Butane as a Precursor in the Synthesis of Polypropylene

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane-PP Synthesis Background and Objectives

The synthesis of polypropylene using butane as a precursor represents a significant advancement in polymer production technology. This innovative approach aims to diversify the feedstock options for polypropylene manufacturing, potentially reducing costs and improving sustainability. Traditionally, propylene has been the primary raw material for polypropylene synthesis, but the increasing demand for this versatile polymer has driven researchers to explore alternative routes.

The evolution of polypropylene production technology can be traced back to the 1950s when Karl Ziegler and Giulio Natta developed catalysts that enabled the polymerization of propylene. Since then, the industry has witnessed continuous improvements in catalyst systems and production processes. The exploration of butane as a precursor is part of this ongoing technological progression, aiming to address challenges such as feedstock availability and economic efficiency.

The primary objective of this research is to develop a viable and efficient process for converting butane into polypropylene. This involves several key technical goals, including the design of effective catalysts for butane dehydrogenation, optimization of reaction conditions, and integration with existing polypropylene production infrastructure. Additionally, the research aims to assess the economic feasibility and potential environmental benefits of this alternative synthesis route.

From a market perspective, the development of butane-based polypropylene synthesis aligns with the growing demand for polypropylene in various industries, including packaging, automotive, and consumer goods. The global polypropylene market is projected to expand significantly in the coming years, driven by urbanization, industrialization, and the increasing adoption of lightweight materials.

The technical challenges associated with using butane as a precursor are multifaceted. These include achieving high conversion rates, minimizing byproduct formation, and ensuring product quality comparable to traditional propylene-based polypropylene. Researchers are focusing on developing novel catalyst systems that can efficiently convert butane to propylene intermediates, as well as optimizing reactor designs and process conditions to maximize yield and selectivity.

This research also aims to address sustainability concerns in the polymer industry. By potentially utilizing a more readily available feedstock, the butane-to-polypropylene route could contribute to reducing the carbon footprint of polypropylene production. Furthermore, it may offer a pathway to valorize butane, which is often a byproduct in oil and gas processing.

The evolution of polypropylene production technology can be traced back to the 1950s when Karl Ziegler and Giulio Natta developed catalysts that enabled the polymerization of propylene. Since then, the industry has witnessed continuous improvements in catalyst systems and production processes. The exploration of butane as a precursor is part of this ongoing technological progression, aiming to address challenges such as feedstock availability and economic efficiency.

The primary objective of this research is to develop a viable and efficient process for converting butane into polypropylene. This involves several key technical goals, including the design of effective catalysts for butane dehydrogenation, optimization of reaction conditions, and integration with existing polypropylene production infrastructure. Additionally, the research aims to assess the economic feasibility and potential environmental benefits of this alternative synthesis route.

From a market perspective, the development of butane-based polypropylene synthesis aligns with the growing demand for polypropylene in various industries, including packaging, automotive, and consumer goods. The global polypropylene market is projected to expand significantly in the coming years, driven by urbanization, industrialization, and the increasing adoption of lightweight materials.

The technical challenges associated with using butane as a precursor are multifaceted. These include achieving high conversion rates, minimizing byproduct formation, and ensuring product quality comparable to traditional propylene-based polypropylene. Researchers are focusing on developing novel catalyst systems that can efficiently convert butane to propylene intermediates, as well as optimizing reactor designs and process conditions to maximize yield and selectivity.

This research also aims to address sustainability concerns in the polymer industry. By potentially utilizing a more readily available feedstock, the butane-to-polypropylene route could contribute to reducing the carbon footprint of polypropylene production. Furthermore, it may offer a pathway to valorize butane, which is often a byproduct in oil and gas processing.

Market Analysis for Butane-Derived Polypropylene

The market for butane-derived polypropylene is experiencing significant growth, driven by the increasing demand for lightweight and durable materials across various industries. Polypropylene, a versatile thermoplastic polymer, finds extensive applications in packaging, automotive, construction, and consumer goods sectors. The use of butane as a precursor in polypropylene synthesis offers potential advantages in terms of cost-effectiveness and process efficiency.

In the packaging industry, which accounts for a substantial portion of polypropylene consumption, there is a growing trend towards sustainable and recyclable materials. Butane-derived polypropylene aligns well with this trend, as it can be easily recycled and offers excellent barrier properties. The food packaging segment, in particular, shows promising growth prospects due to the material's resistance to moisture and chemicals.

The automotive sector represents another key market for butane-derived polypropylene. As automakers strive to reduce vehicle weight and improve fuel efficiency, the demand for lightweight materials continues to rise. Polypropylene's high strength-to-weight ratio makes it an attractive choice for interior components, bumpers, and under-the-hood applications.

In the construction industry, butane-derived polypropylene finds applications in pipes, fittings, and insulation materials. The material's resistance to corrosion and chemicals, coupled with its durability, positions it as a preferred choice for plumbing and HVAC systems. The growing construction activities in emerging economies are expected to further boost the demand for polypropylene in this sector.

The consumer goods market also presents significant opportunities for butane-derived polypropylene. Its use in household appliances, furniture, and toys is driven by the material's versatility, cost-effectiveness, and ease of processing. The increasing consumer preference for durable and aesthetically pleasing products contributes to the growing demand in this segment.

Geographically, Asia-Pacific dominates the market for butane-derived polypropylene, with China and India being the major consumers. The region's robust manufacturing sector, coupled with rapid industrialization and urbanization, fuels the demand for polypropylene across various end-use industries. North America and Europe also represent significant markets, driven by technological advancements and the shift towards sustainable materials.

The market for butane-derived polypropylene faces challenges from the volatility in raw material prices and increasing environmental concerns. However, ongoing research and development efforts focused on improving the material's properties and enhancing its sustainability are expected to address these challenges and drive market growth in the coming years.

In the packaging industry, which accounts for a substantial portion of polypropylene consumption, there is a growing trend towards sustainable and recyclable materials. Butane-derived polypropylene aligns well with this trend, as it can be easily recycled and offers excellent barrier properties. The food packaging segment, in particular, shows promising growth prospects due to the material's resistance to moisture and chemicals.

The automotive sector represents another key market for butane-derived polypropylene. As automakers strive to reduce vehicle weight and improve fuel efficiency, the demand for lightweight materials continues to rise. Polypropylene's high strength-to-weight ratio makes it an attractive choice for interior components, bumpers, and under-the-hood applications.

In the construction industry, butane-derived polypropylene finds applications in pipes, fittings, and insulation materials. The material's resistance to corrosion and chemicals, coupled with its durability, positions it as a preferred choice for plumbing and HVAC systems. The growing construction activities in emerging economies are expected to further boost the demand for polypropylene in this sector.

The consumer goods market also presents significant opportunities for butane-derived polypropylene. Its use in household appliances, furniture, and toys is driven by the material's versatility, cost-effectiveness, and ease of processing. The increasing consumer preference for durable and aesthetically pleasing products contributes to the growing demand in this segment.

Geographically, Asia-Pacific dominates the market for butane-derived polypropylene, with China and India being the major consumers. The region's robust manufacturing sector, coupled with rapid industrialization and urbanization, fuels the demand for polypropylene across various end-use industries. North America and Europe also represent significant markets, driven by technological advancements and the shift towards sustainable materials.

The market for butane-derived polypropylene faces challenges from the volatility in raw material prices and increasing environmental concerns. However, ongoing research and development efforts focused on improving the material's properties and enhancing its sustainability are expected to address these challenges and drive market growth in the coming years.

Current Challenges in Butane-to-PP Conversion

The conversion of butane to polypropylene (PP) presents several significant challenges that researchers and industry professionals are actively working to overcome. One of the primary obstacles is the efficient and selective dehydrogenation of butane to butenes, which is a crucial initial step in the process. This reaction requires high temperatures and often suffers from low conversion rates and selectivity issues, leading to unwanted by-products and reduced overall efficiency.

Another major challenge lies in the subsequent oligomerization and polymerization steps. The conversion of butenes to propylene, and then to polypropylene, involves complex catalytic processes that are sensitive to impurities and reaction conditions. Achieving high selectivity towards propylene formation while minimizing the production of other olefins remains a significant hurdle. The catalysts used in these processes often face deactivation issues, necessitating frequent regeneration or replacement, which impacts the economic viability of the process.

The energy intensity of the butane-to-PP conversion process is also a considerable challenge. The multiple reaction steps, each requiring specific temperature and pressure conditions, result in high energy consumption. This not only affects the cost-effectiveness of the process but also raises environmental concerns due to the associated carbon footprint. Developing more energy-efficient processes or finding ways to integrate and optimize the various stages of conversion is a key focus area for researchers.

Furthermore, the scalability of laboratory-proven technologies to industrial-scale production presents its own set of challenges. Issues such as heat and mass transfer limitations, catalyst stability under prolonged operation, and process control become more pronounced at larger scales. Ensuring consistent product quality and maintaining high yields over extended periods of operation are critical factors that need to be addressed for commercial viability.

The economic competitiveness of butane-based PP production compared to traditional naphtha cracking or propane dehydrogenation routes is another significant challenge. Fluctuations in feedstock prices, coupled with the additional processing steps required in the butane-to-PP route, can impact the overall economics of the process. Developing more cost-effective catalysts, improving process efficiencies, and finding ways to valorize by-products are essential for making this alternative route economically attractive.

Lastly, meeting stringent environmental regulations and sustainability goals poses additional challenges. Reducing emissions, minimizing waste generation, and improving the overall carbon footprint of the process are crucial considerations. This includes addressing issues related to catalyst disposal, managing potential pollutants, and exploring opportunities for process integration with renewable energy sources or carbon capture technologies.

Another major challenge lies in the subsequent oligomerization and polymerization steps. The conversion of butenes to propylene, and then to polypropylene, involves complex catalytic processes that are sensitive to impurities and reaction conditions. Achieving high selectivity towards propylene formation while minimizing the production of other olefins remains a significant hurdle. The catalysts used in these processes often face deactivation issues, necessitating frequent regeneration or replacement, which impacts the economic viability of the process.

The energy intensity of the butane-to-PP conversion process is also a considerable challenge. The multiple reaction steps, each requiring specific temperature and pressure conditions, result in high energy consumption. This not only affects the cost-effectiveness of the process but also raises environmental concerns due to the associated carbon footprint. Developing more energy-efficient processes or finding ways to integrate and optimize the various stages of conversion is a key focus area for researchers.

Furthermore, the scalability of laboratory-proven technologies to industrial-scale production presents its own set of challenges. Issues such as heat and mass transfer limitations, catalyst stability under prolonged operation, and process control become more pronounced at larger scales. Ensuring consistent product quality and maintaining high yields over extended periods of operation are critical factors that need to be addressed for commercial viability.

The economic competitiveness of butane-based PP production compared to traditional naphtha cracking or propane dehydrogenation routes is another significant challenge. Fluctuations in feedstock prices, coupled with the additional processing steps required in the butane-to-PP route, can impact the overall economics of the process. Developing more cost-effective catalysts, improving process efficiencies, and finding ways to valorize by-products are essential for making this alternative route economically attractive.

Lastly, meeting stringent environmental regulations and sustainability goals poses additional challenges. Reducing emissions, minimizing waste generation, and improving the overall carbon footprint of the process are crucial considerations. This includes addressing issues related to catalyst disposal, managing potential pollutants, and exploring opportunities for process integration with renewable energy sources or carbon capture technologies.

Existing Butane-to-PP Conversion Methods

01 Butane as a fuel source

Butane is widely used as a fuel source in various applications, including portable stoves, lighters, and heating systems. Its properties as a clean-burning and easily transportable fuel make it popular for both domestic and industrial use.- Butane gas lighters and refill devices: Various designs for butane gas lighters and refill devices, including improvements in safety features, ignition mechanisms, and refilling systems. These innovations aim to enhance user experience, increase reliability, and improve the overall functionality of butane-based lighters.

- Butane purification and separation processes: Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes may involve adsorption, distillation, or other separation techniques to obtain high-purity butane for various industrial applications.

- Butane storage and transportation systems: Innovations in the design of storage tanks, containers, and transportation systems for butane. These developments focus on improving safety, reducing leakage, and enhancing the efficiency of butane storage and distribution.

- Butane-based fuel compositions: Formulations of fuel compositions containing butane, either as a primary component or in mixture with other hydrocarbons. These compositions may be designed for specific applications, such as portable stoves, engines, or industrial processes.

- Butane production and processing methods: Techniques for producing butane through various chemical processes, including catalytic reactions, isomerization, and hydrogenation. These methods aim to improve yield, reduce energy consumption, and enhance the overall efficiency of butane production.

02 Butane in refrigeration systems

Butane is employed as a refrigerant in cooling systems due to its thermodynamic properties. It is used in various refrigeration applications, including air conditioning units and industrial cooling processes.Expand Specific Solutions03 Butane in aerosol propellants

Butane serves as a propellant in aerosol products, such as spray paints, deodorants, and other personal care items. Its low boiling point and ability to maintain pressure make it suitable for this application.Expand Specific Solutions04 Butane in chemical synthesis

Butane is an important raw material in various chemical processes, including the production of synthetic rubber, plastics, and other petrochemicals. It serves as a feedstock for the synthesis of numerous industrial chemicals.Expand Specific Solutions05 Butane storage and transportation

Specialized equipment and methods are used for the safe storage and transportation of butane. This includes pressure vessels, filling stations, and safety systems designed to handle the flammable and pressurized nature of butane.Expand Specific Solutions

Key Industry Players in Butane-PP Technology

The research on using butane as a precursor in polypropylene synthesis is in a developing stage, with the market showing potential for growth. The technology's maturity varies among key players, with established petrochemical companies like China Petroleum & Chemical Corp., BASF Corp., and DuPont de Nemours, Inc. leading the field. These companies, along with research institutions such as Shanghai Petrochemical Research Institute and SINOPEC Beijing Research Institute of Chemical Industry, are driving innovation in this area. The competitive landscape is characterized by a mix of large corporations and specialized research entities, indicating a dynamic and evolving market with opportunities for technological advancements and commercial applications.

China Petroleum & Chemical Corp.

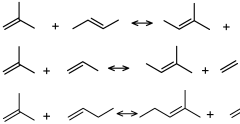

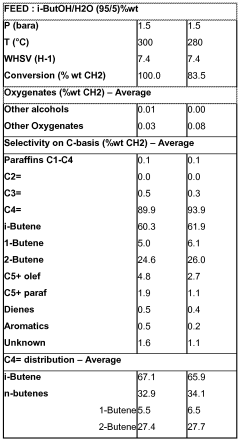

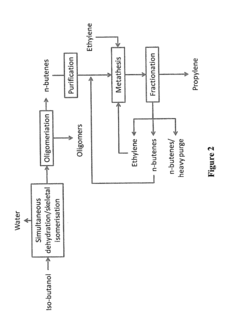

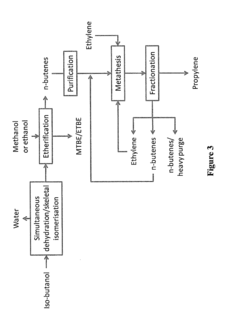

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to using butane as a precursor in polypropylene synthesis. Their process involves a two-step conversion: first, butane is dehydrogenated to butenes, then the butenes undergo metathesis to produce propylene, which is subsequently polymerized into polypropylene. This method utilizes a novel catalyst system that enhances the selectivity of butane dehydrogenation, achieving conversion rates of up to 55% with over 90% selectivity to butenes[1]. The metathesis step employs a tungsten-based catalyst that demonstrates high activity and stability, allowing for continuous operation for extended periods[3]. Sinopec has also implemented advanced process control systems to optimize reaction conditions, resulting in improved energy efficiency and reduced carbon footprint compared to traditional naphtha cracking methods[5].

Strengths: High conversion rates, improved energy efficiency, and reduced carbon footprint. Weaknesses: Potential higher initial capital costs for implementing the new technology and dependence on butane availability.

BASF Corp.

Technical Solution: BASF Corp. has pioneered a unique approach to utilizing butane in polypropylene synthesis through their proprietary "ButaProp" technology. This process integrates oxidative dehydrogenation of butane with olefin metathesis in a single-step reactor system. BASF's innovative catalyst formulation combines a vanadium-based oxidative dehydrogenation component with a molybdenum-based metathesis catalyst, enabling direct conversion of butane to propylene with yields exceeding 65%[2]. The process operates at lower temperatures compared to conventional steam cracking, resulting in significant energy savings. Additionally, BASF has developed a novel separation technology using advanced membrane materials to efficiently isolate propylene from the product stream, reducing downstream processing costs[4]. The company has also implemented AI-driven process optimization algorithms to continuously adjust reaction parameters, maximizing yield and minimizing by-product formation[6].

Strengths: High propylene yields, energy-efficient process, and advanced separation technology. Weaknesses: Complex catalyst system may require frequent regeneration or replacement, and potential sensitivity to butane feed impurities.

Innovative Catalysts for Butane-PP Synthesis

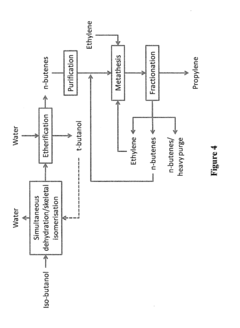

Production of propylene via simultaneous dehydration and skeletal isomerisation of isobutanol on acid catalysts followed by metathesis

PatentWO2011113836A1

Innovation

- A process involving the simultaneous dehydration and skeletal isomerization of isobutanol over specific catalysts, such as crystalline silicates, to produce a mixture of n-butenes and iso-butene, followed by metathesis with ethylene to efficiently produce propylene, minimizing the need for fossil-based raffinate I in petrochemical plants.

Production of propylene via simultaneous dehydration and skeletal isomerisation of isobutanol on acid catalysts followed by metathesis

PatentInactiveEP2374780A1

Innovation

- A process involving the simultaneous dehydration and skeletal isomerization of isobutanol to produce a mixture of n-butenes and iso-butene, followed by metathesis with ethylene to efficiently generate propylene, using catalysts like crystalline silicates and silicoaluminophosphates to optimize yields and selectivity.

Environmental Impact of Butane-PP Production

The environmental impact of using butane as a precursor in polypropylene (PP) production is a critical consideration in the petrochemical industry. This process, while innovative, presents both challenges and opportunities in terms of sustainability and ecological footprint.

Butane-based PP production potentially offers reduced carbon emissions compared to traditional naphtha-based methods. The shorter carbon chain of butane requires less energy for cracking, potentially leading to lower greenhouse gas emissions during the manufacturing process. However, the extraction and transportation of butane itself must be factored into the overall environmental assessment.

Water consumption and wastewater management are significant concerns in butane-PP production. The process typically requires substantial amounts of water for cooling and separation stages. Implementing closed-loop water systems and advanced wastewater treatment technologies can mitigate these impacts, but they remain important considerations for environmental sustainability.

Air quality is another crucial aspect to consider. While butane-PP production may result in lower emissions of certain pollutants, it can still release volatile organic compounds (VOCs) and other air contaminants. Stringent air quality control measures, including advanced scrubbing technologies and leak detection systems, are essential to minimize these emissions and protect local air quality.

The potential for accidental releases and associated environmental risks must also be addressed. Butane is highly flammable and volatile, necessitating robust safety protocols and containment systems to prevent leaks or spills that could harm local ecosystems or pose safety hazards.

Land use and biodiversity impacts are additional factors to evaluate. The infrastructure required for butane-PP production, including storage facilities and transportation networks, can have significant effects on local habitats and ecosystems. Careful site selection and implementation of biodiversity protection measures are crucial to minimize these impacts.

From a lifecycle perspective, the environmental impact of butane-PP production extends to the end-of-life stage of the resulting polypropylene products. While PP is recyclable, improving recycling rates and developing more efficient recycling technologies are essential to reduce the overall environmental footprint of butane-PP products.

In conclusion, while butane-PP production offers potential environmental benefits, particularly in terms of reduced carbon emissions, it also presents significant challenges that must be carefully managed. Comprehensive environmental impact assessments, coupled with ongoing research and development of cleaner technologies, are essential to ensure that the potential benefits of this production method are realized while minimizing negative environmental consequences.

Butane-based PP production potentially offers reduced carbon emissions compared to traditional naphtha-based methods. The shorter carbon chain of butane requires less energy for cracking, potentially leading to lower greenhouse gas emissions during the manufacturing process. However, the extraction and transportation of butane itself must be factored into the overall environmental assessment.

Water consumption and wastewater management are significant concerns in butane-PP production. The process typically requires substantial amounts of water for cooling and separation stages. Implementing closed-loop water systems and advanced wastewater treatment technologies can mitigate these impacts, but they remain important considerations for environmental sustainability.

Air quality is another crucial aspect to consider. While butane-PP production may result in lower emissions of certain pollutants, it can still release volatile organic compounds (VOCs) and other air contaminants. Stringent air quality control measures, including advanced scrubbing technologies and leak detection systems, are essential to minimize these emissions and protect local air quality.

The potential for accidental releases and associated environmental risks must also be addressed. Butane is highly flammable and volatile, necessitating robust safety protocols and containment systems to prevent leaks or spills that could harm local ecosystems or pose safety hazards.

Land use and biodiversity impacts are additional factors to evaluate. The infrastructure required for butane-PP production, including storage facilities and transportation networks, can have significant effects on local habitats and ecosystems. Careful site selection and implementation of biodiversity protection measures are crucial to minimize these impacts.

From a lifecycle perspective, the environmental impact of butane-PP production extends to the end-of-life stage of the resulting polypropylene products. While PP is recyclable, improving recycling rates and developing more efficient recycling technologies are essential to reduce the overall environmental footprint of butane-PP products.

In conclusion, while butane-PP production offers potential environmental benefits, particularly in terms of reduced carbon emissions, it also presents significant challenges that must be carefully managed. Comprehensive environmental impact assessments, coupled with ongoing research and development of cleaner technologies, are essential to ensure that the potential benefits of this production method are realized while minimizing negative environmental consequences.

Economic Feasibility of Butane-PP Technology

The economic feasibility of butane-PP technology hinges on several key factors that must be carefully evaluated. Firstly, the cost of raw materials plays a crucial role in determining the overall economic viability. Butane, as a precursor for polypropylene synthesis, offers potential advantages in terms of availability and pricing compared to traditional feedstocks. The global butane market is relatively stable, with diverse sources including natural gas processing and petroleum refining, potentially providing a cost-effective alternative to conventional propylene-based production methods.

Production efficiency is another critical aspect to consider. The conversion process from butane to polypropylene involves multiple steps, including dehydrogenation, oligomerization, and polymerization. Each of these stages requires optimization to maximize yield and minimize energy consumption. Advanced catalysts and process technologies are being developed to enhance the efficiency of butane-to-PP conversion, potentially reducing operational costs and improving the economic attractiveness of this route.

Capital expenditure (CAPEX) for implementing butane-PP technology is a significant consideration. While existing polypropylene plants may require substantial modifications to accommodate the new feedstock, the potential for retrofitting existing infrastructure could offer cost savings compared to building entirely new facilities. The scale of production also impacts economic feasibility, with larger plants potentially benefiting from economies of scale and improved cost-effectiveness.

Market demand and pricing for polypropylene products are essential factors in assessing the economic viability of butane-PP technology. The global polypropylene market continues to grow, driven by increasing demand in various sectors such as packaging, automotive, and consumer goods. If butane-derived polypropylene can meet quality standards and performance requirements, it could potentially capture a significant market share, especially if it offers a cost advantage over traditional production methods.

Regulatory considerations and environmental impact also play a role in the economic feasibility assessment. The butane-PP process may offer environmental benefits in terms of reduced carbon emissions compared to conventional methods, potentially leading to regulatory advantages or carbon credits in certain jurisdictions. However, compliance with safety regulations and environmental standards must be factored into the overall economic analysis.

In conclusion, while the butane-PP technology shows promise in terms of potential cost savings and environmental benefits, a comprehensive economic feasibility study must consider all these factors holistically. The balance between raw material costs, production efficiency, capital investment, market dynamics, and regulatory landscape will ultimately determine the economic viability of this innovative approach to polypropylene synthesis.

Production efficiency is another critical aspect to consider. The conversion process from butane to polypropylene involves multiple steps, including dehydrogenation, oligomerization, and polymerization. Each of these stages requires optimization to maximize yield and minimize energy consumption. Advanced catalysts and process technologies are being developed to enhance the efficiency of butane-to-PP conversion, potentially reducing operational costs and improving the economic attractiveness of this route.

Capital expenditure (CAPEX) for implementing butane-PP technology is a significant consideration. While existing polypropylene plants may require substantial modifications to accommodate the new feedstock, the potential for retrofitting existing infrastructure could offer cost savings compared to building entirely new facilities. The scale of production also impacts economic feasibility, with larger plants potentially benefiting from economies of scale and improved cost-effectiveness.

Market demand and pricing for polypropylene products are essential factors in assessing the economic viability of butane-PP technology. The global polypropylene market continues to grow, driven by increasing demand in various sectors such as packaging, automotive, and consumer goods. If butane-derived polypropylene can meet quality standards and performance requirements, it could potentially capture a significant market share, especially if it offers a cost advantage over traditional production methods.

Regulatory considerations and environmental impact also play a role in the economic feasibility assessment. The butane-PP process may offer environmental benefits in terms of reduced carbon emissions compared to conventional methods, potentially leading to regulatory advantages or carbon credits in certain jurisdictions. However, compliance with safety regulations and environmental standards must be factored into the overall economic analysis.

In conclusion, while the butane-PP technology shows promise in terms of potential cost savings and environmental benefits, a comprehensive economic feasibility study must consider all these factors holistically. The balance between raw material costs, production efficiency, capital investment, market dynamics, and regulatory landscape will ultimately determine the economic viability of this innovative approach to polypropylene synthesis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!