Role of Magnesium Carbonate in Low-Emission Concrete Products

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Low-Emission Concrete: Background and Objectives

Magnesium carbonate has emerged as a promising component in the development of low-emission concrete products, addressing the urgent need for sustainable construction materials in the face of climate change. The concrete industry, responsible for approximately 8% of global CO2 emissions, has been actively seeking innovative solutions to reduce its carbon footprint. In this context, magnesium carbonate-based concrete has gained significant attention due to its potential to sequester carbon dioxide and enhance the overall environmental performance of construction materials.

The evolution of magnesium carbonate in concrete technology can be traced back to the early 2000s when researchers began exploring alternative binders to traditional Portland cement. Initial studies focused on the carbonation of magnesium-rich minerals and industrial by-products, laying the groundwork for the development of low-carbon concrete formulations. Over the past two decades, advancements in material science and a deeper understanding of carbonation mechanisms have propelled magnesium carbonate to the forefront of sustainable concrete research.

The primary objective of incorporating magnesium carbonate into concrete products is to achieve significant reductions in CO2 emissions throughout the material's lifecycle. This goal aligns with global efforts to mitigate climate change and transition towards a more sustainable built environment. By harnessing the CO2-sequestering properties of magnesium carbonate, researchers aim to create concrete that acts as a carbon sink, effectively removing greenhouse gases from the atmosphere during its service life.

Another crucial objective is to maintain or enhance the mechanical and durability properties of concrete while reducing its environmental impact. Magnesium carbonate-based formulations must meet or exceed the performance standards of conventional concrete to ensure widespread adoption in the construction industry. This includes achieving comparable compressive strength, tensile strength, and resistance to environmental degradation.

The development of magnesium carbonate concrete also seeks to address the challenges associated with raw material availability and production scalability. Researchers are exploring various sources of magnesium, including abundant minerals like olivine and serpentine, as well as industrial by-products, to ensure a sustainable and economically viable supply chain for large-scale production.

As the construction industry faces increasing pressure to adopt more sustainable practices, the role of magnesium carbonate in low-emission concrete products represents a promising avenue for innovation. The ongoing research and development in this field aim to revolutionize concrete technology, offering a path towards carbon-neutral or even carbon-negative building materials. This technological evolution not only addresses environmental concerns but also opens up new opportunities for the construction sector to contribute positively to global climate goals.

The evolution of magnesium carbonate in concrete technology can be traced back to the early 2000s when researchers began exploring alternative binders to traditional Portland cement. Initial studies focused on the carbonation of magnesium-rich minerals and industrial by-products, laying the groundwork for the development of low-carbon concrete formulations. Over the past two decades, advancements in material science and a deeper understanding of carbonation mechanisms have propelled magnesium carbonate to the forefront of sustainable concrete research.

The primary objective of incorporating magnesium carbonate into concrete products is to achieve significant reductions in CO2 emissions throughout the material's lifecycle. This goal aligns with global efforts to mitigate climate change and transition towards a more sustainable built environment. By harnessing the CO2-sequestering properties of magnesium carbonate, researchers aim to create concrete that acts as a carbon sink, effectively removing greenhouse gases from the atmosphere during its service life.

Another crucial objective is to maintain or enhance the mechanical and durability properties of concrete while reducing its environmental impact. Magnesium carbonate-based formulations must meet or exceed the performance standards of conventional concrete to ensure widespread adoption in the construction industry. This includes achieving comparable compressive strength, tensile strength, and resistance to environmental degradation.

The development of magnesium carbonate concrete also seeks to address the challenges associated with raw material availability and production scalability. Researchers are exploring various sources of magnesium, including abundant minerals like olivine and serpentine, as well as industrial by-products, to ensure a sustainable and economically viable supply chain for large-scale production.

As the construction industry faces increasing pressure to adopt more sustainable practices, the role of magnesium carbonate in low-emission concrete products represents a promising avenue for innovation. The ongoing research and development in this field aim to revolutionize concrete technology, offering a path towards carbon-neutral or even carbon-negative building materials. This technological evolution not only addresses environmental concerns but also opens up new opportunities for the construction sector to contribute positively to global climate goals.

Market Demand for Sustainable Construction Materials

The construction industry is experiencing a significant shift towards sustainable practices, driven by increasing environmental concerns and stringent regulations. This trend has created a robust market demand for sustainable construction materials, particularly low-emission concrete products. The incorporation of magnesium carbonate in concrete formulations has emerged as a promising solution to address this demand.

The global sustainable construction materials market is projected to grow substantially in the coming years, with low-emission concrete playing a crucial role. Factors contributing to this growth include urbanization, infrastructure development, and the push for green building certifications. Governments worldwide are implementing policies and incentives to promote the use of eco-friendly construction materials, further stimulating market demand.

In the concrete sector, there is a growing awareness of the environmental impact of traditional Portland cement, which accounts for a significant portion of global CO2 emissions. This has led to increased interest in alternative binders and additives that can reduce the carbon footprint of concrete while maintaining or improving its performance characteristics. Magnesium carbonate-based concrete products are gaining attention due to their potential to sequester CO2 during the curing process, offering a dual benefit of emissions reduction and carbon capture.

The construction industry's focus on lifecycle assessment and embodied carbon is driving demand for materials that not only reduce operational emissions but also minimize the environmental impact during production and end-of-life stages. Magnesium carbonate-based concrete aligns well with these objectives, positioning it as a desirable option for environmentally conscious builders and developers.

Market research indicates that the Asia-Pacific region is expected to be a major growth area for sustainable construction materials, including low-emission concrete products. This is attributed to rapid urbanization, increasing environmental regulations, and government initiatives promoting sustainable development. North America and Europe are also significant markets, with a strong emphasis on green building practices and certifications driving demand for innovative, low-carbon construction materials.

The adoption of magnesium carbonate in concrete is further supported by the growing trend of circular economy principles in construction. As the industry seeks ways to reduce waste and utilize by-products, magnesium carbonate derived from industrial processes or natural sources offers an opportunity to create value from materials that might otherwise be discarded.

The global sustainable construction materials market is projected to grow substantially in the coming years, with low-emission concrete playing a crucial role. Factors contributing to this growth include urbanization, infrastructure development, and the push for green building certifications. Governments worldwide are implementing policies and incentives to promote the use of eco-friendly construction materials, further stimulating market demand.

In the concrete sector, there is a growing awareness of the environmental impact of traditional Portland cement, which accounts for a significant portion of global CO2 emissions. This has led to increased interest in alternative binders and additives that can reduce the carbon footprint of concrete while maintaining or improving its performance characteristics. Magnesium carbonate-based concrete products are gaining attention due to their potential to sequester CO2 during the curing process, offering a dual benefit of emissions reduction and carbon capture.

The construction industry's focus on lifecycle assessment and embodied carbon is driving demand for materials that not only reduce operational emissions but also minimize the environmental impact during production and end-of-life stages. Magnesium carbonate-based concrete aligns well with these objectives, positioning it as a desirable option for environmentally conscious builders and developers.

Market research indicates that the Asia-Pacific region is expected to be a major growth area for sustainable construction materials, including low-emission concrete products. This is attributed to rapid urbanization, increasing environmental regulations, and government initiatives promoting sustainable development. North America and Europe are also significant markets, with a strong emphasis on green building practices and certifications driving demand for innovative, low-carbon construction materials.

The adoption of magnesium carbonate in concrete is further supported by the growing trend of circular economy principles in construction. As the industry seeks ways to reduce waste and utilize by-products, magnesium carbonate derived from industrial processes or natural sources offers an opportunity to create value from materials that might otherwise be discarded.

Current State and Challenges in Low-Emission Concrete Technology

The current state of low-emission concrete technology is characterized by significant advancements and ongoing challenges. Concrete, being the most widely used construction material globally, contributes substantially to carbon emissions. The industry has made considerable progress in developing low-emission alternatives, with magnesium carbonate emerging as a promising component.

Recent years have seen a surge in research and development focused on reducing the carbon footprint of concrete production. Innovative approaches include the use of supplementary cementitious materials, alternative binders, and carbon capture technologies. Magnesium carbonate, in particular, has gained attention for its potential to sequester CO2 and enhance concrete properties.

One of the primary challenges in low-emission concrete technology is achieving comparable or superior performance to traditional Portland cement-based concrete. While magnesium carbonate shows promise in CO2 sequestration, ensuring long-term durability and strength remains a critical concern. Researchers are working to optimize mix designs and curing processes to address these issues.

Another significant challenge is the scalability of low-emission concrete solutions. While laboratory results are encouraging, translating these innovations to large-scale production presents logistical and economic hurdles. The availability of raw materials, particularly for magnesium carbonate-based concretes, is a limiting factor in some regions.

The regulatory landscape also poses challenges for the adoption of low-emission concrete technologies. Current building codes and standards are often based on traditional concrete compositions, necessitating extensive testing and validation for new formulations. This process can be time-consuming and costly, potentially slowing the uptake of innovative solutions.

Cost remains a significant barrier to widespread implementation. Low-emission concrete products, including those incorporating magnesium carbonate, often come with higher upfront costs compared to conventional alternatives. While lifecycle cost analyses may demonstrate long-term benefits, the initial investment can deter adoption, particularly in price-sensitive markets.

Environmental impact assessment of new concrete technologies is another ongoing challenge. While the focus is on reducing CO2 emissions, it's crucial to consider the overall environmental footprint, including water usage, energy consumption, and potential ecological impacts of raw material extraction.

Despite these challenges, the concrete industry is making steady progress towards more sustainable practices. Collaborative efforts between academia, industry, and government bodies are driving innovation and addressing barriers to implementation. As research continues and technologies mature, low-emission concrete products, including those leveraging magnesium carbonate, are poised to play a crucial role in the construction industry's sustainability efforts.

Recent years have seen a surge in research and development focused on reducing the carbon footprint of concrete production. Innovative approaches include the use of supplementary cementitious materials, alternative binders, and carbon capture technologies. Magnesium carbonate, in particular, has gained attention for its potential to sequester CO2 and enhance concrete properties.

One of the primary challenges in low-emission concrete technology is achieving comparable or superior performance to traditional Portland cement-based concrete. While magnesium carbonate shows promise in CO2 sequestration, ensuring long-term durability and strength remains a critical concern. Researchers are working to optimize mix designs and curing processes to address these issues.

Another significant challenge is the scalability of low-emission concrete solutions. While laboratory results are encouraging, translating these innovations to large-scale production presents logistical and economic hurdles. The availability of raw materials, particularly for magnesium carbonate-based concretes, is a limiting factor in some regions.

The regulatory landscape also poses challenges for the adoption of low-emission concrete technologies. Current building codes and standards are often based on traditional concrete compositions, necessitating extensive testing and validation for new formulations. This process can be time-consuming and costly, potentially slowing the uptake of innovative solutions.

Cost remains a significant barrier to widespread implementation. Low-emission concrete products, including those incorporating magnesium carbonate, often come with higher upfront costs compared to conventional alternatives. While lifecycle cost analyses may demonstrate long-term benefits, the initial investment can deter adoption, particularly in price-sensitive markets.

Environmental impact assessment of new concrete technologies is another ongoing challenge. While the focus is on reducing CO2 emissions, it's crucial to consider the overall environmental footprint, including water usage, energy consumption, and potential ecological impacts of raw material extraction.

Despite these challenges, the concrete industry is making steady progress towards more sustainable practices. Collaborative efforts between academia, industry, and government bodies are driving innovation and addressing barriers to implementation. As research continues and technologies mature, low-emission concrete products, including those leveraging magnesium carbonate, are poised to play a crucial role in the construction industry's sustainability efforts.

Existing Solutions for Incorporating Magnesium Carbonate in Concrete

01 Magnesium carbonate production methods

Various methods for producing magnesium carbonate are described, including processes that aim to reduce emissions. These methods may involve specific reaction conditions, raw materials, or equipment to optimize production and minimize environmental impact.- Magnesium carbonate production methods: Various methods for producing magnesium carbonate are described, including processes that aim to reduce emissions. These methods may involve specific reaction conditions, raw materials, or equipment to optimize production and minimize environmental impact.

- Emission control in magnesium carbonate manufacturing: Techniques for controlling and reducing emissions during the production of magnesium carbonate are discussed. These may include the use of scrubbers, filters, or other emission control devices to capture and treat gases released during the manufacturing process.

- Utilization of magnesium carbonate in emission reduction: Magnesium carbonate is explored as a material for reducing emissions in various applications. This includes its use in carbon capture technologies, as a component in air purification systems, or as an additive in materials designed to absorb pollutants.

- Magnesium carbonate in sustainable construction materials: The incorporation of magnesium carbonate in construction materials is investigated as a means to reduce carbon emissions. This includes its use in cement formulations, insulation materials, or other building products that can contribute to lower environmental impact.

- Recycling and waste management of magnesium carbonate: Processes for recycling magnesium carbonate and managing waste from its production or use are explored. These methods aim to reduce overall emissions by minimizing waste and promoting circular economy principles in the magnesium carbonate lifecycle.

02 Emission control in magnesium carbonate manufacturing

Techniques for controlling and reducing emissions during the production of magnesium carbonate are discussed. These may include the use of scrubbers, filters, or other emission control devices to capture and treat gases released during the manufacturing process.Expand Specific Solutions03 Utilization of magnesium carbonate in emission reduction

Applications of magnesium carbonate in reducing emissions from various industrial processes are explored. This includes its use as a sorbent for capturing carbon dioxide or other pollutants from flue gases or ambient air.Expand Specific Solutions04 Magnesium carbonate in sustainable construction materials

The incorporation of magnesium carbonate into construction materials for reducing carbon emissions is discussed. This includes its use in cement formulations or as a component in carbon-negative building materials.Expand Specific Solutions05 Recycling and waste management of magnesium carbonate

Methods for recycling magnesium carbonate and managing waste from its production or use are presented. These approaches aim to minimize environmental impact and reduce overall emissions associated with the material's lifecycle.Expand Specific Solutions

Key Players in Green Concrete and Magnesium-Based Materials

The role of magnesium carbonate in low-emission concrete products is attracting increasing attention in the construction industry, which is currently in a transitional phase towards more sustainable practices. The market for these innovative materials is growing, driven by environmental regulations and the push for greener building solutions. While the technology is still evolving, several key players are making significant strides in research and development. Companies like Calera Corp., Calix Ltd., and Solidia Technologies are at the forefront, developing proprietary processes to incorporate magnesium carbonate into concrete products, aiming to reduce carbon emissions and improve material performance. As the technology matures, collaboration between academic institutions and industry leaders is likely to accelerate innovation in this promising field.

Calera Corp.

Technical Solution: Calera Corp. has developed a innovative process for producing low-emission concrete products using magnesium carbonate. Their technology, known as Mineralization via Aqueous Precipitation (MAP), captures CO2 from industrial emissions and combines it with calcium and magnesium extracted from seawater or brine to form carbonate minerals[1]. These minerals are then used as a cement substitute or aggregate in concrete production. The process can sequester up to 0.5 tons of CO2 per ton of cement produced[2], significantly reducing the carbon footprint of concrete manufacturing. Calera's approach not only reduces emissions but also creates a valuable building material, potentially offering a scalable solution for carbon-negative concrete production[3].

Strengths: Carbon-negative process, utilizes industrial waste CO2, produces high-quality building materials. Weaknesses: Requires proximity to seawater or brine sources, may have higher initial production costs compared to traditional cement.

Calix Ltd.

Technical Solution: Calix Ltd. has developed a proprietary technology called LEILAC (Low Emissions Intensity Lime And Cement) that can be applied to the production of low-emission concrete products incorporating magnesium carbonate. Their process involves a novel kiln design that allows for the efficient capture of pure CO2 during the calcination of limestone or dolomite[7]. This captured CO2 can then be utilized or sequestered, significantly reducing emissions from cement production. Calix's technology can be retrofitted to existing cement plants, making it a potentially scalable solution for the industry. The company has also explored the use of magnesium oxide derived from magnesite as a supplementary cementitious material, which can further reduce the carbon footprint of concrete when combined with their CO2 capture technology[8].

Strengths: Can be retrofitted to existing plants, produces pure CO2 stream for easy capture, applicable to both lime and cement production. Weaknesses: High initial capital investment, requires integration with carbon capture and storage infrastructure.

Core Innovations in Magnesium Carbonate-Based Concrete Formulations

Process for producing cement binder compositions containing magnesium

PatentInactiveEP2611753A1

Innovation

- A process for producing cement binder compositions comprising one or more magnesium carbonates from magnesite, involving the heating of magnesite to produce magnesium oxide, contacting the oxide with a source of carbonate ions, and blending the resulting magnesium carbonates with magnesium oxide to create a cement binder with controlled hydraulic and structural properties, which can be used to produce magnesium cements that are potentially 'carbon negative'.

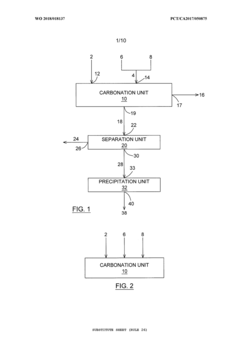

Production of low carbon footprint magnesia

PatentWO2018018137A1

Innovation

- A process integrating CO2 sequestration by contacting CO2-containing emissions with magnesium-containing materials, such as serpentinite, to produce magnesium carbonate, which is then calcined to produce magnesia, with recycled CO2 used to enhance the carbonation process, reducing atmospheric CO2 release and energy consumption.

Environmental Impact Assessment of Magnesium Carbonate Concrete

The environmental impact assessment of magnesium carbonate concrete is a critical aspect of evaluating its potential as a low-emission alternative to traditional concrete products. This assessment encompasses various factors, including carbon footprint, energy consumption, resource utilization, and overall ecological effects throughout the material's lifecycle.

Magnesium carbonate concrete offers significant potential for reducing greenhouse gas emissions compared to conventional Portland cement-based concrete. The production process of magnesium carbonate binders typically requires lower temperatures, resulting in reduced energy consumption and associated carbon dioxide emissions. Furthermore, the ability of magnesium carbonate to sequester CO2 during the curing process contributes to its carbon-negative potential, effectively removing carbon dioxide from the atmosphere.

The raw material sourcing for magnesium carbonate concrete also plays a crucial role in its environmental impact. Magnesium carbonate can be derived from various sources, including magnesite deposits and industrial by-products. The use of waste materials or industrial by-products as a source of magnesium carbonate can significantly reduce the environmental burden associated with raw material extraction and processing.

Water consumption is another important consideration in the environmental assessment of magnesium carbonate concrete. Preliminary studies suggest that magnesium carbonate-based concrete may require less water during mixing and curing compared to traditional concrete, potentially reducing the overall water footprint of construction projects.

The durability and longevity of magnesium carbonate concrete structures also contribute to their environmental performance. If these structures demonstrate enhanced resistance to weathering, chemical attack, and other degradation mechanisms, they could potentially have longer service lives, reducing the need for frequent repairs or replacements and thus lowering the long-term environmental impact.

Recycling and end-of-life considerations are essential components of the environmental impact assessment. Research into the recyclability of magnesium carbonate concrete and its potential for use as a secondary raw material in new construction or other applications is ongoing. The ability to effectively recycle and repurpose this material could significantly enhance its overall environmental profile.

It is important to note that the environmental benefits of magnesium carbonate concrete may vary depending on specific formulations, production methods, and local conditions. Comprehensive life cycle assessments (LCAs) are necessary to accurately quantify the environmental impacts and benefits of magnesium carbonate concrete compared to traditional concrete products across different geographic regions and application scenarios.

Magnesium carbonate concrete offers significant potential for reducing greenhouse gas emissions compared to conventional Portland cement-based concrete. The production process of magnesium carbonate binders typically requires lower temperatures, resulting in reduced energy consumption and associated carbon dioxide emissions. Furthermore, the ability of magnesium carbonate to sequester CO2 during the curing process contributes to its carbon-negative potential, effectively removing carbon dioxide from the atmosphere.

The raw material sourcing for magnesium carbonate concrete also plays a crucial role in its environmental impact. Magnesium carbonate can be derived from various sources, including magnesite deposits and industrial by-products. The use of waste materials or industrial by-products as a source of magnesium carbonate can significantly reduce the environmental burden associated with raw material extraction and processing.

Water consumption is another important consideration in the environmental assessment of magnesium carbonate concrete. Preliminary studies suggest that magnesium carbonate-based concrete may require less water during mixing and curing compared to traditional concrete, potentially reducing the overall water footprint of construction projects.

The durability and longevity of magnesium carbonate concrete structures also contribute to their environmental performance. If these structures demonstrate enhanced resistance to weathering, chemical attack, and other degradation mechanisms, they could potentially have longer service lives, reducing the need for frequent repairs or replacements and thus lowering the long-term environmental impact.

Recycling and end-of-life considerations are essential components of the environmental impact assessment. Research into the recyclability of magnesium carbonate concrete and its potential for use as a secondary raw material in new construction or other applications is ongoing. The ability to effectively recycle and repurpose this material could significantly enhance its overall environmental profile.

It is important to note that the environmental benefits of magnesium carbonate concrete may vary depending on specific formulations, production methods, and local conditions. Comprehensive life cycle assessments (LCAs) are necessary to accurately quantify the environmental impacts and benefits of magnesium carbonate concrete compared to traditional concrete products across different geographic regions and application scenarios.

Regulatory Framework for Low-Emission Construction Materials

The regulatory framework for low-emission construction materials is evolving rapidly as governments and international organizations recognize the urgent need to reduce carbon emissions in the construction sector. This framework encompasses a wide range of policies, standards, and incentives designed to promote the adoption of sustainable building practices and materials.

At the international level, the Paris Agreement has set the stage for countries to implement stricter regulations on greenhouse gas emissions, including those from the construction industry. The United Nations Sustainable Development Goals, particularly Goal 11 (Sustainable Cities and Communities) and Goal 13 (Climate Action), also provide a global context for the development of low-emission construction regulations.

In the European Union, the Construction Products Regulation (CPR) sets harmonized rules for the marketing of construction products and includes provisions for environmental performance declarations. The EU's Green Deal and Circular Economy Action Plan further emphasize the importance of sustainable construction materials and practices.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for environmentally preferable purchasing in construction, while individual states have implemented their own regulations. California, for instance, has adopted the California Green Building Standards Code (CALGreen), which sets mandatory requirements for sustainable construction practices.

Many countries have introduced building codes and standards that specifically address the carbon footprint of construction materials. These include the UK's Part L of the Building Regulations, which focuses on the conservation of fuel and power, and Australia's National Construction Code, which incorporates energy efficiency requirements.

Certification systems such as LEED (Leadership in Energy and Environmental Design), BREEAM (Building Research Establishment Environmental Assessment Method), and Green Star play a crucial role in the regulatory landscape by providing voluntary standards that often influence or complement mandatory regulations.

Financial incentives and penalties are increasingly being used to drive the adoption of low-emission construction materials. These may include tax credits for using sustainable materials, carbon taxes on high-emission products, or preferential treatment in public procurement processes for projects utilizing low-emission materials.

As research into innovative low-emission materials like magnesium carbonate-based concrete progresses, regulatory frameworks are expected to evolve to accommodate and encourage these new technologies. This may involve updating existing standards, creating new categories for novel materials, and developing testing protocols to verify environmental claims.

At the international level, the Paris Agreement has set the stage for countries to implement stricter regulations on greenhouse gas emissions, including those from the construction industry. The United Nations Sustainable Development Goals, particularly Goal 11 (Sustainable Cities and Communities) and Goal 13 (Climate Action), also provide a global context for the development of low-emission construction regulations.

In the European Union, the Construction Products Regulation (CPR) sets harmonized rules for the marketing of construction products and includes provisions for environmental performance declarations. The EU's Green Deal and Circular Economy Action Plan further emphasize the importance of sustainable construction materials and practices.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for environmentally preferable purchasing in construction, while individual states have implemented their own regulations. California, for instance, has adopted the California Green Building Standards Code (CALGreen), which sets mandatory requirements for sustainable construction practices.

Many countries have introduced building codes and standards that specifically address the carbon footprint of construction materials. These include the UK's Part L of the Building Regulations, which focuses on the conservation of fuel and power, and Australia's National Construction Code, which incorporates energy efficiency requirements.

Certification systems such as LEED (Leadership in Energy and Environmental Design), BREEAM (Building Research Establishment Environmental Assessment Method), and Green Star play a crucial role in the regulatory landscape by providing voluntary standards that often influence or complement mandatory regulations.

Financial incentives and penalties are increasingly being used to drive the adoption of low-emission construction materials. These may include tax credits for using sustainable materials, carbon taxes on high-emission products, or preferential treatment in public procurement processes for projects utilizing low-emission materials.

As research into innovative low-emission materials like magnesium carbonate-based concrete progresses, regulatory frameworks are expected to evolve to accommodate and encourage these new technologies. This may involve updating existing standards, creating new categories for novel materials, and developing testing protocols to verify environmental claims.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!