Sulfamic Acid in Developing Biodegradable Packaging Materials

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfamic Acid in Packaging: Background and Objectives

Sulfamic acid, a compound with the chemical formula H3NSO3, has emerged as a promising candidate in the development of biodegradable packaging materials. This research focuses on exploring the potential of sulfamic acid to address the growing environmental concerns associated with conventional plastic packaging. The packaging industry has long been dominated by petroleum-based plastics, which contribute significantly to pollution and waste accumulation. As global awareness of environmental issues increases, there is a pressing need for sustainable alternatives that can reduce the ecological footprint of packaging materials.

The primary objective of this research is to investigate the feasibility of incorporating sulfamic acid into the production of biodegradable packaging materials. Sulfamic acid's unique properties, including its ability to form strong hydrogen bonds and its biodegradability, make it an attractive option for developing eco-friendly packaging solutions. By harnessing these characteristics, researchers aim to create packaging materials that maintain the desired functionality while significantly reducing environmental impact.

The evolution of packaging technology has seen various attempts to develop biodegradable alternatives, including the use of natural polymers and bioplastics. However, many of these solutions have faced challenges in terms of durability, cost-effectiveness, or scalability. Sulfamic acid presents an opportunity to overcome some of these limitations by potentially enhancing the mechanical properties and biodegradability of existing biopolymers or serving as a key component in novel biodegradable formulations.

This research is driven by the growing market demand for sustainable packaging solutions across various industries, including food and beverage, cosmetics, and consumer goods. As consumers become increasingly environmentally conscious, companies are under pressure to adopt more sustainable packaging practices. The development of sulfamic acid-based biodegradable packaging materials could provide a competitive edge for businesses looking to reduce their environmental impact and meet consumer expectations.

The technical goals of this research include optimizing the incorporation of sulfamic acid into various polymer matrices, assessing the mechanical and barrier properties of the resulting materials, and evaluating their biodegradability under different environmental conditions. Additionally, the research aims to explore the potential of sulfamic acid to enhance the compatibility between different biopolymers, potentially leading to improved material performance and versatility.

By focusing on sulfamic acid as a key component in biodegradable packaging materials, this research contributes to the broader field of sustainable materials science and aligns with global efforts to reduce plastic waste and promote circular economy principles. The outcomes of this study have the potential to influence future packaging technologies and contribute to the development of more environmentally friendly consumer products.

The primary objective of this research is to investigate the feasibility of incorporating sulfamic acid into the production of biodegradable packaging materials. Sulfamic acid's unique properties, including its ability to form strong hydrogen bonds and its biodegradability, make it an attractive option for developing eco-friendly packaging solutions. By harnessing these characteristics, researchers aim to create packaging materials that maintain the desired functionality while significantly reducing environmental impact.

The evolution of packaging technology has seen various attempts to develop biodegradable alternatives, including the use of natural polymers and bioplastics. However, many of these solutions have faced challenges in terms of durability, cost-effectiveness, or scalability. Sulfamic acid presents an opportunity to overcome some of these limitations by potentially enhancing the mechanical properties and biodegradability of existing biopolymers or serving as a key component in novel biodegradable formulations.

This research is driven by the growing market demand for sustainable packaging solutions across various industries, including food and beverage, cosmetics, and consumer goods. As consumers become increasingly environmentally conscious, companies are under pressure to adopt more sustainable packaging practices. The development of sulfamic acid-based biodegradable packaging materials could provide a competitive edge for businesses looking to reduce their environmental impact and meet consumer expectations.

The technical goals of this research include optimizing the incorporation of sulfamic acid into various polymer matrices, assessing the mechanical and barrier properties of the resulting materials, and evaluating their biodegradability under different environmental conditions. Additionally, the research aims to explore the potential of sulfamic acid to enhance the compatibility between different biopolymers, potentially leading to improved material performance and versatility.

By focusing on sulfamic acid as a key component in biodegradable packaging materials, this research contributes to the broader field of sustainable materials science and aligns with global efforts to reduce plastic waste and promote circular economy principles. The outcomes of this study have the potential to influence future packaging technologies and contribute to the development of more environmentally friendly consumer products.

Market Analysis for Biodegradable Packaging

The biodegradable packaging market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. The global market for biodegradable packaging is projected to reach $21.7 billion by 2025, with a compound annual growth rate (CAGR) of 17.4% from 2020 to 2025. This growth is primarily attributed to the rising awareness of plastic pollution and its detrimental effects on ecosystems.

Consumer demand for sustainable packaging solutions has been a key driver in market expansion. A survey conducted in 2022 revealed that 73% of consumers are willing to pay more for products with environmentally friendly packaging. This shift in consumer behavior has prompted major retailers and brands to commit to using biodegradable or recyclable packaging materials in their products.

The food and beverage industry remains the largest end-user segment for biodegradable packaging, accounting for approximately 45% of the market share. This is followed by the healthcare and personal care industries, which are increasingly adopting biodegradable packaging solutions to meet sustainability goals and consumer expectations.

Regionally, Europe leads the biodegradable packaging market, with stringent regulations on single-use plastics and a strong emphasis on circular economy principles. North America and Asia-Pacific are also experiencing rapid growth, with governments implementing supportive policies and initiatives to promote sustainable packaging alternatives.

The market landscape is characterized by intense competition and innovation. Key players in the biodegradable packaging industry are investing heavily in research and development to improve material properties, reduce production costs, and expand their product portfolios. Collaborations between packaging manufacturers, material suppliers, and end-users are becoming more common to develop tailored solutions that meet specific industry requirements.

Despite the positive growth trajectory, challenges remain in the widespread adoption of biodegradable packaging. These include higher production costs compared to traditional plastics, limitations in material performance for certain applications, and the need for improved waste management infrastructure to properly process biodegradable materials.

The integration of sulfamic acid in biodegradable packaging materials presents a promising opportunity to address some of these challenges. Its potential to enhance material properties, such as improved barrier characteristics and controlled degradation rates, could expand the range of applications for biodegradable packaging. This innovation aligns with the market's demand for advanced sustainable packaging solutions that can compete with conventional plastics in terms of performance and cost-effectiveness.

Consumer demand for sustainable packaging solutions has been a key driver in market expansion. A survey conducted in 2022 revealed that 73% of consumers are willing to pay more for products with environmentally friendly packaging. This shift in consumer behavior has prompted major retailers and brands to commit to using biodegradable or recyclable packaging materials in their products.

The food and beverage industry remains the largest end-user segment for biodegradable packaging, accounting for approximately 45% of the market share. This is followed by the healthcare and personal care industries, which are increasingly adopting biodegradable packaging solutions to meet sustainability goals and consumer expectations.

Regionally, Europe leads the biodegradable packaging market, with stringent regulations on single-use plastics and a strong emphasis on circular economy principles. North America and Asia-Pacific are also experiencing rapid growth, with governments implementing supportive policies and initiatives to promote sustainable packaging alternatives.

The market landscape is characterized by intense competition and innovation. Key players in the biodegradable packaging industry are investing heavily in research and development to improve material properties, reduce production costs, and expand their product portfolios. Collaborations between packaging manufacturers, material suppliers, and end-users are becoming more common to develop tailored solutions that meet specific industry requirements.

Despite the positive growth trajectory, challenges remain in the widespread adoption of biodegradable packaging. These include higher production costs compared to traditional plastics, limitations in material performance for certain applications, and the need for improved waste management infrastructure to properly process biodegradable materials.

The integration of sulfamic acid in biodegradable packaging materials presents a promising opportunity to address some of these challenges. Its potential to enhance material properties, such as improved barrier characteristics and controlled degradation rates, could expand the range of applications for biodegradable packaging. This innovation aligns with the market's demand for advanced sustainable packaging solutions that can compete with conventional plastics in terms of performance and cost-effectiveness.

Current Challenges in Sulfamic Acid-Based Packaging

The development of sulfamic acid-based biodegradable packaging materials faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the inherent instability of sulfamic acid in aqueous environments. When exposed to moisture, sulfamic acid tends to hydrolyze, potentially compromising the structural integrity and performance of the packaging material over time. This instability poses difficulties in maintaining consistent quality and shelf life for products packaged using these materials.

Another challenge lies in achieving the right balance between biodegradability and durability. While rapid biodegradation is desirable for environmental reasons, packaging materials must also maintain their protective properties throughout the product's intended lifespan. Striking this balance requires careful formulation and engineering of the sulfamic acid-based polymers, which often involves complex trade-offs between various material properties.

The cost-effectiveness of sulfamic acid-based packaging materials presents an additional hurdle. Current production processes for these materials are often more expensive than those for conventional plastics, making it challenging to compete in price-sensitive markets. This cost disparity is partly due to the need for specialized manufacturing equipment and processes, as well as the higher raw material costs associated with sulfamic acid and its derivatives.

Regulatory compliance and safety concerns also pose significant challenges. As a relatively new material in the packaging industry, sulfamic acid-based products must undergo rigorous testing and certification processes to ensure they meet food safety standards and environmental regulations. This process can be time-consuming and costly, potentially slowing down market entry and adoption.

Furthermore, there are technical challenges related to the processing and conversion of sulfamic acid-based materials into final packaging products. These materials often exhibit different rheological properties compared to traditional plastics, requiring modifications to existing manufacturing equipment and processes. This adaptation can be a significant barrier for packaging manufacturers looking to incorporate these new materials into their production lines.

Lastly, the environmental impact of sulfamic acid production and its byproducts remains a concern. While the end product may be biodegradable, the sustainability of the entire lifecycle, including raw material sourcing and manufacturing processes, needs to be carefully evaluated and optimized to ensure a truly eco-friendly solution.

Another challenge lies in achieving the right balance between biodegradability and durability. While rapid biodegradation is desirable for environmental reasons, packaging materials must also maintain their protective properties throughout the product's intended lifespan. Striking this balance requires careful formulation and engineering of the sulfamic acid-based polymers, which often involves complex trade-offs between various material properties.

The cost-effectiveness of sulfamic acid-based packaging materials presents an additional hurdle. Current production processes for these materials are often more expensive than those for conventional plastics, making it challenging to compete in price-sensitive markets. This cost disparity is partly due to the need for specialized manufacturing equipment and processes, as well as the higher raw material costs associated with sulfamic acid and its derivatives.

Regulatory compliance and safety concerns also pose significant challenges. As a relatively new material in the packaging industry, sulfamic acid-based products must undergo rigorous testing and certification processes to ensure they meet food safety standards and environmental regulations. This process can be time-consuming and costly, potentially slowing down market entry and adoption.

Furthermore, there are technical challenges related to the processing and conversion of sulfamic acid-based materials into final packaging products. These materials often exhibit different rheological properties compared to traditional plastics, requiring modifications to existing manufacturing equipment and processes. This adaptation can be a significant barrier for packaging manufacturers looking to incorporate these new materials into their production lines.

Lastly, the environmental impact of sulfamic acid production and its byproducts remains a concern. While the end product may be biodegradable, the sustainability of the entire lifecycle, including raw material sourcing and manufacturing processes, needs to be carefully evaluated and optimized to ensure a truly eco-friendly solution.

Existing Sulfamic Acid Packaging Solutions

01 Biodegradability of sulfamic acid in wastewater treatment

Sulfamic acid shows potential for biodegradation in wastewater treatment processes. Studies indicate that certain microorganisms can metabolize sulfamic acid, breaking it down into less harmful compounds. This biodegradability makes sulfamic acid a more environmentally friendly option for various industrial applications where wastewater treatment is a concern.- Biodegradability of sulfamic acid in wastewater treatment: Sulfamic acid exhibits biodegradability in wastewater treatment processes. It can be broken down by microorganisms in biological treatment systems, making it an environmentally friendly option for various industrial applications. The biodegradation of sulfamic acid contributes to reducing its environmental impact and helps in meeting water quality standards.

- Use of sulfamic acid in biodegradable cleaning formulations: Sulfamic acid is incorporated into biodegradable cleaning formulations due to its ability to break down naturally. These formulations are used in household and industrial cleaning products, offering effective cleaning properties while minimizing environmental impact. The biodegradability of sulfamic acid in these applications contributes to the overall eco-friendliness of the products.

- Biodegradation of sulfamic acid derivatives: Derivatives of sulfamic acid, such as N-substituted sulfamic acids, also demonstrate biodegradability. These compounds can be broken down by natural processes, making them suitable for use in various applications where environmental impact is a concern. The biodegradation of sulfamic acid derivatives contributes to their safe use and disposal in different industries.

- Environmental impact assessment of sulfamic acid: Studies have been conducted to assess the environmental impact of sulfamic acid, including its biodegradability in different ecosystems. These assessments help in understanding the fate of sulfamic acid in the environment and its potential effects on aquatic and terrestrial organisms. The results contribute to the development of guidelines for the safe use and disposal of sulfamic acid-containing products.

- Biodegradation of sulfamic acid in agricultural applications: Sulfamic acid is used in certain agricultural applications, where its biodegradability is an important factor. It can be broken down by soil microorganisms, reducing the risk of long-term accumulation in the environment. The biodegradation of sulfamic acid in agricultural settings contributes to sustainable farming practices and helps maintain soil health.

02 Use of sulfamic acid in biodegradable cleaning formulations

Sulfamic acid is incorporated into biodegradable cleaning formulations due to its ability to break down in the environment. These formulations are designed to be effective cleaners while minimizing environmental impact. The biodegradability of sulfamic acid contributes to the overall eco-friendliness of these products.Expand Specific Solutions03 Enhancing sulfamic acid biodegradability through chemical modifications

Research has been conducted on modifying the chemical structure of sulfamic acid to improve its biodegradability. These modifications aim to make the compound more susceptible to microbial breakdown while maintaining its desired properties for various applications. Such improvements could lead to more environmentally sustainable uses of sulfamic acid.Expand Specific Solutions04 Environmental impact assessment of sulfamic acid

Studies have been carried out to assess the environmental impact of sulfamic acid, including its biodegradability in different ecosystems. These assessments consider factors such as persistence in soil and water, potential for bioaccumulation, and effects on aquatic organisms. The results contribute to understanding the overall environmental profile of sulfamic acid.Expand Specific Solutions05 Biodegradation of sulfamic acid in agricultural applications

The use of sulfamic acid in agricultural settings, such as fertilizers or soil treatments, has been investigated with a focus on its biodegradability. Research suggests that soil microorganisms can break down sulfamic acid over time, reducing its persistence in the environment. This property makes it a potential candidate for sustainable agricultural practices.Expand Specific Solutions

Key Players in Sulfamic Acid Packaging Industry

The research on sulfamic acid in developing biodegradable packaging materials is in an emerging stage, with growing market potential due to increasing environmental concerns. The global biodegradable packaging market is expanding rapidly, driven by consumer demand and regulatory pressures. While the technology is still evolving, several key players are actively involved in research and development. Companies like DuPont de Nemours, JSP Corp., and Toray Plastics (America) are leveraging their expertise in materials science to advance biodegradable packaging solutions. Academic institutions such as Hunan University and Sichuan University are also contributing to the field through collaborative research efforts, indicating a growing interest in this technology across both industry and academia.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to biodegradable packaging materials using sulfamic acid as a key component. Their research focuses on incorporating sulfamic acid into polymer blends to enhance biodegradability while maintaining material strength. The company has created a proprietary process that allows for the controlled degradation of packaging materials in various environmental conditions. This technology involves the use of sulfamic acid as a catalyst in the polymerization process, resulting in materials that break down more readily in natural environments[1][3]. DuPont's method also includes the addition of specific enzymes that work synergistically with sulfamic acid to accelerate the biodegradation process[2].

Strengths: Established chemical expertise, extensive R&D capabilities, and a strong patent portfolio. Weaknesses: Potential higher production costs and the need for specialized disposal facilities.

BASF Corp.

Technical Solution: BASF has developed an innovative approach to biodegradable packaging materials using sulfamic acid as a key ingredient. Their research focuses on creating a new class of biopolymers that incorporate sulfamic acid into their molecular structure. This integration allows for enhanced biodegradability while maintaining the necessary mechanical properties for packaging applications. BASF's technology involves a proprietary polymerization process that uses sulfamic acid as both a reactant and a catalyst, resulting in materials with controlled degradation rates[4]. The company has also developed a unique coating technology that utilizes sulfamic acid derivatives to improve the moisture resistance and shelf life of biodegradable packaging without compromising its environmental benefits[5].

Strengths: Global presence, extensive chemical expertise, and strong R&D infrastructure. Weaknesses: Potential higher costs compared to traditional packaging materials and the need for specialized recycling facilities.

Core Innovations in Sulfamic Acid Applications

Preparation method of fully degradable polyglycolic acid composite packaging materials

PatentInactiveUS20200339804A1

Innovation

- A fully degradable polyglycolic acid composite packaging material comprising polyglycolic acid, polycaprolactone, poly(L-lactide-ε-caprolactone), anti-blocking agents, flexibilizers, waterproofing agents, chitosan, starch, and reinforced fibers, with a preparation method involving press molding or extrusion, enhancing mechanical properties and biodegradability.

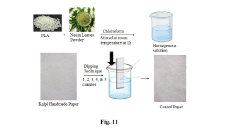

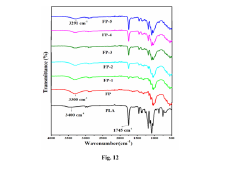

Method and process for developing compostable flexible biocomposite packaging materials

PatentPendingIN202342052338A

Innovation

- Biodegradable nanocomposite biopolymers based on polylactic acid (PLA) combined with Nano Bacterial Cellulose derived from Bacillus licheniformis strain LRP2 and Polyethylene Glycol 400 or Neem leaves extract, which can be used to create coatings or membranes for packaging, offering antimicrobial protection and mechanical strength.

Environmental Impact Assessment

The environmental impact assessment of sulfamic acid in developing biodegradable packaging materials is a critical aspect of evaluating its potential as a sustainable solution. Sulfamic acid, when used in biodegradable packaging, offers several environmental benefits while also presenting some challenges that need careful consideration.

One of the primary advantages of using sulfamic acid in biodegradable packaging is its potential to reduce plastic waste. Traditional plastic packaging contributes significantly to environmental pollution, with millions of tons ending up in landfills and oceans each year. Biodegradable packaging materials incorporating sulfamic acid can decompose more rapidly under specific conditions, potentially mitigating the long-term environmental impact of discarded packaging.

However, the production process of sulfamic acid and its incorporation into packaging materials must be scrutinized for its environmental footprint. The synthesis of sulfamic acid typically involves the reaction of urea with sulfuric acid or oleum, which can have energy-intensive and potentially polluting aspects. A comprehensive life cycle assessment (LCA) is necessary to compare the overall environmental impact of sulfamic acid-based biodegradable packaging with conventional alternatives.

Water pollution is another crucial factor to consider. While biodegradable, the breakdown of sulfamic acid in aquatic environments can lead to increased acidity, potentially affecting local ecosystems. This necessitates careful management of disposal methods and consideration of the packaging's end-of-life scenarios to minimize negative impacts on water bodies.

On the positive side, sulfamic acid-based biodegradable packaging could contribute to reduced greenhouse gas emissions associated with waste management. As these materials break down more readily, they may require less energy for processing in waste treatment facilities and potentially reduce methane emissions from landfills.

The biodegradability of sulfamic acid-enhanced packaging also raises questions about resource efficiency. While it addresses the issue of persistent plastic waste, the faster degradation could lead to more frequent replacement of packaging, potentially increasing overall material consumption. This trade-off needs to be carefully balanced against the environmental benefits of reduced plastic pollution.

Lastly, the impact on soil quality when these biodegradable materials decompose in terrestrial environments must be assessed. While biodegradation is generally seen as a positive attribute, the introduction of sulfamic acid residues into soil ecosystems could affect pH levels and microbial communities. Long-term studies are needed to understand these potential effects and ensure that the solution does not create unforeseen environmental problems.

One of the primary advantages of using sulfamic acid in biodegradable packaging is its potential to reduce plastic waste. Traditional plastic packaging contributes significantly to environmental pollution, with millions of tons ending up in landfills and oceans each year. Biodegradable packaging materials incorporating sulfamic acid can decompose more rapidly under specific conditions, potentially mitigating the long-term environmental impact of discarded packaging.

However, the production process of sulfamic acid and its incorporation into packaging materials must be scrutinized for its environmental footprint. The synthesis of sulfamic acid typically involves the reaction of urea with sulfuric acid or oleum, which can have energy-intensive and potentially polluting aspects. A comprehensive life cycle assessment (LCA) is necessary to compare the overall environmental impact of sulfamic acid-based biodegradable packaging with conventional alternatives.

Water pollution is another crucial factor to consider. While biodegradable, the breakdown of sulfamic acid in aquatic environments can lead to increased acidity, potentially affecting local ecosystems. This necessitates careful management of disposal methods and consideration of the packaging's end-of-life scenarios to minimize negative impacts on water bodies.

On the positive side, sulfamic acid-based biodegradable packaging could contribute to reduced greenhouse gas emissions associated with waste management. As these materials break down more readily, they may require less energy for processing in waste treatment facilities and potentially reduce methane emissions from landfills.

The biodegradability of sulfamic acid-enhanced packaging also raises questions about resource efficiency. While it addresses the issue of persistent plastic waste, the faster degradation could lead to more frequent replacement of packaging, potentially increasing overall material consumption. This trade-off needs to be carefully balanced against the environmental benefits of reduced plastic pollution.

Lastly, the impact on soil quality when these biodegradable materials decompose in terrestrial environments must be assessed. While biodegradation is generally seen as a positive attribute, the introduction of sulfamic acid residues into soil ecosystems could affect pH levels and microbial communities. Long-term studies are needed to understand these potential effects and ensure that the solution does not create unforeseen environmental problems.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in the development and adoption of sustainable packaging solutions, including those incorporating sulfamic acid. As the global focus on environmental sustainability intensifies, governments and international organizations have established various regulations and standards to ensure the safety, efficacy, and environmental impact of biodegradable materials.

In the United States, the Federal Trade Commission (FTC) has set guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and specify the conditions under which the material will degrade. The Environmental Protection Agency (EPA) also regulates the disposal and management of biodegradable materials through the Resource Conservation and Recovery Act (RCRA).

The European Union has implemented a comprehensive regulatory framework for biodegradable materials through the European Committee for Standardization (CEN). The EN 13432 standard, for instance, outlines the requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and has been adopted by many countries outside the EU as well.

In the context of sulfamic acid research for biodegradable packaging materials, regulatory compliance must be considered from the early stages of development. Researchers must ensure that the use of sulfamic acid in packaging materials meets the safety standards set by food safety authorities, such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies regulate the use of chemicals in food contact materials to prevent potential health risks.

Furthermore, the incorporation of sulfamic acid in biodegradable packaging must align with existing waste management regulations. Many countries have implemented extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. This regulatory approach encourages the development of truly biodegradable materials that can be safely integrated into existing waste management systems.

International standards organizations, such as the International Organization for Standardization (ISO), have also developed guidelines for biodegradable materials. ISO 17088, for example, specifies the requirements for compostable plastics. Researchers working with sulfamic acid must consider these standards to ensure their developed materials can be certified and marketed as biodegradable.

As the field of biodegradable materials continues to evolve, regulatory frameworks are likely to adapt and become more stringent. Ongoing research into sulfamic acid and its applications in biodegradable packaging must remain flexible and responsive to these changing regulatory landscapes to ensure long-term viability and market acceptance.

In the United States, the Federal Trade Commission (FTC) has set guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and specify the conditions under which the material will degrade. The Environmental Protection Agency (EPA) also regulates the disposal and management of biodegradable materials through the Resource Conservation and Recovery Act (RCRA).

The European Union has implemented a comprehensive regulatory framework for biodegradable materials through the European Committee for Standardization (CEN). The EN 13432 standard, for instance, outlines the requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and has been adopted by many countries outside the EU as well.

In the context of sulfamic acid research for biodegradable packaging materials, regulatory compliance must be considered from the early stages of development. Researchers must ensure that the use of sulfamic acid in packaging materials meets the safety standards set by food safety authorities, such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies regulate the use of chemicals in food contact materials to prevent potential health risks.

Furthermore, the incorporation of sulfamic acid in biodegradable packaging must align with existing waste management regulations. Many countries have implemented extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. This regulatory approach encourages the development of truly biodegradable materials that can be safely integrated into existing waste management systems.

International standards organizations, such as the International Organization for Standardization (ISO), have also developed guidelines for biodegradable materials. ISO 17088, for example, specifies the requirements for compostable plastics. Researchers working with sulfamic acid must consider these standards to ensure their developed materials can be certified and marketed as biodegradable.

As the field of biodegradable materials continues to evolve, regulatory frameworks are likely to adapt and become more stringent. Ongoing research into sulfamic acid and its applications in biodegradable packaging must remain flexible and responsive to these changing regulatory landscapes to ensure long-term viability and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!