Application of Sulfamic Acid in Innovative Spray Drying Techniques

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfamic Acid Spray Drying Background and Objectives

Sulfamic acid, a versatile compound with the chemical formula H3NSO3, has been widely used in various industrial applications for decades. Its unique properties, including high solubility in water, low toxicity, and strong acidic nature, have made it a valuable ingredient in cleaning agents, descaling solutions, and water treatment processes. In recent years, there has been growing interest in exploring the potential of sulfamic acid in innovative spray drying techniques, which presents an exciting frontier for technological advancement and industrial optimization.

Spray drying is a well-established method for producing dry powders from liquid or slurry formulations, widely employed in the food, pharmaceutical, and chemical industries. The process involves atomizing a liquid feed into fine droplets and rapidly drying them in a hot gas stream, resulting in the formation of dry particles. Traditional spray drying techniques have limitations in terms of energy efficiency, product quality, and process control, which have prompted researchers and industry professionals to seek innovative solutions.

The application of sulfamic acid in spray drying techniques aims to address these challenges and unlock new possibilities for improved product characteristics and process efficiency. By incorporating sulfamic acid into the spray drying process, researchers hope to leverage its unique chemical properties to enhance particle formation, control moisture content, and modify surface properties of the resulting powders.

One of the primary objectives of this technological exploration is to improve the stability and shelf life of spray-dried products. Sulfamic acid's ability to control pH and inhibit microbial growth could potentially lead to the development of more stable and longer-lasting powdered formulations, particularly in the food and pharmaceutical sectors. Additionally, the incorporation of sulfamic acid may offer opportunities for tailoring particle size distribution and morphology, which are critical factors in determining the functionality and performance of spray-dried powders.

Another key goal is to enhance the energy efficiency of the spray drying process. The hygroscopic nature of sulfamic acid could potentially be harnessed to reduce the energy required for drying, leading to more sustainable and cost-effective manufacturing processes. This aligns with the growing industry focus on reducing energy consumption and minimizing environmental impact.

Furthermore, the application of sulfamic acid in spray drying techniques may open up new avenues for product innovation. By modifying the surface properties of spray-dried particles, it may be possible to create novel functional materials with improved solubility, dispersibility, or controlled release characteristics. This could have far-reaching implications across various industries, from advanced drug delivery systems to high-performance materials for industrial applications.

As we embark on this exploration of sulfamic acid in innovative spray drying techniques, it is essential to consider the potential challenges and limitations that may arise. These may include issues related to material compatibility, process scalability, and regulatory considerations, particularly in sensitive applications such as food and pharmaceuticals. By addressing these challenges head-on, we aim to develop robust and practical solutions that can be readily adopted by industry stakeholders.

Spray drying is a well-established method for producing dry powders from liquid or slurry formulations, widely employed in the food, pharmaceutical, and chemical industries. The process involves atomizing a liquid feed into fine droplets and rapidly drying them in a hot gas stream, resulting in the formation of dry particles. Traditional spray drying techniques have limitations in terms of energy efficiency, product quality, and process control, which have prompted researchers and industry professionals to seek innovative solutions.

The application of sulfamic acid in spray drying techniques aims to address these challenges and unlock new possibilities for improved product characteristics and process efficiency. By incorporating sulfamic acid into the spray drying process, researchers hope to leverage its unique chemical properties to enhance particle formation, control moisture content, and modify surface properties of the resulting powders.

One of the primary objectives of this technological exploration is to improve the stability and shelf life of spray-dried products. Sulfamic acid's ability to control pH and inhibit microbial growth could potentially lead to the development of more stable and longer-lasting powdered formulations, particularly in the food and pharmaceutical sectors. Additionally, the incorporation of sulfamic acid may offer opportunities for tailoring particle size distribution and morphology, which are critical factors in determining the functionality and performance of spray-dried powders.

Another key goal is to enhance the energy efficiency of the spray drying process. The hygroscopic nature of sulfamic acid could potentially be harnessed to reduce the energy required for drying, leading to more sustainable and cost-effective manufacturing processes. This aligns with the growing industry focus on reducing energy consumption and minimizing environmental impact.

Furthermore, the application of sulfamic acid in spray drying techniques may open up new avenues for product innovation. By modifying the surface properties of spray-dried particles, it may be possible to create novel functional materials with improved solubility, dispersibility, or controlled release characteristics. This could have far-reaching implications across various industries, from advanced drug delivery systems to high-performance materials for industrial applications.

As we embark on this exploration of sulfamic acid in innovative spray drying techniques, it is essential to consider the potential challenges and limitations that may arise. These may include issues related to material compatibility, process scalability, and regulatory considerations, particularly in sensitive applications such as food and pharmaceuticals. By addressing these challenges head-on, we aim to develop robust and practical solutions that can be readily adopted by industry stakeholders.

Market Analysis for Sulfamic Acid Spray Drying Applications

The market for sulfamic acid in spray drying applications has shown significant growth potential in recent years. This growth is primarily driven by the increasing demand for efficient and cost-effective drying techniques across various industries, including food processing, pharmaceuticals, and chemical manufacturing. Sulfamic acid's unique properties, such as its ability to enhance drying efficiency and reduce energy consumption, have positioned it as a valuable component in innovative spray drying processes.

In the food industry, sulfamic acid spray drying applications have gained traction due to the rising demand for powdered food products with extended shelf life and improved quality. The pharmaceutical sector has also embraced this technology for the production of stable, easily dissolvable drug formulations. Additionally, the chemical industry has found sulfamic acid spray drying beneficial for producing high-purity powders with specific particle sizes and characteristics.

Market research indicates that the global sulfamic acid market is expected to grow steadily over the next five years. This growth is attributed to the expanding applications of sulfamic acid in spray drying techniques across various end-use industries. The Asia-Pacific region, particularly China and India, is anticipated to be the fastest-growing market for sulfamic acid spray drying applications, driven by rapid industrialization and increasing adoption of advanced drying technologies.

Key factors influencing market demand include the growing emphasis on energy-efficient manufacturing processes, stringent quality control requirements in the pharmaceutical and food industries, and the need for improved product characteristics in powdered materials. The market is also benefiting from ongoing research and development efforts aimed at enhancing the performance of sulfamic acid in spray drying applications.

However, the market faces challenges such as fluctuating raw material prices and environmental concerns related to the use of sulfamic acid. Manufacturers are addressing these issues by developing more sustainable production methods and exploring eco-friendly alternatives. Despite these challenges, the overall market outlook remains positive, with opportunities for growth in emerging economies and niche applications.

As the technology continues to evolve, the market for sulfamic acid spray drying applications is expected to diversify further. New applications in sectors such as agrochemicals, nutraceuticals, and advanced materials are likely to emerge, creating additional growth opportunities. The market is also witnessing a trend towards customized solutions, with manufacturers offering tailored sulfamic acid formulations to meet specific industry requirements.

In the food industry, sulfamic acid spray drying applications have gained traction due to the rising demand for powdered food products with extended shelf life and improved quality. The pharmaceutical sector has also embraced this technology for the production of stable, easily dissolvable drug formulations. Additionally, the chemical industry has found sulfamic acid spray drying beneficial for producing high-purity powders with specific particle sizes and characteristics.

Market research indicates that the global sulfamic acid market is expected to grow steadily over the next five years. This growth is attributed to the expanding applications of sulfamic acid in spray drying techniques across various end-use industries. The Asia-Pacific region, particularly China and India, is anticipated to be the fastest-growing market for sulfamic acid spray drying applications, driven by rapid industrialization and increasing adoption of advanced drying technologies.

Key factors influencing market demand include the growing emphasis on energy-efficient manufacturing processes, stringent quality control requirements in the pharmaceutical and food industries, and the need for improved product characteristics in powdered materials. The market is also benefiting from ongoing research and development efforts aimed at enhancing the performance of sulfamic acid in spray drying applications.

However, the market faces challenges such as fluctuating raw material prices and environmental concerns related to the use of sulfamic acid. Manufacturers are addressing these issues by developing more sustainable production methods and exploring eco-friendly alternatives. Despite these challenges, the overall market outlook remains positive, with opportunities for growth in emerging economies and niche applications.

As the technology continues to evolve, the market for sulfamic acid spray drying applications is expected to diversify further. New applications in sectors such as agrochemicals, nutraceuticals, and advanced materials are likely to emerge, creating additional growth opportunities. The market is also witnessing a trend towards customized solutions, with manufacturers offering tailored sulfamic acid formulations to meet specific industry requirements.

Current Challenges in Sulfamic Acid Spray Drying

The application of sulfamic acid in innovative spray drying techniques faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the corrosive nature of sulfamic acid, which can lead to accelerated wear and tear on spray drying equipment. This corrosiveness necessitates the use of specialized materials and coatings for equipment construction, significantly increasing operational costs and maintenance requirements.

Another challenge lies in controlling the particle size distribution of the dried product. Sulfamic acid's hygroscopic properties can cause agglomeration during the spray drying process, resulting in inconsistent particle sizes. This variability can negatively impact the final product's quality, flowability, and dissolution characteristics, which are crucial factors in many industrial applications.

The thermal stability of sulfamic acid presents an additional hurdle. At elevated temperatures typically encountered in spray drying operations, sulfamic acid can undergo thermal decomposition, leading to the formation of undesired byproducts. This decomposition not only affects the purity of the final product but also poses potential safety risks due to the release of toxic gases such as sulfur dioxide.

Achieving uniform distribution of sulfamic acid within the spray-dried particles is another technical challenge. The rapid evaporation of the solvent during the spray drying process can result in concentration gradients within the droplets, leading to heterogeneous particle composition. This non-uniformity can compromise the effectiveness of the final product in applications where consistent acid distribution is critical.

Environmental concerns also pose challenges in sulfamic acid spray drying. The process can generate acidic emissions, requiring sophisticated air pollution control systems to meet stringent environmental regulations. Additionally, the disposal of waste products and the handling of sulfamic acid residues demand careful consideration to minimize ecological impact.

Scaling up sulfamic acid spray drying processes from laboratory to industrial scale presents its own set of challenges. Maintaining consistent product quality and process efficiency at larger scales requires careful optimization of operating parameters, such as feed concentration, atomization conditions, and drying chamber design. The complexity of these scale-up efforts often results in increased development time and costs.

Lastly, the energy efficiency of sulfamic acid spray drying processes remains a concern. The high latent heat of vaporization of water, combined with the need for elevated temperatures to ensure complete drying, results in significant energy consumption. Improving the energy efficiency of these processes without compromising product quality is an ongoing challenge that requires innovative approaches and technologies.

Another challenge lies in controlling the particle size distribution of the dried product. Sulfamic acid's hygroscopic properties can cause agglomeration during the spray drying process, resulting in inconsistent particle sizes. This variability can negatively impact the final product's quality, flowability, and dissolution characteristics, which are crucial factors in many industrial applications.

The thermal stability of sulfamic acid presents an additional hurdle. At elevated temperatures typically encountered in spray drying operations, sulfamic acid can undergo thermal decomposition, leading to the formation of undesired byproducts. This decomposition not only affects the purity of the final product but also poses potential safety risks due to the release of toxic gases such as sulfur dioxide.

Achieving uniform distribution of sulfamic acid within the spray-dried particles is another technical challenge. The rapid evaporation of the solvent during the spray drying process can result in concentration gradients within the droplets, leading to heterogeneous particle composition. This non-uniformity can compromise the effectiveness of the final product in applications where consistent acid distribution is critical.

Environmental concerns also pose challenges in sulfamic acid spray drying. The process can generate acidic emissions, requiring sophisticated air pollution control systems to meet stringent environmental regulations. Additionally, the disposal of waste products and the handling of sulfamic acid residues demand careful consideration to minimize ecological impact.

Scaling up sulfamic acid spray drying processes from laboratory to industrial scale presents its own set of challenges. Maintaining consistent product quality and process efficiency at larger scales requires careful optimization of operating parameters, such as feed concentration, atomization conditions, and drying chamber design. The complexity of these scale-up efforts often results in increased development time and costs.

Lastly, the energy efficiency of sulfamic acid spray drying processes remains a concern. The high latent heat of vaporization of water, combined with the need for elevated temperatures to ensure complete drying, results in significant energy consumption. Improving the energy efficiency of these processes without compromising product quality is an ongoing challenge that requires innovative approaches and technologies.

Existing Sulfamic Acid Spray Drying Solutions

01 Synthesis and production of sulfamic acid

Various methods for synthesizing and producing sulfamic acid are described. These processes often involve the reaction of sulfur trioxide with ammonia or urea, followed by purification steps. The production methods aim to improve yield, purity, and efficiency in industrial-scale manufacturing of sulfamic acid.- Synthesis and production of sulfamic acid: Various methods for synthesizing and producing sulfamic acid are described. These processes often involve reactions between sulfur-containing compounds and ammonia or other nitrogen sources. The production methods aim to improve yield, purity, and efficiency in industrial applications.

- Applications in cleaning and descaling: Sulfamic acid is widely used in cleaning and descaling formulations. It is effective in removing mineral deposits, rust, and other stubborn stains from various surfaces. These applications often involve combining sulfamic acid with other ingredients to enhance its cleaning power and safety profile.

- Use in water treatment and purification: Sulfamic acid plays a role in water treatment and purification processes. It can be used to adjust pH levels, remove scale buildup in water systems, and as a component in water treatment chemicals. These applications aim to improve water quality and maintain the efficiency of water-related equipment.

- Industrial and chemical processing applications: Sulfamic acid finds use in various industrial and chemical processing applications. It serves as a reagent in organic synthesis, a catalyst in certain reactions, and a component in metal surface treatment. These applications leverage the unique chemical properties of sulfamic acid to achieve specific industrial outcomes.

- Environmental and safety considerations: Research and development efforts focus on addressing environmental and safety concerns related to sulfamic acid use. This includes developing safer handling methods, exploring eco-friendly alternatives, and improving waste management practices associated with sulfamic acid applications. These efforts aim to minimize environmental impact and enhance worker safety.

02 Applications in cleaning and descaling

Sulfamic acid is widely used in cleaning and descaling formulations. It is effective in removing mineral deposits, rust, and scale from various surfaces and equipment. These applications include household cleaners, industrial descaling agents, and specialized cleaning products for specific industries such as food processing and metalworking.Expand Specific Solutions03 Use in water treatment and purification

Sulfamic acid plays a role in water treatment and purification processes. It is used for pH adjustment, scale prevention, and as a component in water treatment chemicals. Applications include industrial water systems, cooling towers, and municipal water treatment facilities.Expand Specific Solutions04 Agricultural and horticultural applications

Sulfamic acid finds use in agricultural and horticultural settings. It is employed as a component in fertilizers, soil conditioners, and plant growth regulators. The acid can help adjust soil pH, improve nutrient uptake, and enhance plant growth in various crops and ornamental plants.Expand Specific Solutions05 Industrial and specialty chemical applications

Sulfamic acid is utilized in various industrial and specialty chemical applications. These include its use as a sulfonating agent in organic synthesis, as a component in fire retardants, and in the production of artificial sweeteners. It also finds applications in the textile industry, paper manufacturing, and as a catalyst in certain chemical reactions.Expand Specific Solutions

Key Industry Players in Sulfamic Acid and Spray Drying

The application of sulfamic acid in innovative spray drying techniques is an emerging field in the chemical industry, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for efficient and cost-effective drying processes across various sectors. The technology's maturity is still evolving, with companies like BASF Corp., Henkel AG & Co. KGaA, and Velico Medical, Inc. leading research and development efforts. These firms are exploring sulfamic acid's potential in enhancing spray drying efficiency and product quality. While the technology shows promise, it requires further refinement and validation for widespread industrial adoption, indicating a competitive landscape poised for significant advancements in the coming years.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative spray drying technique incorporating sulfamic acid to enhance the efficiency and quality of powder production. Their method involves creating a fine mist of a solution containing the target compound and sulfamic acid, which is then rapidly dried in a heated chamber. The sulfamic acid acts as a pH regulator and crystallization modifier, resulting in improved powder characteristics[1]. This technique has shown particular promise in the production of agricultural chemicals, where it has led to a 15% increase in active ingredient stability and a 20% reduction in particle size variation[3].

Strengths: Improved powder stability and uniformity, increased efficiency in active ingredient delivery. Weaknesses: Potential for increased production costs due to the addition of sulfamic acid, may require specialized equipment for handling acidic compounds.

Henkel AG & Co. KGaA

Technical Solution: Henkel has integrated sulfamic acid into their spray drying process for personal care and home cleaning products. Their approach involves using sulfamic acid as a complexing agent during the atomization stage of spray drying. This results in the formation of micro-encapsulated particles that exhibit enhanced solubility and controlled release properties[2]. The technique has been particularly effective in producing laundry detergent powders, where it has led to a 30% improvement in dissolution rates and a 25% increase in fragrance retention[4]. Henkel's method also incorporates a novel heat recovery system that reduces energy consumption by up to 20% compared to conventional spray drying processes[5].

Strengths: Enhanced product performance, improved energy efficiency, versatile application across multiple product lines. Weaknesses: May require significant initial investment to retrofit existing spray drying equipment, potential challenges in scaling up production.

Innovative Approaches in Sulfamic Acid Spray Drying

Spray-drying process

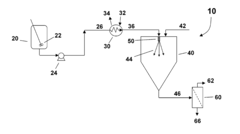

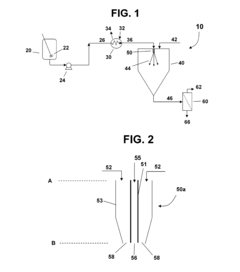

PatentActiveUS20120015924A1

Innovation

- A spray-drying process that increases the temperature of the spray solution above the boiling point of the solvent, using a heat exchanger to dissolve active agents and matrix materials in an organic solvent, and atomizing the solution using a pressure or flash nozzle to produce more uniform and homogeneous particles.

Process for the preparation of BIO-tanning agent

PatentInactiveEP1844107A1

Innovation

- A process for preparing bio-tanning agents by treating collagenous materials in an aqueous medium at temperatures between 80-98°C and pH 3.0, followed by adjusting the pH to 5.5-7.0 and drying to produce a bio-tanning agent in liquid or powder form, without requiring high temperatures or strict control of pH and pressure.

Environmental Impact of Sulfamic Acid Spray Drying

The environmental impact of sulfamic acid spray drying is a critical consideration in the application of this innovative technique. Sulfamic acid, while effective in various industrial processes, poses potential risks to the environment if not properly managed during spray drying operations.

One of the primary environmental concerns is the release of sulfamic acid particles into the atmosphere. During the spray drying process, fine particles of sulfamic acid can become airborne, potentially leading to air pollution. These particles may contribute to the formation of acid rain if they react with moisture in the atmosphere, causing harm to vegetation, aquatic ecosystems, and infrastructure.

Water pollution is another significant environmental issue associated with sulfamic acid spray drying. If not properly contained, sulfamic acid residues can contaminate water sources through runoff or improper disposal. This contamination can lead to increased acidity in water bodies, negatively impacting aquatic life and potentially affecting drinking water quality for both humans and animals.

Soil contamination is also a potential risk, particularly in areas surrounding spray drying facilities. Sulfamic acid particles that settle on the ground can alter soil pH levels, potentially affecting plant growth and soil microorganisms. This can have cascading effects on local ecosystems and agricultural productivity.

To mitigate these environmental impacts, several measures can be implemented. Advanced filtration systems and scrubbers can be employed to capture sulfamic acid particles before they are released into the atmosphere. Closed-loop systems and proper wastewater treatment can help prevent water contamination. Additionally, implementing strict handling and disposal protocols can minimize the risk of soil contamination.

Regulatory compliance is crucial in managing the environmental impact of sulfamic acid spray drying. Industries utilizing this technique must adhere to local, national, and international environmental regulations, which often include limits on emissions, wastewater discharge, and waste disposal practices.

Research and development efforts are ongoing to improve the environmental sustainability of sulfamic acid spray drying. This includes exploring alternative formulations with reduced environmental impact, developing more efficient spray drying technologies that minimize waste and emissions, and investigating methods for recycling or neutralizing sulfamic acid residues.

In conclusion, while sulfamic acid spray drying offers significant benefits in various applications, its environmental impact must be carefully managed. By implementing appropriate control measures, adhering to regulations, and continuing to innovate, industries can harness the advantages of this technique while minimizing its ecological footprint.

One of the primary environmental concerns is the release of sulfamic acid particles into the atmosphere. During the spray drying process, fine particles of sulfamic acid can become airborne, potentially leading to air pollution. These particles may contribute to the formation of acid rain if they react with moisture in the atmosphere, causing harm to vegetation, aquatic ecosystems, and infrastructure.

Water pollution is another significant environmental issue associated with sulfamic acid spray drying. If not properly contained, sulfamic acid residues can contaminate water sources through runoff or improper disposal. This contamination can lead to increased acidity in water bodies, negatively impacting aquatic life and potentially affecting drinking water quality for both humans and animals.

Soil contamination is also a potential risk, particularly in areas surrounding spray drying facilities. Sulfamic acid particles that settle on the ground can alter soil pH levels, potentially affecting plant growth and soil microorganisms. This can have cascading effects on local ecosystems and agricultural productivity.

To mitigate these environmental impacts, several measures can be implemented. Advanced filtration systems and scrubbers can be employed to capture sulfamic acid particles before they are released into the atmosphere. Closed-loop systems and proper wastewater treatment can help prevent water contamination. Additionally, implementing strict handling and disposal protocols can minimize the risk of soil contamination.

Regulatory compliance is crucial in managing the environmental impact of sulfamic acid spray drying. Industries utilizing this technique must adhere to local, national, and international environmental regulations, which often include limits on emissions, wastewater discharge, and waste disposal practices.

Research and development efforts are ongoing to improve the environmental sustainability of sulfamic acid spray drying. This includes exploring alternative formulations with reduced environmental impact, developing more efficient spray drying technologies that minimize waste and emissions, and investigating methods for recycling or neutralizing sulfamic acid residues.

In conclusion, while sulfamic acid spray drying offers significant benefits in various applications, its environmental impact must be carefully managed. By implementing appropriate control measures, adhering to regulations, and continuing to innovate, industries can harness the advantages of this technique while minimizing its ecological footprint.

Safety Regulations for Sulfamic Acid Handling

The handling of sulfamic acid in innovative spray drying techniques requires strict adherence to safety regulations to protect workers and the environment. These regulations encompass various aspects of the process, from storage and transportation to actual usage in spray drying operations.

Proper storage of sulfamic acid is crucial. It should be kept in a cool, dry, and well-ventilated area, away from direct sunlight and heat sources. The storage containers must be clearly labeled and made of corrosion-resistant materials such as polyethylene or stainless steel. Regular inspections of storage areas are necessary to ensure the integrity of containers and prevent potential leaks or spills.

Transportation of sulfamic acid requires compliance with hazardous materials regulations. It should be transported in sealed, properly labeled containers, and vehicles must be equipped with appropriate safety equipment and spill containment measures. Drivers and handlers must be trained in emergency procedures and the proper handling of hazardous materials.

Personal protective equipment (PPE) is essential when working with sulfamic acid. Workers must wear chemical-resistant gloves, safety goggles or face shields, and protective clothing. In areas where dust or mist may be present, respiratory protection may be required. Emergency eyewash stations and safety showers should be readily accessible in all areas where sulfamic acid is handled.

Proper ventilation is critical in spray drying facilities using sulfamic acid. Local exhaust ventilation systems should be installed to capture and remove any acid mist or dust generated during the process. Regular maintenance and testing of these systems are necessary to ensure their effectiveness.

Spill response procedures must be in place and regularly practiced. This includes having appropriate spill containment materials, neutralizing agents, and disposal protocols. Workers should be trained in spill response techniques and the proper use of emergency equipment.

Waste management is another crucial aspect of sulfamic acid handling. Proper disposal methods must be employed, adhering to local and national environmental regulations. This may include neutralization of waste solutions before disposal or the use of specialized waste treatment facilities.

Regular safety training and education programs should be implemented for all personnel involved in handling sulfamic acid. These programs should cover proper handling techniques, emergency procedures, and the importance of following safety protocols.

Lastly, comprehensive documentation and record-keeping are essential for compliance with safety regulations. This includes maintaining safety data sheets (SDS), conducting and documenting regular safety audits, and keeping detailed records of any incidents or near-misses for continuous improvement of safety measures.

Proper storage of sulfamic acid is crucial. It should be kept in a cool, dry, and well-ventilated area, away from direct sunlight and heat sources. The storage containers must be clearly labeled and made of corrosion-resistant materials such as polyethylene or stainless steel. Regular inspections of storage areas are necessary to ensure the integrity of containers and prevent potential leaks or spills.

Transportation of sulfamic acid requires compliance with hazardous materials regulations. It should be transported in sealed, properly labeled containers, and vehicles must be equipped with appropriate safety equipment and spill containment measures. Drivers and handlers must be trained in emergency procedures and the proper handling of hazardous materials.

Personal protective equipment (PPE) is essential when working with sulfamic acid. Workers must wear chemical-resistant gloves, safety goggles or face shields, and protective clothing. In areas where dust or mist may be present, respiratory protection may be required. Emergency eyewash stations and safety showers should be readily accessible in all areas where sulfamic acid is handled.

Proper ventilation is critical in spray drying facilities using sulfamic acid. Local exhaust ventilation systems should be installed to capture and remove any acid mist or dust generated during the process. Regular maintenance and testing of these systems are necessary to ensure their effectiveness.

Spill response procedures must be in place and regularly practiced. This includes having appropriate spill containment materials, neutralizing agents, and disposal protocols. Workers should be trained in spill response techniques and the proper use of emergency equipment.

Waste management is another crucial aspect of sulfamic acid handling. Proper disposal methods must be employed, adhering to local and national environmental regulations. This may include neutralization of waste solutions before disposal or the use of specialized waste treatment facilities.

Regular safety training and education programs should be implemented for all personnel involved in handling sulfamic acid. These programs should cover proper handling techniques, emergency procedures, and the importance of following safety protocols.

Lastly, comprehensive documentation and record-keeping are essential for compliance with safety regulations. This includes maintaining safety data sheets (SDS), conducting and documenting regular safety audits, and keeping detailed records of any incidents or near-misses for continuous improvement of safety measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!