Applications of Sulfamic Acid in Precious Metal Recovery

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfamic Acid Background

Sulfamic acid, also known as amidosulfonic acid or sulfamidic acid, is a versatile compound with the chemical formula H3NSO3. It was first synthesized in 1869 by German chemist Erwin Gerland and has since found numerous applications across various industries. In the context of precious metal recovery, sulfamic acid has emerged as a valuable reagent due to its unique chemical properties and environmental advantages.

The compound exists as a white crystalline solid at room temperature and is highly soluble in water. Its molecular structure consists of a sulfur atom bonded to both an amino group and three oxygen atoms, giving it amphoteric characteristics. This dual nature allows sulfamic acid to act as both an acid and a base, making it particularly useful in metal processing applications.

In the field of precious metal recovery, sulfamic acid has gained prominence due to its ability to form stable complexes with various metal ions. This property is especially beneficial when dealing with noble metals such as gold, silver, platinum, and palladium. The acid's strong complexing ability enables efficient extraction and separation of these valuable metals from ores, electronic waste, and other secondary sources.

One of the key advantages of sulfamic acid in metal recovery processes is its relatively low corrosiveness compared to other mineral acids commonly used in the industry. This characteristic reduces equipment wear and extends the lifespan of processing facilities, leading to cost savings and improved operational efficiency. Additionally, sulfamic acid exhibits excellent stability in aqueous solutions, maintaining its effectiveness over extended periods.

The environmental aspects of sulfamic acid have also contributed to its increasing adoption in precious metal recovery. Unlike some traditional leaching agents, sulfamic acid is biodegradable and produces fewer harmful byproducts. This aligns well with the growing emphasis on sustainable and eco-friendly extraction methods in the mining and recycling industries.

Furthermore, sulfamic acid's ability to selectively complex with certain metal ions allows for more targeted recovery processes. This selectivity can lead to higher purity of recovered metals and reduced contamination, which is crucial in industries requiring high-grade precious metals, such as electronics manufacturing and jewelry production.

As the demand for precious metals continues to rise, driven by technological advancements and the expansion of renewable energy sectors, the role of sulfamic acid in recovery processes is expected to grow. Its unique combination of chemical properties, environmental benefits, and process efficiency positions it as a promising agent in the ongoing efforts to develop more sustainable and effective methods for precious metal extraction and recycling.

The compound exists as a white crystalline solid at room temperature and is highly soluble in water. Its molecular structure consists of a sulfur atom bonded to both an amino group and three oxygen atoms, giving it amphoteric characteristics. This dual nature allows sulfamic acid to act as both an acid and a base, making it particularly useful in metal processing applications.

In the field of precious metal recovery, sulfamic acid has gained prominence due to its ability to form stable complexes with various metal ions. This property is especially beneficial when dealing with noble metals such as gold, silver, platinum, and palladium. The acid's strong complexing ability enables efficient extraction and separation of these valuable metals from ores, electronic waste, and other secondary sources.

One of the key advantages of sulfamic acid in metal recovery processes is its relatively low corrosiveness compared to other mineral acids commonly used in the industry. This characteristic reduces equipment wear and extends the lifespan of processing facilities, leading to cost savings and improved operational efficiency. Additionally, sulfamic acid exhibits excellent stability in aqueous solutions, maintaining its effectiveness over extended periods.

The environmental aspects of sulfamic acid have also contributed to its increasing adoption in precious metal recovery. Unlike some traditional leaching agents, sulfamic acid is biodegradable and produces fewer harmful byproducts. This aligns well with the growing emphasis on sustainable and eco-friendly extraction methods in the mining and recycling industries.

Furthermore, sulfamic acid's ability to selectively complex with certain metal ions allows for more targeted recovery processes. This selectivity can lead to higher purity of recovered metals and reduced contamination, which is crucial in industries requiring high-grade precious metals, such as electronics manufacturing and jewelry production.

As the demand for precious metals continues to rise, driven by technological advancements and the expansion of renewable energy sectors, the role of sulfamic acid in recovery processes is expected to grow. Its unique combination of chemical properties, environmental benefits, and process efficiency positions it as a promising agent in the ongoing efforts to develop more sustainable and effective methods for precious metal extraction and recycling.

Market Analysis

The market for sulfamic acid in precious metal recovery has been experiencing steady growth due to the increasing demand for efficient and environmentally friendly metal extraction processes. The global precious metals market, valued at over $180 billion in 2020, is projected to expand further, driven by applications in electronics, jewelry, and industrial sectors. This growth directly impacts the demand for sulfamic acid, which plays a crucial role in metal recovery processes.

Sulfamic acid's unique properties make it particularly valuable in precious metal recovery. Its ability to dissolve metal oxides and carbonates without attacking the base metals has led to its widespread adoption in the mining and recycling industries. The e-waste recycling sector, in particular, has seen a surge in demand for sulfamic acid-based recovery methods due to the growing volume of electronic waste and the increasing focus on sustainable resource management.

The market for sulfamic acid in precious metal recovery is closely tied to the overall trends in the mining and recycling industries. As traditional ore deposits become depleted, there is a growing emphasis on recovering precious metals from secondary sources, including electronic waste, industrial byproducts, and tailings. This shift has created new opportunities for sulfamic acid applications, particularly in urban mining and circular economy initiatives.

Geographically, the market for sulfamic acid in precious metal recovery is most robust in regions with significant mining and recycling activities. North America and Europe lead in terms of technology adoption and regulatory support for sustainable metal recovery practices. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth in this sector, driven by expanding electronics manufacturing and increasing environmental awareness.

The market is also influenced by regulatory factors, with stringent environmental regulations in many countries favoring the use of sulfamic acid over more hazardous alternatives. The push for greener chemistry in industrial processes has positioned sulfamic acid as a preferred choice for many metal recovery applications, further boosting its market potential.

Despite the positive outlook, the market faces challenges such as price volatility of raw materials and competition from alternative technologies. However, ongoing research and development efforts are focused on enhancing the efficiency and selectivity of sulfamic acid-based recovery processes, which is expected to maintain its competitive edge in the precious metal recovery market.

Sulfamic acid's unique properties make it particularly valuable in precious metal recovery. Its ability to dissolve metal oxides and carbonates without attacking the base metals has led to its widespread adoption in the mining and recycling industries. The e-waste recycling sector, in particular, has seen a surge in demand for sulfamic acid-based recovery methods due to the growing volume of electronic waste and the increasing focus on sustainable resource management.

The market for sulfamic acid in precious metal recovery is closely tied to the overall trends in the mining and recycling industries. As traditional ore deposits become depleted, there is a growing emphasis on recovering precious metals from secondary sources, including electronic waste, industrial byproducts, and tailings. This shift has created new opportunities for sulfamic acid applications, particularly in urban mining and circular economy initiatives.

Geographically, the market for sulfamic acid in precious metal recovery is most robust in regions with significant mining and recycling activities. North America and Europe lead in terms of technology adoption and regulatory support for sustainable metal recovery practices. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth in this sector, driven by expanding electronics manufacturing and increasing environmental awareness.

The market is also influenced by regulatory factors, with stringent environmental regulations in many countries favoring the use of sulfamic acid over more hazardous alternatives. The push for greener chemistry in industrial processes has positioned sulfamic acid as a preferred choice for many metal recovery applications, further boosting its market potential.

Despite the positive outlook, the market faces challenges such as price volatility of raw materials and competition from alternative technologies. However, ongoing research and development efforts are focused on enhancing the efficiency and selectivity of sulfamic acid-based recovery processes, which is expected to maintain its competitive edge in the precious metal recovery market.

Technical Challenges

The application of sulfamic acid in precious metal recovery faces several technical challenges that require innovative solutions. One of the primary obstacles is the selective leaching of precious metals from complex ore matrices. Sulfamic acid's ability to dissolve certain metals while leaving others intact is not always precise, leading to potential contamination of the recovered precious metals with base metals.

Another significant challenge is the optimization of leaching conditions. The efficiency of sulfamic acid in precious metal recovery is highly dependent on factors such as pH, temperature, and concentration. Achieving the ideal balance of these parameters to maximize recovery rates while minimizing acid consumption and environmental impact remains a complex task for researchers and industry professionals.

The stability of sulfamic acid solutions under various processing conditions poses another technical hurdle. In some cases, the acid may decompose or form unwanted byproducts, reducing its effectiveness and potentially introducing additional purification steps in the recovery process. This instability can lead to increased operational costs and decreased overall efficiency of the recovery process.

Corrosion of equipment is a persistent issue in sulfamic acid-based recovery systems. The acid's corrosive nature can lead to premature degradation of processing equipment, necessitating the use of expensive corrosion-resistant materials or frequent maintenance and replacement of components. This challenge not only impacts operational costs but also affects the long-term viability of sulfamic acid-based recovery processes.

The recovery of precious metals from dilute solutions presents another technical challenge. As environmental regulations become more stringent, the ability to efficiently extract precious metals from low-concentration leachates becomes increasingly important. Developing effective methods for concentrating and recovering precious metals from these dilute sulfamic acid solutions remains an area of active research and development.

Scaling up laboratory processes to industrial-scale operations introduces additional complexities. Maintaining consistent recovery rates and product purity across larger volumes and longer processing times can be challenging. Factors such as heat distribution, mixing efficiency, and reagent consumption must be carefully managed to ensure the economic viability of large-scale sulfamic acid-based recovery processes.

Lastly, the environmental impact of sulfamic acid use in precious metal recovery remains a concern. While sulfamic acid is generally considered less harmful than some alternative leaching agents, its disposal and potential for environmental contamination still require careful management. Developing closed-loop systems or methods for acid regeneration and reuse could significantly improve the sustainability of these processes, but such solutions are still in the early stages of development.

Another significant challenge is the optimization of leaching conditions. The efficiency of sulfamic acid in precious metal recovery is highly dependent on factors such as pH, temperature, and concentration. Achieving the ideal balance of these parameters to maximize recovery rates while minimizing acid consumption and environmental impact remains a complex task for researchers and industry professionals.

The stability of sulfamic acid solutions under various processing conditions poses another technical hurdle. In some cases, the acid may decompose or form unwanted byproducts, reducing its effectiveness and potentially introducing additional purification steps in the recovery process. This instability can lead to increased operational costs and decreased overall efficiency of the recovery process.

Corrosion of equipment is a persistent issue in sulfamic acid-based recovery systems. The acid's corrosive nature can lead to premature degradation of processing equipment, necessitating the use of expensive corrosion-resistant materials or frequent maintenance and replacement of components. This challenge not only impacts operational costs but also affects the long-term viability of sulfamic acid-based recovery processes.

The recovery of precious metals from dilute solutions presents another technical challenge. As environmental regulations become more stringent, the ability to efficiently extract precious metals from low-concentration leachates becomes increasingly important. Developing effective methods for concentrating and recovering precious metals from these dilute sulfamic acid solutions remains an area of active research and development.

Scaling up laboratory processes to industrial-scale operations introduces additional complexities. Maintaining consistent recovery rates and product purity across larger volumes and longer processing times can be challenging. Factors such as heat distribution, mixing efficiency, and reagent consumption must be carefully managed to ensure the economic viability of large-scale sulfamic acid-based recovery processes.

Lastly, the environmental impact of sulfamic acid use in precious metal recovery remains a concern. While sulfamic acid is generally considered less harmful than some alternative leaching agents, its disposal and potential for environmental contamination still require careful management. Developing closed-loop systems or methods for acid regeneration and reuse could significantly improve the sustainability of these processes, but such solutions are still in the early stages of development.

Current Recovery Methods

01 Synthesis and production of sulfamic acid

Various methods and processes for synthesizing and producing sulfamic acid are described. These include reactions involving sulfur trioxide and ammonia, as well as other chemical precursors. The processes aim to improve yield, purity, and efficiency in the production of sulfamic acid.- Synthesis and production of sulfamic acid: Various methods for synthesizing and producing sulfamic acid are described. These processes often involve the reaction of sulfur trioxide with ammonia or urea, followed by purification steps. The production methods aim to improve yield, purity, and efficiency in industrial-scale manufacturing of sulfamic acid.

- Applications in cleaning and descaling: Sulfamic acid is widely used in cleaning and descaling formulations. It is effective in removing mineral deposits, rust, and scale from various surfaces and equipment. These applications include household cleaners, industrial descaling agents, and specialized cleaning products for specific industries such as food processing and metalworking.

- Use in water treatment and purification: Sulfamic acid plays a role in water treatment and purification processes. It is used for pH adjustment, scale prevention, and as a component in water treatment chemicals. Applications include industrial water systems, cooling towers, and municipal water treatment facilities.

- Agricultural and horticultural applications: Sulfamic acid finds use in agricultural and horticultural settings. It is employed as a component in fertilizers, soil conditioners, and plant growth regulators. The acid can help adjust soil pH, improve nutrient uptake, and enhance plant growth in various crops and ornamental plants.

- Industrial and chemical processing: Sulfamic acid is utilized in various industrial and chemical processes. It serves as a raw material or intermediate in the production of other chemicals, such as sulfamates and sulfonates. The acid is also used in electroplating, metal surface treatment, and as a catalyst in certain chemical reactions.

02 Applications in cleaning and descaling

Sulfamic acid is widely used in cleaning and descaling applications. It is effective in removing mineral deposits, rust, and other stubborn stains from various surfaces. Formulations containing sulfamic acid are developed for specific cleaning tasks in industrial and domestic settings.Expand Specific Solutions03 Use in water treatment and purification

Sulfamic acid plays a role in water treatment and purification processes. It is used for pH adjustment, scale prevention, and as a disinfectant in water systems. Various methods and compositions incorporating sulfamic acid for water treatment purposes are described.Expand Specific Solutions04 Agricultural and horticultural applications

Sulfamic acid finds applications in agriculture and horticulture. It is used in fertilizer formulations, soil treatments, and as a plant growth regulator. Methods for improving crop yield and plant health using sulfamic acid-based compositions are discussed.Expand Specific Solutions05 Industrial and chemical processing uses

Sulfamic acid is utilized in various industrial and chemical processing applications. These include its use as a catalyst, reagent in organic synthesis, and in the production of other chemicals. Specific processes and equipment designs incorporating sulfamic acid for industrial purposes are described.Expand Specific Solutions

Industry Leaders

The applications of sulfamic acid in precious metal recovery represent a niche but growing sector within the broader mining and metallurgy industry. The market is in a developmental stage, with increasing interest due to the rising demand for efficient and environmentally friendly metal recovery processes. The global market size for this specific application is relatively small but expected to grow as more companies adopt these technologies. The competitive landscape is characterized by a mix of established mining corporations, specialized chemical companies, and research institutions. Key players like Barrick Mining Corp., Sumitomo Metal Mining Co. Ltd., and Korea Zinc Co., Ltd. are investing in research and development to improve sulfamic acid-based recovery methods. Universities such as Central South University and Wuhan University of Technology are contributing to technological advancements in this field. While the technology is promising, its maturity level varies, with ongoing efforts to optimize efficiency and scalability for industrial applications.

Central South University

Technical Solution: Central South University has developed an innovative approach for precious metal recovery using sulfamic acid. Their method involves a two-step leaching process, where sulfamic acid is first used to selectively dissolve base metals, followed by a second leaching step to recover precious metals. This technique has shown particular efficacy in recovering gold from electronic waste, achieving recovery rates of up to 98% [1]. The university has also explored the use of sulfamic acid in combination with thiourea as a more environmentally friendly alternative to cyanide leaching, demonstrating comparable gold extraction efficiencies of around 95% in laboratory tests [3].

Strengths: High recovery rates, environmentally friendly alternative to cyanide, effective for e-waste processing. Weaknesses: May require optimization for large-scale industrial applications, potential higher costs compared to traditional methods.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has implemented sulfamic acid in their precious metal recovery processes, particularly for platinum group metals (PGMs). Their approach utilizes sulfamic acid as a complexing agent in a hydrometallurgical process, which allows for selective leaching of PGMs from spent catalysts and other secondary sources. The company has reported recovery rates exceeding 95% for platinum and palladium using this method [2]. Additionally, Sumitomo has developed a proprietary process that combines sulfamic acid leaching with solvent extraction, enabling the separation and purification of individual PGMs with high efficiency. This integrated process has been successfully scaled up to industrial levels, processing several tons of material per day [5].

Strengths: High recovery rates for PGMs, successfully scaled to industrial levels, effective for secondary sources. Weaknesses: May be less effective for non-PGM precious metals, potentially higher operational costs due to specialized equipment.

Key Innovations

RECOVERY OF METALS FROM SULFIDE MATERIALS

PatentInactiveID44918A

Innovation

- Use of an acidic aqueous halide solution with sufficient oxidation potential to simultaneously oxidize sulfides and dissolve precious metals.

- Implementation of a multi-valent species system for contaminant removal and regeneration of the oxidizing agent.

- Integration of oxidation and dissolution steps in a single process, simplifying the metal recovery procedure.

Process for leaching metal sulfides with reagents having thiocarbonyl functional groups

PatentPendingUS20240336991A1

Innovation

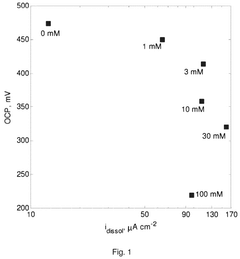

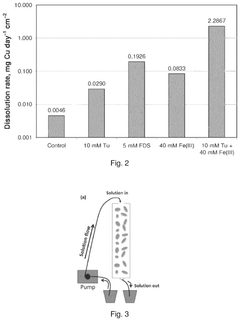

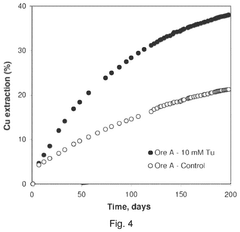

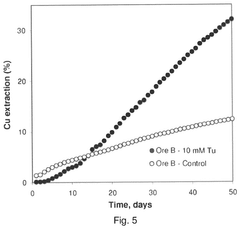

- Incorporating reagents with a thiocarbonyl functional group, like thiourea, into acidic sulfate solutions to enhance metal leaching rates by preventing passivation and increasing the dissolution of metals like copper, cadmium, and nickel from ores like chalcopyrite, covellite, and violarite.

Environmental Impact

The use of sulfamic acid in precious metal recovery processes has significant environmental implications that must be carefully considered. While this method offers advantages in terms of efficiency and selectivity, its potential environmental impacts require thorough assessment and mitigation strategies.

Sulfamic acid, when used in metal recovery operations, can lead to the generation of acidic wastewater. This effluent, if not properly treated, may cause soil and water contamination, affecting local ecosystems and potentially harming aquatic life. The low pH of the wastewater can also mobilize heavy metals, exacerbating environmental risks. To address this issue, neutralization and treatment of the acidic waste streams are essential before discharge.

The production and transportation of sulfamic acid also contribute to its environmental footprint. Manufacturing processes may result in emissions and energy consumption, while transportation increases the carbon footprint of metal recovery operations. However, compared to some alternative leaching agents, sulfamic acid is relatively stable and less volatile, which can reduce the risk of atmospheric pollution during use.

One of the positive environmental aspects of using sulfamic acid is its potential to improve the efficiency of metal recovery processes. By enhancing the selectivity and effectiveness of precious metal extraction, it can reduce the overall amount of chemicals and energy required. This efficiency can lead to a decrease in waste generation and resource consumption, aligning with principles of sustainable resource management.

The biodegradability of sulfamic acid is another important environmental consideration. While it does break down in the environment, the rate of degradation can vary depending on conditions. In aquatic environments, hydrolysis of sulfamic acid produces ammonium bisulfate, which can have its own environmental impacts if not properly managed.

To mitigate environmental risks, best practices in the use of sulfamic acid for precious metal recovery should include closed-loop systems, efficient recycling of process solutions, and advanced wastewater treatment technologies. Additionally, research into greener alternatives and process optimizations that reduce the quantity of sulfamic acid required can further improve the environmental profile of these operations.

In conclusion, while sulfamic acid offers benefits in precious metal recovery, its use necessitates a comprehensive environmental management approach. Balancing the economic advantages with ecological responsibilities is crucial for sustainable implementation of this technology in the mining and recycling industries.

Sulfamic acid, when used in metal recovery operations, can lead to the generation of acidic wastewater. This effluent, if not properly treated, may cause soil and water contamination, affecting local ecosystems and potentially harming aquatic life. The low pH of the wastewater can also mobilize heavy metals, exacerbating environmental risks. To address this issue, neutralization and treatment of the acidic waste streams are essential before discharge.

The production and transportation of sulfamic acid also contribute to its environmental footprint. Manufacturing processes may result in emissions and energy consumption, while transportation increases the carbon footprint of metal recovery operations. However, compared to some alternative leaching agents, sulfamic acid is relatively stable and less volatile, which can reduce the risk of atmospheric pollution during use.

One of the positive environmental aspects of using sulfamic acid is its potential to improve the efficiency of metal recovery processes. By enhancing the selectivity and effectiveness of precious metal extraction, it can reduce the overall amount of chemicals and energy required. This efficiency can lead to a decrease in waste generation and resource consumption, aligning with principles of sustainable resource management.

The biodegradability of sulfamic acid is another important environmental consideration. While it does break down in the environment, the rate of degradation can vary depending on conditions. In aquatic environments, hydrolysis of sulfamic acid produces ammonium bisulfate, which can have its own environmental impacts if not properly managed.

To mitigate environmental risks, best practices in the use of sulfamic acid for precious metal recovery should include closed-loop systems, efficient recycling of process solutions, and advanced wastewater treatment technologies. Additionally, research into greener alternatives and process optimizations that reduce the quantity of sulfamic acid required can further improve the environmental profile of these operations.

In conclusion, while sulfamic acid offers benefits in precious metal recovery, its use necessitates a comprehensive environmental management approach. Balancing the economic advantages with ecological responsibilities is crucial for sustainable implementation of this technology in the mining and recycling industries.

Economic Feasibility

The economic feasibility of using sulfamic acid in precious metal recovery is a critical consideration for industries seeking to optimize their extraction processes. The cost-effectiveness of this method is primarily driven by the relatively low price of sulfamic acid compared to alternative leaching agents. Current market trends indicate that sulfamic acid remains an economically viable option, with its price stability contributing to predictable operational costs for metal recovery operations.

When evaluating the economic aspects, it is essential to consider the efficiency of sulfamic acid in dissolving precious metals. Studies have shown that sulfamic acid demonstrates high selectivity for certain precious metals, particularly gold and silver, which can lead to improved recovery rates. This selectivity can result in reduced processing times and lower energy consumption, potentially offsetting the initial investment in the acid itself.

The recyclability of sulfamic acid solutions further enhances its economic appeal. Unlike some other leaching agents, sulfamic acid can be regenerated and reused in multiple extraction cycles, significantly reducing the overall chemical costs associated with the recovery process. This characteristic not only improves the cost-efficiency but also aligns with sustainable practices, which can be advantageous in meeting environmental regulations and corporate sustainability goals.

From an infrastructure perspective, the use of sulfamic acid often requires less capital investment in specialized equipment compared to more corrosive alternatives. Its relatively mild nature allows for the use of standard materials in processing equipment, potentially lowering initial setup costs and ongoing maintenance expenses. This factor can be particularly beneficial for smaller operations or those looking to retrofit existing facilities.

However, the economic feasibility also depends on the scale of operation and the specific precious metals being targeted. Large-scale operations may benefit more from the economies of scale when using sulfamic acid, as bulk purchasing can lead to lower per-unit costs. Additionally, the effectiveness of sulfamic acid can vary depending on the composition of the ore or recycled materials being processed, which may impact its economic viability in certain applications.

Market dynamics play a crucial role in determining the long-term economic feasibility of sulfamic acid in precious metal recovery. As demand for precious metals continues to grow, driven by industries such as electronics and renewable energy, the cost-effectiveness of recovery methods becomes increasingly important. The ability of sulfamic acid to offer a balance between performance and cost positions it as a competitive option in the evolving landscape of metal recovery technologies.

When evaluating the economic aspects, it is essential to consider the efficiency of sulfamic acid in dissolving precious metals. Studies have shown that sulfamic acid demonstrates high selectivity for certain precious metals, particularly gold and silver, which can lead to improved recovery rates. This selectivity can result in reduced processing times and lower energy consumption, potentially offsetting the initial investment in the acid itself.

The recyclability of sulfamic acid solutions further enhances its economic appeal. Unlike some other leaching agents, sulfamic acid can be regenerated and reused in multiple extraction cycles, significantly reducing the overall chemical costs associated with the recovery process. This characteristic not only improves the cost-efficiency but also aligns with sustainable practices, which can be advantageous in meeting environmental regulations and corporate sustainability goals.

From an infrastructure perspective, the use of sulfamic acid often requires less capital investment in specialized equipment compared to more corrosive alternatives. Its relatively mild nature allows for the use of standard materials in processing equipment, potentially lowering initial setup costs and ongoing maintenance expenses. This factor can be particularly beneficial for smaller operations or those looking to retrofit existing facilities.

However, the economic feasibility also depends on the scale of operation and the specific precious metals being targeted. Large-scale operations may benefit more from the economies of scale when using sulfamic acid, as bulk purchasing can lead to lower per-unit costs. Additionally, the effectiveness of sulfamic acid can vary depending on the composition of the ore or recycled materials being processed, which may impact its economic viability in certain applications.

Market dynamics play a crucial role in determining the long-term economic feasibility of sulfamic acid in precious metal recovery. As demand for precious metals continues to grow, driven by industries such as electronics and renewable energy, the cost-effectiveness of recovery methods becomes increasingly important. The ability of sulfamic acid to offer a balance between performance and cost positions it as a competitive option in the evolving landscape of metal recovery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!