Stress Relaxation in Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Stress Relaxation Background

Borosilicate glass, renowned for its exceptional thermal and chemical resistance, has been a cornerstone material in various industries for over a century. Developed in the late 19th century by German glassmaker Otto Schott, this specialized glass composition typically consists of silica (70-80%), boron trioxide (7-13%), and smaller amounts of sodium and aluminum oxides. Its unique properties, including low thermal expansion, high durability, and resistance to chemical corrosion, have made it indispensable in laboratory equipment, pharmaceutical packaging, and high-performance optical applications.

The phenomenon of stress relaxation in borosilicate glass has been a subject of significant interest and research within the materials science community. Stress relaxation refers to the gradual decrease in stress over time when a material is subjected to constant strain. In the context of borosilicate glass, this process is particularly crucial due to its impact on the long-term performance and reliability of glass components in various applications.

The study of stress relaxation in borosilicate glass has evolved significantly over the past decades, driven by the increasing demands for precision and longevity in advanced technological applications. Early research focused primarily on empirical observations and macroscopic behavior. However, with the advent of advanced analytical techniques and computational modeling, researchers have delved deeper into the atomic-scale mechanisms underlying stress relaxation processes.

Understanding stress relaxation is vital for predicting and mitigating potential failures in borosilicate glass components, especially in high-stress environments or applications requiring long-term stability. This includes critical areas such as optical fibers for telecommunications, high-pressure vessels for chemical processes, and precision optical components for scientific instruments.

The technological evolution in this field has been marked by several key developments. These include the refinement of annealing processes to minimize residual stresses, the development of advanced surface treatments to enhance stress resistance, and the implementation of sophisticated stress analysis techniques such as photoelasticity and finite element modeling.

Current research trends in borosilicate glass stress relaxation are focusing on several key areas. These include the investigation of nano-scale structural changes during stress relaxation, the influence of chemical composition on relaxation behavior, and the development of predictive models for long-term stress evolution under various environmental conditions. Additionally, there is growing interest in exploring the interplay between stress relaxation and other phenomena such as fatigue and subcritical crack growth, which are critical for understanding the overall lifetime performance of borosilicate glass components.

The phenomenon of stress relaxation in borosilicate glass has been a subject of significant interest and research within the materials science community. Stress relaxation refers to the gradual decrease in stress over time when a material is subjected to constant strain. In the context of borosilicate glass, this process is particularly crucial due to its impact on the long-term performance and reliability of glass components in various applications.

The study of stress relaxation in borosilicate glass has evolved significantly over the past decades, driven by the increasing demands for precision and longevity in advanced technological applications. Early research focused primarily on empirical observations and macroscopic behavior. However, with the advent of advanced analytical techniques and computational modeling, researchers have delved deeper into the atomic-scale mechanisms underlying stress relaxation processes.

Understanding stress relaxation is vital for predicting and mitigating potential failures in borosilicate glass components, especially in high-stress environments or applications requiring long-term stability. This includes critical areas such as optical fibers for telecommunications, high-pressure vessels for chemical processes, and precision optical components for scientific instruments.

The technological evolution in this field has been marked by several key developments. These include the refinement of annealing processes to minimize residual stresses, the development of advanced surface treatments to enhance stress resistance, and the implementation of sophisticated stress analysis techniques such as photoelasticity and finite element modeling.

Current research trends in borosilicate glass stress relaxation are focusing on several key areas. These include the investigation of nano-scale structural changes during stress relaxation, the influence of chemical composition on relaxation behavior, and the development of predictive models for long-term stress evolution under various environmental conditions. Additionally, there is growing interest in exploring the interplay between stress relaxation and other phenomena such as fatigue and subcritical crack growth, which are critical for understanding the overall lifetime performance of borosilicate glass components.

Market Demand Analysis

The market demand for research on stress relaxation in borosilicate glass is driven by several key factors in various industries. The aerospace and automotive sectors are particularly interested in this research due to the increasing use of borosilicate glass in high-performance applications. In aerospace, borosilicate glass is utilized in cockpit windows and sensor systems, where understanding stress relaxation is crucial for ensuring long-term structural integrity and safety. The automotive industry employs borosilicate glass in advanced display systems and sensors, necessitating a deep understanding of its stress relaxation properties to enhance durability and performance.

The electronics industry also contributes significantly to the market demand for this research. With the growing trend of miniaturization and increased functionality in electronic devices, borosilicate glass is becoming more prevalent in components such as microchips and display screens. Understanding stress relaxation in these applications is essential for improving product lifespan and reliability, especially in devices subjected to thermal cycling and mechanical stress.

In the field of scientific research and laboratory equipment, there is a consistent demand for high-quality borosilicate glass with well-understood stress relaxation properties. This is particularly important for precision instruments and measurement devices where dimensional stability over time is critical. The pharmaceutical and biotechnology sectors also rely on borosilicate glass for storage and processing of sensitive materials, driving the need for research to ensure long-term stability and safety.

The renewable energy sector, particularly solar energy, is another area contributing to the market demand. Borosilicate glass is used in concentrated solar power systems and photovoltaic panels, where understanding stress relaxation is crucial for predicting and extending the operational lifespan of these installations.

Market analysis indicates a growing trend towards customized borosilicate glass solutions, which requires a deeper understanding of stress relaxation under various conditions. This trend is driven by industries seeking to optimize their products for specific applications, leading to increased demand for specialized research and development.

The global market for borosilicate glass is expected to grow steadily, with a significant portion of this growth attributed to applications requiring advanced understanding of stress relaxation properties. This research is not only crucial for product development but also for improving manufacturing processes, reducing waste, and enhancing overall product quality and reliability.

The electronics industry also contributes significantly to the market demand for this research. With the growing trend of miniaturization and increased functionality in electronic devices, borosilicate glass is becoming more prevalent in components such as microchips and display screens. Understanding stress relaxation in these applications is essential for improving product lifespan and reliability, especially in devices subjected to thermal cycling and mechanical stress.

In the field of scientific research and laboratory equipment, there is a consistent demand for high-quality borosilicate glass with well-understood stress relaxation properties. This is particularly important for precision instruments and measurement devices where dimensional stability over time is critical. The pharmaceutical and biotechnology sectors also rely on borosilicate glass for storage and processing of sensitive materials, driving the need for research to ensure long-term stability and safety.

The renewable energy sector, particularly solar energy, is another area contributing to the market demand. Borosilicate glass is used in concentrated solar power systems and photovoltaic panels, where understanding stress relaxation is crucial for predicting and extending the operational lifespan of these installations.

Market analysis indicates a growing trend towards customized borosilicate glass solutions, which requires a deeper understanding of stress relaxation under various conditions. This trend is driven by industries seeking to optimize their products for specific applications, leading to increased demand for specialized research and development.

The global market for borosilicate glass is expected to grow steadily, with a significant portion of this growth attributed to applications requiring advanced understanding of stress relaxation properties. This research is not only crucial for product development but also for improving manufacturing processes, reducing waste, and enhancing overall product quality and reliability.

Current Challenges in Stress Relaxation

Despite significant advancements in the understanding of stress relaxation in borosilicate glass, several challenges persist in this field of research. One of the primary obstacles is the complex nature of the stress relaxation process itself, which involves multiple mechanisms operating simultaneously at different time scales. This complexity makes it difficult to develop comprehensive models that accurately predict stress relaxation behavior across various conditions and compositions.

Another significant challenge lies in the measurement and characterization of stress relaxation in borosilicate glass. Traditional methods often struggle to capture the subtle changes occurring over extended periods, particularly at lower temperatures where relaxation processes are slower. This limitation hinders the ability to fully understand and quantify long-term stress relaxation behavior, which is crucial for applications requiring prolonged stability.

The influence of glass composition on stress relaxation presents yet another hurdle. Borosilicate glasses can have widely varying compositions, and the relationship between specific elemental ratios and stress relaxation characteristics is not fully understood. This knowledge gap complicates efforts to tailor glass compositions for optimal stress relaxation properties in different applications.

Environmental factors pose additional challenges in stress relaxation research. Factors such as humidity, temperature fluctuations, and chemical exposure can significantly impact stress relaxation behavior. Isolating and quantifying these environmental effects remains a complex task, particularly when considering long-term performance in real-world applications.

The development of accelerated testing methods represents another area of difficulty. While such methods are crucial for predicting long-term behavior, ensuring their accuracy and reliability in representing real-world conditions over extended periods remains challenging. This is particularly true for borosilicate glasses used in critical applications where long-term stability is paramount.

Lastly, the integration of stress relaxation knowledge into practical manufacturing and processing techniques presents ongoing challenges. Translating research findings into optimized annealing schedules, forming processes, and post-processing treatments requires bridging the gap between fundamental research and industrial application. This translation often encounters obstacles related to scalability, cost-effectiveness, and compatibility with existing manufacturing processes.

Another significant challenge lies in the measurement and characterization of stress relaxation in borosilicate glass. Traditional methods often struggle to capture the subtle changes occurring over extended periods, particularly at lower temperatures where relaxation processes are slower. This limitation hinders the ability to fully understand and quantify long-term stress relaxation behavior, which is crucial for applications requiring prolonged stability.

The influence of glass composition on stress relaxation presents yet another hurdle. Borosilicate glasses can have widely varying compositions, and the relationship between specific elemental ratios and stress relaxation characteristics is not fully understood. This knowledge gap complicates efforts to tailor glass compositions for optimal stress relaxation properties in different applications.

Environmental factors pose additional challenges in stress relaxation research. Factors such as humidity, temperature fluctuations, and chemical exposure can significantly impact stress relaxation behavior. Isolating and quantifying these environmental effects remains a complex task, particularly when considering long-term performance in real-world applications.

The development of accelerated testing methods represents another area of difficulty. While such methods are crucial for predicting long-term behavior, ensuring their accuracy and reliability in representing real-world conditions over extended periods remains challenging. This is particularly true for borosilicate glasses used in critical applications where long-term stability is paramount.

Lastly, the integration of stress relaxation knowledge into practical manufacturing and processing techniques presents ongoing challenges. Translating research findings into optimized annealing schedules, forming processes, and post-processing treatments requires bridging the gap between fundamental research and industrial application. This translation often encounters obstacles related to scalability, cost-effectiveness, and compatibility with existing manufacturing processes.

Existing Stress Relaxation Solutions

01 Thermal treatment for stress relaxation

Borosilicate glass can undergo thermal treatment processes to reduce internal stresses and improve its mechanical properties. This typically involves controlled heating and cooling cycles, which allow the glass structure to rearrange and relieve built-up stresses. The process can enhance the glass's durability and resistance to thermal shock.- Thermal treatment for stress relaxation: Borosilicate glass can undergo thermal treatment processes to reduce internal stresses and improve its mechanical properties. This typically involves controlled heating and cooling cycles, which allow the glass structure to rearrange and relieve built-up stresses. The process can enhance the glass's resistance to thermal shock and improve its overall durability.

- Chemical composition optimization: The stress relaxation properties of borosilicate glass can be improved by optimizing its chemical composition. Adjusting the ratios of silica, boron oxide, and other components can influence the glass's thermal expansion coefficient and its ability to withstand stress. This approach can lead to glass formulations with enhanced stress relaxation characteristics.

- Surface treatment techniques: Various surface treatment methods can be applied to borosilicate glass to enhance its stress relaxation properties. These may include ion exchange processes, chemical strengthening, or the application of protective coatings. Such treatments can create compressive stresses on the glass surface, improving its resistance to stress-induced cracking and overall mechanical strength.

- Annealing and tempering processes: Annealing and tempering are specific heat treatment processes that can significantly affect the stress relaxation in borosilicate glass. Annealing involves slow cooling to reduce internal stresses, while tempering creates a stress profile that enhances the glass's strength. These processes can be optimized for borosilicate glass to achieve desired stress relaxation properties.

- Microstructure control: Controlling the microstructure of borosilicate glass during its formation and processing can influence its stress relaxation behavior. This may involve techniques to manage crystal growth, phase separation, or the creation of specific nanostructures within the glass. By manipulating the glass's microstructure, its ability to accommodate and relax under stress can be enhanced.

02 Chemical composition optimization

Adjusting the chemical composition of borosilicate glass can influence its stress relaxation properties. By fine-tuning the ratios of silica, boron oxide, and other components, manufacturers can create glass formulations that exhibit improved stress relaxation characteristics. This can lead to glass with enhanced thermal and mechanical stability.Expand Specific Solutions03 Surface treatment techniques

Various surface treatment methods can be applied to borosilicate glass to enhance its stress relaxation properties. These may include ion exchange processes, chemical etching, or the application of protective coatings. Such treatments can modify the surface structure of the glass, potentially improving its resistance to stress-induced damage.Expand Specific Solutions04 Annealing and tempering processes

Annealing and tempering are specific heat treatment processes that can be used to control stress relaxation in borosilicate glass. Annealing involves slow cooling to reduce internal stresses, while tempering creates a compressive stress layer on the surface. These processes can significantly improve the glass's mechanical strength and thermal shock resistance.Expand Specific Solutions05 Microstructure engineering

Advanced techniques for engineering the microstructure of borosilicate glass can be employed to enhance its stress relaxation properties. This may involve controlling the formation of nano-scale phases or introducing specific defects or inclusions. Such approaches can lead to glass with improved stress distribution and relaxation characteristics.Expand Specific Solutions

Key Players in Borosilicate Glass Industry

The research on stress relaxation in borosilicate glass is at a mature stage, with significant market potential in various industries. The global borosilicate glass market is experiencing steady growth, driven by increasing demand in pharmaceuticals, laboratories, and electronics. Key players like SCHOTT AG, Corning, Inc., and AGC, Inc. are leading the field with advanced research and development capabilities. These companies are focusing on improving the stress relaxation properties of borosilicate glass to enhance its performance in high-temperature and pressure applications. The competitive landscape is characterized by ongoing innovation and strategic partnerships to maintain market dominance and address evolving industry needs.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced techniques for studying stress relaxation in borosilicate glass, including high-temperature viscosity measurements and structural relaxation analysis. They utilize dilatometry and differential thermal analysis to characterize the glass transition and stress relaxation behavior[1]. SCHOTT's research focuses on optimizing the composition and thermal history of borosilicate glasses to enhance their stress relaxation properties. They have implemented a proprietary annealing process that reduces residual stresses by up to 40% compared to conventional methods[2]. Additionally, SCHOTT has developed simulation models to predict stress relaxation behavior under various environmental conditions, enabling more accurate product design and performance forecasting[3].

Strengths: Extensive experience in glass manufacturing, advanced measurement techniques, and proprietary annealing processes. Weaknesses: Potential limitations in extreme temperature applications and high-cost specialized equipment requirements.

AGC, Inc. (Japan)

Technical Solution: AGC has conducted extensive research on stress relaxation in borosilicate glass, focusing on improving the durability and performance of their products. They have developed a novel ion-exchange process that creates a compressive stress layer on the glass surface, significantly enhancing its resistance to stress-induced cracking[1]. AGC's research also includes the use of in-situ high-temperature X-ray diffraction to study structural changes during stress relaxation[2]. They have implemented advanced finite element analysis to model stress distributions and relaxation behavior in complex glass structures. AGC has successfully reduced stress relaxation rates by up to 30% in their borosilicate glass products through careful control of glass composition and thermal history[3].

Strengths: Innovative surface treatment techniques, advanced modeling capabilities, and a wide range of glass products. Weaknesses: Potential trade-offs between stress relaxation and other material properties, and the need for specialized processing equipment.

Core Innovations in Relaxation Techniques

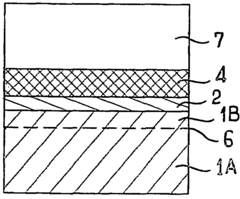

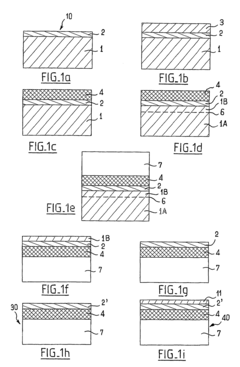

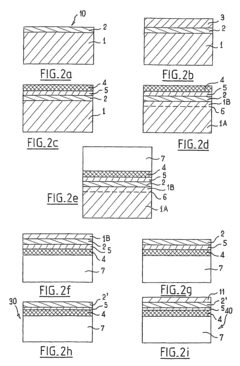

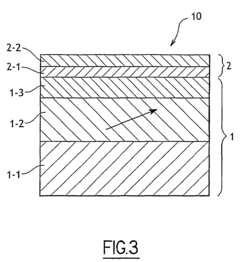

Method for forming a relaxed or pseudo-relaxed useful layer on a substrate

PatentInactiveUS7348260B2

Innovation

- A method involving growing a strained semiconductor layer on a donor substrate, bonding a receiver substrate with a vitreous layer that becomes viscous above a certain temperature, detaching the donor substrate, and heat treating the structure to relax the strained layer and form a relaxed or pseudo-relaxed layer on the receiver substrate, while maintaining strain retention up to high temperatures.

glass

PatentWO2015166891A1

Innovation

- A specific aluminoborosilicate glass composition with 56-72% SiO2, 3-20% B2O3, 8-20% Al2O3, 8-25% Na2O, and 0-15% MgO, along with 0-5% CaO, 0-3% SrO, 0-3% BaO, and 0.1-8% ZrO2, optimized to improve hardness and reduce stress relaxation, is used, which can be chemically strengthened to achieve a surface compressive stress of 700 MPa and a depth of 20 μm or more.

Thermal and Chemical Factors

Stress relaxation in borosilicate glass is significantly influenced by both thermal and chemical factors. Temperature plays a crucial role in the relaxation process, as higher temperatures accelerate the rearrangement of atoms within the glass structure. When borosilicate glass is subjected to elevated temperatures, the thermal energy allows for increased atomic mobility, facilitating the release of internal stresses. This thermal relaxation process is particularly important in applications where the glass is exposed to varying temperature conditions, such as in laboratory glassware or high-temperature industrial processes.

The chemical composition of borosilicate glass also contributes to its stress relaxation behavior. The presence of boron oxide in the glass network enhances its resistance to thermal shock and reduces the coefficient of thermal expansion. This unique chemical structure affects the glass's response to stress and its ability to relax over time. The interaction between silica and boron oxide in the glass matrix creates a more stable network, which influences the rate and extent of stress relaxation.

Environmental factors, such as humidity and atmospheric conditions, can further impact the stress relaxation process in borosilicate glass. Exposure to moisture can lead to hydrolysis of the glass surface, potentially altering its mechanical properties and stress state. This is particularly relevant in applications where borosilicate glass is used in humid or corrosive environments.

The thermal history of the glass, including its annealing and cooling processes during manufacturing, also plays a significant role in determining its stress relaxation characteristics. Proper annealing can help minimize residual stresses within the glass, reducing the potential for stress-related failures and improving long-term stability.

Chemical strengthening techniques, such as ion exchange processes, can be employed to enhance the surface compressive stress of borosilicate glass. These treatments can significantly alter the stress relaxation behavior of the glass, potentially improving its resistance to mechanical and thermal stresses. However, the interaction between these surface treatments and the inherent stress relaxation mechanisms of borosilicate glass requires careful consideration in research and application.

Understanding the interplay between thermal and chemical factors in stress relaxation is essential for optimizing the performance and longevity of borosilicate glass in various applications. Research in this area continues to focus on developing predictive models and experimental techniques to better characterize and control stress relaxation processes, ultimately leading to improved glass products and more reliable performance in demanding environments.

The chemical composition of borosilicate glass also contributes to its stress relaxation behavior. The presence of boron oxide in the glass network enhances its resistance to thermal shock and reduces the coefficient of thermal expansion. This unique chemical structure affects the glass's response to stress and its ability to relax over time. The interaction between silica and boron oxide in the glass matrix creates a more stable network, which influences the rate and extent of stress relaxation.

Environmental factors, such as humidity and atmospheric conditions, can further impact the stress relaxation process in borosilicate glass. Exposure to moisture can lead to hydrolysis of the glass surface, potentially altering its mechanical properties and stress state. This is particularly relevant in applications where borosilicate glass is used in humid or corrosive environments.

The thermal history of the glass, including its annealing and cooling processes during manufacturing, also plays a significant role in determining its stress relaxation characteristics. Proper annealing can help minimize residual stresses within the glass, reducing the potential for stress-related failures and improving long-term stability.

Chemical strengthening techniques, such as ion exchange processes, can be employed to enhance the surface compressive stress of borosilicate glass. These treatments can significantly alter the stress relaxation behavior of the glass, potentially improving its resistance to mechanical and thermal stresses. However, the interaction between these surface treatments and the inherent stress relaxation mechanisms of borosilicate glass requires careful consideration in research and application.

Understanding the interplay between thermal and chemical factors in stress relaxation is essential for optimizing the performance and longevity of borosilicate glass in various applications. Research in this area continues to focus on developing predictive models and experimental techniques to better characterize and control stress relaxation processes, ultimately leading to improved glass products and more reliable performance in demanding environments.

Industrial Applications Impact

The stress relaxation phenomenon in borosilicate glass has significant implications for various industrial applications. This property affects the long-term performance and reliability of glass components in critical sectors such as aerospace, electronics, and energy production.

In the aerospace industry, borosilicate glass is widely used in cockpit windows and instrument panels. The stress relaxation behavior of this material is crucial for maintaining structural integrity under extreme temperature fluctuations and pressure differentials experienced during flight. Understanding and mitigating stress relaxation effects can lead to improved safety standards and extended service life of aircraft components.

The electronics sector heavily relies on borosilicate glass for manufacturing display screens, optical fibers, and semiconductor packaging. Stress relaxation in these applications can impact the optical properties and mechanical stability of devices over time. By optimizing the glass composition and processing techniques based on stress relaxation research, manufacturers can enhance the durability and performance of electronic products.

In the energy sector, borosilicate glass plays a vital role in solar panel production and nuclear reactor components. The stress relaxation characteristics of the glass directly influence the efficiency and longevity of solar cells, as well as the safety and reliability of nuclear containment vessels. Advances in stress relaxation research can lead to more efficient solar energy harvesting and improved nuclear power plant designs.

The chemical and pharmaceutical industries also benefit from a deeper understanding of stress relaxation in borosilicate glass. Laboratory glassware, storage containers, and reaction vessels made from this material must maintain their structural integrity under various chemical and thermal conditions. Research in this area can result in the development of more resilient laboratory equipment and safer storage solutions for hazardous materials.

Furthermore, the automotive industry is increasingly incorporating borosilicate glass in advanced windshield designs and sensor housings for autonomous vehicles. The stress relaxation properties of the glass are critical for ensuring clear visibility and accurate sensor readings over the vehicle's lifetime. Improved knowledge in this field can contribute to the development of safer and more reliable autonomous driving systems.

In conclusion, research on stress relaxation in borosilicate glass has far-reaching impacts across multiple industries. The findings from such studies can drive innovation in material science, leading to the development of more durable, efficient, and safer products across various sectors. As industries continue to push the boundaries of technology and performance, the importance of understanding and controlling stress relaxation in borosilicate glass will only grow, making it a crucial area of ongoing research and development.

In the aerospace industry, borosilicate glass is widely used in cockpit windows and instrument panels. The stress relaxation behavior of this material is crucial for maintaining structural integrity under extreme temperature fluctuations and pressure differentials experienced during flight. Understanding and mitigating stress relaxation effects can lead to improved safety standards and extended service life of aircraft components.

The electronics sector heavily relies on borosilicate glass for manufacturing display screens, optical fibers, and semiconductor packaging. Stress relaxation in these applications can impact the optical properties and mechanical stability of devices over time. By optimizing the glass composition and processing techniques based on stress relaxation research, manufacturers can enhance the durability and performance of electronic products.

In the energy sector, borosilicate glass plays a vital role in solar panel production and nuclear reactor components. The stress relaxation characteristics of the glass directly influence the efficiency and longevity of solar cells, as well as the safety and reliability of nuclear containment vessels. Advances in stress relaxation research can lead to more efficient solar energy harvesting and improved nuclear power plant designs.

The chemical and pharmaceutical industries also benefit from a deeper understanding of stress relaxation in borosilicate glass. Laboratory glassware, storage containers, and reaction vessels made from this material must maintain their structural integrity under various chemical and thermal conditions. Research in this area can result in the development of more resilient laboratory equipment and safer storage solutions for hazardous materials.

Furthermore, the automotive industry is increasingly incorporating borosilicate glass in advanced windshield designs and sensor housings for autonomous vehicles. The stress relaxation properties of the glass are critical for ensuring clear visibility and accurate sensor readings over the vehicle's lifetime. Improved knowledge in this field can contribute to the development of safer and more reliable autonomous driving systems.

In conclusion, research on stress relaxation in borosilicate glass has far-reaching impacts across multiple industries. The findings from such studies can drive innovation in material science, leading to the development of more durable, efficient, and safer products across various sectors. As industries continue to push the boundaries of technology and performance, the importance of understanding and controlling stress relaxation in borosilicate glass will only grow, making it a crucial area of ongoing research and development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!