Evaluating Sulfamic Acid for Heavy Oil Desulfurization

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfamic Acid Desulfurization Background and Objectives

Sulfamic acid desulfurization has emerged as a promising technique in the field of heavy oil processing, addressing the critical need for efficient and environmentally friendly methods to reduce sulfur content in petroleum products. The background of this technology dates back to the early 2000s when environmental regulations began to tighten, necessitating more effective desulfurization processes for heavy oil fractions.

The evolution of sulfamic acid desulfurization has been driven by the increasing global demand for cleaner fuels and the challenges posed by conventional hydrodesulfurization methods. Traditional approaches often struggle with heavy oil due to its complex molecular structure and high sulfur content, leading researchers to explore alternative chemical treatments.

Sulfamic acid, a compound known for its ability to react with organic sulfur compounds, has shown particular promise in this context. Its unique chemical properties allow it to target and remove sulfur from heavy oil fractions under milder conditions compared to conventional methods, potentially offering significant advantages in terms of energy efficiency and operational costs.

The primary objective of evaluating sulfamic acid for heavy oil desulfurization is to develop a more effective and economically viable process for reducing sulfur levels in heavy petroleum fractions. This goal aligns with broader industry efforts to meet stringent environmental regulations while maintaining operational efficiency.

Specific technical objectives include optimizing reaction conditions, such as temperature, pressure, and acid concentration, to maximize sulfur removal efficiency. Additionally, researchers aim to understand the reaction mechanisms between sulfamic acid and various sulfur-containing compounds present in heavy oil, enabling the development of more targeted and efficient desulfurization processes.

Another crucial objective is to assess the scalability of sulfamic acid desulfurization for industrial applications. This involves evaluating the process's performance on different types of heavy oil feedstocks, as well as investigating potential integration with existing refinery operations.

Furthermore, the environmental impact of sulfamic acid desulfurization is a key consideration. Objectives in this area include minimizing waste generation, exploring acid recovery and recycling methods, and ensuring that the overall process contributes to a reduction in the carbon footprint of oil refining operations.

As the technology continues to evolve, researchers are also focusing on combining sulfamic acid treatment with other desulfurization techniques to create hybrid processes that leverage the strengths of multiple approaches. This synergistic approach aims to overcome the limitations of individual methods and achieve even higher levels of sulfur removal efficiency.

The evolution of sulfamic acid desulfurization has been driven by the increasing global demand for cleaner fuels and the challenges posed by conventional hydrodesulfurization methods. Traditional approaches often struggle with heavy oil due to its complex molecular structure and high sulfur content, leading researchers to explore alternative chemical treatments.

Sulfamic acid, a compound known for its ability to react with organic sulfur compounds, has shown particular promise in this context. Its unique chemical properties allow it to target and remove sulfur from heavy oil fractions under milder conditions compared to conventional methods, potentially offering significant advantages in terms of energy efficiency and operational costs.

The primary objective of evaluating sulfamic acid for heavy oil desulfurization is to develop a more effective and economically viable process for reducing sulfur levels in heavy petroleum fractions. This goal aligns with broader industry efforts to meet stringent environmental regulations while maintaining operational efficiency.

Specific technical objectives include optimizing reaction conditions, such as temperature, pressure, and acid concentration, to maximize sulfur removal efficiency. Additionally, researchers aim to understand the reaction mechanisms between sulfamic acid and various sulfur-containing compounds present in heavy oil, enabling the development of more targeted and efficient desulfurization processes.

Another crucial objective is to assess the scalability of sulfamic acid desulfurization for industrial applications. This involves evaluating the process's performance on different types of heavy oil feedstocks, as well as investigating potential integration with existing refinery operations.

Furthermore, the environmental impact of sulfamic acid desulfurization is a key consideration. Objectives in this area include minimizing waste generation, exploring acid recovery and recycling methods, and ensuring that the overall process contributes to a reduction in the carbon footprint of oil refining operations.

As the technology continues to evolve, researchers are also focusing on combining sulfamic acid treatment with other desulfurization techniques to create hybrid processes that leverage the strengths of multiple approaches. This synergistic approach aims to overcome the limitations of individual methods and achieve even higher levels of sulfur removal efficiency.

Market Demand for Heavy Oil Desulfurization

The global demand for heavy oil desulfurization technologies has been steadily increasing due to stricter environmental regulations and the growing need for cleaner energy sources. As heavy oil reserves become more prevalent in the global energy mix, the market for efficient desulfurization methods continues to expand.

The heavy oil industry faces significant challenges in meeting sulfur content requirements set by regulatory bodies worldwide. These regulations aim to reduce sulfur dioxide emissions, which contribute to air pollution and acid rain. Consequently, refineries and oil producers are actively seeking cost-effective and efficient desulfurization technologies to comply with these standards and maintain their market competitiveness.

The market for heavy oil desulfurization is primarily driven by the petroleum refining sector, where the removal of sulfur from crude oil is crucial for producing high-quality fuels and petrochemical products. Additionally, the power generation industry, which relies on heavy fuel oils, contributes to the demand for desulfurization technologies to meet emission standards.

Geographically, the market demand is particularly strong in regions with significant heavy oil production and processing capabilities. North America, especially Canada and the United States, shows substantial demand due to their vast heavy oil reserves. The Middle East, with its large oil production capacity, also represents a significant market for desulfurization technologies. Emerging economies in Asia-Pacific, such as China and India, are experiencing rapid growth in refining capacity, further driving the demand for advanced desulfurization solutions.

The market size for heavy oil desulfurization technologies is substantial and growing. This growth is attributed to the increasing production of heavy crude oil, stringent environmental regulations, and the need for upgrading existing refinery infrastructure to handle heavier crude feedstocks.

Key market trends include the development of more efficient and cost-effective desulfurization processes, the integration of desulfurization technologies with other refining processes, and the exploration of novel catalysts and additives to enhance sulfur removal. There is also a growing interest in technologies that can simultaneously address other impurities in heavy oil, such as metals and nitrogen compounds.

The potential application of sulfamic acid in heavy oil desulfurization represents an opportunity to address market demands for more effective and environmentally friendly desulfurization methods. If proven successful, this approach could offer refineries a new tool to meet increasingly stringent sulfur content regulations while potentially reducing operational costs and environmental impact.

The heavy oil industry faces significant challenges in meeting sulfur content requirements set by regulatory bodies worldwide. These regulations aim to reduce sulfur dioxide emissions, which contribute to air pollution and acid rain. Consequently, refineries and oil producers are actively seeking cost-effective and efficient desulfurization technologies to comply with these standards and maintain their market competitiveness.

The market for heavy oil desulfurization is primarily driven by the petroleum refining sector, where the removal of sulfur from crude oil is crucial for producing high-quality fuels and petrochemical products. Additionally, the power generation industry, which relies on heavy fuel oils, contributes to the demand for desulfurization technologies to meet emission standards.

Geographically, the market demand is particularly strong in regions with significant heavy oil production and processing capabilities. North America, especially Canada and the United States, shows substantial demand due to their vast heavy oil reserves. The Middle East, with its large oil production capacity, also represents a significant market for desulfurization technologies. Emerging economies in Asia-Pacific, such as China and India, are experiencing rapid growth in refining capacity, further driving the demand for advanced desulfurization solutions.

The market size for heavy oil desulfurization technologies is substantial and growing. This growth is attributed to the increasing production of heavy crude oil, stringent environmental regulations, and the need for upgrading existing refinery infrastructure to handle heavier crude feedstocks.

Key market trends include the development of more efficient and cost-effective desulfurization processes, the integration of desulfurization technologies with other refining processes, and the exploration of novel catalysts and additives to enhance sulfur removal. There is also a growing interest in technologies that can simultaneously address other impurities in heavy oil, such as metals and nitrogen compounds.

The potential application of sulfamic acid in heavy oil desulfurization represents an opportunity to address market demands for more effective and environmentally friendly desulfurization methods. If proven successful, this approach could offer refineries a new tool to meet increasingly stringent sulfur content regulations while potentially reducing operational costs and environmental impact.

Current Challenges in Sulfamic Acid Desulfurization

Despite the promising potential of sulfamic acid for heavy oil desulfurization, several significant challenges currently hinder its widespread adoption and effectiveness in industrial applications. These challenges span across technical, economic, and environmental domains, requiring comprehensive solutions to advance this technology.

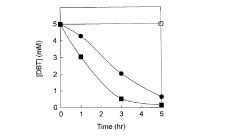

One of the primary technical challenges is the limited efficiency of sulfamic acid in removing certain types of sulfur compounds, particularly dibenzothiophenes and their alkylated derivatives. These compounds are notoriously resistant to conventional desulfurization methods, and while sulfamic acid shows improvement over traditional approaches, its effectiveness still falls short of regulatory requirements in many cases.

The reaction kinetics and mass transfer limitations pose another significant hurdle. The interaction between sulfamic acid and sulfur compounds in heavy oil occurs at the interface between the aqueous and oil phases. This interfacial reaction is often slow and incomplete, leading to extended processing times and reduced overall desulfurization efficiency. Enhancing the contact area and improving mass transfer rates remain critical challenges to overcome.

Temperature sensitivity is a notable issue in sulfamic acid desulfurization processes. The reaction's efficiency is highly dependent on maintaining optimal temperature conditions, which can be difficult to achieve consistently in large-scale industrial operations. Fluctuations in temperature can lead to reduced desulfurization rates or unwanted side reactions, compromising the quality of the treated oil.

Corrosion of equipment is a significant concern when using sulfamic acid. The acidic nature of the compound can lead to accelerated wear and tear on processing equipment, potentially resulting in increased maintenance costs and operational downtime. Developing corrosion-resistant materials or effective protective coatings is crucial for the long-term viability of this technology.

The recovery and recycling of sulfamic acid present both economic and environmental challenges. Efficient separation of the acid from the treated oil and its subsequent regeneration are essential for making the process economically feasible. However, current recovery methods often result in significant acid losses and generate waste streams that require additional treatment.

Environmental concerns also arise from the potential release of sulfamic acid or its byproducts into ecosystems. Stringent waste management protocols and effective treatment of effluents are necessary to mitigate environmental risks, adding complexity and cost to the overall process.

Scaling up the sulfamic acid desulfurization process from laboratory to industrial scale presents its own set of challenges. Maintaining reaction efficiency, ensuring uniform mixing, and managing heat transfer in large reactors are complex engineering problems that require innovative solutions.

One of the primary technical challenges is the limited efficiency of sulfamic acid in removing certain types of sulfur compounds, particularly dibenzothiophenes and their alkylated derivatives. These compounds are notoriously resistant to conventional desulfurization methods, and while sulfamic acid shows improvement over traditional approaches, its effectiveness still falls short of regulatory requirements in many cases.

The reaction kinetics and mass transfer limitations pose another significant hurdle. The interaction between sulfamic acid and sulfur compounds in heavy oil occurs at the interface between the aqueous and oil phases. This interfacial reaction is often slow and incomplete, leading to extended processing times and reduced overall desulfurization efficiency. Enhancing the contact area and improving mass transfer rates remain critical challenges to overcome.

Temperature sensitivity is a notable issue in sulfamic acid desulfurization processes. The reaction's efficiency is highly dependent on maintaining optimal temperature conditions, which can be difficult to achieve consistently in large-scale industrial operations. Fluctuations in temperature can lead to reduced desulfurization rates or unwanted side reactions, compromising the quality of the treated oil.

Corrosion of equipment is a significant concern when using sulfamic acid. The acidic nature of the compound can lead to accelerated wear and tear on processing equipment, potentially resulting in increased maintenance costs and operational downtime. Developing corrosion-resistant materials or effective protective coatings is crucial for the long-term viability of this technology.

The recovery and recycling of sulfamic acid present both economic and environmental challenges. Efficient separation of the acid from the treated oil and its subsequent regeneration are essential for making the process economically feasible. However, current recovery methods often result in significant acid losses and generate waste streams that require additional treatment.

Environmental concerns also arise from the potential release of sulfamic acid or its byproducts into ecosystems. Stringent waste management protocols and effective treatment of effluents are necessary to mitigate environmental risks, adding complexity and cost to the overall process.

Scaling up the sulfamic acid desulfurization process from laboratory to industrial scale presents its own set of challenges. Maintaining reaction efficiency, ensuring uniform mixing, and managing heat transfer in large reactors are complex engineering problems that require innovative solutions.

Existing Sulfamic Acid Desulfurization Methods

01 Sulfamic acid as a desulfurizing agent

Sulfamic acid is used as an effective desulfurizing agent in various industrial processes. It can react with sulfur-containing compounds to remove sulfur from gases, liquids, or solids. This method is particularly useful in flue gas desulfurization and petroleum refining.- Sulfamic acid as a desulfurizing agent: Sulfamic acid is used as an effective desulfurizing agent in various industrial processes. It can react with sulfur-containing compounds to remove sulfur from gases, liquids, or solids. This method is particularly useful in flue gas desulfurization and petroleum refining.

- Desulfurization of flue gas using sulfamic acid: Sulfamic acid is employed in flue gas desulfurization systems to remove sulfur dioxide from exhaust gases. This process involves the reaction of sulfamic acid with sulfur dioxide, forming stable compounds that can be easily separated from the gas stream. The method is effective in reducing sulfur emissions from power plants and industrial facilities.

- Sulfamic acid in petroleum desulfurization: In the petroleum industry, sulfamic acid is used for desulfurization of crude oil and refined products. The process involves the reaction of sulfamic acid with sulfur-containing compounds in the oil, converting them into forms that can be easily removed. This method helps in producing low-sulfur fuels and improving the quality of petroleum products.

- Combination of sulfamic acid with other compounds for enhanced desulfurization: Sulfamic acid is often combined with other compounds to enhance its desulfurization efficiency. These combinations can include oxidizing agents, catalysts, or other acids. The synergistic effects of these mixtures can improve the overall desulfurization process, making it more effective and economical.

- Innovative desulfurization equipment using sulfamic acid: Various types of equipment and systems have been developed to utilize sulfamic acid for desulfurization. These include specialized reactors, scrubbers, and absorption towers designed to optimize the contact between sulfamic acid and sulfur-containing compounds. Such equipment aims to improve the efficiency and effectiveness of the desulfurization process in industrial applications.

02 Desulfurization of flue gas using sulfamic acid

Sulfamic acid is employed in flue gas desulfurization systems to remove sulfur dioxide from exhaust gases. This process involves the reaction of sulfamic acid with sulfur dioxide, forming stable compounds that can be easily separated from the gas stream. The method is effective in reducing sulfur emissions from power plants and industrial facilities.Expand Specific Solutions03 Sulfamic acid in petroleum desulfurization

Sulfamic acid is utilized in the desulfurization of petroleum products. It can react with sulfur-containing compounds in crude oil and refined products, effectively reducing the sulfur content. This process is important for meeting environmental regulations and improving the quality of fuel products.Expand Specific Solutions04 Combination of sulfamic acid with other desulfurizing agents

Sulfamic acid is often used in combination with other desulfurizing agents to enhance the overall efficiency of the desulfurization process. These combinations can include metal oxides, activated carbon, or other chemical compounds, resulting in improved sulfur removal rates and broader applicability across different industrial sectors.Expand Specific Solutions05 Regeneration and recycling of sulfamic acid in desulfurization processes

Methods for regenerating and recycling sulfamic acid in desulfurization processes have been developed to improve the economic viability and sustainability of these systems. These techniques involve recovering the spent sulfamic acid, treating it to remove impurities, and reconverting it back to its active form for reuse in the desulfurization process.Expand Specific Solutions

Key Players in Sulfamic Acid Desulfurization Industry

The desulfurization of heavy oil using sulfamic acid is an emerging technology in the petroleum industry, currently in its early development stage. The market size for this specific application is relatively small but growing, driven by increasing environmental regulations and the need for cleaner fuels. The technology's maturity is still evolving, with major players like China Petroleum & Chemical Corp., ExxonMobil Technology & Engineering Co., and Saudi Arabian Oil Co. investing in research and development. These companies, along with research institutions such as Sinopec Research Institute of Petroleum Processing and Council of Scientific & Industrial Research, are at the forefront of advancing this technology. However, the process is not yet widely commercialized, indicating a competitive landscape that is still taking shape.

China Petroleum & Chemical Corp.

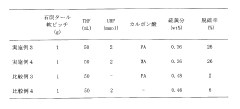

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to heavy oil desulfurization using sulfamic acid. Their process involves a two-stage reaction system where sulfamic acid is first used to break down complex sulfur compounds in heavy oil fractions. This is followed by a catalytic hydrodesulfurization step, which further reduces sulfur content. The company has reported achieving up to 90% sulfur removal efficiency in laboratory tests [1]. Sinopec's method also incorporates a novel recycling system for the sulfamic acid, improving the overall economics of the process. Additionally, they have implemented advanced process control systems to optimize reaction conditions, resulting in reduced energy consumption and improved product quality [3].

Strengths: High sulfur removal efficiency, improved economics through acid recycling, and optimized process control. Weaknesses: May require significant modifications to existing refinery infrastructure and potential corrosion issues with sulfamic acid.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a proprietary sulfamic acid-based desulfurization technology for heavy oil treatment. Their approach combines sulfamic acid with specific organic solvents to create a biphasic system that enhances sulfur extraction from heavy oil fractions. The process operates at moderate temperatures (80-120°C) and pressures (5-10 bar), making it less energy-intensive compared to conventional hydrodesulfurization [2]. ExxonMobil's technology also incorporates a novel sulfur recovery unit that converts the extracted sulfur compounds into marketable products, improving the overall economics of the process. The company has reported achieving sulfur removal rates of up to 85% in pilot plant trials, with minimal impact on oil quality and yield [4].

Strengths: Moderate operating conditions, improved economics through sulfur recovery, and minimal impact on oil quality. Weaknesses: May be less effective for certain types of sulfur compounds and potential challenges in scaling up to commercial production.

Core Innovations in Sulfamic Acid Application

Oxidation desulfurization method of heavy oil

PatentInactiveJP2013018866A

Innovation

- Treatment of coal-based heavy oil with hydrogen peroxide and organic carboxylic acid in tetrahydrofuran, utilizing a urea-hydrogen peroxide adduct and organic dicarboxylic acid anhydride to convert sulfur compounds into polar compounds for efficient removal.

Method for desulfurizing heavy oil by using supercritical extraction

PatentWO2021201321A1

Innovation

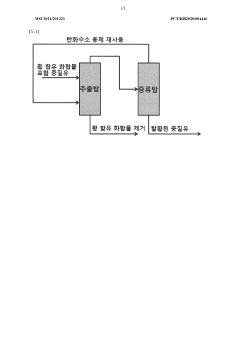

- A method involving the use of a hydrocarbon solvent under supercritical conditions to extract and separate sulfur-containing compounds from heavy oil, eliminating the need for hydrogen and catalysts, and reusing the solvent to achieve desulfurization, which reduces by-product production and maintains environmental friendliness.

Environmental Impact of Sulfamic Acid Desulfurization

The environmental impact of sulfamic acid desulfurization in heavy oil processing is a critical consideration for the industry. This process, while effective in reducing sulfur content, has several potential environmental implications that must be carefully evaluated and managed.

Sulfamic acid desulfurization generates acidic wastewater as a byproduct. This wastewater contains residual sulfamic acid, sulfur compounds, and other contaminants. If not properly treated, it can pose significant risks to aquatic ecosystems and water resources. The low pH of the wastewater can disrupt the natural balance of receiving water bodies, affecting aquatic life and biodiversity. Additionally, the presence of sulfur compounds in the effluent may contribute to the formation of acid rain if released into the atmosphere.

Air emissions are another environmental concern associated with sulfamic acid desulfurization. The process can release sulfur dioxide and other sulfur-containing gases, which are known contributors to air pollution and acid rain formation. These emissions may require additional control measures to comply with air quality regulations and minimize their impact on local air quality and human health.

The production and transportation of sulfamic acid itself also have environmental implications. The manufacturing process of sulfamic acid involves energy-intensive steps and potential chemical hazards. Transportation of the acid to oil processing facilities carries risks of spills or accidents, which could result in localized environmental damage and pose safety hazards to communities along transportation routes.

Solid waste generation is another aspect to consider. The desulfurization process may produce sulfur-rich sludge or other solid residues that require proper disposal or treatment. These wastes may be classified as hazardous due to their chemical composition, necessitating specialized handling and disposal methods to prevent soil and groundwater contamination.

From a broader perspective, the use of sulfamic acid for desulfurization contributes to the overall environmental footprint of heavy oil processing. While it helps reduce sulfur content in the final product, thus lowering sulfur dioxide emissions during fuel combustion, the environmental costs of the desulfurization process itself must be weighed against these benefits.

To mitigate these environmental impacts, industry practitioners are exploring various strategies. These include developing more efficient desulfurization processes that minimize acid consumption and waste generation, implementing advanced wastewater treatment technologies, and investigating alternative desulfurization methods with potentially lower environmental impacts. Additionally, life cycle assessments are being conducted to comprehensively evaluate the environmental trade-offs of sulfamic acid desulfurization compared to other sulfur removal techniques.

Sulfamic acid desulfurization generates acidic wastewater as a byproduct. This wastewater contains residual sulfamic acid, sulfur compounds, and other contaminants. If not properly treated, it can pose significant risks to aquatic ecosystems and water resources. The low pH of the wastewater can disrupt the natural balance of receiving water bodies, affecting aquatic life and biodiversity. Additionally, the presence of sulfur compounds in the effluent may contribute to the formation of acid rain if released into the atmosphere.

Air emissions are another environmental concern associated with sulfamic acid desulfurization. The process can release sulfur dioxide and other sulfur-containing gases, which are known contributors to air pollution and acid rain formation. These emissions may require additional control measures to comply with air quality regulations and minimize their impact on local air quality and human health.

The production and transportation of sulfamic acid itself also have environmental implications. The manufacturing process of sulfamic acid involves energy-intensive steps and potential chemical hazards. Transportation of the acid to oil processing facilities carries risks of spills or accidents, which could result in localized environmental damage and pose safety hazards to communities along transportation routes.

Solid waste generation is another aspect to consider. The desulfurization process may produce sulfur-rich sludge or other solid residues that require proper disposal or treatment. These wastes may be classified as hazardous due to their chemical composition, necessitating specialized handling and disposal methods to prevent soil and groundwater contamination.

From a broader perspective, the use of sulfamic acid for desulfurization contributes to the overall environmental footprint of heavy oil processing. While it helps reduce sulfur content in the final product, thus lowering sulfur dioxide emissions during fuel combustion, the environmental costs of the desulfurization process itself must be weighed against these benefits.

To mitigate these environmental impacts, industry practitioners are exploring various strategies. These include developing more efficient desulfurization processes that minimize acid consumption and waste generation, implementing advanced wastewater treatment technologies, and investigating alternative desulfurization methods with potentially lower environmental impacts. Additionally, life cycle assessments are being conducted to comprehensively evaluate the environmental trade-offs of sulfamic acid desulfurization compared to other sulfur removal techniques.

Economic Feasibility of Sulfamic Acid Technology

The economic feasibility of sulfamic acid technology for heavy oil desulfurization is a critical factor in determining its potential for widespread adoption in the petroleum industry. This analysis considers various economic aspects, including capital expenditure, operational costs, and potential returns on investment.

Initial capital costs for implementing sulfamic acid desulfurization technology are relatively moderate compared to other desulfurization methods. The primary investments include equipment for acid handling, reaction vessels, and separation units. These costs are offset by the technology's ability to be integrated into existing refinery infrastructure, reducing the need for extensive modifications.

Operational expenses primarily consist of the cost of sulfamic acid, energy consumption, and maintenance. Sulfamic acid is commercially available and reasonably priced, making it an attractive option for large-scale use. The energy requirements for the process are lower than those of conventional hydrodesulfurization, potentially leading to significant cost savings over time.

The efficiency of sulfamic acid in removing sulfur compounds from heavy oil can result in higher-quality products that command premium prices in the market. This improved product value can contribute substantially to the overall economic viability of the technology.

Environmental regulations play a crucial role in the economic assessment. As sulfur emission standards become increasingly stringent, refineries face potential fines and penalties for non-compliance. Sulfamic acid technology offers a cost-effective solution to meet these regulatory requirements, potentially avoiding significant financial liabilities.

The scalability of sulfamic acid desulfurization is another economic advantage. The process can be applied to various capacities, allowing refineries to adjust their operations based on market demands and feedstock availability. This flexibility can lead to optimized resource utilization and improved economic performance.

Recovery and recycling of sulfamic acid within the process can further enhance its economic attractiveness. Efficient recycling systems can significantly reduce the ongoing operational costs associated with acid consumption, improving the long-term economic sustainability of the technology.

When comparing sulfamic acid technology to alternative desulfurization methods, it demonstrates favorable economics in terms of both capital and operational expenditures. The lower energy intensity and milder operating conditions contribute to reduced utility costs and potentially longer equipment lifespans.

In conclusion, the economic feasibility of sulfamic acid technology for heavy oil desulfurization appears promising. Its moderate capital requirements, operational cost advantages, and potential for producing higher-value products position it as an economically viable option for refineries seeking to meet stringent environmental standards while maintaining profitability.

Initial capital costs for implementing sulfamic acid desulfurization technology are relatively moderate compared to other desulfurization methods. The primary investments include equipment for acid handling, reaction vessels, and separation units. These costs are offset by the technology's ability to be integrated into existing refinery infrastructure, reducing the need for extensive modifications.

Operational expenses primarily consist of the cost of sulfamic acid, energy consumption, and maintenance. Sulfamic acid is commercially available and reasonably priced, making it an attractive option for large-scale use. The energy requirements for the process are lower than those of conventional hydrodesulfurization, potentially leading to significant cost savings over time.

The efficiency of sulfamic acid in removing sulfur compounds from heavy oil can result in higher-quality products that command premium prices in the market. This improved product value can contribute substantially to the overall economic viability of the technology.

Environmental regulations play a crucial role in the economic assessment. As sulfur emission standards become increasingly stringent, refineries face potential fines and penalties for non-compliance. Sulfamic acid technology offers a cost-effective solution to meet these regulatory requirements, potentially avoiding significant financial liabilities.

The scalability of sulfamic acid desulfurization is another economic advantage. The process can be applied to various capacities, allowing refineries to adjust their operations based on market demands and feedstock availability. This flexibility can lead to optimized resource utilization and improved economic performance.

Recovery and recycling of sulfamic acid within the process can further enhance its economic attractiveness. Efficient recycling systems can significantly reduce the ongoing operational costs associated with acid consumption, improving the long-term economic sustainability of the technology.

When comparing sulfamic acid technology to alternative desulfurization methods, it demonstrates favorable economics in terms of both capital and operational expenditures. The lower energy intensity and milder operating conditions contribute to reduced utility costs and potentially longer equipment lifespans.

In conclusion, the economic feasibility of sulfamic acid technology for heavy oil desulfurization appears promising. Its moderate capital requirements, operational cost advantages, and potential for producing higher-value products position it as an economically viable option for refineries seeking to meet stringent environmental standards while maintaining profitability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!