient and cost-effective production methods. This includes exploring new synthesis techniques for graphene, improving the scalability of manufacturing processes, and optimizing the integration of graphene into existing battery production lines.

The first stage in graphene battery manufacturing is the synthesis of graphene itself. This can be achieved through various methods, including chemical vapor deposition (CVD), liquid-phase exfoliation, and reduction of graphene oxide. Each method has its advantages and challenges, with CVD offering high-quality graphene but at a higher cost, while liquid-phase exfoliation provides scalability but may result in lower-quality graphene.

Once the graphene is produced, it must be incorporated into the battery structure. This typically involves creating a composite material by combining graphene with other battery components such as lithium, sulfur, or metal oxides. The precise mixing and blending of these materials are crucial to achieve the desired electrochemical properties and performance characteristics of the battery.

The next step in the manufacturing process is the fabrication of electrodes. This involves coating or depositing the graphene-based composite onto current collectors, usually made of copper or aluminum foils. Advanced coating techniques, such as roll-to-roll processing, are being developed to enable large-scale, continuous production of graphene-enhanced electrodes.

Assembly of the battery cells follows electrode fabrication. This step includes stacking or winding the electrodes with separators and electrolytes to form the core of the battery. The integration of graphene into this process requires careful consideration of factors such as electrode thickness, porosity, and uniformity to maximize the benefits of graphene's unique properties.

Encapsulation and sealing of the battery cells are critical to ensure their longevity and safety. This process must be carried out in controlled environments to prevent contamination and moisture ingress, which can significantly impact battery performance and lifespan.

Quality control and testing are integral parts of the manufacturing process. Each stage of production must be monitored and validated to ensure consistency and adherence to specifications. Advanced characterization techniques, including electron microscopy and spectroscopy, are employed to assess the structure and composition of graphene-enhanced battery components.

As the field of graphene batteries continues to evolve, researchers and manufacturers are focusing on developing more efficient and cost-effective production methods. This includes exploring new synthesis techniques for graphene, improving the scalability of manufacturing processes, and optimizing the integration of graphene into existing battery production lines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!