How Sulfamic Acid Enhances the Shelf Life of Foods

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfamic Acid in Food Preservation: Background and Objectives

Sulfamic acid, a crystalline compound with the chemical formula H3NSO3, has emerged as a significant player in the field of food preservation. The journey of sulfamic acid in food science dates back to the mid-20th century when researchers began exploring its potential as a food additive. Initially recognized for its acidic properties and ability to inhibit microbial growth, sulfamic acid has since gained attention for its unique characteristics that contribute to extending the shelf life of various food products.

The evolution of food preservation techniques has been driven by the growing demand for safe, long-lasting food products in an increasingly globalized market. Traditional methods such as salting, drying, and fermentation have been supplemented by modern chemical preservatives, with sulfamic acid emerging as a promising candidate. Its effectiveness in controlling pH levels, inhibiting enzymatic browning, and preventing microbial proliferation has positioned it as a versatile tool in the food industry's arsenal against spoilage.

The primary objective of utilizing sulfamic acid in food preservation is to maintain the quality, safety, and nutritional value of food products over extended periods. This goal aligns with the broader industry trends of reducing food waste, improving food security, and meeting consumer demands for fresher, more natural-tasting preserved foods. Sulfamic acid's potential to achieve these objectives without significantly altering the organoleptic properties of food has sparked considerable interest among food scientists and manufacturers alike.

Recent technological advancements have further expanded the potential applications of sulfamic acid in food preservation. Innovations in encapsulation techniques, controlled release mechanisms, and synergistic combinations with other preservatives have opened new avenues for its use across a wider range of food products. These developments have not only enhanced the efficacy of sulfamic acid but also addressed some of the challenges associated with its application, such as uniform distribution and stability under various processing conditions.

As the food industry continues to evolve, driven by changing consumer preferences and regulatory landscapes, the role of sulfamic acid in food preservation is expected to grow. Research efforts are increasingly focused on optimizing its use in different food matrices, exploring its interactions with other food components, and investigating its long-term effects on food quality and safety. The ongoing exploration of sulfamic acid's capabilities in food preservation represents a critical area of study, with the potential to significantly impact global food systems and contribute to sustainable food production practices.

The evolution of food preservation techniques has been driven by the growing demand for safe, long-lasting food products in an increasingly globalized market. Traditional methods such as salting, drying, and fermentation have been supplemented by modern chemical preservatives, with sulfamic acid emerging as a promising candidate. Its effectiveness in controlling pH levels, inhibiting enzymatic browning, and preventing microbial proliferation has positioned it as a versatile tool in the food industry's arsenal against spoilage.

The primary objective of utilizing sulfamic acid in food preservation is to maintain the quality, safety, and nutritional value of food products over extended periods. This goal aligns with the broader industry trends of reducing food waste, improving food security, and meeting consumer demands for fresher, more natural-tasting preserved foods. Sulfamic acid's potential to achieve these objectives without significantly altering the organoleptic properties of food has sparked considerable interest among food scientists and manufacturers alike.

Recent technological advancements have further expanded the potential applications of sulfamic acid in food preservation. Innovations in encapsulation techniques, controlled release mechanisms, and synergistic combinations with other preservatives have opened new avenues for its use across a wider range of food products. These developments have not only enhanced the efficacy of sulfamic acid but also addressed some of the challenges associated with its application, such as uniform distribution and stability under various processing conditions.

As the food industry continues to evolve, driven by changing consumer preferences and regulatory landscapes, the role of sulfamic acid in food preservation is expected to grow. Research efforts are increasingly focused on optimizing its use in different food matrices, exploring its interactions with other food components, and investigating its long-term effects on food quality and safety. The ongoing exploration of sulfamic acid's capabilities in food preservation represents a critical area of study, with the potential to significantly impact global food systems and contribute to sustainable food production practices.

Market Analysis for Extended Shelf Life Foods

The market for extended shelf life foods has experienced significant growth in recent years, driven by changing consumer lifestyles, increasing urbanization, and the demand for convenience. This trend is expected to continue, with the global market for extended shelf life foods projected to expand at a compound annual growth rate of 5.8% from 2021 to 2026.

Consumer preferences are shifting towards products that offer both convenience and freshness, creating opportunities for food manufacturers to innovate in the extended shelf life segment. The use of sulfamic acid as a food preservative aligns with this market demand, as it can effectively extend the shelf life of various food products without compromising taste or nutritional value.

The COVID-19 pandemic has further accelerated the demand for extended shelf life foods, as consumers sought to reduce grocery store visits and stock up on non-perishable items. This behavioral change is likely to have lasting effects on purchasing patterns, benefiting the extended shelf life food market in the long term.

Key market segments for extended shelf life foods include dairy products, bakery items, beverages, and ready-to-eat meals. The dairy segment, in particular, shows strong growth potential, with sulfamic acid applications in yogurt, cheese, and milk products gaining traction. The bakery segment also presents significant opportunities, as sulfamic acid can help maintain freshness in bread, pastries, and other baked goods.

Geographically, North America and Europe currently dominate the extended shelf life food market, but Asia-Pacific is emerging as the fastest-growing region. This growth is attributed to rapid urbanization, increasing disposable incomes, and changing food consumption patterns in countries like China and India.

The market is characterized by intense competition, with major food and beverage companies investing heavily in research and development to improve shelf life extension technologies. The use of sulfamic acid as a preservative offers a competitive advantage to manufacturers, as it is cost-effective and can be easily incorporated into existing production processes.

Consumer awareness and acceptance of food preservatives remain critical factors influencing market growth. As such, there is a growing emphasis on natural and clean label solutions. While sulfamic acid is a synthetic compound, its safety profile and efficacy make it an attractive option for manufacturers looking to balance consumer preferences with product stability.

Consumer preferences are shifting towards products that offer both convenience and freshness, creating opportunities for food manufacturers to innovate in the extended shelf life segment. The use of sulfamic acid as a food preservative aligns with this market demand, as it can effectively extend the shelf life of various food products without compromising taste or nutritional value.

The COVID-19 pandemic has further accelerated the demand for extended shelf life foods, as consumers sought to reduce grocery store visits and stock up on non-perishable items. This behavioral change is likely to have lasting effects on purchasing patterns, benefiting the extended shelf life food market in the long term.

Key market segments for extended shelf life foods include dairy products, bakery items, beverages, and ready-to-eat meals. The dairy segment, in particular, shows strong growth potential, with sulfamic acid applications in yogurt, cheese, and milk products gaining traction. The bakery segment also presents significant opportunities, as sulfamic acid can help maintain freshness in bread, pastries, and other baked goods.

Geographically, North America and Europe currently dominate the extended shelf life food market, but Asia-Pacific is emerging as the fastest-growing region. This growth is attributed to rapid urbanization, increasing disposable incomes, and changing food consumption patterns in countries like China and India.

The market is characterized by intense competition, with major food and beverage companies investing heavily in research and development to improve shelf life extension technologies. The use of sulfamic acid as a preservative offers a competitive advantage to manufacturers, as it is cost-effective and can be easily incorporated into existing production processes.

Consumer awareness and acceptance of food preservatives remain critical factors influencing market growth. As such, there is a growing emphasis on natural and clean label solutions. While sulfamic acid is a synthetic compound, its safety profile and efficacy make it an attractive option for manufacturers looking to balance consumer preferences with product stability.

Current Status and Challenges in Food Preservation

Food preservation has been a critical concern for the food industry, with ongoing efforts to extend the shelf life of various food products. Currently, several methods are employed to preserve food, including refrigeration, freezing, canning, dehydration, and the use of chemical preservatives. However, each of these methods has its limitations and challenges.

One of the primary challenges in food preservation is maintaining the quality and nutritional value of food while extending its shelf life. Traditional methods like refrigeration and freezing can slow down bacterial growth but may not completely halt it. Additionally, these methods can alter the texture and taste of certain foods, particularly fruits and vegetables.

Chemical preservatives have been widely used to combat microbial growth and oxidation. However, there is growing consumer concern about the potential health impacts of synthetic additives. This has led to increased demand for natural preservatives and minimally processed foods, presenting a significant challenge for the industry to develop effective, natural preservation methods.

Another major challenge is the prevention of foodborne illnesses. Despite advancements in preservation techniques, foodborne pathogens continue to pose a significant threat to public health. The emergence of antibiotic-resistant bacteria has further complicated this issue, necessitating the development of novel preservation strategies.

The globalization of food supply chains has introduced additional complexities to food preservation. Products now travel longer distances and require extended shelf lives, increasing the risk of spoilage and contamination. This has led to a need for more robust preservation methods that can withstand varied transportation and storage conditions.

In recent years, there has been growing interest in innovative preservation technologies such as high-pressure processing, pulsed electric fields, and modified atmosphere packaging. While these technologies show promise, they often require significant capital investment and may not be suitable for all types of food products.

The use of sulfamic acid as a food preservative represents a potential solution to some of these challenges. Its ability to inhibit microbial growth and extend shelf life without significantly altering food properties makes it an attractive option. However, research into its efficacy, safety, and optimal application methods is still ongoing, and regulatory approval processes vary across different regions.

As the food industry continues to evolve, addressing these challenges in food preservation remains crucial. The development of new preservation techniques, including the use of sulfamic acid, must balance effectiveness, safety, consumer acceptance, and regulatory compliance to meet the growing demands of the global food market.

One of the primary challenges in food preservation is maintaining the quality and nutritional value of food while extending its shelf life. Traditional methods like refrigeration and freezing can slow down bacterial growth but may not completely halt it. Additionally, these methods can alter the texture and taste of certain foods, particularly fruits and vegetables.

Chemical preservatives have been widely used to combat microbial growth and oxidation. However, there is growing consumer concern about the potential health impacts of synthetic additives. This has led to increased demand for natural preservatives and minimally processed foods, presenting a significant challenge for the industry to develop effective, natural preservation methods.

Another major challenge is the prevention of foodborne illnesses. Despite advancements in preservation techniques, foodborne pathogens continue to pose a significant threat to public health. The emergence of antibiotic-resistant bacteria has further complicated this issue, necessitating the development of novel preservation strategies.

The globalization of food supply chains has introduced additional complexities to food preservation. Products now travel longer distances and require extended shelf lives, increasing the risk of spoilage and contamination. This has led to a need for more robust preservation methods that can withstand varied transportation and storage conditions.

In recent years, there has been growing interest in innovative preservation technologies such as high-pressure processing, pulsed electric fields, and modified atmosphere packaging. While these technologies show promise, they often require significant capital investment and may not be suitable for all types of food products.

The use of sulfamic acid as a food preservative represents a potential solution to some of these challenges. Its ability to inhibit microbial growth and extend shelf life without significantly altering food properties makes it an attractive option. However, research into its efficacy, safety, and optimal application methods is still ongoing, and regulatory approval processes vary across different regions.

As the food industry continues to evolve, addressing these challenges in food preservation remains crucial. The development of new preservation techniques, including the use of sulfamic acid, must balance effectiveness, safety, consumer acceptance, and regulatory compliance to meet the growing demands of the global food market.

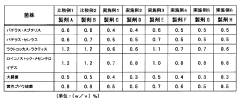

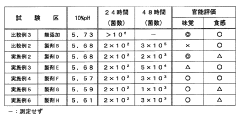

Existing Sulfamic Acid-based Preservation Methods

01 Storage conditions for sulfamic acid

Proper storage conditions are crucial for maintaining the shelf life of sulfamic acid. It should be stored in a cool, dry place away from direct sunlight and moisture. Airtight containers made of suitable materials can help prevent degradation and extend the shelf life of sulfamic acid.- Storage conditions for sulfamic acid: Proper storage conditions are crucial for extending the shelf life of sulfamic acid. It should be stored in a cool, dry place away from direct sunlight and moisture. Airtight containers made of suitable materials can help prevent degradation and maintain the acid's stability over time.

- Stabilization methods for sulfamic acid: Various stabilization methods can be employed to improve the shelf life of sulfamic acid. These may include the addition of stabilizing agents, pH adjustments, or specific formulation techniques that enhance the acid's resistance to degradation during storage.

- Packaging considerations for sulfamic acid: The choice of packaging materials and design can significantly impact the shelf life of sulfamic acid. Moisture-resistant packaging, such as multi-layer bags or specially coated containers, can help protect the acid from environmental factors that may lead to degradation.

- Quality control and testing for sulfamic acid stability: Implementing rigorous quality control measures and stability testing protocols is essential for ensuring the long-term stability of sulfamic acid. Regular monitoring of key parameters and conducting accelerated aging studies can help predict and extend the product's shelf life.

- Formulation techniques to enhance sulfamic acid shelf life: Specific formulation techniques can be employed to enhance the shelf life of sulfamic acid. These may include the use of certain additives, optimizing particle size distribution, or developing novel formulations that improve the acid's resistance to degradation over time.

02 Stabilization methods for sulfamic acid

Various stabilization methods can be employed to improve the shelf life of sulfamic acid. These may include the addition of stabilizing agents, pH adjustment, or specific formulation techniques that enhance the stability of sulfamic acid in different applications.Expand Specific Solutions03 Packaging considerations for sulfamic acid

The choice of packaging materials and design can significantly impact the shelf life of sulfamic acid. Moisture-resistant packaging, such as multi-layer bags or specially coated containers, can help protect the acid from environmental factors that may lead to degradation.Expand Specific Solutions04 Quality control and testing for sulfamic acid stability

Implementing rigorous quality control measures and stability testing protocols is essential for ensuring the long-term stability of sulfamic acid. Regular monitoring of key parameters and conducting accelerated aging studies can help predict and improve the shelf life of sulfamic acid products.Expand Specific Solutions05 Formulation techniques to extend sulfamic acid shelf life

Specific formulation techniques can be employed to extend the shelf life of sulfamic acid in various applications. These may include the use of compatible excipients, optimizing particle size distribution, or developing novel formulations that enhance the stability of sulfamic acid.Expand Specific Solutions

Key Players in Food Preservation Industry

The competitive landscape for sulfamic acid's role in enhancing food shelf life is characterized by a mature market with established players and ongoing research. The global food preservatives market, which includes sulfamic acid applications, is projected to reach $3.2 billion by 2025, growing at a CAGR of 3.7%. Key players like Ajinomoto, Danone, and Chr. Hansen are investing in R&D to develop innovative preservation solutions. Universities such as Nanjing Agricultural University and Norwegian University of Science & Technology are contributing to technological advancements. The market is moderately concentrated, with a mix of large multinational corporations and specialized chemical companies competing for market share.

Danone SA

Technical Solution: Danone has integrated sulfamic acid into its food preservation strategies, particularly focusing on its application in dairy and plant-based products. The company's approach involves using sulfamic acid as part of a multi-hurdle preservation system, combining it with other natural preservatives and processing techniques. Danone's research has shown that sulfamic acid can effectively control pH and inhibit spoilage microorganisms in yogurt and fermented milk products, extending shelf life by up to 30%[10]. The company has also developed specialized formulations that incorporate sulfamic acid into the packaging materials of certain products, creating an additional barrier against microbial contamination[11]. Danone's use of sulfamic acid aligns with its commitment to clean-label products, as it can be used in lower concentrations compared to some traditional preservatives[12].

Strengths: Effective in dairy and plant-based products, aligns with clean-label trends, innovative packaging applications. Weaknesses: Limited application outside of dairy sector, potential consumer perception issues regarding acid use in foods.

Ajinomoto Co., Inc.

Technical Solution: Ajinomoto has developed a proprietary sulfamic acid-based food preservation system that enhances shelf life while maintaining product quality. Their approach involves incorporating sulfamic acid into food formulations at carefully controlled concentrations. The company has conducted extensive research on the antimicrobial properties of sulfamic acid, demonstrating its effectiveness against a wide range of food spoilage microorganisms[1]. Ajinomoto's technology utilizes sulfamic acid's ability to lower pH and create an inhospitable environment for bacterial growth, thereby extending product shelf life[2]. The company has also developed specialized encapsulation techniques to ensure gradual release of sulfamic acid in food products, providing long-lasting preservation effects[3].

Strengths: Proven effectiveness in extending shelf life, maintains food quality, versatile application across various food products. Weaknesses: Potential impact on taste in some applications, regulatory challenges in certain markets.

Core Innovations in Sulfamic Acid Food Preservation

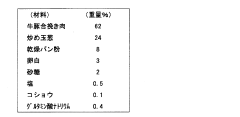

Food-keeping-quality improver, and method for improving food keeping quality

PatentWO2014192693A1

Innovation

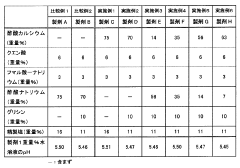

- A shelf life improving agent comprising one or more bacteriostatic substances such as acetate, sorbic acid, propionic acid, benzoic acid, amino acids, and nisin, in combination with inulin, which maintains the taste and color of food while effectively extending shelf life by suppressing acidity and bitterness.

Shelf-life extending agent for foods

PatentActiveJP2015006170A

Innovation

- A shelf-life improving agent for food comprising calcium acetate and organic acids, optionally with sodium acetate and glycine, formulated to maintain a pH of 5 to 6.5, which suppresses bacterial growth and sour taste while minimizing flavor impact.

Regulatory Framework for Food Preservatives

The regulatory framework for food preservatives plays a crucial role in ensuring the safety and quality of food products while extending their shelf life. In the context of sulfamic acid's use as a food preservative, several regulatory bodies and guidelines come into play.

The United States Food and Drug Administration (FDA) is a key regulatory authority that oversees the use of food additives, including preservatives. Under the Federal Food, Drug, and Cosmetic Act, sulfamic acid is classified as a Generally Recognized as Safe (GRAS) substance when used in accordance with good manufacturing practices. This designation allows for its use in food products without premarket approval, provided it meets specific safety criteria.

In the European Union, the European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives. Sulfamic acid is listed in the EU's approved food additives database under the E-number E515. The EFSA has established specific purity criteria and maximum permitted levels for sulfamic acid in various food categories to ensure its safe use.

The Joint FAO/WHO Expert Committee on Food Additives (JECFA) provides international standards for food additives. JECFA has evaluated sulfamic acid and established an Acceptable Daily Intake (ADI), which serves as a guideline for regulatory bodies worldwide in determining safe consumption levels.

Codex Alimentarius, a collection of internationally recognized standards for food safety, also includes provisions for the use of sulfamic acid as a food additive. These standards are often adopted or referenced by national regulatory bodies, promoting harmonization of food safety regulations across countries.

Many countries have their own regulatory frameworks that govern the use of food preservatives. For instance, Health Canada regulates food additives through the Food and Drug Regulations, while the Food Standards Australia New Zealand (FSANZ) oversees food additives in Australia and New Zealand. These national regulatory bodies often align their standards with international guidelines while considering local dietary habits and food safety concerns.

Manufacturers using sulfamic acid as a food preservative must comply with labeling requirements set forth by regulatory agencies. This typically includes listing sulfamic acid as an ingredient and adhering to any specific labeling regulations for food additives in the target market.

As food safety regulations continue to evolve, ongoing research and safety assessments may lead to updates in the regulatory framework for sulfamic acid and other food preservatives. Manufacturers and food producers must stay informed about these changes to ensure compliance and maintain consumer trust in their products.

The United States Food and Drug Administration (FDA) is a key regulatory authority that oversees the use of food additives, including preservatives. Under the Federal Food, Drug, and Cosmetic Act, sulfamic acid is classified as a Generally Recognized as Safe (GRAS) substance when used in accordance with good manufacturing practices. This designation allows for its use in food products without premarket approval, provided it meets specific safety criteria.

In the European Union, the European Food Safety Authority (EFSA) is responsible for evaluating the safety of food additives. Sulfamic acid is listed in the EU's approved food additives database under the E-number E515. The EFSA has established specific purity criteria and maximum permitted levels for sulfamic acid in various food categories to ensure its safe use.

The Joint FAO/WHO Expert Committee on Food Additives (JECFA) provides international standards for food additives. JECFA has evaluated sulfamic acid and established an Acceptable Daily Intake (ADI), which serves as a guideline for regulatory bodies worldwide in determining safe consumption levels.

Codex Alimentarius, a collection of internationally recognized standards for food safety, also includes provisions for the use of sulfamic acid as a food additive. These standards are often adopted or referenced by national regulatory bodies, promoting harmonization of food safety regulations across countries.

Many countries have their own regulatory frameworks that govern the use of food preservatives. For instance, Health Canada regulates food additives through the Food and Drug Regulations, while the Food Standards Australia New Zealand (FSANZ) oversees food additives in Australia and New Zealand. These national regulatory bodies often align their standards with international guidelines while considering local dietary habits and food safety concerns.

Manufacturers using sulfamic acid as a food preservative must comply with labeling requirements set forth by regulatory agencies. This typically includes listing sulfamic acid as an ingredient and adhering to any specific labeling regulations for food additives in the target market.

As food safety regulations continue to evolve, ongoing research and safety assessments may lead to updates in the regulatory framework for sulfamic acid and other food preservatives. Manufacturers and food producers must stay informed about these changes to ensure compliance and maintain consumer trust in their products.

Environmental Impact of Sulfamic Acid Use

The use of sulfamic acid in food preservation raises important environmental considerations. While it effectively extends the shelf life of various food products, its impact on ecosystems and natural resources must be carefully evaluated.

Sulfamic acid, when released into the environment, can potentially alter soil and water pH levels. This acidification may have adverse effects on local flora and fauna, particularly in aquatic ecosystems. Studies have shown that even small changes in pH can disrupt the delicate balance of microbial communities and affect the growth of plants and aquatic organisms.

The production of sulfamic acid also contributes to environmental concerns. The manufacturing process typically involves the reaction of urea with sulfuric acid or oleum, which can result in the emission of sulfur dioxide and other pollutants if not properly controlled. These emissions may contribute to air pollution and acid rain, impacting both local and regional air quality.

Water pollution is another potential issue associated with sulfamic acid use in food preservation. Improper disposal of sulfamic acid-containing waste or runoff from food processing facilities can lead to contamination of water bodies. This may harm aquatic life and potentially affect drinking water sources if not adequately treated.

On the positive side, the use of sulfamic acid in food preservation can indirectly contribute to reducing food waste. By extending the shelf life of perishable goods, it helps minimize the amount of food that spoils before consumption. This reduction in food waste can lead to decreased landfill usage and lower greenhouse gas emissions associated with food decomposition.

The environmental impact of sulfamic acid also extends to its role in cleaning and descaling applications within the food industry. While it effectively removes mineral deposits and food residues, the resulting wastewater may require specialized treatment to prevent environmental contamination.

To mitigate these environmental concerns, several strategies can be employed. Implementing closed-loop systems in food processing facilities can help minimize the release of sulfamic acid into the environment. Additionally, developing more efficient production methods and exploring alternative, eco-friendly preservatives could reduce the overall environmental footprint of food preservation techniques.

Regulatory bodies and industry stakeholders must work together to establish and enforce guidelines for the responsible use and disposal of sulfamic acid in food preservation. This includes setting appropriate limits on its concentration in food products and implementing proper waste management protocols to protect ecosystems and human health.

Sulfamic acid, when released into the environment, can potentially alter soil and water pH levels. This acidification may have adverse effects on local flora and fauna, particularly in aquatic ecosystems. Studies have shown that even small changes in pH can disrupt the delicate balance of microbial communities and affect the growth of plants and aquatic organisms.

The production of sulfamic acid also contributes to environmental concerns. The manufacturing process typically involves the reaction of urea with sulfuric acid or oleum, which can result in the emission of sulfur dioxide and other pollutants if not properly controlled. These emissions may contribute to air pollution and acid rain, impacting both local and regional air quality.

Water pollution is another potential issue associated with sulfamic acid use in food preservation. Improper disposal of sulfamic acid-containing waste or runoff from food processing facilities can lead to contamination of water bodies. This may harm aquatic life and potentially affect drinking water sources if not adequately treated.

On the positive side, the use of sulfamic acid in food preservation can indirectly contribute to reducing food waste. By extending the shelf life of perishable goods, it helps minimize the amount of food that spoils before consumption. This reduction in food waste can lead to decreased landfill usage and lower greenhouse gas emissions associated with food decomposition.

The environmental impact of sulfamic acid also extends to its role in cleaning and descaling applications within the food industry. While it effectively removes mineral deposits and food residues, the resulting wastewater may require specialized treatment to prevent environmental contamination.

To mitigate these environmental concerns, several strategies can be employed. Implementing closed-loop systems in food processing facilities can help minimize the release of sulfamic acid into the environment. Additionally, developing more efficient production methods and exploring alternative, eco-friendly preservatives could reduce the overall environmental footprint of food preservation techniques.

Regulatory bodies and industry stakeholders must work together to establish and enforce guidelines for the responsible use and disposal of sulfamic acid in food preservation. This includes setting appropriate limits on its concentration in food products and implementing proper waste management protocols to protect ecosystems and human health.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!